Synergistic waste mercury regeneration technique and soaking precipitation pool thereof

A technology, waste mercury technology, applied in the field of ore mining, can solve the problems of mercury volatility and toxicity, low mercury utilization rate, and difficult to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

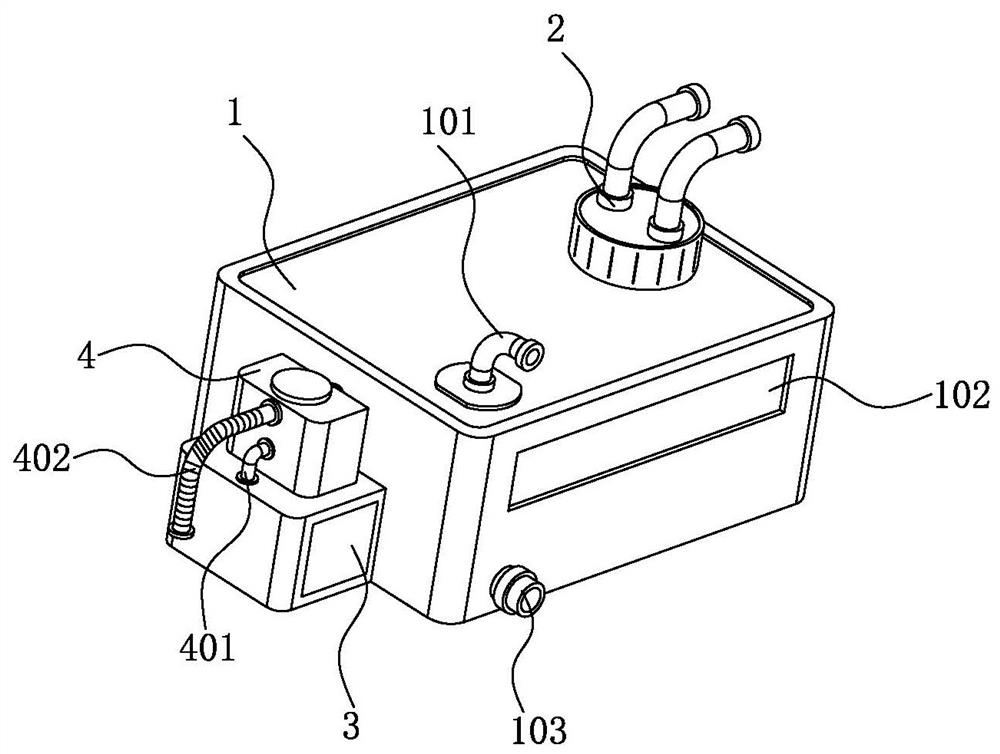

[0019] see figure 1 As shown, the present invention is a method for twisting the twisted grass rope of a fully automatic straw pad forming machine. The waste mercury regeneration technology includes the following steps: collecting the original waste mercury, and injecting the original waste mercury through the corrugated suction pipe 402 In the particle filter 4, the particle filter 4 filters the particle impurities on the surface of the original waste mercury, and the particle impurities are discharged into the particle collection box 3 through the particle discharge pipe 401; the remaining waste in the particle filter 4 Mercury will be discharged into the interior of the precipitation tank body 1. At this time, 2% and above nitric acid is poured into the interior of the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com