A kind of nano particle modified normal temperature curing fluorocarbon coating and preparation method thereof

A room temperature curing, nano-particle technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not reaching the design life of railway structures, high maintenance and repair costs of railway structures, and achieve better shielding and reflection effects , good shielding effect, and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

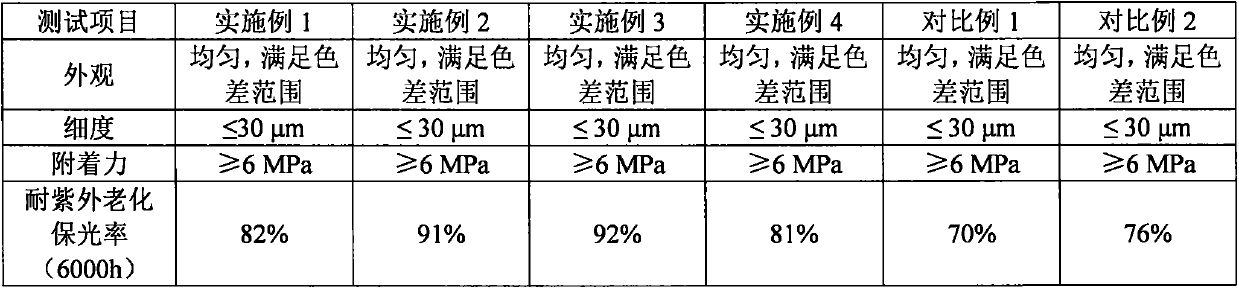

Examples

Embodiment 1

[0021] (1) The weight percent of each raw material in A component is:

[0022] FEVE fluorocarbon resin, 42%;

[0023] Nano titanium dioxide filler, 30%;

[0024] Disco-shaped nano-europium trioxide filler, 2%;

[0025] Solvent, 17%;

[0026] Leveling agent, 2%;

[0027] Defoamer, 2%;

[0028] Wetting and dispersing agent, 2%;

[0029] Thixotropic agent, 1%;

[0030] Pigments, 2%.

[0031] According to R=1.05, component B calculates the amount of isocyanate required, and the weight percentage of each raw material is:

[0032] HDI biuret, 20%;

[0033] HDI trimer, 20%;

[0034] Solvent, 60%.

[0035] (2) The preparation steps include:

[0036] (1) Prepare the raw materials of component A and component B according to the weight percentage

[0037] (2) Add leveling agent, wetting and dispersing agent, defoamer, pigment, nano-titanium dioxide and disk-shaped nano-europium trioxide filler of said weight in the high-speed dispersion kettle, carry out high-speed dispersion...

Embodiment 2

[0041] (1) The weight percent of each raw material in A component is:

[0042] FEVE fluorocarbon resin, 42%;

[0043] Nano titanium dioxide filler, 27%;

[0044] Disco-shaped nano europium trioxide filler, 5%;

[0045] Solvent, 17%;

[0046] Leveling agent, 2%;

[0047] Defoamer, 2%;

[0048] Wetting and dispersing agent, 2%;

[0049] Thixotropic agent, 1%;

[0050] Pigments, 2%.

[0051] According to R=1.05, component B calculates the amount of isocyanate required, and the weight percentage of each raw material is:

[0052] HDI biuret, 20%;

[0053] HDI trimer, 20%;

[0054] Solvent, 60%.

[0055] The raw materials used in component B are the same as in Example 1.

[0056] (2) The preparation method is the same as in Example 1.

Embodiment 3

[0058] (1) The weight percent of each raw material in A component is:

[0059] FEVE fluorocarbon resin, 42%;

[0060] Nano titanium dioxide filler, 24%;

[0061] Disco-shaped nano europium trioxide filler, 8%;

[0062] Solvent, 17%;

[0063] Leveling agent, 2%;

[0064] Defoamer, 2%;

[0065] Wetting and dispersing agent, 2%;

[0066] Thixotropic agent, 1%;

[0067] Pigments, 2%.

[0068] According to R=1.05, component B calculates the amount of isocyanate required, and the weight percentage of each raw material is:

[0069] HDI biuret, 20%;

[0070] HDI trimer, 20%;

[0071] Solvent, 60%.

[0072] The raw materials used in component B are the same as in Example 1.

[0073] (2) The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com