Water purification and filtration processing tank

A treatment pool and water purification technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high maintenance costs, difficult cleaning of filter layers, and high energy consumption. Achieve the effect of low cost, high efficiency and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

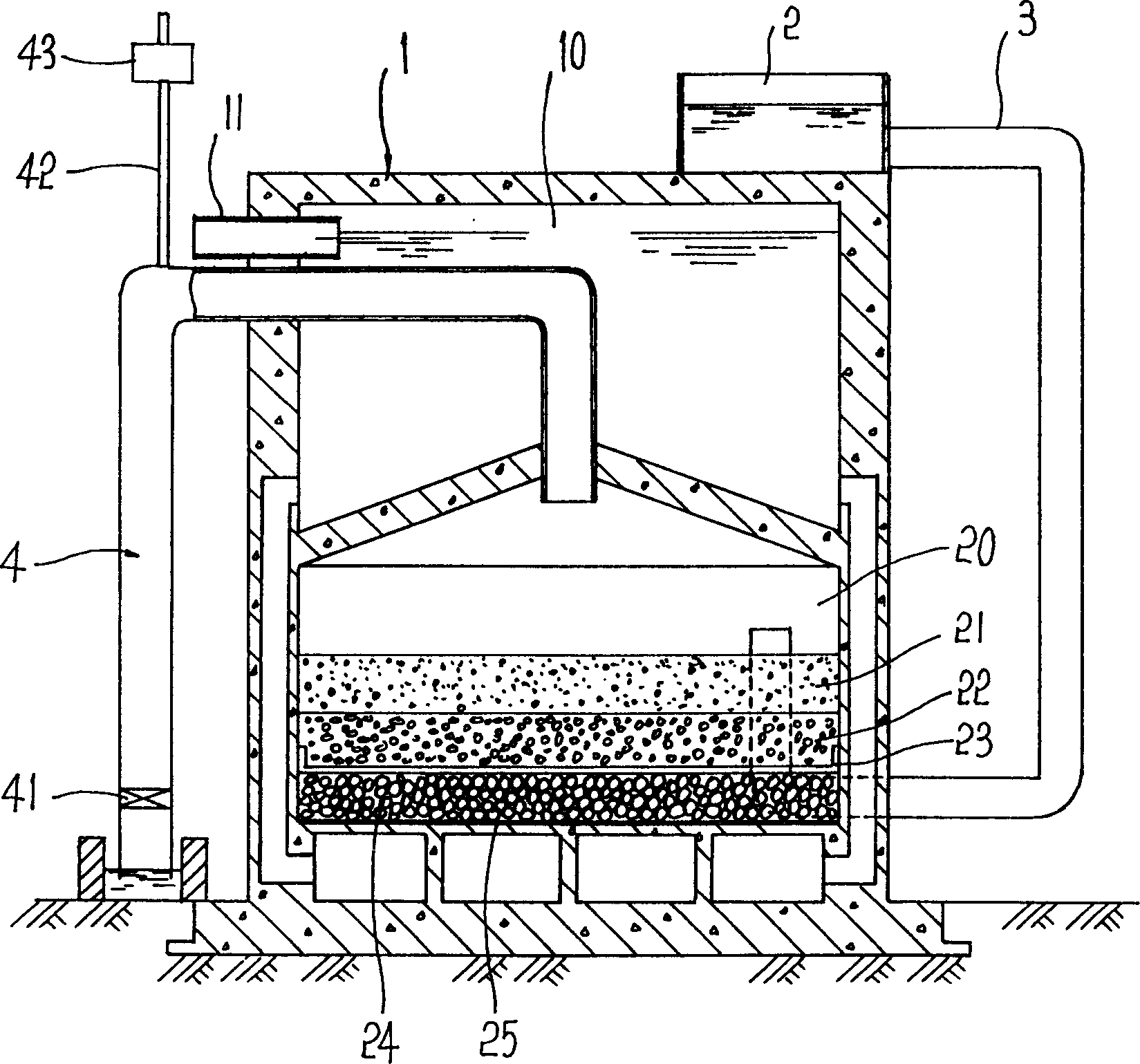

[0009] Such as figure 1 As shown, a kind of water purification and filtration treatment pool of the present invention comprises a concrete pool main body 1, and a water inlet tank 2 is arranged on the top of the pool main body 1, and the interior of the pool main body 1 is divided into an upper clean water chamber 10 and a lower filtering chamber isolated from each other. Room 20, clean water room 10 is provided with water outlet pipe 11; in the middle of filter room 20, there are fine sand filter layer 21, medium sand filter layer 22, fine filter screen 23, stone filter layer 24 and coarse filter screen 25 from top to bottom; The sand fineness of fine sand filter layer 21 is 60~100 orders, the sand grain fineness of medium sand filter layer 22 is 12~60 orders, the fine filter screen 23 is 12 orders, the stone particle diameter of stone filter layer 24 is greater than 8 orders, Coarse filter screen 25 is 8 orders. The lower part of the filter chamber 20 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com