Method for resourceful treatment of cadmium-containing heavy metal wastewater

A heavy metal and resource-based technology, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of cumbersome and lengthy treatment processes, failure to meet environmental protection requirements, waste, etc., and achieve obvious economic benefits and Environmental benefits, solve the problem of heavy metal treatment, the effect of less additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

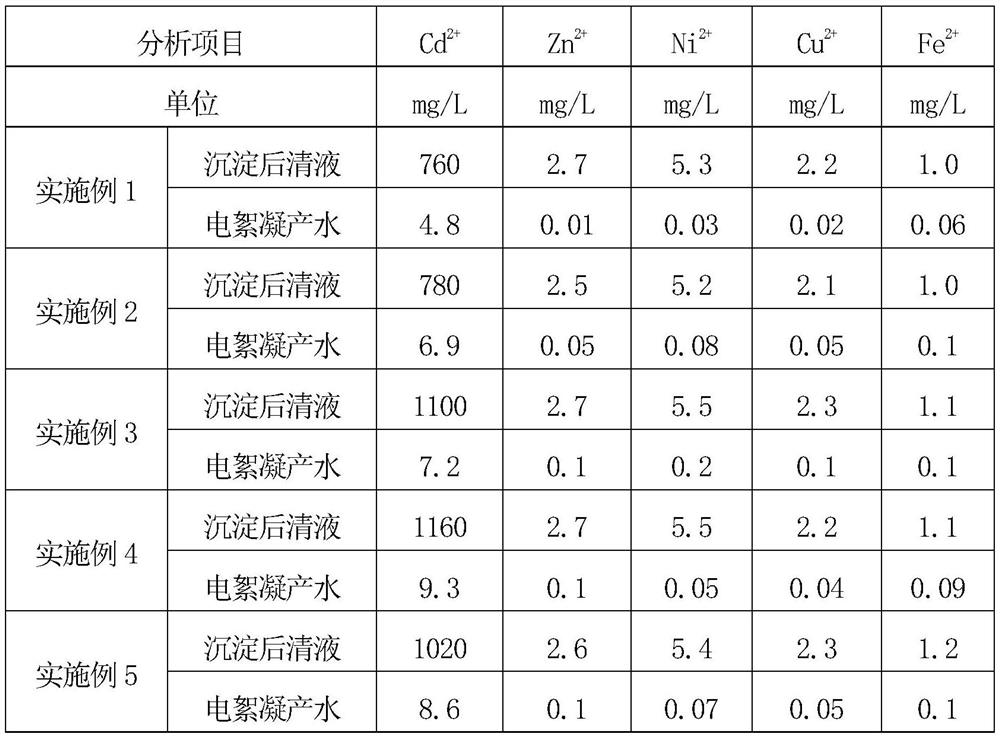

Embodiment 1

[0021] 1. Add precipitant ammonium carbonate to the deplating wastewater of cadmium-containing plating parts in a factory according to the molar ratio of precipitant to cadmium ion 1.20:1, and wash the precipitate with 0.01mol / L nitric acid aqueous solution, which can be used for repeated washing . The precipitate after washing with nitric acid aqueous solution was rinsed with clear water, filtered, moved into a quartz crucible, and heat-treated in a muffle furnace. The heat-treatment temperature was controlled to be 550° C., and the treatment time was 3 hours. After heat treatment, close the furnace and cool naturally to obtain high-purity cadmium oxide. Cadmium oxide is used to make cyanide cadmium plating solution.

[0022] 2. Pump the supernatant after precipitation in step 1 into the electrocoagulation device to remove heavy metal ions. The electrocoagulation device plate is aluminum plate, the plate thickness is 3mm, the distance between the plates is 20mm, and the curr...

Embodiment 2

[0025] 1. Add precipitant sodium carbonate to the deplating wastewater of cadmium-containing plating parts in a factory according to the molar ratio of precipitant to cadmium ion 1.20:1, and wash the precipitate with 0.01mol / L nitric acid aqueous solution, which can be used for repeated washing. The precipitate after washing with nitric acid aqueous solution was rinsed with water, filtered, moved into a quartz crucible, and subjected to heat treatment in a muffle furnace. The heat treatment temperature was controlled at 600°C and the treatment time was 1 hour. After heat treatment, close the furnace and cool naturally to obtain high-purity cadmium oxide. Cadmium oxide is used to make cyanide cadmium plating solution.

[0026] 2. Pump the supernatant after precipitation in step 1 into the electrocoagulation device to remove heavy metal ions. The electrode plate of the electrocoagulation device is aluminum plate, the thickness of the plate is 5mm, the distance between the plates...

Embodiment 3

[0029] 1. Add precipitant ammonium carbonate to the deplating wastewater of cadmium-containing plating parts in a factory according to the molar ratio of precipitant to cadmium ion 1.10:1, and wash the precipitate with 0.01mol / L nitric acid aqueous solution, which can be used for repeated washing. The precipitate after washing with nitric acid aqueous solution was rinsed with water, filtered, moved into a quartz crucible, and subjected to heat treatment in a muffle furnace. The heat treatment temperature was controlled at 500° C., and the treatment time was 2 hours. After heat treatment, close the furnace and cool naturally to obtain high-purity cadmium oxide. Cadmium oxide is used to make cyanide cadmium plating solution.

[0030] 2. Pump the supernatant after precipitation in step 1 into the electrocoagulation device to remove heavy metal ions. The electrode plate of the electrocoagulation device is aluminum plate, the thickness of the plate is 4mm, the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com