Cleaning air-drying regeneration system for cloth bag and cleaning air-drying regeneration method for cloth bag

A regeneration system and bag technology, which are applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems that the filter material cannot be removed, restore the filter performance of the bag, and reduce the service life of the bag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the features and functions of the preferred embodiments of the present invention will be described in detail as follows in order to facilitate a complete understanding.

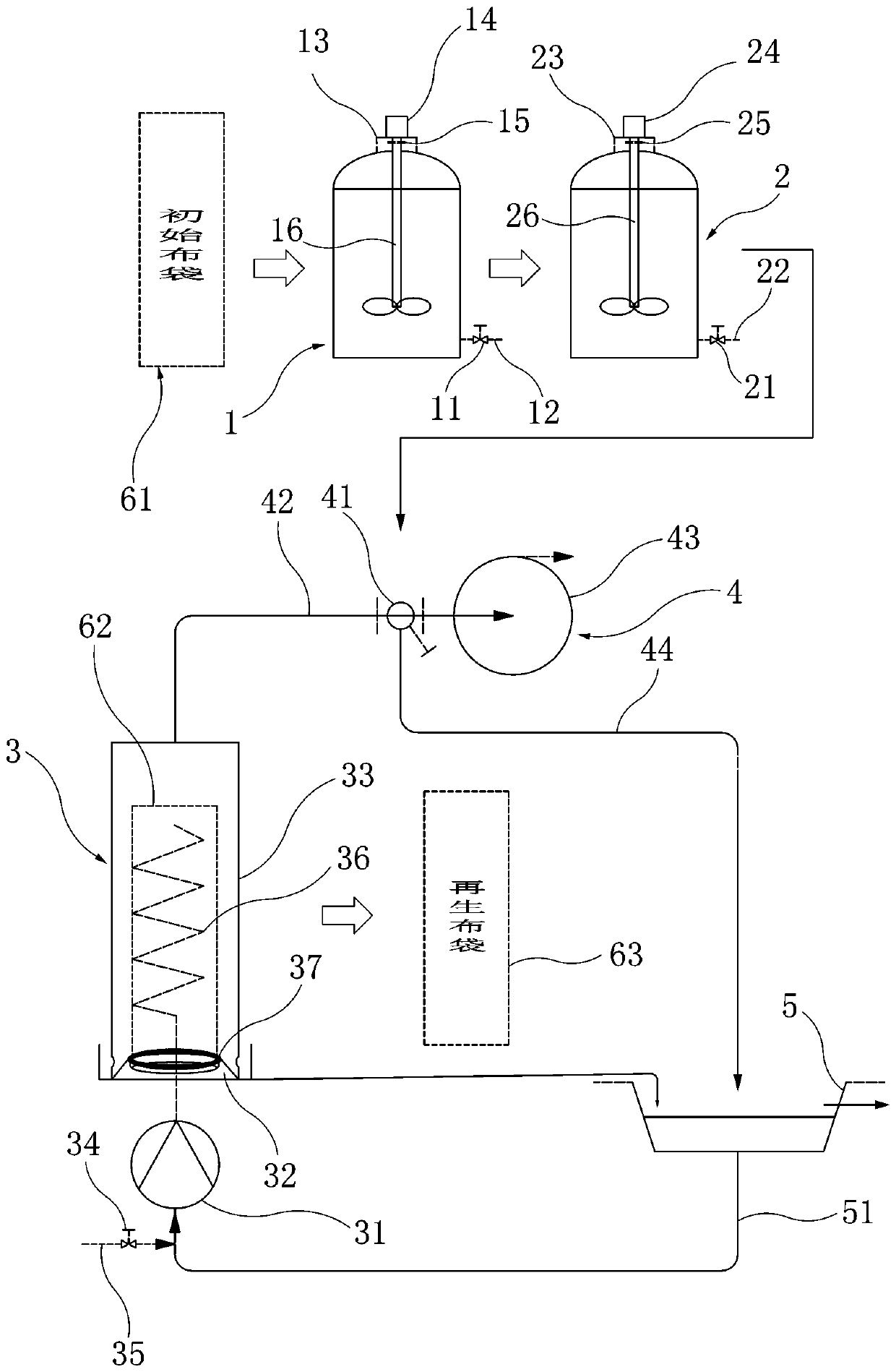

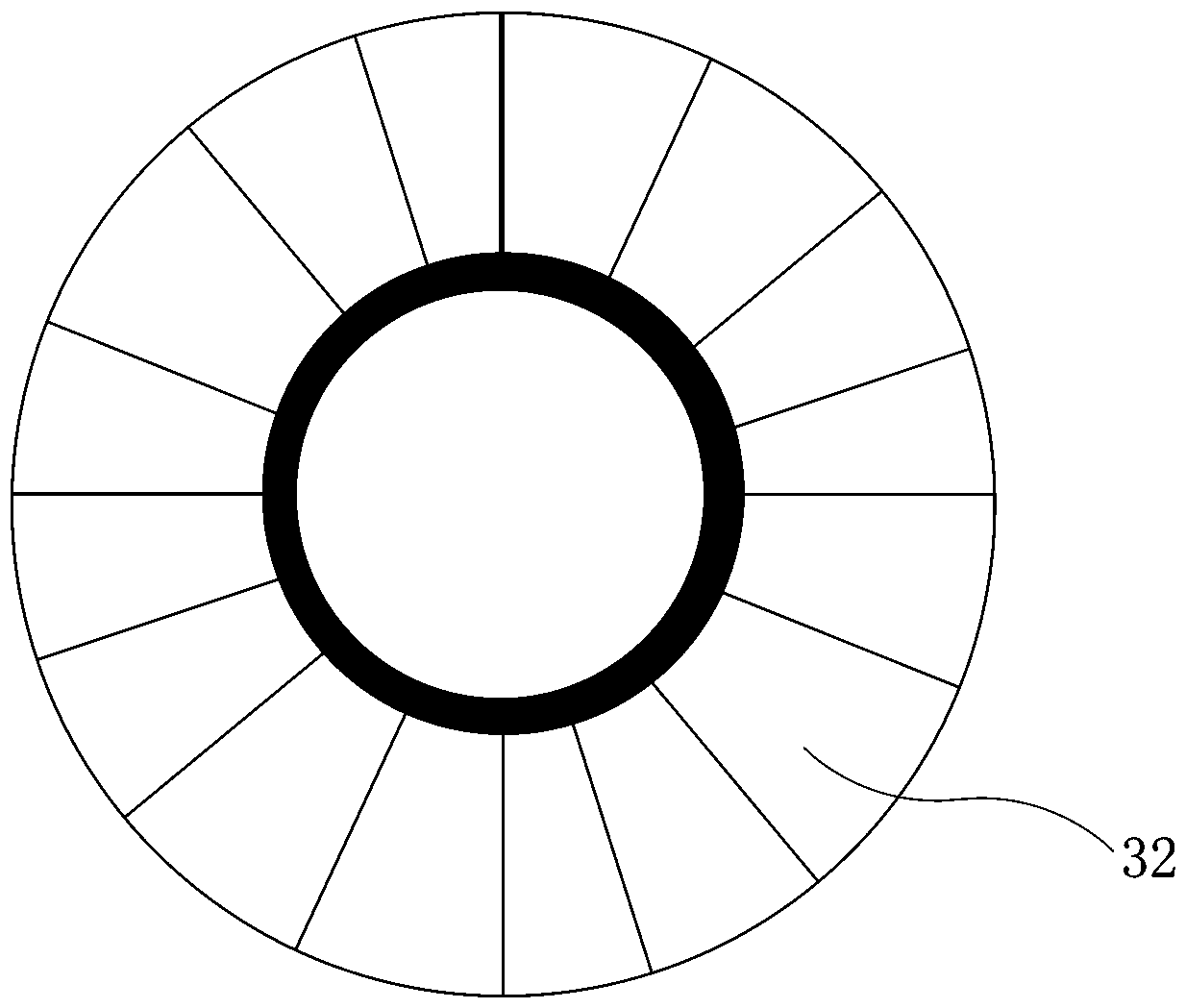

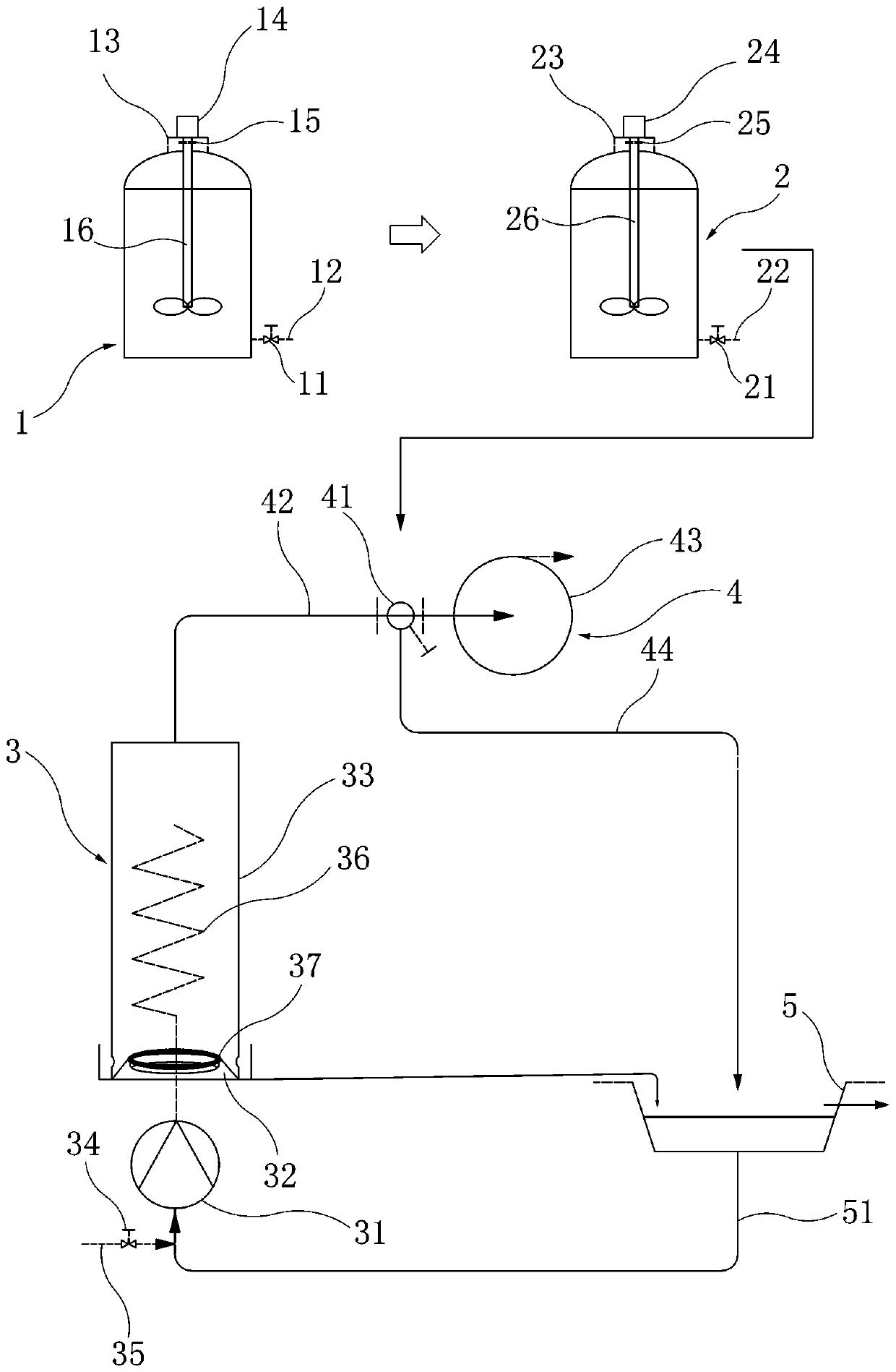

[0043] see image 3 and figure 2 As shown, the present invention discloses a cleaning and air-drying regeneration system for cloth bags, comprising: a soaking device 1, a surface activation device 2, a spunlace device 3, an air-drying device 4, and a filtration and circulation device 5 arranged in sequence, and the filtration and circulation device 5 It is a circulation tank that accommodates filter materials, and the air-drying device 4 is connected to the hydroentanglement device 3 and the filtration circulation device 5 respectively through pipelines, and the filtration circulation device 5 is connected to the hydroentanglement device 3 through pipelines; Soaking device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com