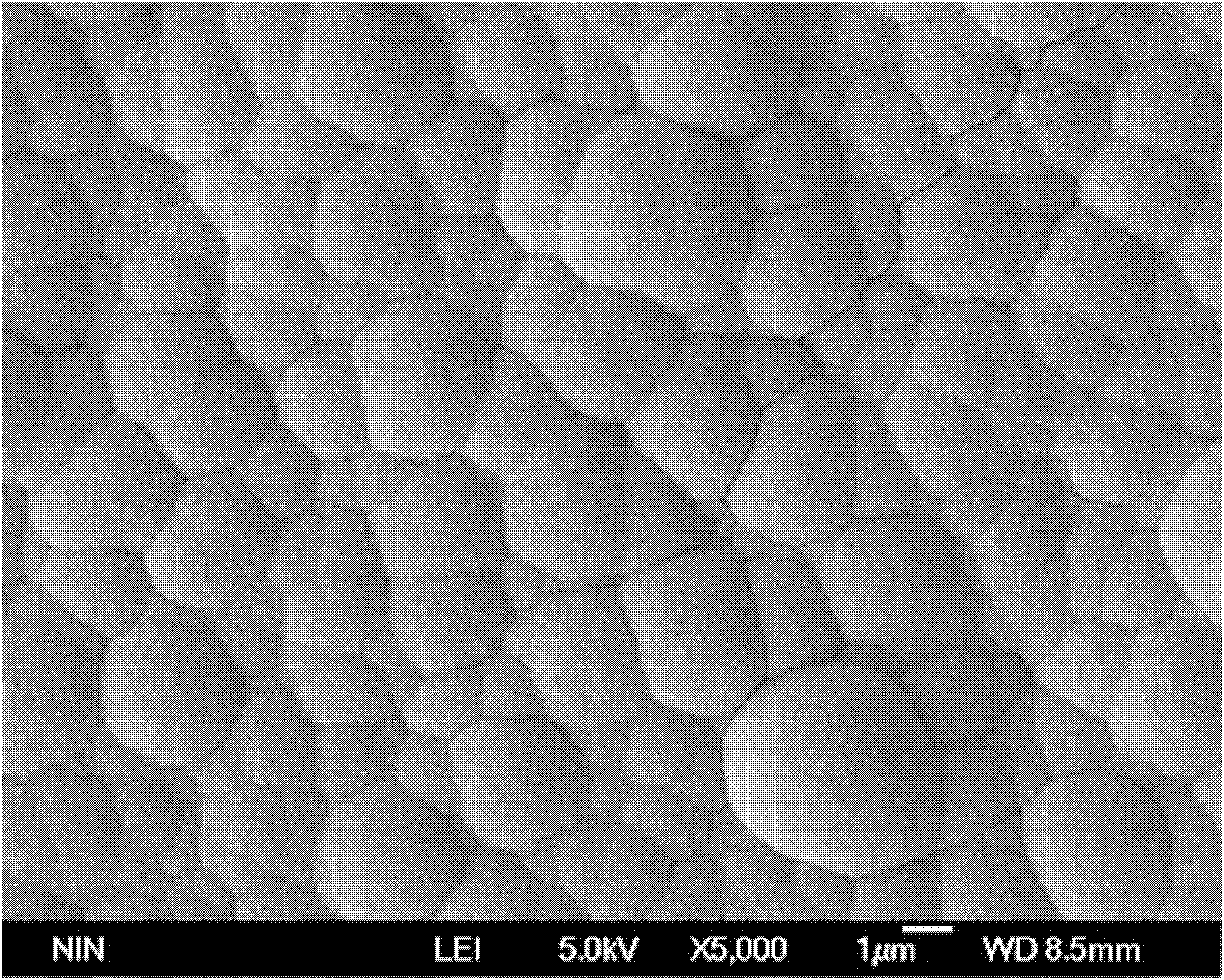

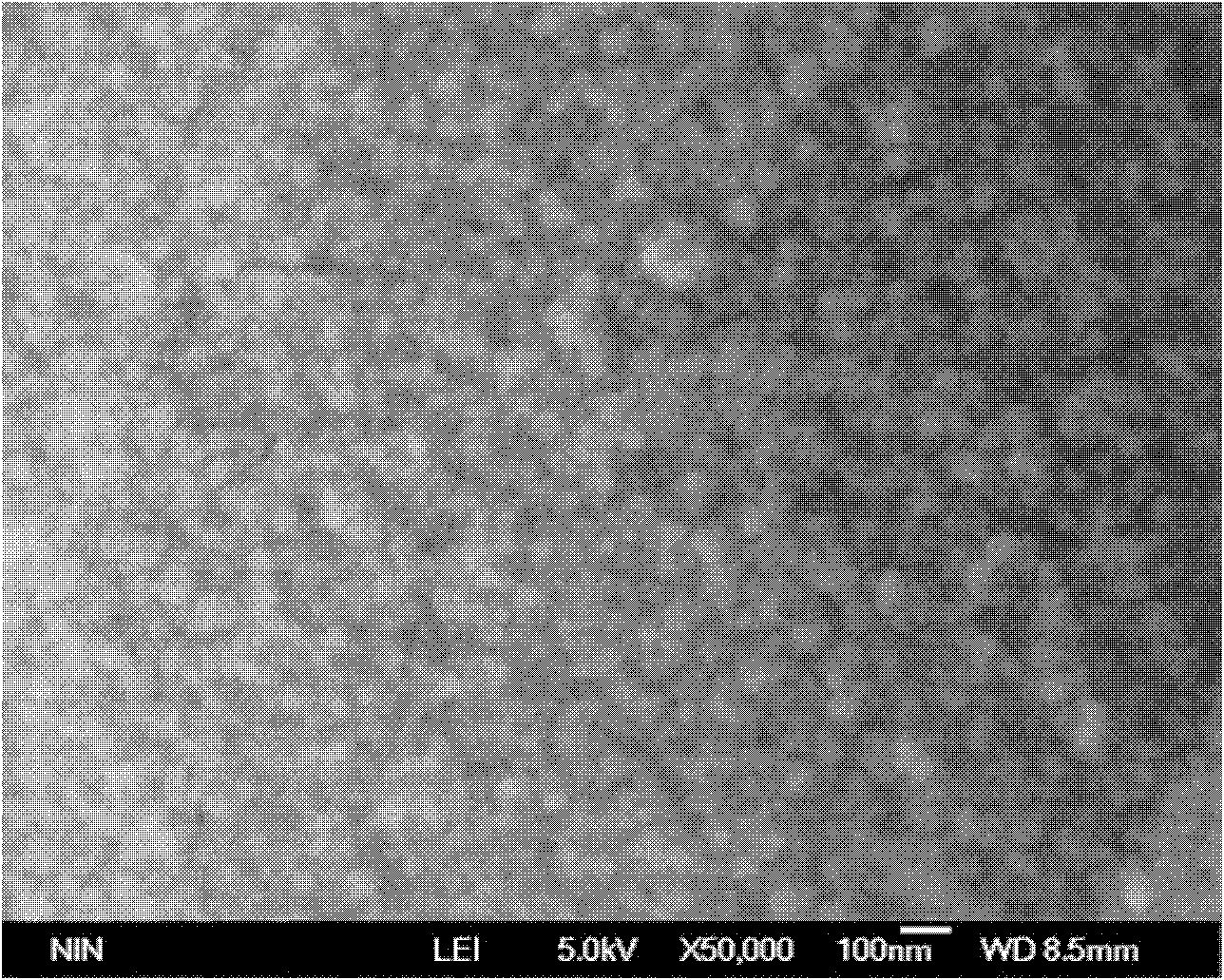

Method for preparing cadmium sulfide nanometer membrane by self assembly

A nano-film and cadmium sulfide technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of high cost of cadmium sulfide film and difficulty in preparing nano-film, and achieve easy large-area film production, The effect of uniform size and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: 1) get the analytically pure cadmium carbonate (CdCO) of 2.00g 3 ) was placed in a beaker, and 3mL of trimethylamine (C3H9N) was added dropwise to the beaker to obtain a mixture A; 2) Add deionized water to the mixture A and stir evenly to form a 200mL transparent solution B; 3) Add to the solution B 2.00 g of PVP (polyvinylpyrrolidone) was stirred evenly by magnetic force at room temperature to obtain solution C.

[0012] 4) Add 3.00 g of analytically pure thioacetamide (TAA, molecular formula: CH3CSNH2) to solution C and stir evenly to obtain solution D; 5) adjust the pH value of solution D to 4.5 to obtain precursor solution E; 6) take ITO Substrate First, place the ITO substrate in solution F for ultrasonic cleaning for 15 minutes to remove the acidic substances on the surface of the ITO substrate, then place the ITO substrate in solution G for ultrasonic cleaning for 15 minutes, and remove the alkaline substances with absolute ethanol and deionized wa...

Embodiment 2

[0015] Embodiment 2: 1) get the analytically pure cadmium carbonate (CdCO) of 5.00g 3 ) was placed in a beaker, and 5 mL of trimethylamine (C3H9N) was added dropwise to the beaker to obtain a mixture A; 2) Add deionized water to the mixture A and stir evenly to form a 200 mL transparent solution B; 3) Add to the solution B 3.00 g of PVP (polyvinylpyrrolidone) was stirred evenly by magnetic force at room temperature to obtain solution C.

[0016] 4) Add 4.00 g of analytically pure thioacetamide (TAA, molecular formula: CH3CSNH2) to solution C and stir evenly to obtain solution D; 5) adjust the pH value of solution D to 6.0 to obtain precursor solution E; 6) take ITO Substrate First, place the ITO substrate in solution F for ultrasonic cleaning for 15 minutes to remove the acidic substances on the surface of the ITO substrate, then place the ITO substrate in solution G for ultrasonic cleaning for 15 minutes, and remove the alkaline substances with absolute ethanol and deionized ...

Embodiment 3

[0018] Embodiment 3: 1) get the analytically pure cadmium carbonate (CdCO) of 6.00g 3 ) was placed in a beaker, and 6 mL of trimethylamine (C3H9N) was added dropwise to the beaker to obtain a mixture A; 2) Add deionized water to the mixture A and stir evenly to form a 200 mL transparent solution B; 3) Add to the solution B 6.00 g of PVP (polyvinylpyrrolidone) was stirred evenly by magnetic force at room temperature to obtain solution C.

[0019] 4) Add 5.5 g of analytically pure thioacetamide (TAA, molecular formula: CH3CSNH2) to solution C and stir evenly to obtain solution D; 5) adjust the pH value of solution D to 8.0 to obtain precursor solution E; 6) take ITO Substrate First, place the ITO substrate in solution F for ultrasonic cleaning for 15 minutes to remove the acidic substances on the surface of the ITO substrate, then place the ITO substrate in solution G for ultrasonic cleaning for 15 minutes, and remove the alkaline substances with absolute ethanol and deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com