Anti-corrosion anti-abrasion creep-resistant electric wire cable material for household electrical appliances and preparation method of anti-corrosion anti-abrasion creep-resistant electric wire cable material

A technology for wire and cable materials and household appliances, which is applied in the field of corrosion-resistant, wear-resistant and creep-resistant wire and cable materials for household appliances and its preparation field, which can solve the problems of poor wear resistance, poor creep resistance, poor corrosion resistance, etc., and achieve the goal of not being easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

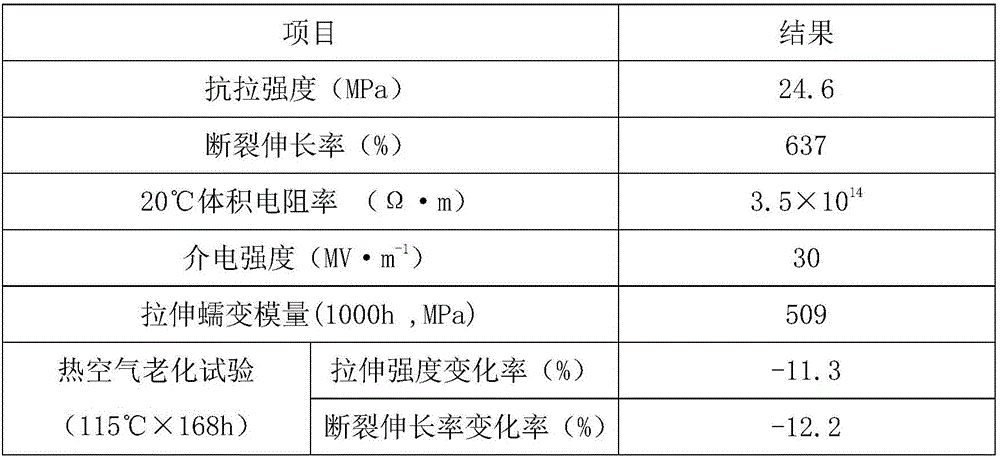

Image

Examples

Embodiment Construction

[0012] A corrosion-resistant, wear-resistant and creep-resistant wire and cable material for household appliances, made of the following raw materials (kg): polyethylene 76, polyvinylidene fluoride 33, allyl diglycol carbonate resin 26, silicon Boron calcium stone 13, boron-rich slag 8, pentaerythritol tetraisostearate 12, p-polyphenylene 20, carbide slag 11, triisononyl trimellitate 13, lead-zinc flotation tailings 12, nano-diamond 17 , Candelilla wax 10, cadmium carbonate 8, carbonyl iron powder 9, lanthanum laurate 3, porous powder quartz 15.

[0013] A method for preparing a corrosion-resistant, wear-resistant and creep-resistant wire and cable material for household appliances, comprising the following steps:

[0014] (1) Mix calcium boronite, boron-rich slag, calcium carbide slag, and lead-zinc flotation tailings evenly, pulverize, sieve, then heat and melt to form a molten liquid, stir well, put it into clean water for water quenching, and dry Drying, crushing, sieving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com