Novel lightweight high-porosity ceramic filter material and preparation method thereof

A high-porosity, ceramic filter material technology, applied in ceramic products, ceramic material production, chemical instruments and methods, etc., can solve the problems affecting the filtration cycle and effluent quality, the lack of roughness of the surface structure, affecting the hydraulic retention time, etc. Achieve the effects of overcoming difficult-to-control and easy-running materials, abundant micropores, and overcoming large head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

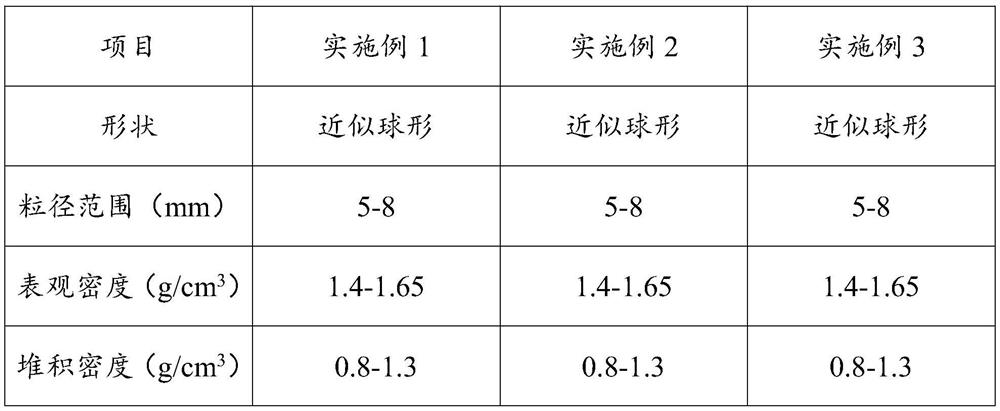

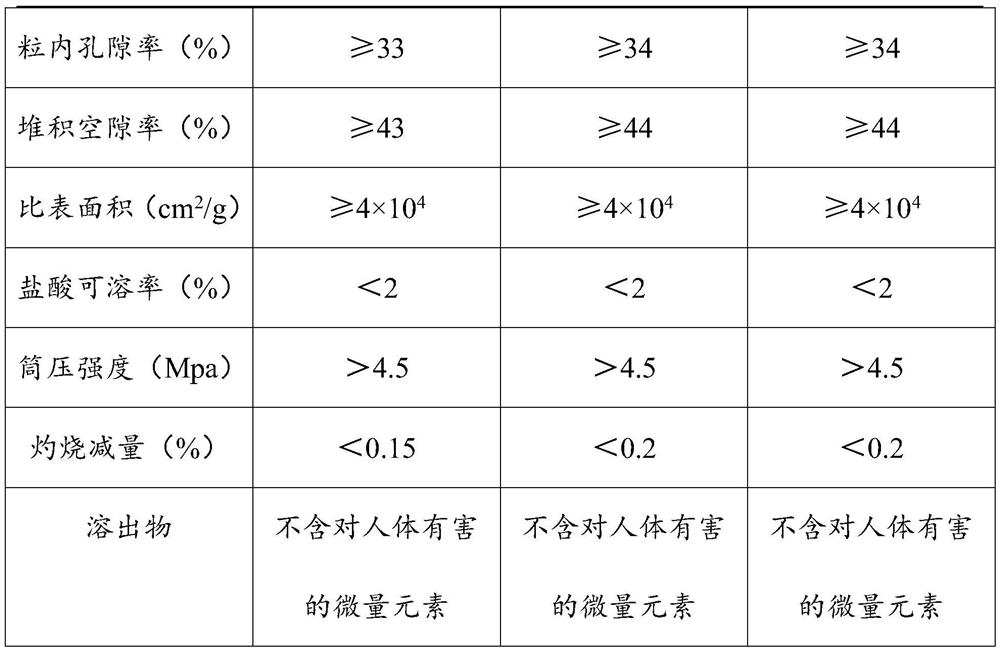

Embodiment 1

[0030](1) 30 copies of powder coal beads, 20 coal gangue, 15 pieces of diatomaceous earth, 6 copies of 2 parts of hydroxymethylcellulose, 2 rice bran, and 8 pieces of limestone.

[0031](2) After mixing the raw material weighing step (1), the ball mill is performed, and the ball is over 200 mesh sieve;

[0032](3) Mix the billet mixed with step (2) to make a plasticity with water in a mortar, and then prepute a small ball having a particle size of 5-8 mm;

[0033](4) Place the sample formed by step (3) in the drying tank at 50 ° C constant temperature drying 1H;

[0034](5) The sample after drying step (4) was sintered, and then decomposed at 530 ° C before sintering, sintered at 1170 ° C for 3 h.

[0035](6) A layer of carbon nanofibers are attached to the surface of the sample after the sintering of step (5).

Embodiment 2

[0037](1) 35 pieces of powder coal ash, 25 coal gangue, 20 pieces of diatomaceous earth, 25 copies of dolomite powder, 3 rice bran, and 9 石 石 石;;

[0038](2) After mixing the raw material weighing step (1), the ball mill is performed, and the ball is over 200 mesh sieve;

[0039](3) Mix the billet mixed with step (2) to make a plasticity with water in a mortar, and then prepute a small ball having a particle size of 5-8 mm;

[0040](4) Place the sample formed by step (3) in the drying tank at a constant temperature of 55 ° C for 2 h;

[0041](5) The sample after drying after (4) was sintered, and then decomposed at 700 ° C for 2 h before sintering, and 4 h was sintered at 1180 ° C.

[0042](6) A layer of carbon nanofibers are attached to the surface of the sample after the sintering of step (5).

Embodiment 3

[0044](1) 40 copies of powder coal ash, 30 coal gangue, 25 diatomaceous earth, 9 pieces of hydroxymethylcellulose, 9 parts of Dolomite powder, 3 rice bran, and 10 grade stone;

[0045](2) After mixing the raw material weighing step (1), the ball mill is performed, and the ball is over 200 mesh sieve;

[0046](3) Mix the billet mixed with step (2) to make a plasticity with water in a mortar, and then prepute a small ball having a particle size of 5-8 mm;

[0047](4) Place the sample formed by step (3) in the drying tank at 60 ° C constant temperature drying 2h;

[0048](5) The sample after drying step (4) was sintered, and the first was decomposed at 850 ° C for 2 h before sintering, and 4 h was sintered at 1200 ° C.

[0049](6) A layer of carbon nanofibers are attached to the surface of the sample after the sintering of step (5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com