Preparation method and application of calcite-otavite solid solution

A technology of calcite and solid solution, which is applied in the field of environmental protection and safety, can solve problems such as secondary pollution, and achieve the effect of easy control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

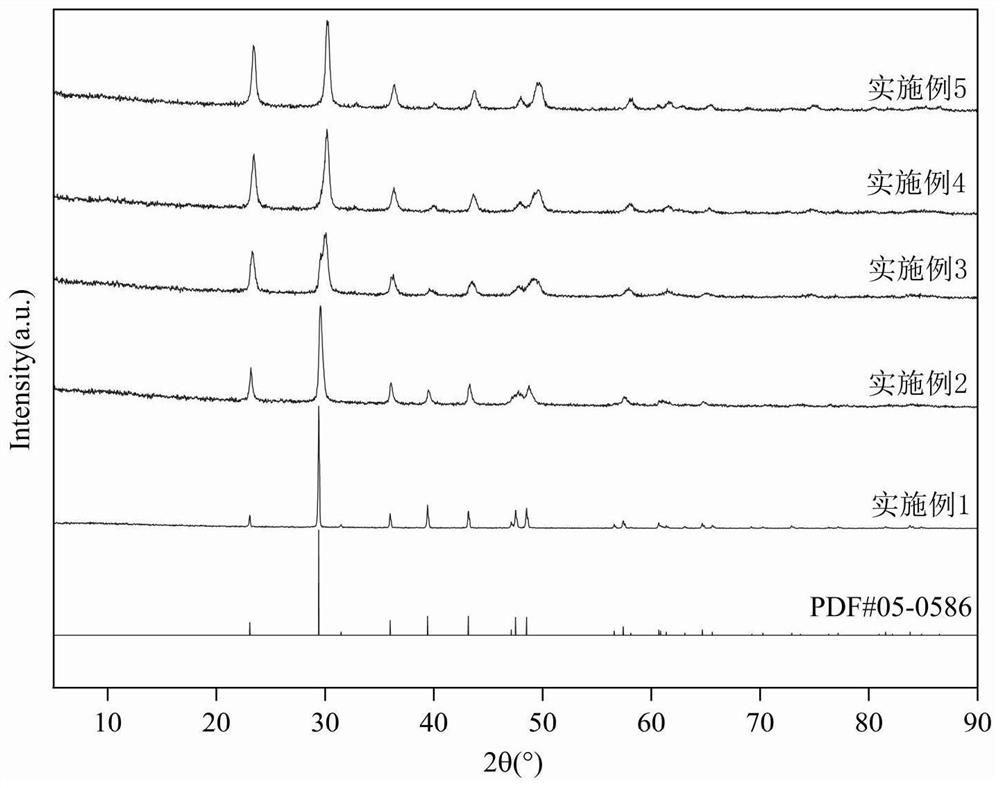

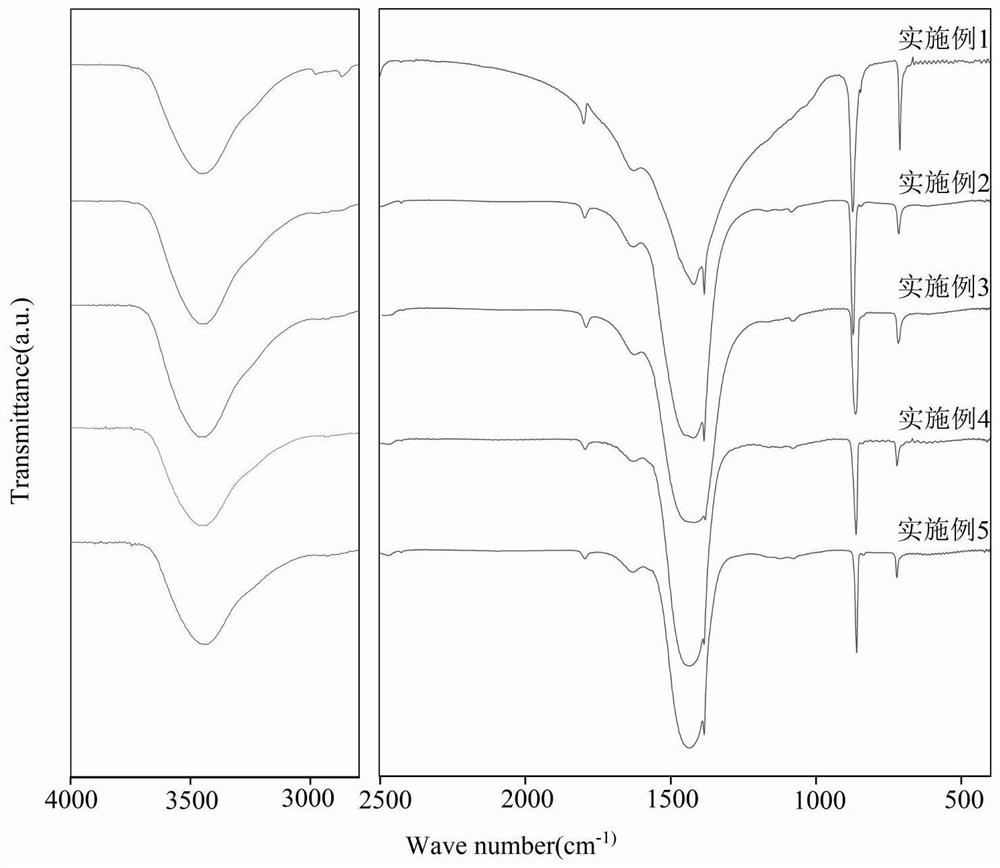

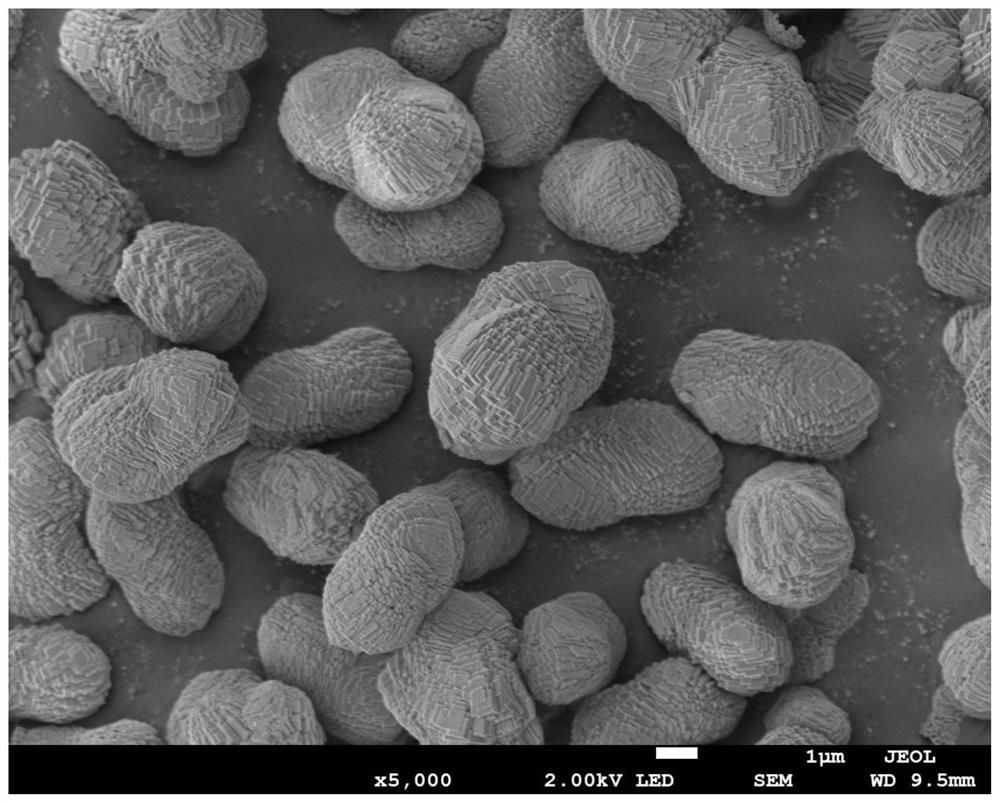

Embodiment 1

[0021] At room temperature, take 500mL 0.1mol / L potassium carbonate solution in a 600mL beaker, place it on a magnetic stirrer and stir at 700rmp at 20°C, then mix 50mL 0.04mol / L calcium nitrate and 0mL 0.04mol / L cadmium nitrate mixed solution Add it into the beaker at a speed of 5mL / s, and react for 30s; then add the metal nitric acid solution of 0.8007g calcium carbonate (analytical pure) dissolved in 1.25mL of concentrated nitric acid into the beaker at a speed of 0.5mL / s, and react for 1min. The reaction is stopped, and the calcite single crystal solid solution with a molar ratio of cadmium nitrate / (calcium nitrate+cadmium nitrate) of 0.0:1.0 can be prepared by aging in the open at room temperature for 2 days. The prepared reactant was subjected to solid-liquid separation, and the solid-phase precipitate was washed three times with 50 mL of ultrapure water and once with 50 mL of absolute ethanol, and finally dried in a blast oven at 90°C for 24 hours to obtain highly crysta...

Embodiment 2

[0023] At room temperature, take 500mL 0.1mol / L potassium carbonate solution in a 600mL beaker, place it on a magnetic stirrer and stir at 700rmp at 20°C, then mix 40mL 0.04mol / L calcium nitrate and 10mL 0.04mol / L cadmium nitrate mixed solution Add it to the beaker at a speed of 5mL / s, and react for 30s; Put it into a beaker, stop the reaction after reacting for 1 minute, and age in the open for 2 days at room temperature to prepare a calcite-lingerite mixed crystal solid solution with a molar ratio of cadmium nitrate / (calcium nitrate+cadmium nitrate) of 0.2:1.0. The prepared reactant was subjected to solid-liquid separation, and the solid-phase precipitate was washed three times with 50mL ultrapure water and once with 50mL absolute ethanol, and finally dried in a blast drying oven at 90°C for 24 hours to obtain highly crystalline calcite- Rhododendron solid solution.

[0024] Leaching test: degassed ultrapure water, dissolved at 25°C for 1200h, cadmium leaching concentration...

Embodiment 3

[0028] At room temperature, take 500mL 0.1mol / L potassium carbonate solution in a 600mL beaker, place it on a magnetic stirrer and stir at 20°C 700rmp, then mix 25mL 0.04mol / L calcium nitrate and 25mL 0.04mol / L cadmium nitrate mixed solution Add in the beaker with the speed of 5mL / s, after reacting for 30s; Then the metal nitric acid solution of 0.4004g calcium carbonate (analytical pure)+0.6897g cadmium carbonate (analytical pure) dissolved with 1.25mL concentrated nitric acid is mixed with 0.5mL / s Add it into the beaker at a high speed, stop the reaction after reacting for 1 minute, and age it in the open for 2 days at room temperature to prepare a calcite-diamondite mixed crystal solid solution with a molar ratio of cadmium nitrate / (calcium nitrate+cadmium nitrate) of 0.5:1.0. The prepared reactant was subjected to solid-liquid separation, and the solid-phase precipitate was washed three times with 50mL ultrapure water and once with 50mL absolute ethanol, and finally dried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com