Method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater

A waste water treatment and recycling technology, applied in fluorine/hydrogen fluoride, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of shortage of fluorine resources, large sludge output, limited outlets, etc., and reduce mining volume , cost reduction, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

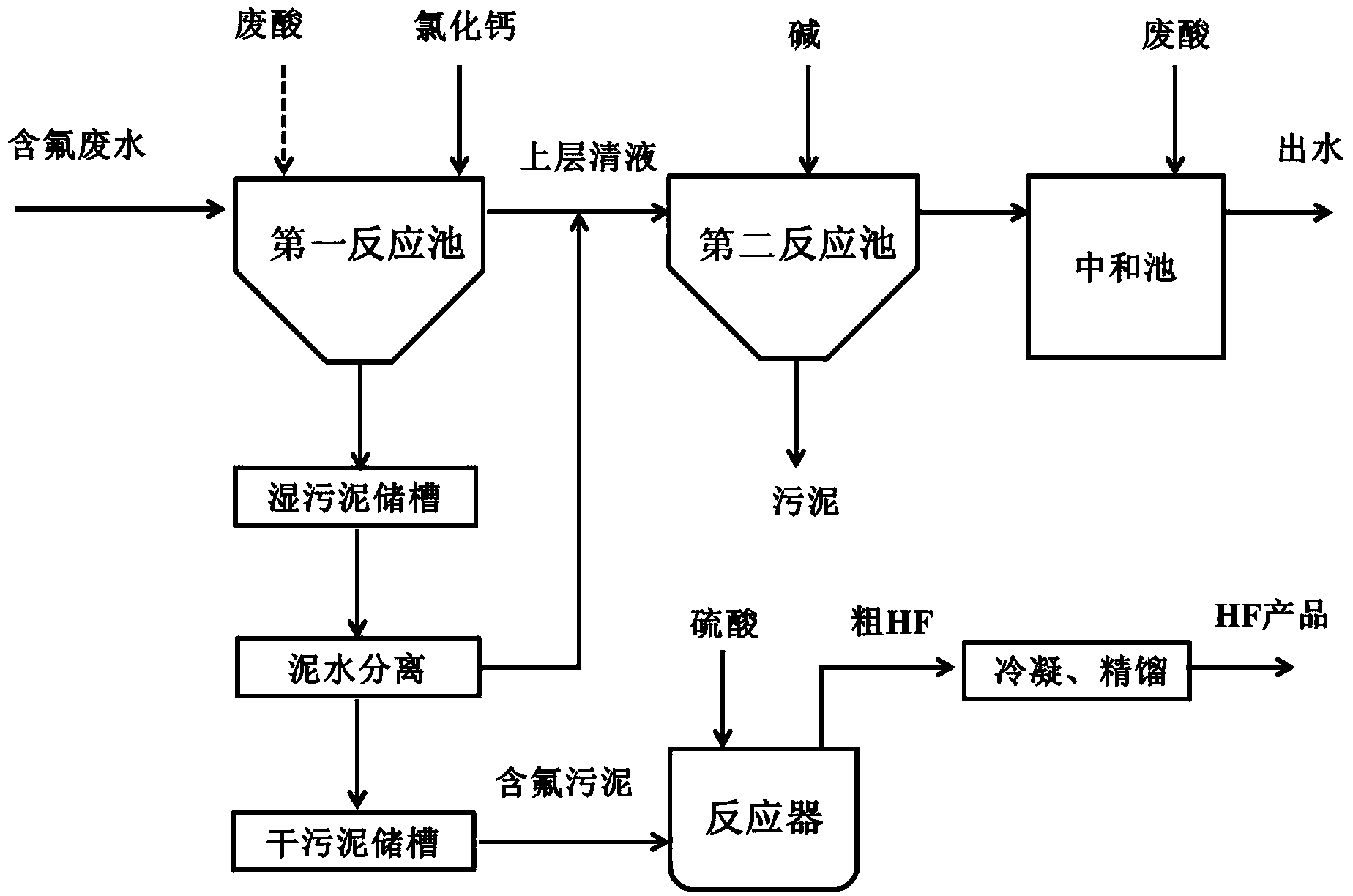

[0032] The method for the treatment of fluorine-containing wastewater and the resource utilization of the generated fluorine-containing sludge in this embodiment, the steps are as follows:

[0033] (a) 1 ton of fluorine-containing waste water (F-concentration of 7200 mg / L after testing) flows into the first reaction tank, adding waste hydrochloric acid to adjust the pH to 2.1, adding 21.0 kg of calcium chloride, stirring to make it fully mixed, and standing still to make the fluorine Calcium oxide crystal precipitation;

[0034] (b) Extract the crystallized calcium fluoride slurry from the bottom of the first reaction tank, and transport it to the calcium fluoride wet sludge storage tank. After the calcium fluoride slurry is precipitated, the upper liquid flows into the second reaction tank, and the bottom solid is dried at 40°C for 15 hours to obtain 12.7 kg of calcium fluoride dry sludge (86% recovery rate), with a particle size of 38.5 μm and a purity of 94.8%.

[0035] (...

Embodiment 2

[0040] The method for the treatment of fluorine-containing wastewater and the resource utilization of the generated fluorine-containing sludge in this embodiment, the steps are as follows:

[0041] (a) 1t of fluorine-containing waste water (F-concentration of 3500mg / L after testing) flows into the first reaction tank, add mixed waste acid containing hydrochloric acid and sulfuric acid to adjust the pH to 5, add 10.2kg of calcium chloride, stir to make it fully Mix and let stand to precipitate calcium fluoride crystals;

[0042] (b) Extract the crystallized calcium fluoride slurry from the bottom of the first reaction tank, and transport it to the calcium fluoride wet sludge storage tank. After the calcium fluoride slurry was centrifuged, the upper liquid flowed into the second reaction tank, and the bottom solid was dried at 50°C for 13 hours to obtain 5.4kg of calcium fluoride dry sludge (75% recovery rate), with a particle size of 5.2 μm and a purity of 93.5%.

[0043] (c)...

Embodiment 3

[0048] The method for the treatment of fluorine-containing wastewater and the resource utilization of the generated fluorine-containing sludge in this embodiment, the steps are as follows:

[0049] (a) 1 ton of fluorine-containing waste water (F-concentration of 5800 mg / L after testing) flows into the first reaction pool, adding waste sulfuric acid to adjust the pH to 3.5, adding 16.9 kg of calcium chloride, stirring to make it fully mixed, and standing still to make the fluorine Calcium oxide crystal precipitation;

[0050] (b) Extract the crystallized calcium fluoride slurry from the bottom of the first reaction tank, and transport it to the calcium fluoride wet sludge storage tank. After the calcium fluoride slurry is precipitated, the upper liquid flows into the second reaction tank, and the bottom solid is dried at 70°C for 10 hours to obtain 9.6 kg of calcium fluoride dry sludge (81% recovery rate), with a particle size of 20.6 μm and a purity of 84.2%.

[0051] (c) th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com