Patents

Literature

59results about "Alkali metal iodides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing radioactive <124>I ions

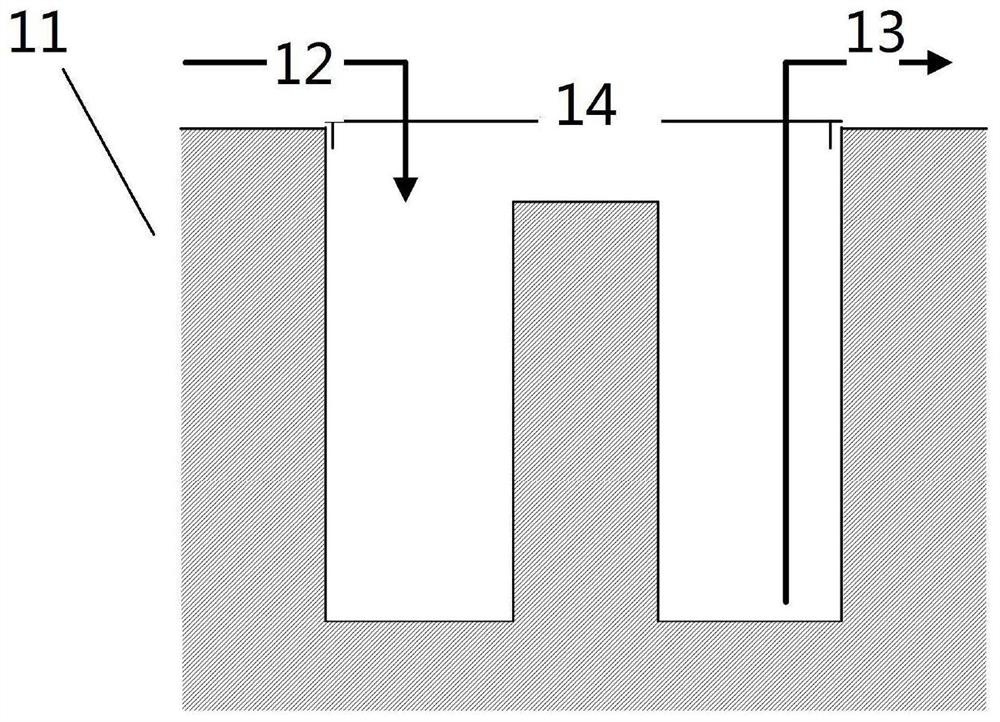

ActiveCN103771341ANo leaksImprove radiation effectIodineAlkali metal iodidesAngle of incidenceDistillation

The invention discloses a method for preparing radioactive <124>I ions. The preparation method comprises the following steps: a, taking aluminium oxide powder and tellurium dioxide powder in a mass ratio of 1:18-22, uniformly mixing the powder, and pressing the obtained mixture into a tellurium target with a thickness of 50-60 mg / cm<2>; b, placing the prepared tellurium target in a circular accelerator, and irradiating the tellurium target 2-3 h by Te (p, n) <124>I, wherein the incident p particle beam intensity is 18-20 mu A, the energy is 18.5-20 MeV, and the angle of incidence is 6-10 DEG; meanwhile, cooling the tellurium target by using water in the process of irradiating, and after the irradiating is completed, placing the tellurium target to cool 4-6 h; c, placing the tellurium target in a quartz distillation tube of a destructive distillation device to distill, meanwhile, controlling the temperature to 750 DEG C so as to heat the tellurium target, so that radioactive <124>I ions are escaped, and collecting the radioactive <124>I ions. The problems that radionuclide <124>I prepared in the prior art is low in yield and low in recovery rate are solved.

Owner:MITRO BIOTECH CO LTD

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Process for recovery of low sodium salt from bittern

InactiveUS20030143152A1High yieldYield maximizationCalcium/strontium/barium sulfatesMagnesium sulfatesEvaporationChloride

A new process for recovery of Low Sodium Salt from bittern has been described in the present invention, the said process comprising desulphatation of bittern (by-product of salt industry), evaporation of bittern in solar pans and processing of solid mixture with water to produce a mixture of sodium and potassium chlorides and optionally preparing "free flowing" and iodized, by known techniques.

Owner:COUNCIL OF SCI & IND RES

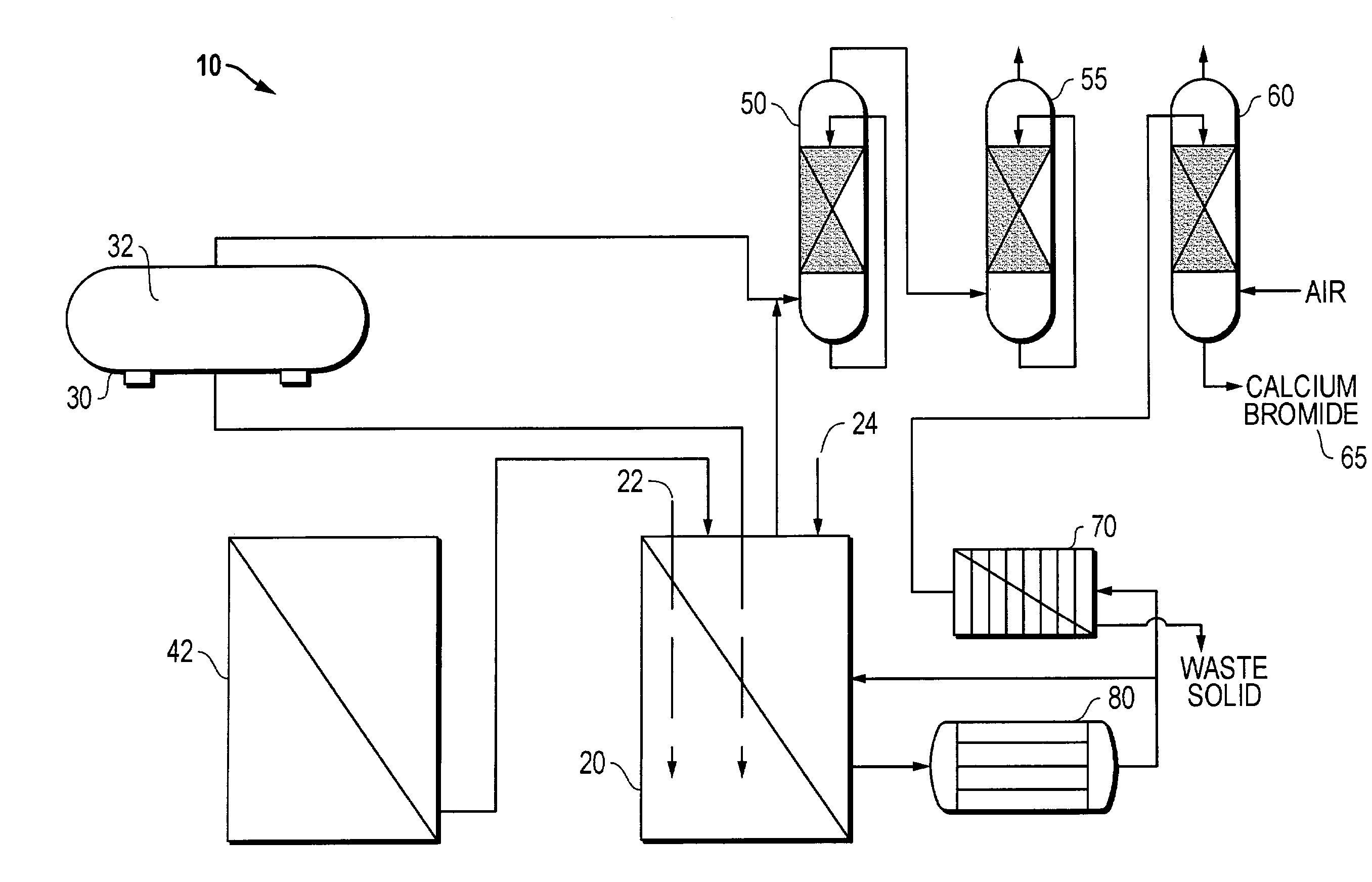

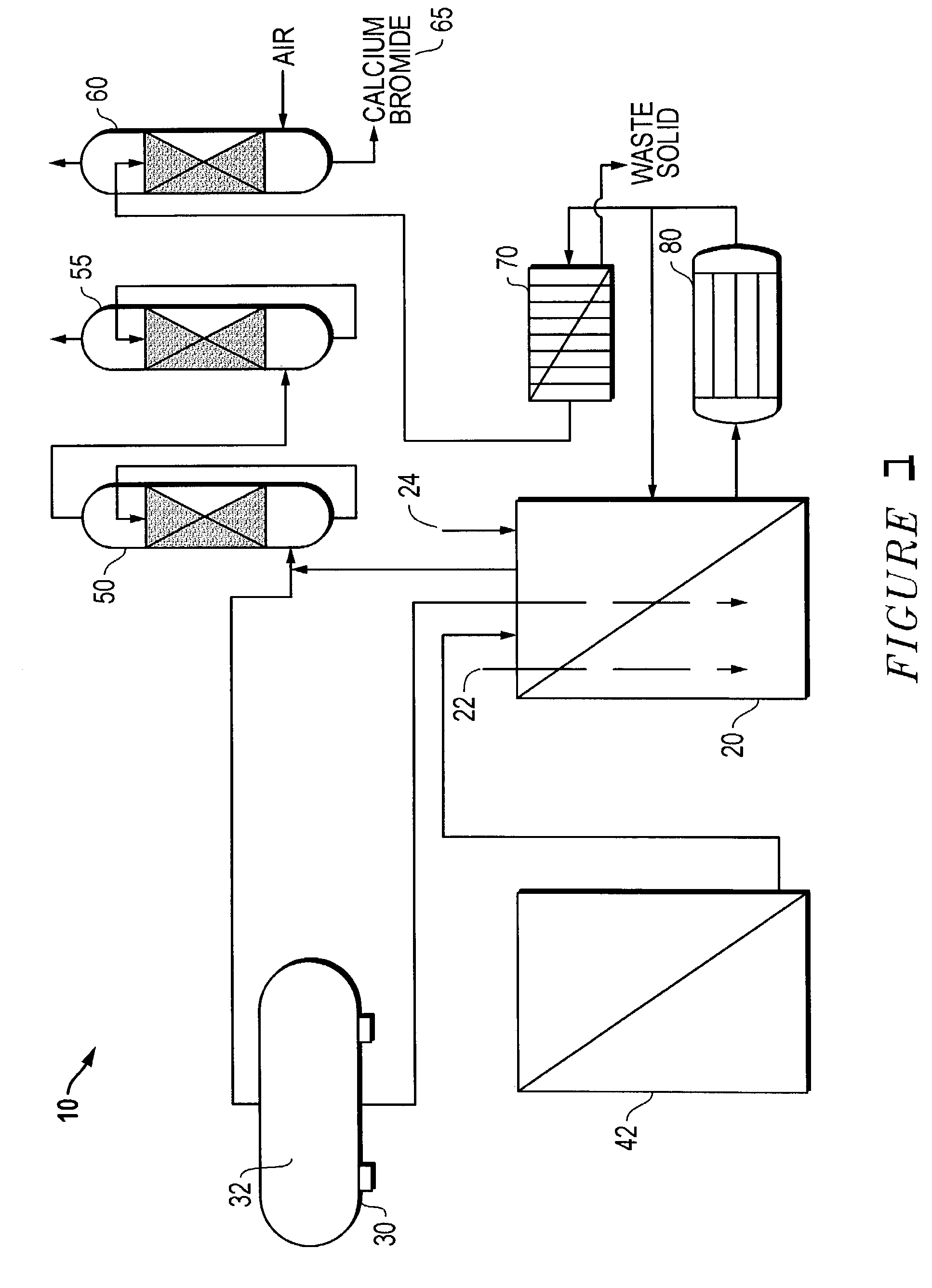

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Method for producing a halide brine

ActiveUS7087209B2Simple and inexpensive methodLow costMagnesium halidesGallium/indium/thallium compoundsHalogenSalt water

A method for producing halide brine wherein an alkali and a reducing agent are added to an aqueous fluid having a density greater than 8.30 lb / gal., (0.996 kg / L) water, waste water or sea water for example. The resulting fluid is then contacted with a halogen to form a halide brine. The reaction occurs in a conventional reactor such as a mixing tank.

Owner:TETRA TECH INC

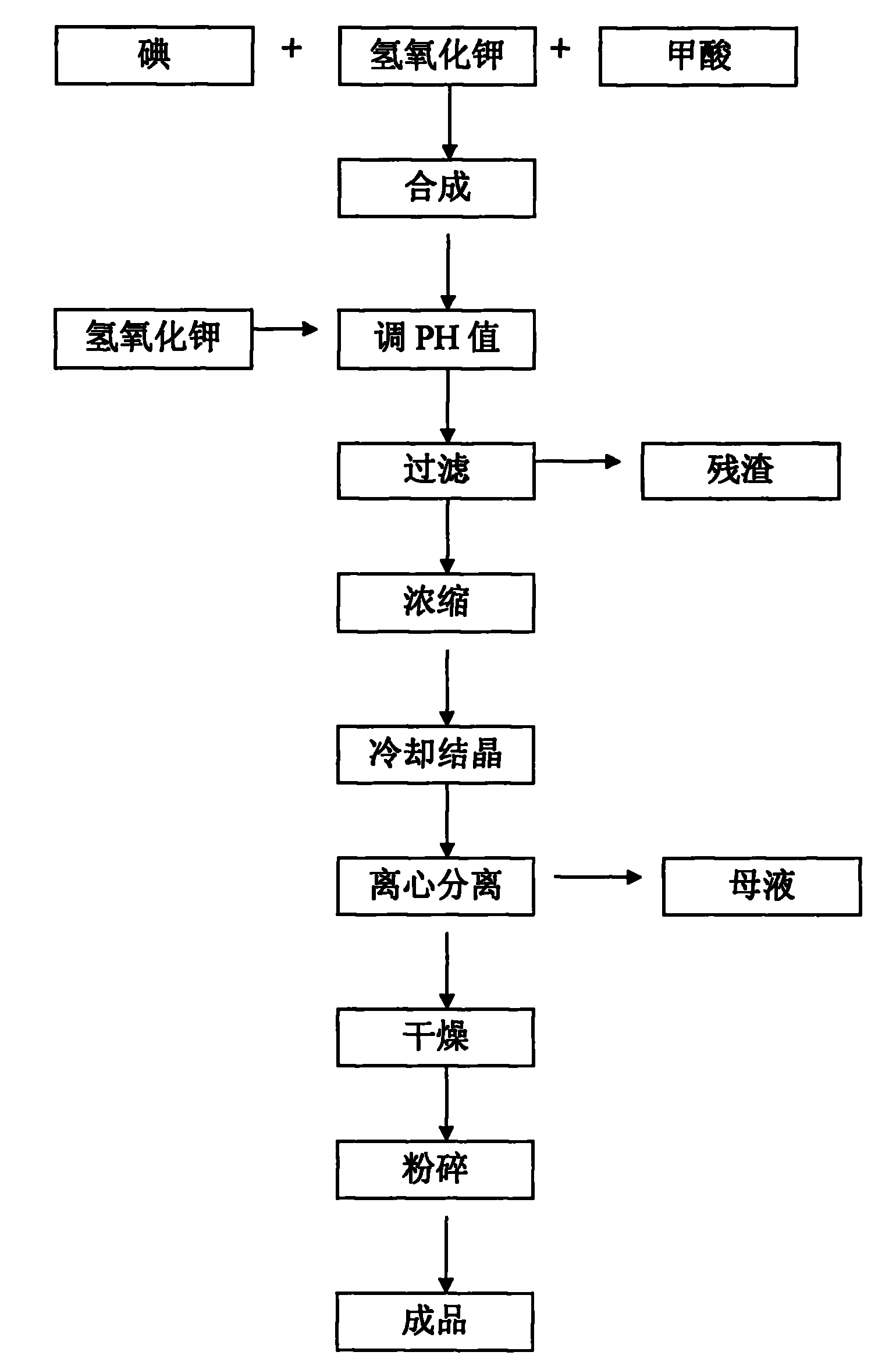

Preparation method of potassium iodide

InactiveCN102101683APromote safe productionEasy to produceAlkali metal iodidesEvaporationPotassium hydroxide

The invention relates to a preparation method of potassium iodide. The preparation method is implemented based on the following technical scheme: (1) adding 765 parts of iodine tablets in a reaction container with a stirrer, then adding distilled water, and stirring; slowly adding 337 parts of potassium hydroxide solution with the relative density of 1.3 under the state of stirring until the reaction is complete, wherein when the solution in the reaction is puce and the pH value of the solution is 5-6, potassium iodate crystals occur in the container; and (2) slowly adding 277 parts of formic acid solution in the solution to reduce the potassium iodate, then adding potassium hydroxide for regulating the pH value to 9-10, introducing steam, carrying out heat preservation for 1-2 hours, standing, filtering to remove undissolved substances so as to obtain a silvery solution, carrying out evaporation concentration until most crystals are separated out, carrying out cooling crystallization and centrifugal separation, and drying, so as to obtain a finished product. According to the preparation method of the potassium iodide, the potassium iodide can be safely, conveniently and reliably produced, and the large-scale production is ensured to be possible, thus the preparation method can be widely applied.

Owner:庄朝晖

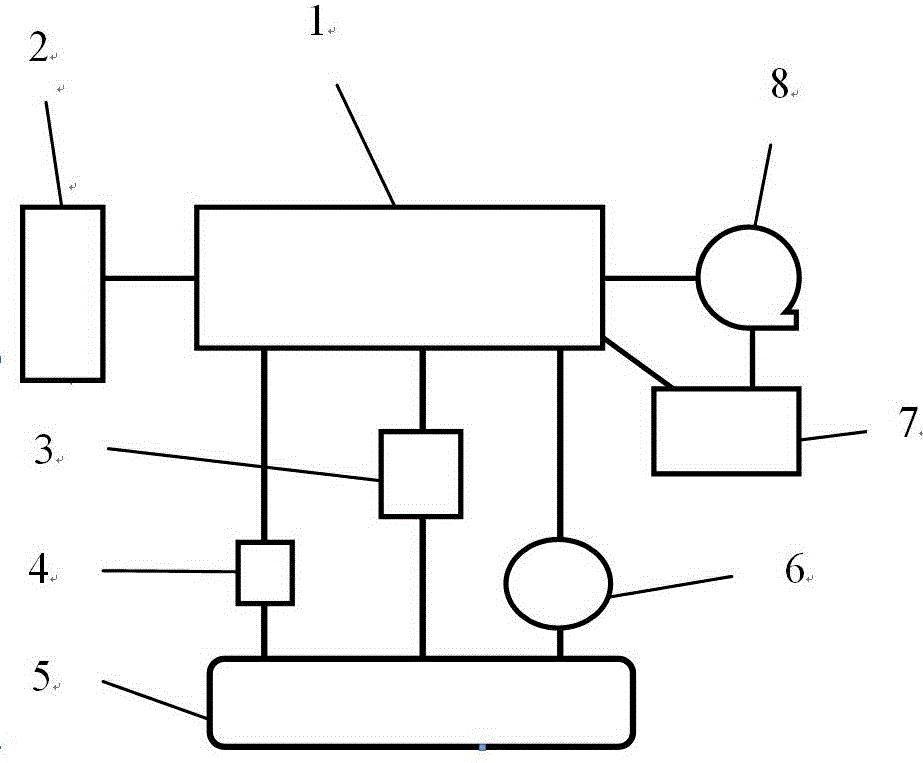

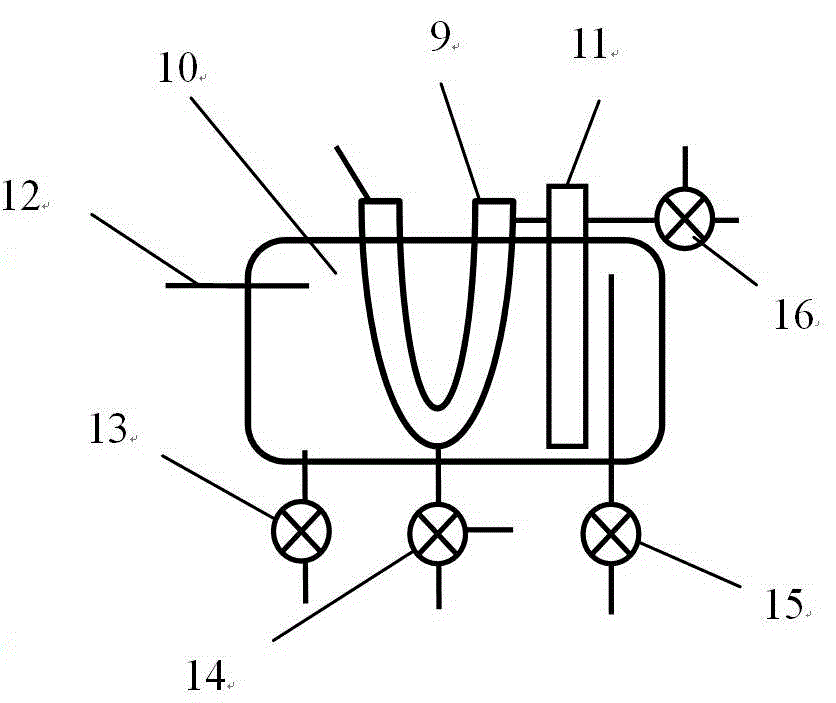

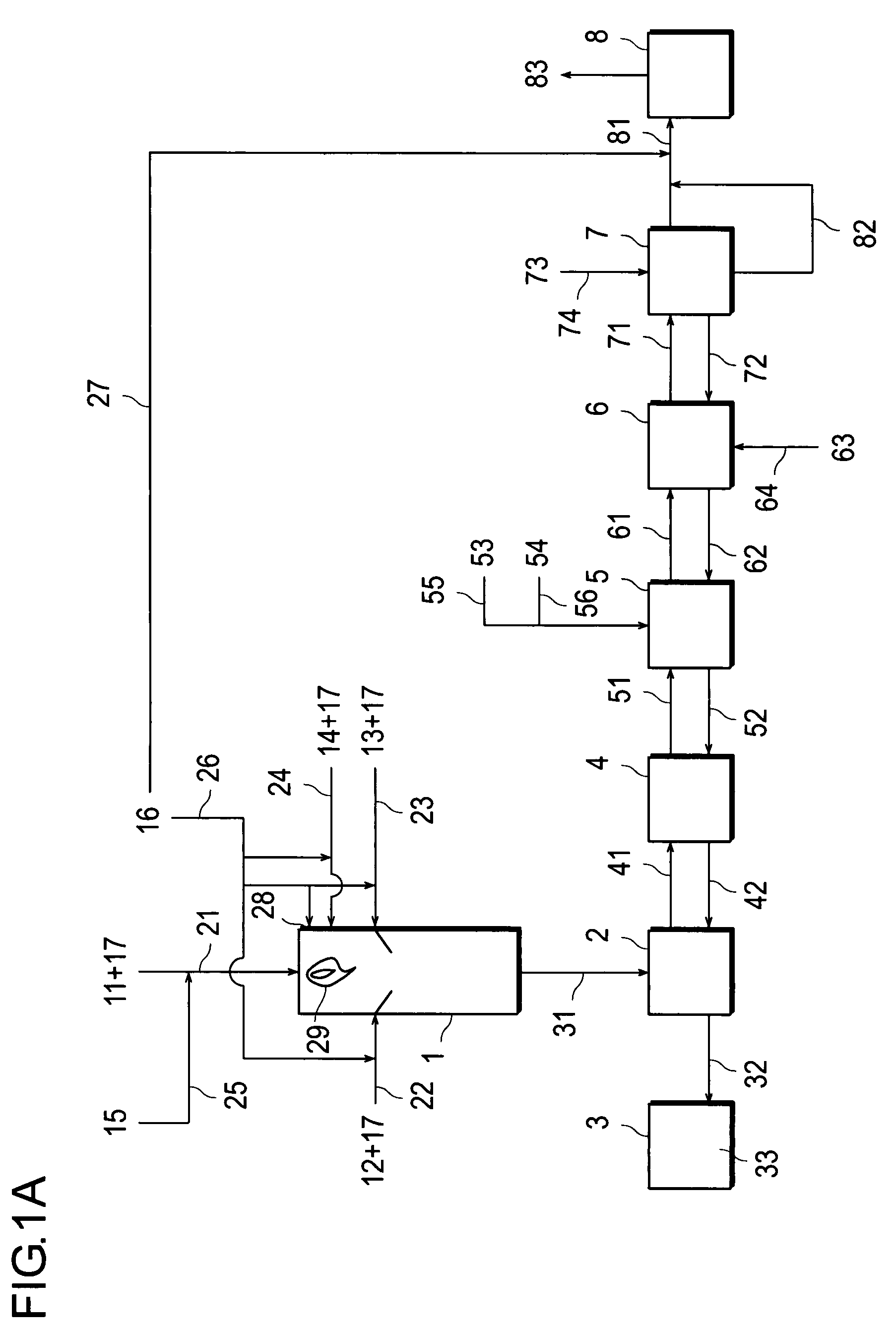

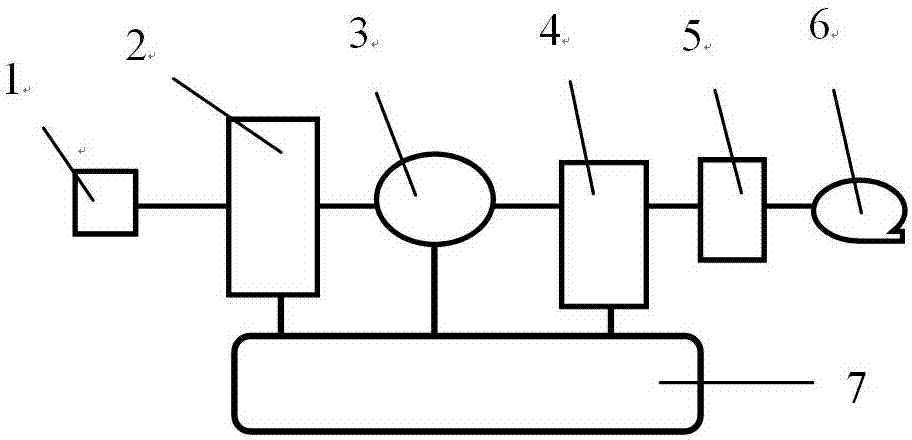

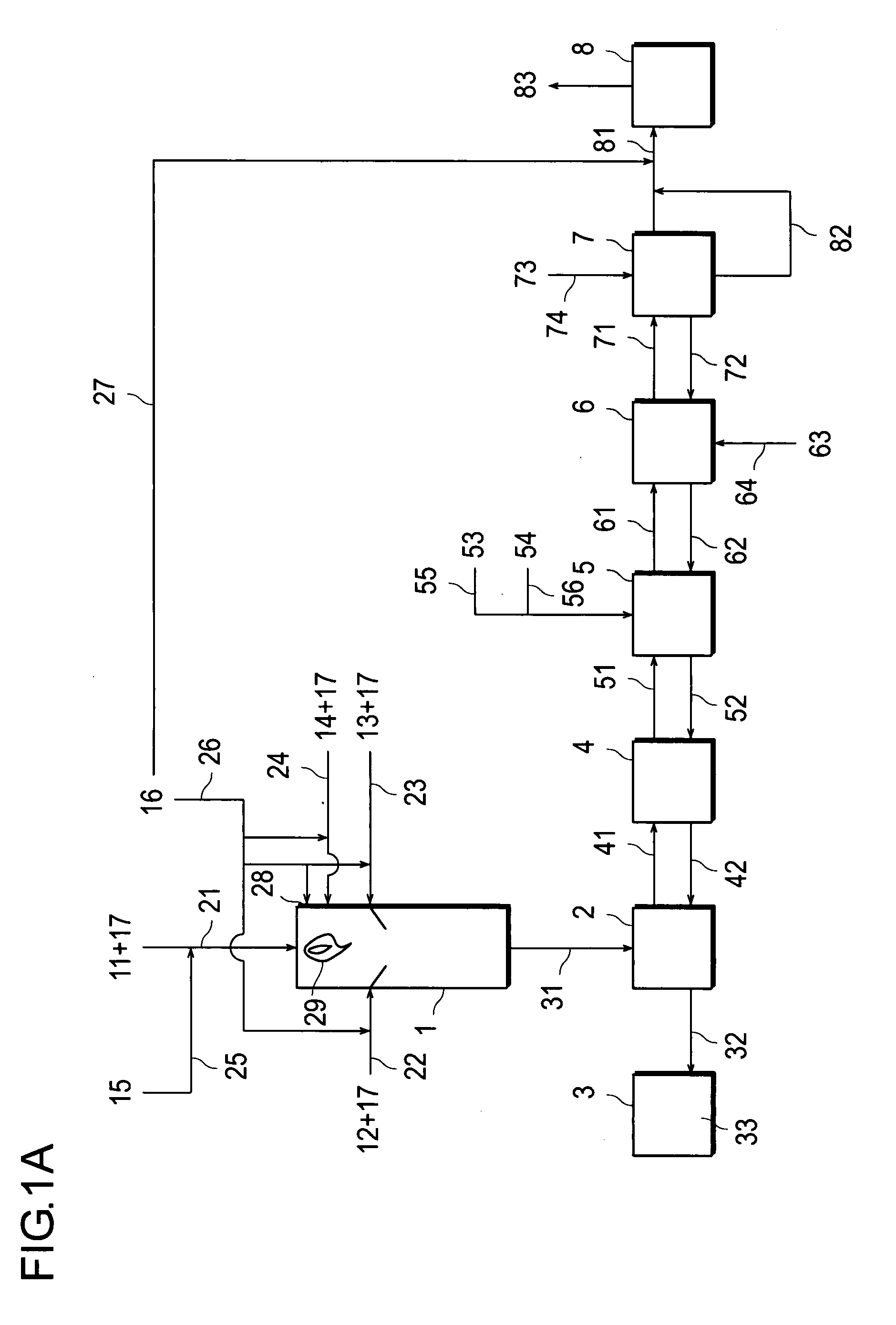

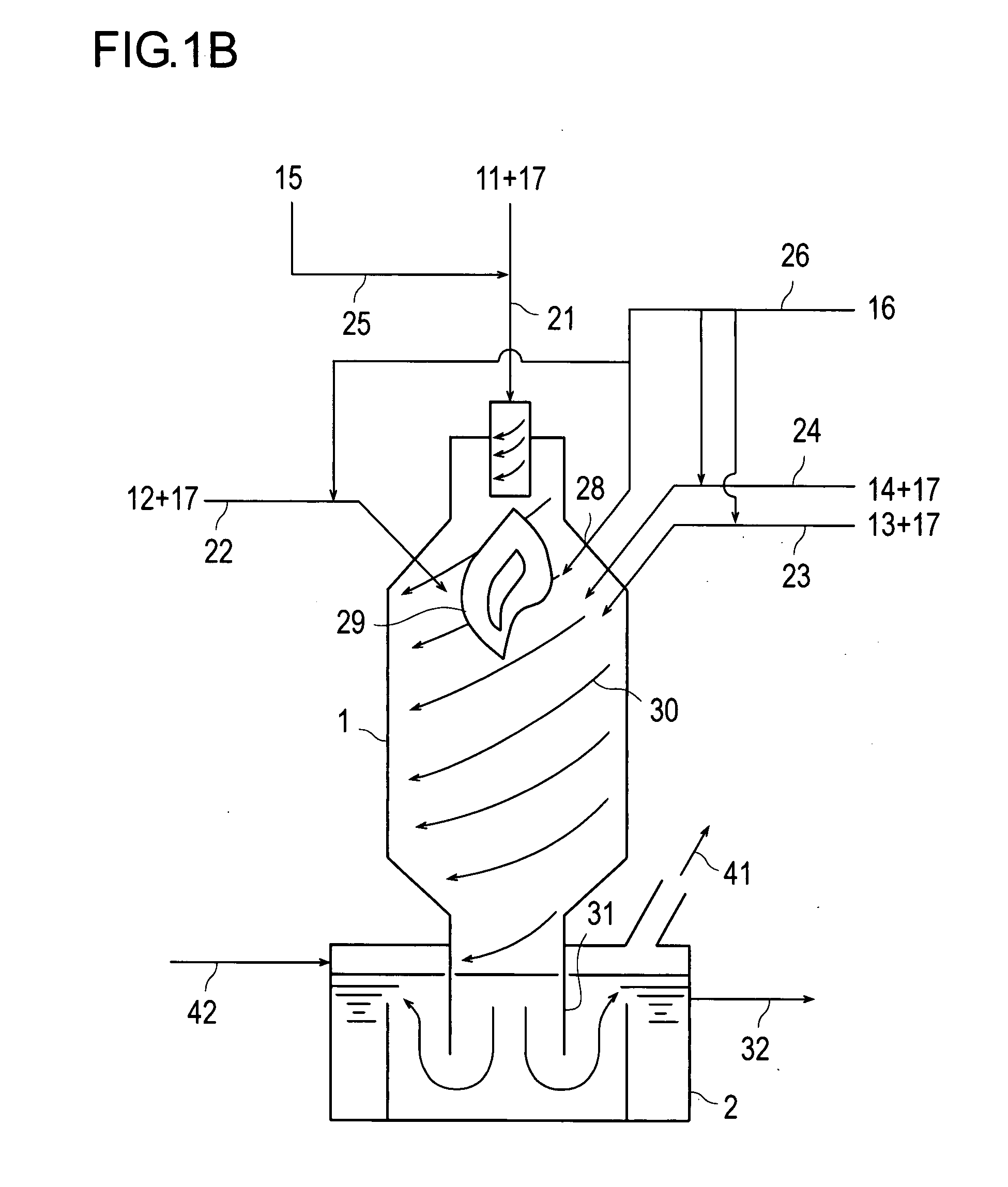

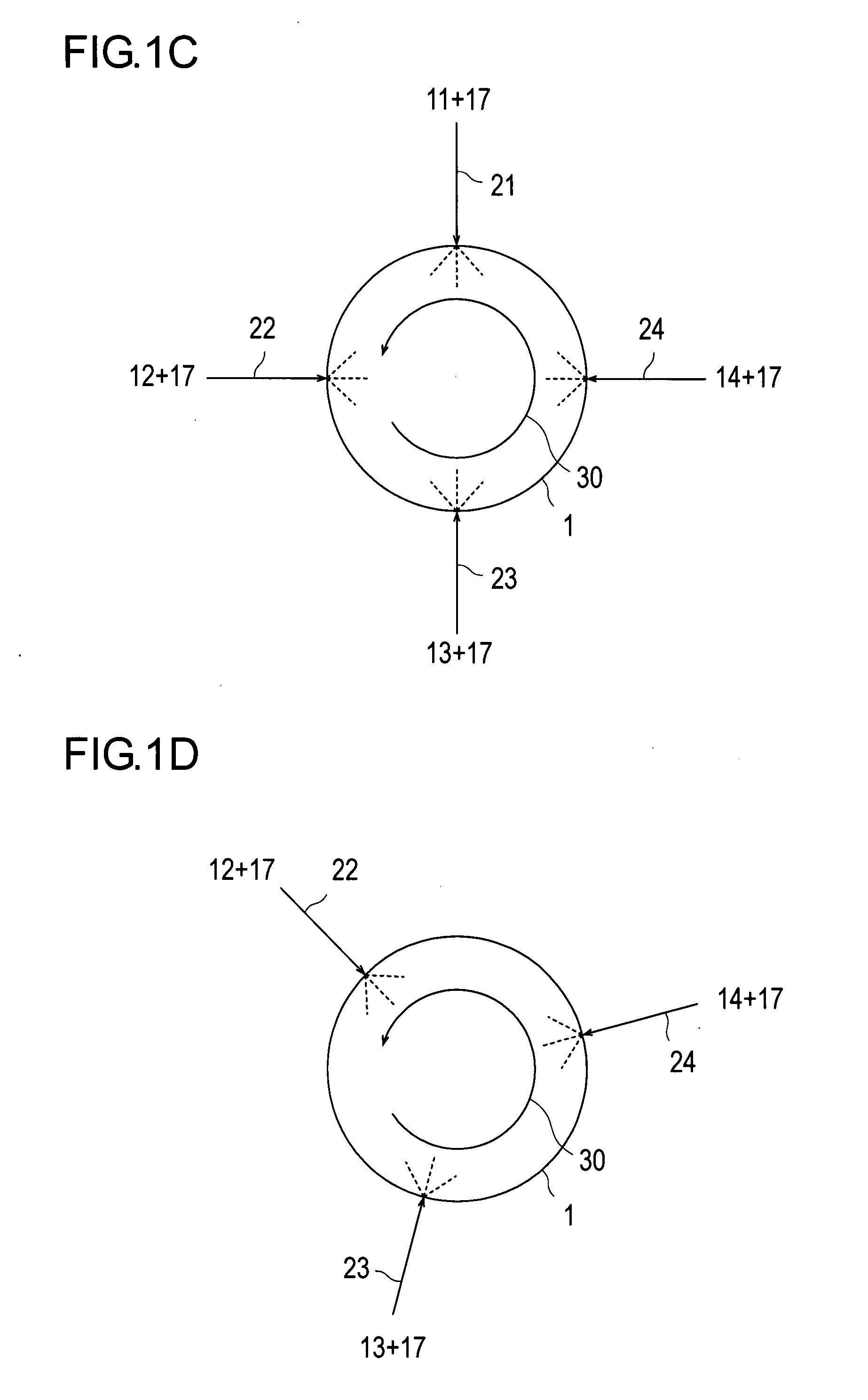

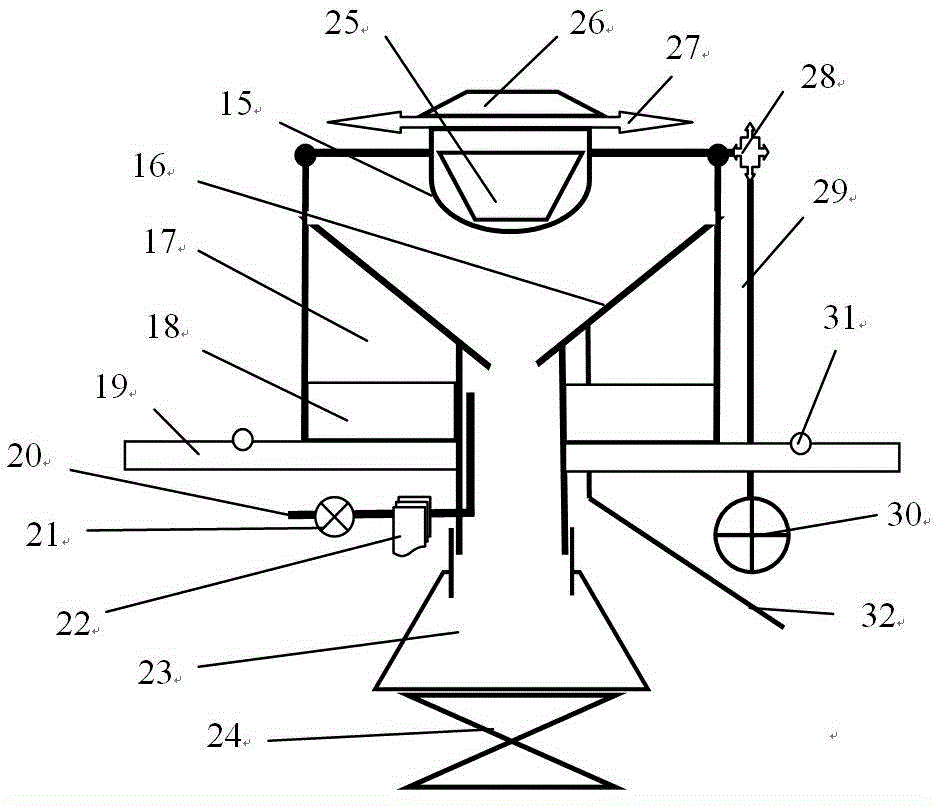

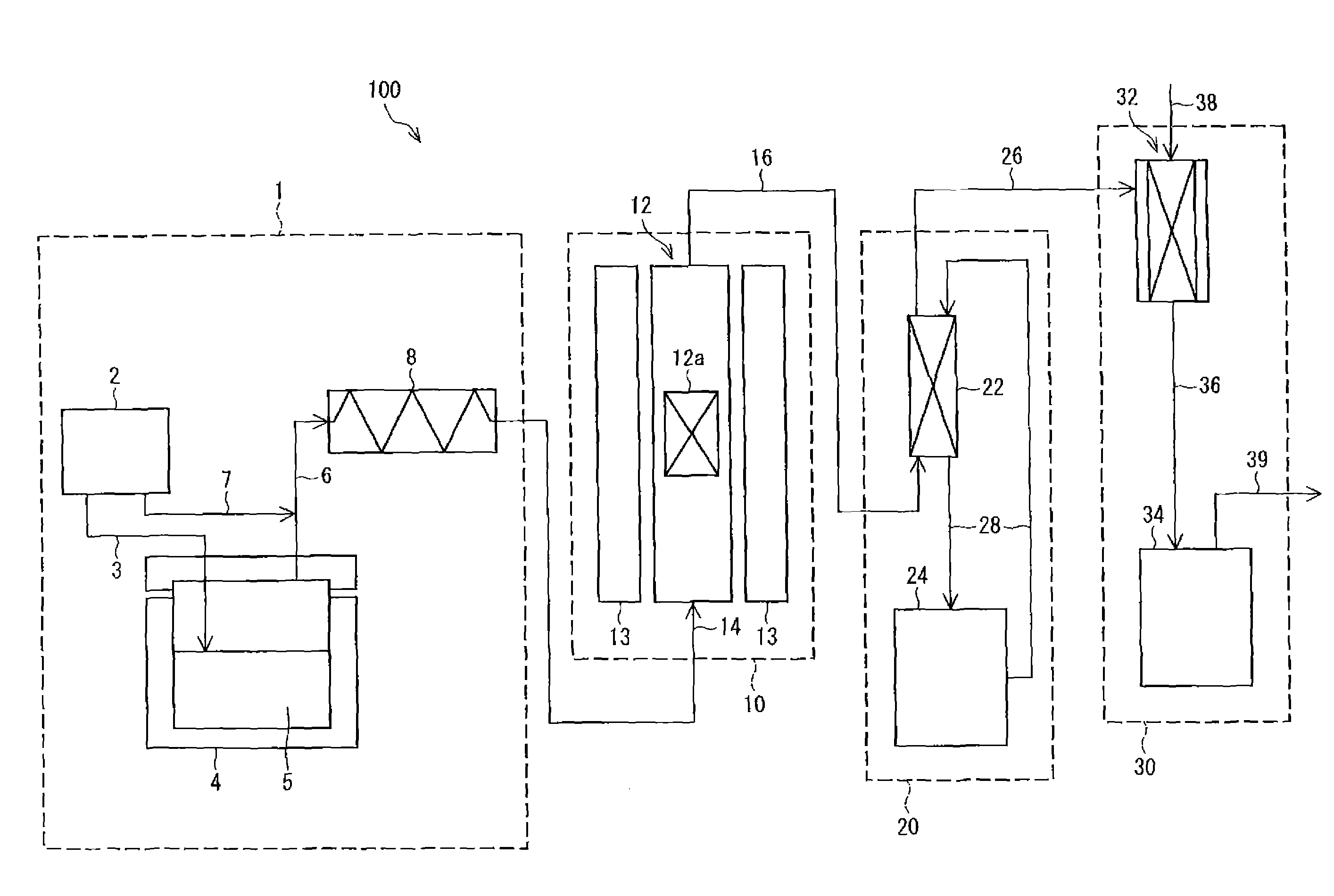

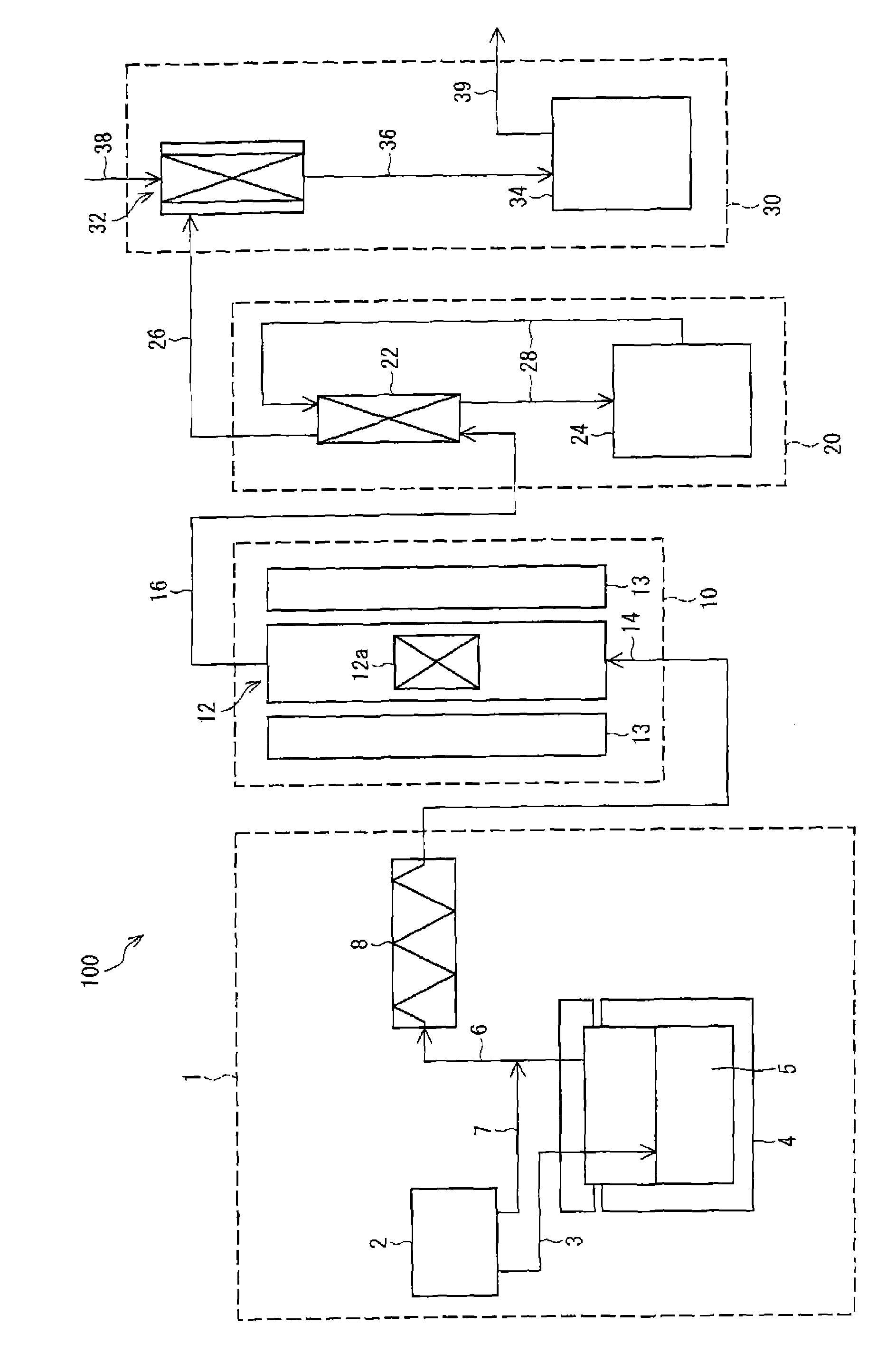

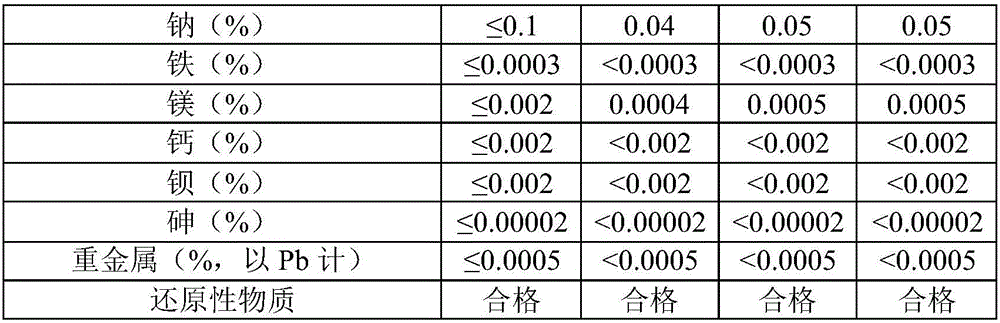

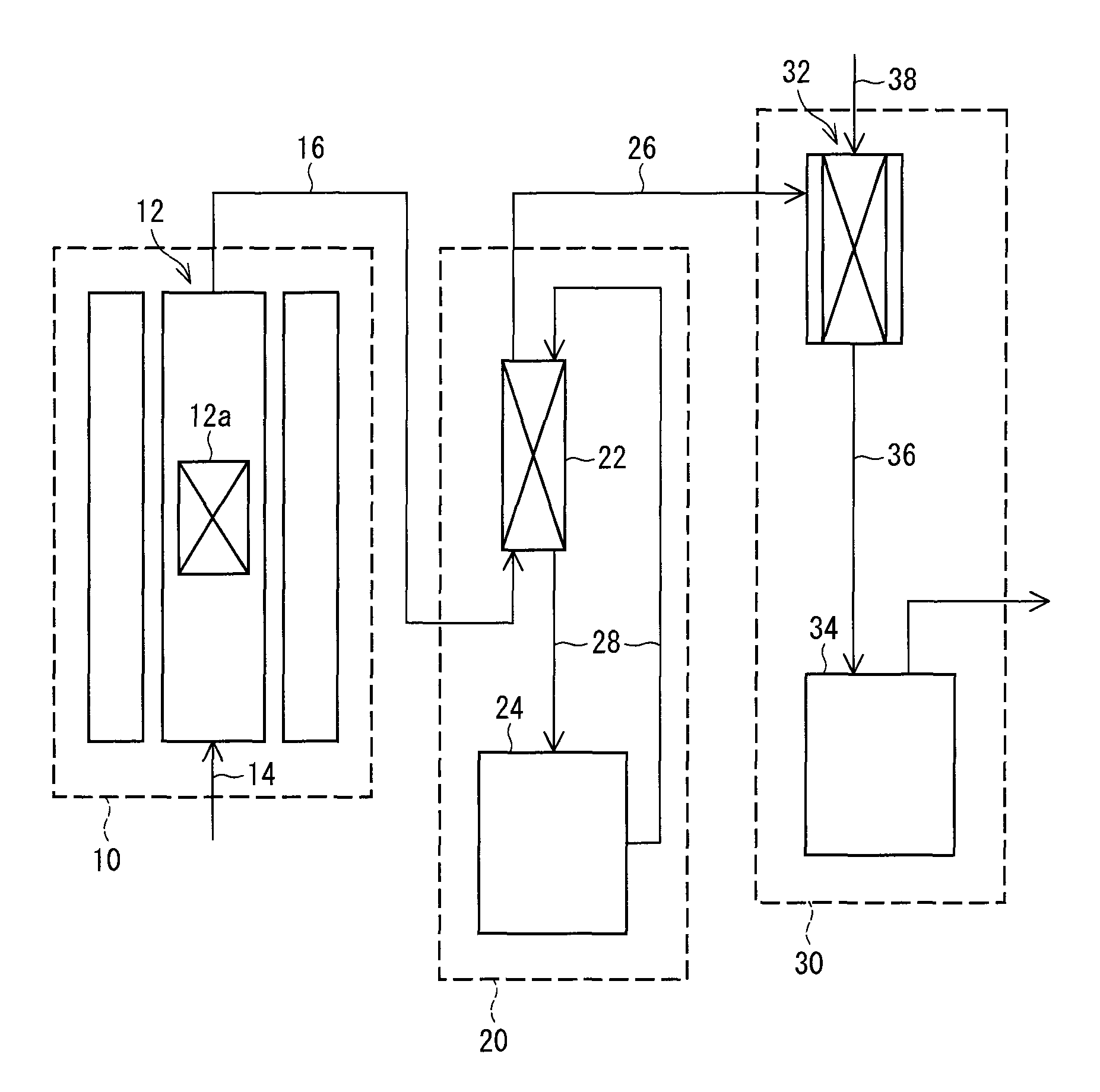

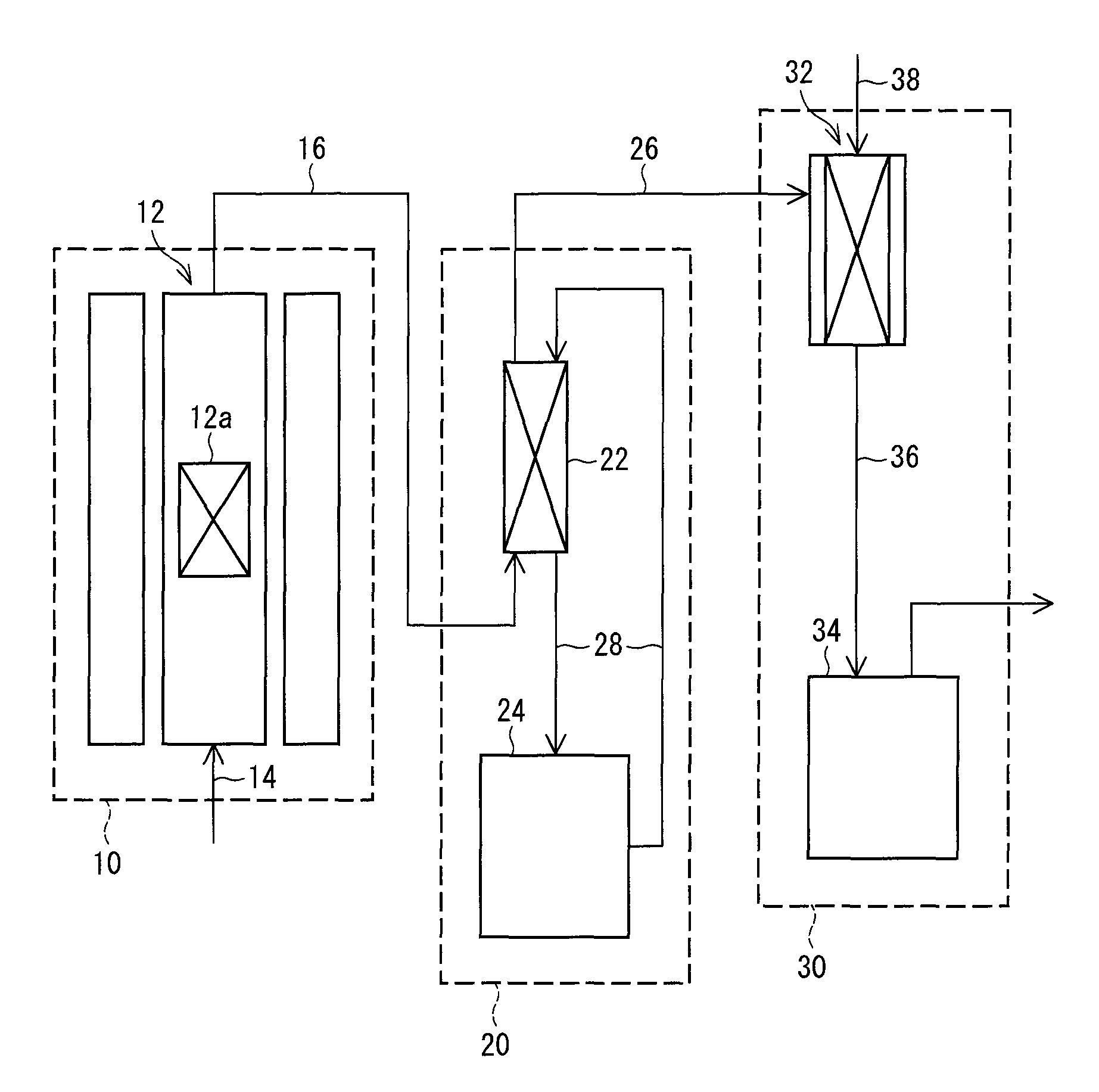

System and method for producing iodine compound

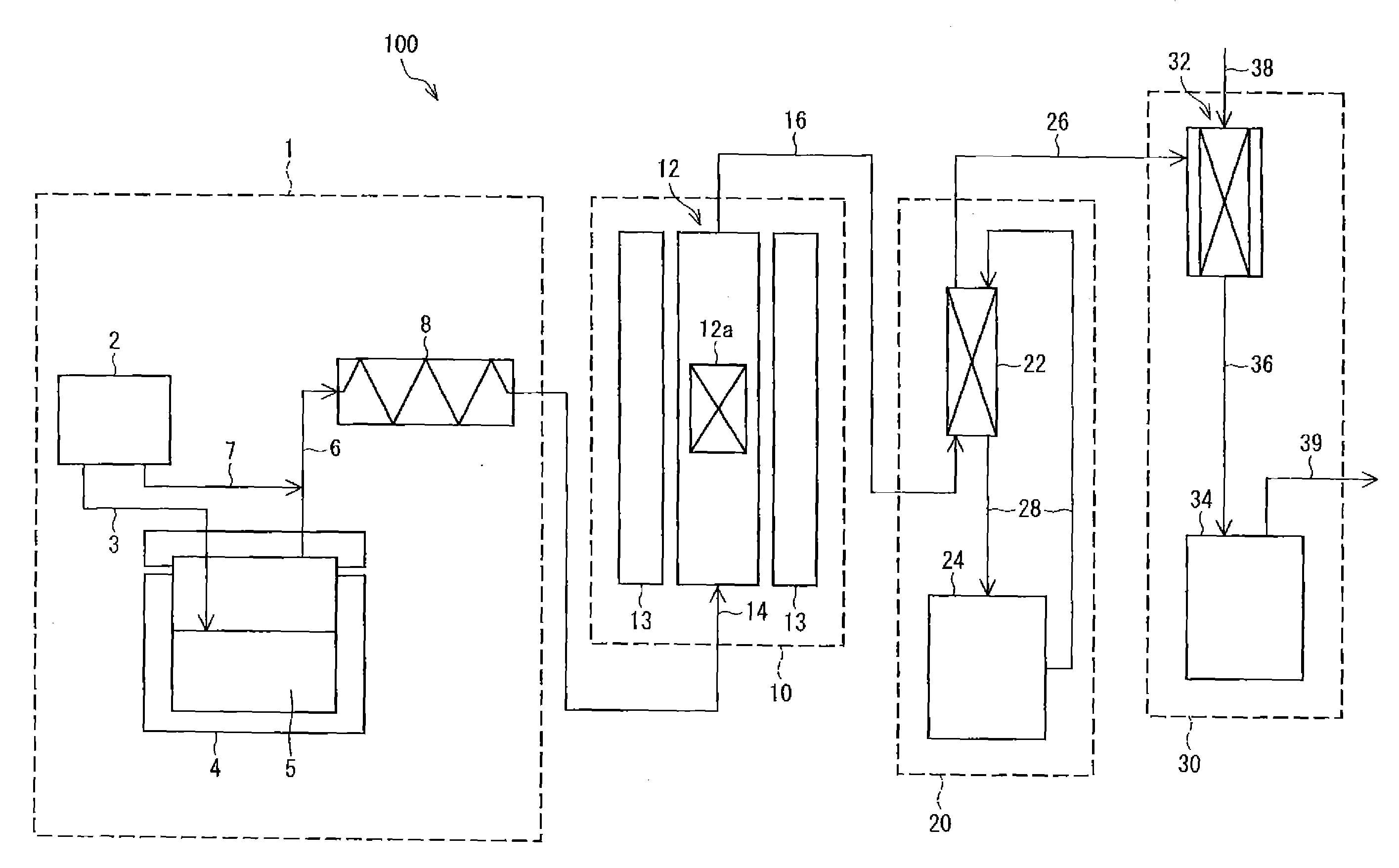

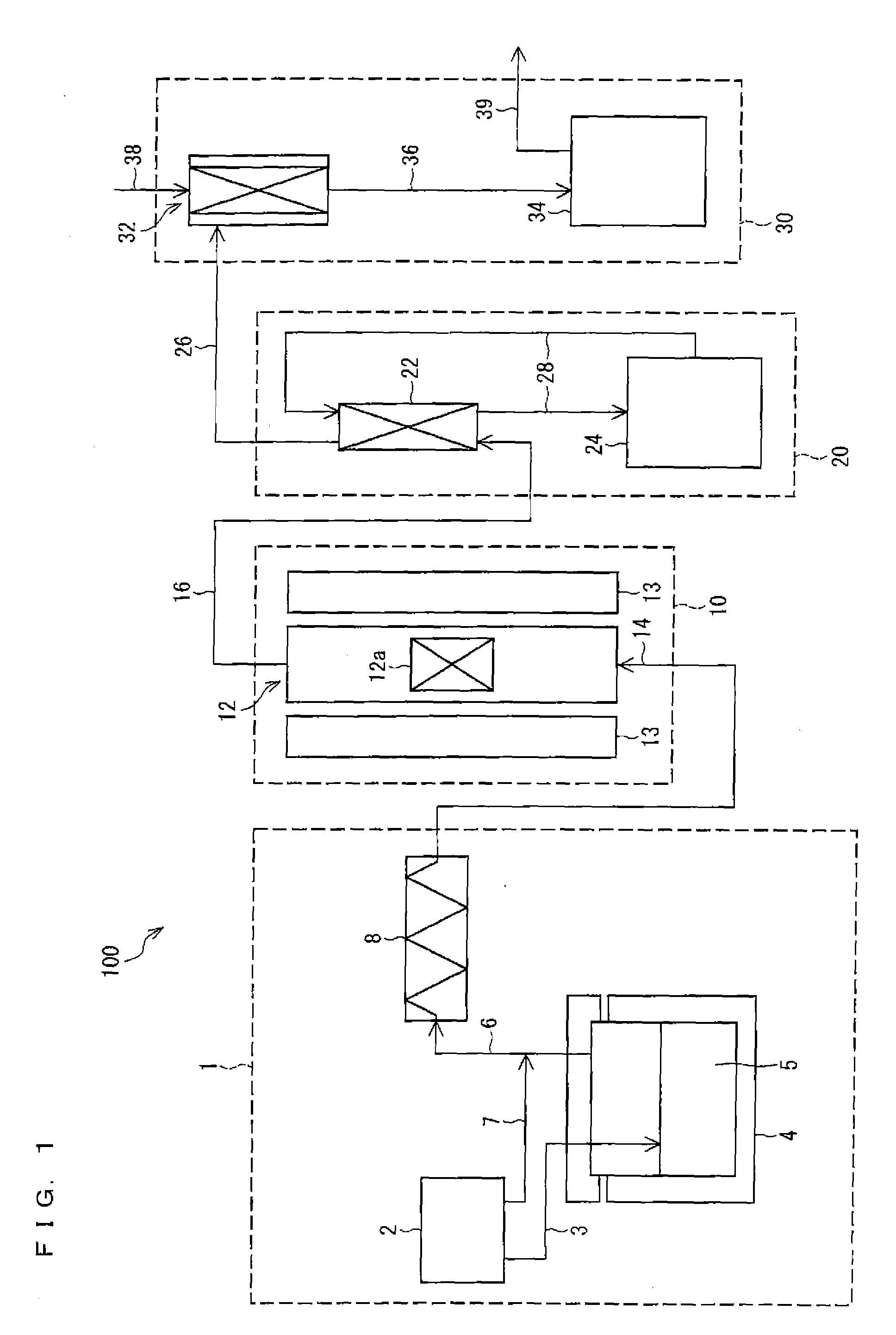

ActiveUS20100308261A1Avoid erosionSolution to short lifeHydrogen iodideIodide preparationTowerReagent

A system (100) of the present invention for producing an iodine compound includes: a raw material adjusting unit (1) for supplying hydrogen-containing gas to at least one of liquid iodine in an iodine melting pot (4) and gaseous iodine obtained by evaporating liquid iodine so as to obtain a mixture gas; a hydrogen iodide producing unit (10) including a hydrogen iodide producing tower (12) having a catalyst layer (12a) for converting the introduced mixture gas into crude hydrogen iodide gas; a hydrogen iodide refining unit for removing unreacted iodine from the introduced crude hydrogen iodide gas so as to obtain hydrogen iodide gas; and an iodine compound producing unit (30) for producing a target iodine compound from the obtained hydrogen iodide gas and a reaction material. This allows producing an iodine compound with high purity easily, efficiently, and with low cost.

Owner:NIPPON CHEMICALS CO LTD

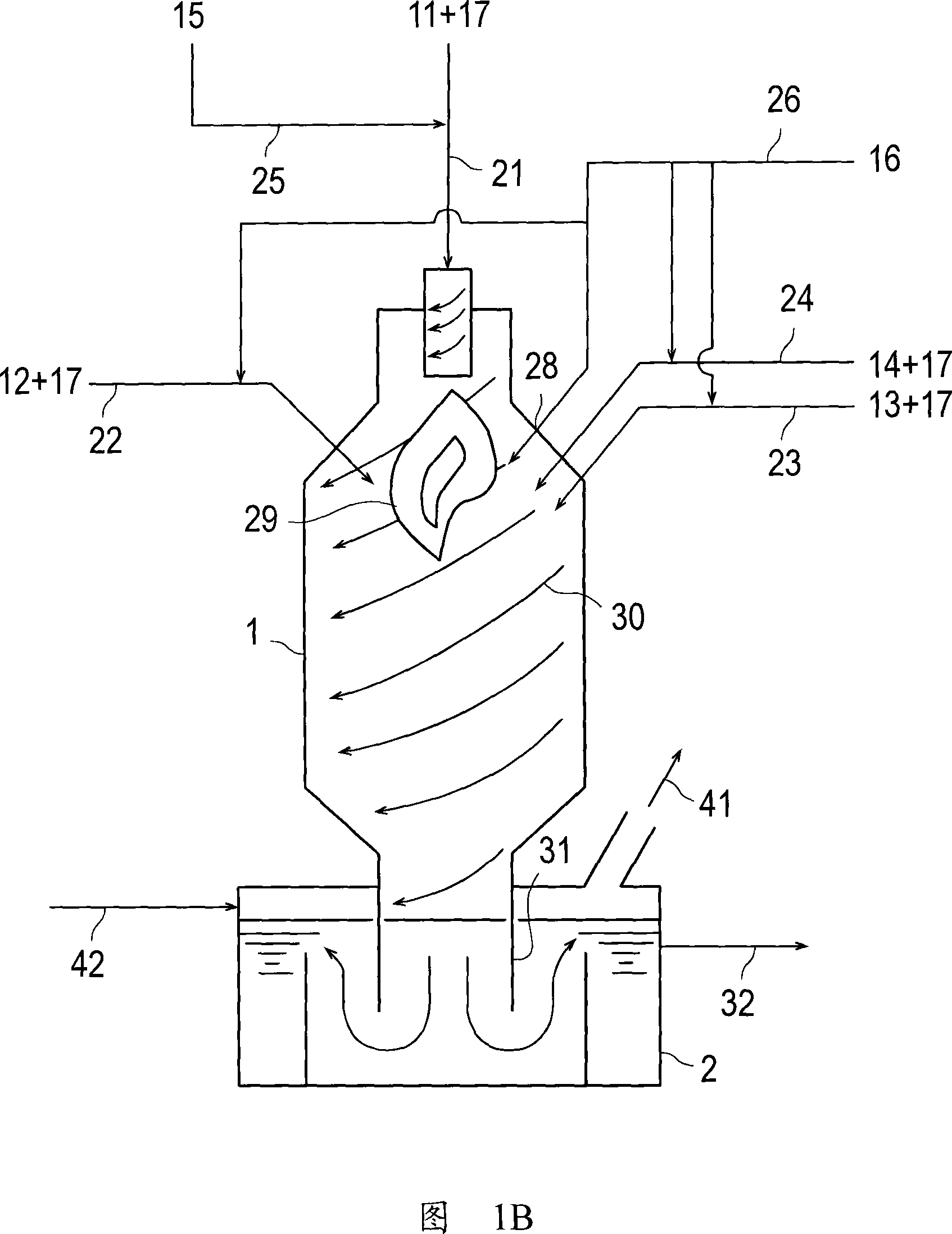

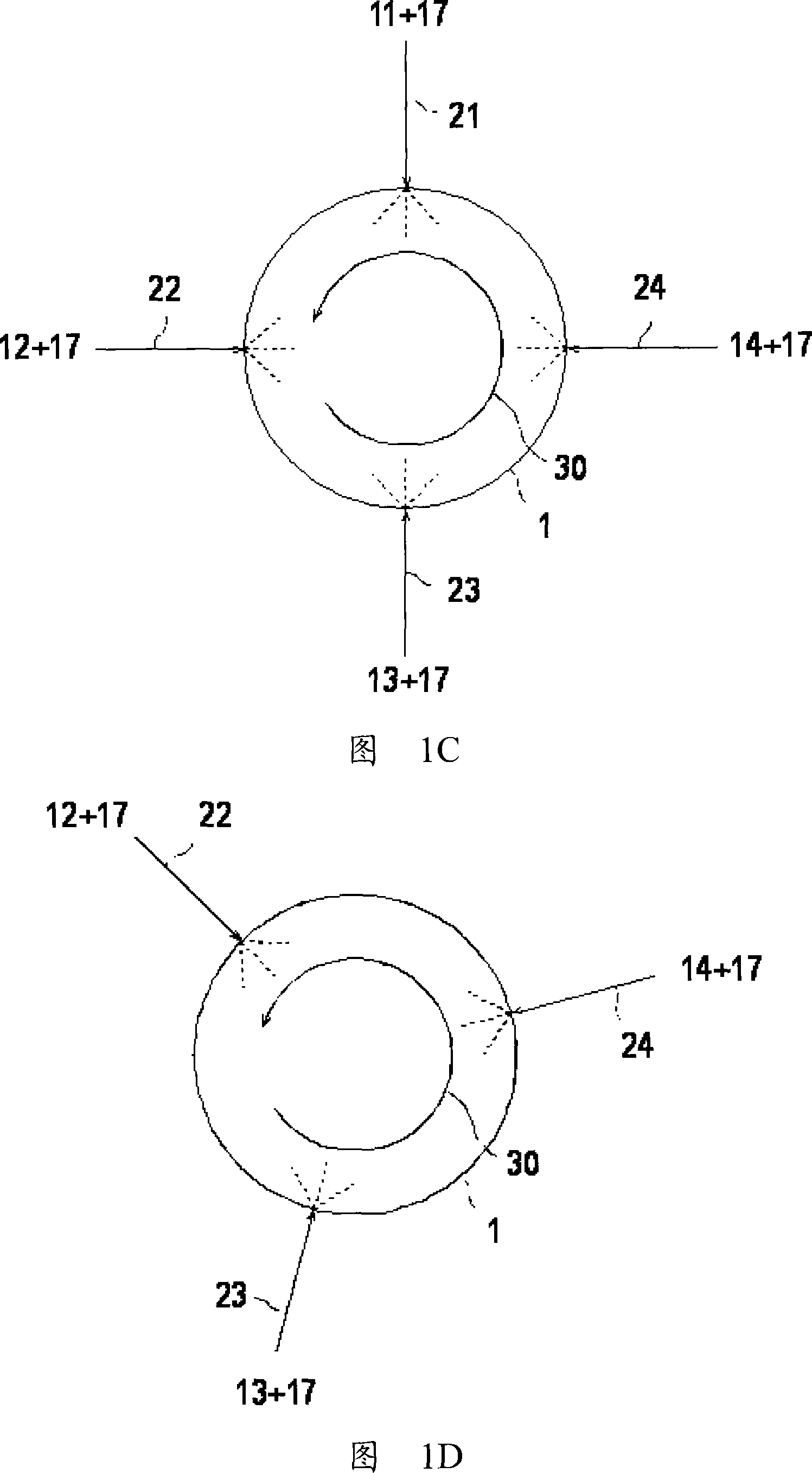

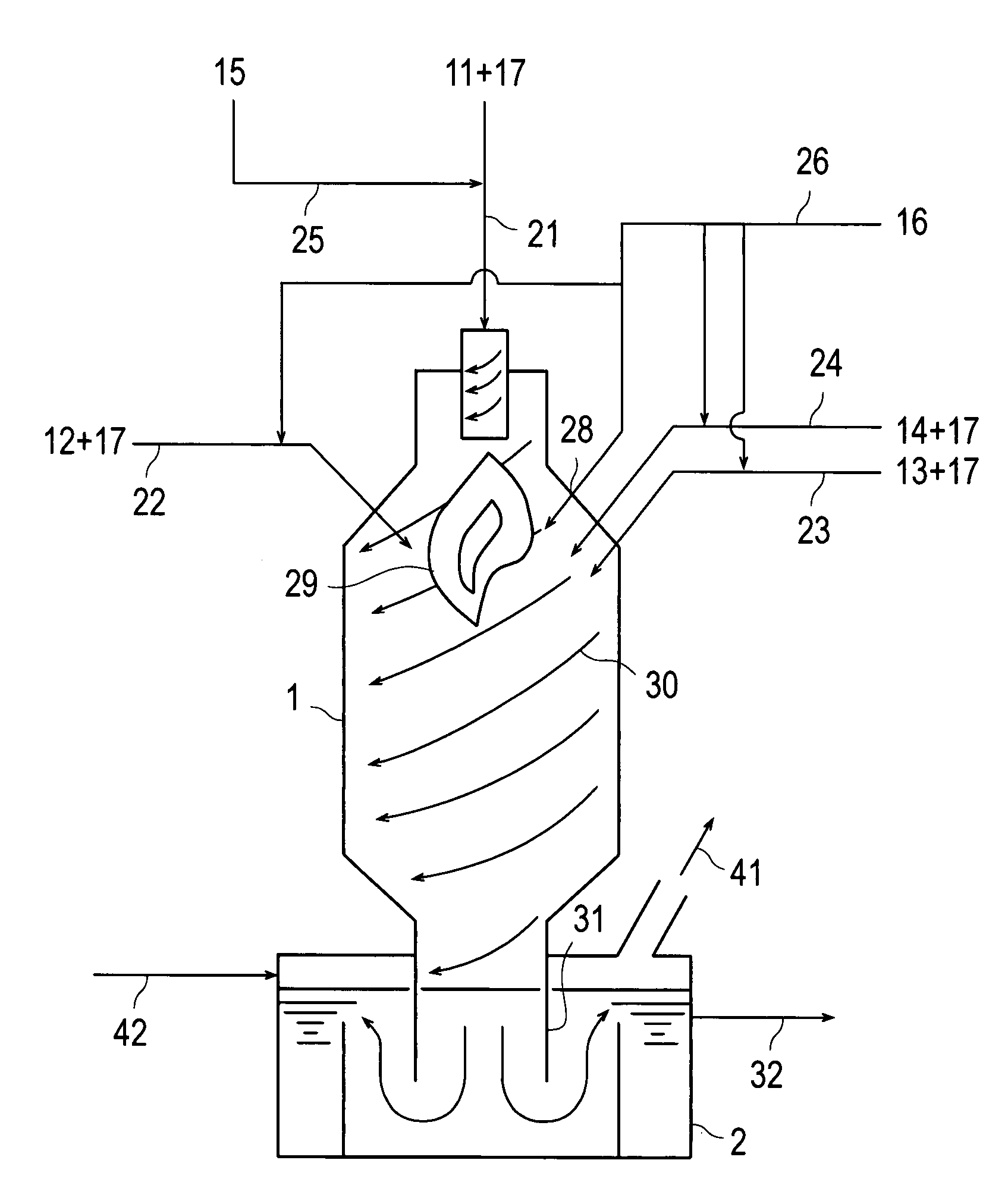

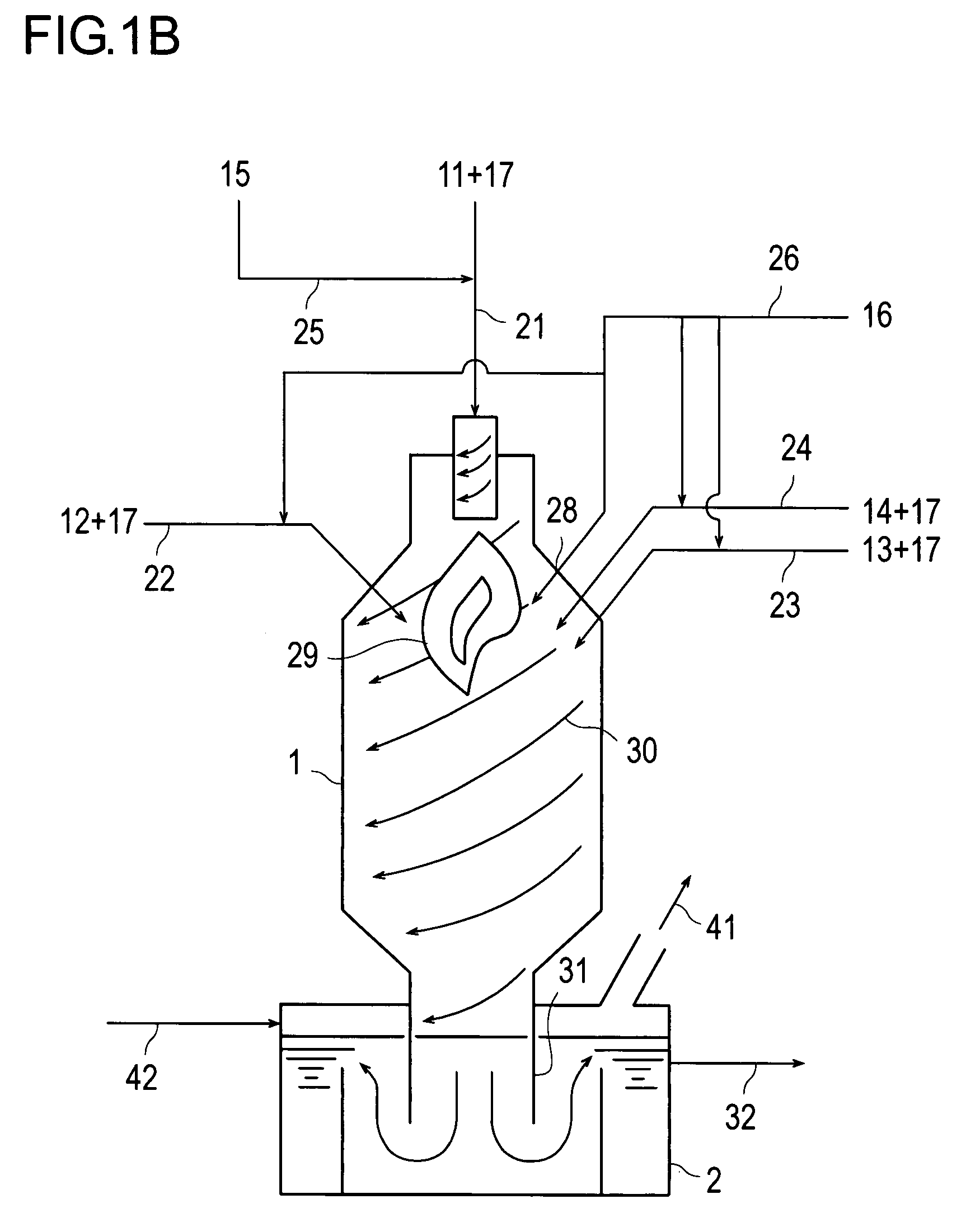

Process for the recovery of iodine

The invention aims at providing a process for the recovery of iodine which can be easily and economically carried out without premixing an iodine compound with an alkali metal compound and a solvent prior to the introduction into a combustion furnace. The aim is attained by a process for the recovery of iodine which is characterized by feeding separately an iodine-containing solution containing iodine and / or an iodine compound and a basic alkali metal compound solution and / or a basic alkaline earth metal compound solution into a roasting furnace to conduct oxidative decomposition of combustibles through heat treatment and fix iodine as stable salts and making the iodine and / or iodine salts contained in the effluent from the heat treatment step absorbed in water or an aqueous solution

Owner:NIPPON CHEMICALS CO LTD

Process for recovery of low sodium salt from bittern

InactiveUS6890509B2Calcium/strontium/barium sulfatesAlkali metal carbonates shape formationEvaporationChloride

A new process for recovery of Low Sodium Salt from bittern has been described in the present invention, the said process comprising desulphatation of bittern (by-product of salt industry), evaporation of bittern in solar pans and processing of solid mixture with water to produce a mixture of sodium and potassium chlorides and optionally preparing “free flowing” and iodized, by known techniques.

Owner:COUNCIL OF SCI & IND RES

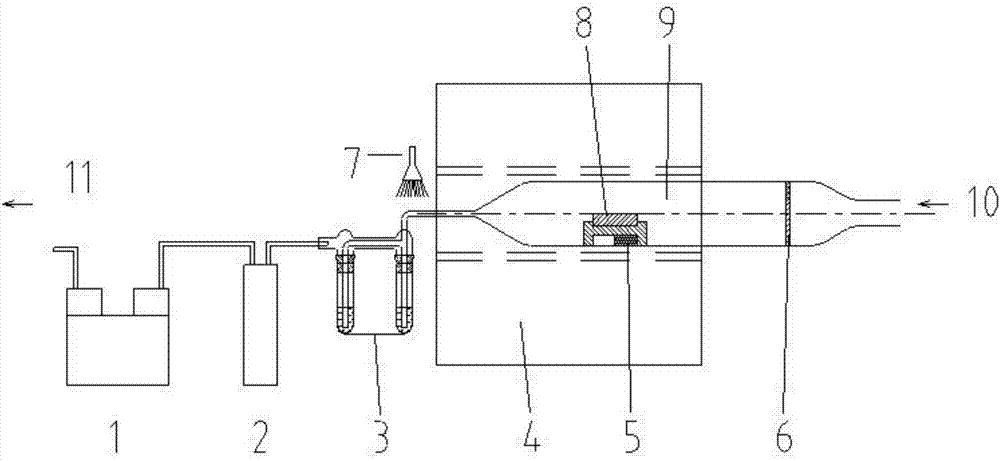

Radioiodine-131 vapor trapping device

InactiveCN104524957AEfficient captureEfficient productionDispersed particle separationAlkali metal iodidesRadioactive drugIodine

The invention provides a radioiodine-131 vapor trapping device which comprises a cold trap, an overflow groove, an alkaline liquor bottle, a heater, a nitrogen bottle, a refrigerating fluid storage tank, a product bottle and a vacuum pump, wherein the cold trap is respectively connected to the overflow groove, the alkaline liquor bottle, the heater, the refrigerating fluid storage tank, the product bottle and the vacuum pump by virtue of pipelines; the alkaline liquor bottle, the heater and the refrigerating fluid storage tank are respectively connected to the nitrogen bottle; and the product bottle is connected to the vacuum pump. The device disclosed by the invention can be used for effectively trapping radioiodine-131 vapor and converting the radioiodine-131 vapor into a Na131I solution which can be more than 10Ci / mL in concentration, so that the device is more conducive to the production of radioactive drugs having high specific activity. The device disclosed by the invention is compact and smart, and is convenient to operate.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

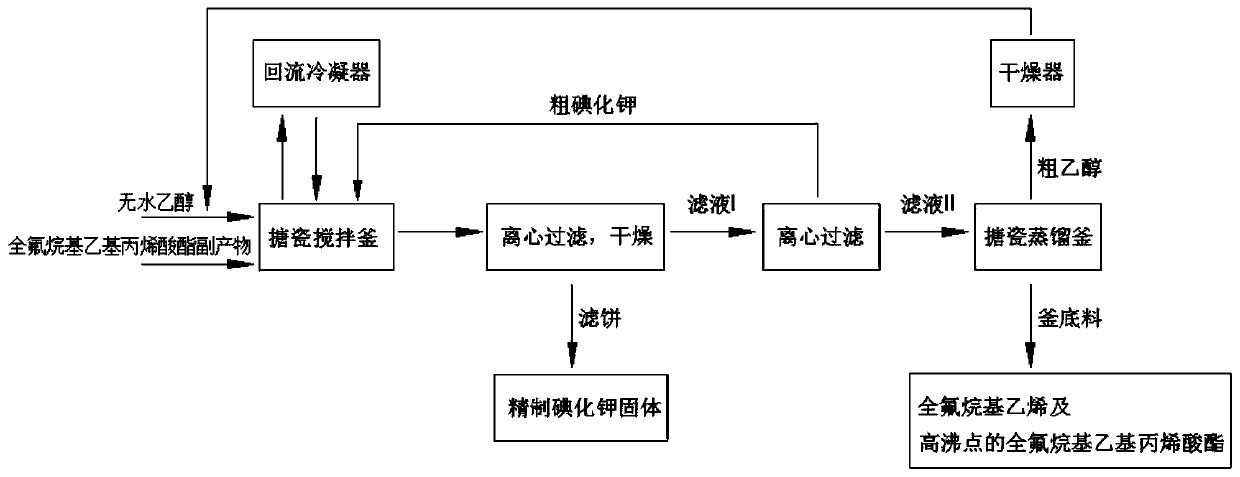

Method for purifying KI in perfluoroalkylethyl acrylate synthesized by-product

ActiveCN103241747ATo achieve the purpose of removing organic matterAchieve enrichmentAlkali metal halide purificationAlkali metal iodidesUltrafiltrationFiltration

The invention provides a method for purifying KI in a perfluoroalkylethyl acrylate synthesized by-product. The method comprises the following steps of: dissolving a perfluoroalkylethyl acrylate synthesized by-product KI crude product into hot deionized water with the volume 1.4-5 times that of the crude product, and after the obtained mixture is adsorbed by using an adsorbent, carrying out filtration on the obtained product by using an ultrafiltration membrane so as to remove colloidal and macromolecular organic matters in a solution; and then, conveying filter liquor to a reverse osmosis membrane to filter, so that at this moment, micromolecular organic matters in the filter liquor and water are gathered together, thereby realizing the gathering of KI. According to the invention, a reverse osmosis operation is applied to the purification of KI, thereby realizing the re-separation of potassium iodide, water and other impurities. According to the invention, a solid with a KI content of more than 99% can be obtained, and the yield is over 96%. In the whole production, physical separation is completely adopted, and no chemical substance is introduced, thereby achieving an effect of clean production. A KI solution is gathered by using reverse osmosis, thereby reducing the energy consumption.

Owner:SICHUAN XIAIFU TECH

Production method of medical sodium iodide

A process for preparing medicinal sodium iodide from iodine, Fe powder and dicarbonate includes such steps as preparing ferrous iodide, reaction between ferrous iodide and dicarbonate to obtain ferrous carbonate, sodium iodide and water, separating sodium iodide, removing SO4 radicals, filtering, concentrating and crystallizing.

Owner:自贡市金典化工有限公司

Method for recovering iodine

InactiveUS7736617B2Recovering iodine simply and economicallyIodide preparationIodineIodised saltAlkaline earth metal

An object of the present invention is to provide a method for recovering iodine, which can be carried out simply and economically without practicing mixing processing operation of iodine-containing material, an alkali metal compound and a solvent in advance before introducing to a combustion furnace. The object of the present invention can be attained by a method for recovering iodine which comprises feeding an iodine-containing solution containing iodine and / or iodine compound, a basic alkali metal compound solution and / or a basic alkaline earth metal compound solution separately to a roasting furnace, oxidatively decomposing a combustible material by heat treatment, and absorbing iodine and / or iodine salt contained in a component at heat treatment exit with water or an aqueous solution.

Owner:NIPPON CHEMICALS CO LTD

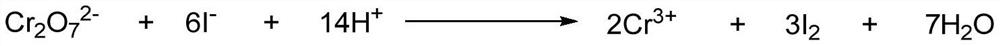

Analytical pure potassium iodide preparation method using waste liquid containing iodine

InactiveCN106517252AFix security issuesSimple and fast operationAlkali metal iodidesSludgeImpurity ions

The invention discloses an analytical pure potassium iodide preparation method using waste liquid containing iodine. The method comprises the steps of at first reducing all inorganic iodine of different forms in waste liquid containing iodine into iodide ions, using hydrogenperoxide as oxidant, under 80 DEG C oxidizing the iodide ions directly into iodine elements, subliming and overflowing, making sure that the iodine elements do not get oxidized further, breaking iodine clock reaction, after KOH absorbing iodine vapor, generating IO3<->, using hydrazine for reduction, making sure that no other impurity ions are introduced into potassium iodide solution, at last acquiring the analytical pure potassium iodide. The method is applicable for the treatment of waste liquid containing iodine of any forms and concentrations. The method has the advantages of being environment-friendly and economical, being simple and convenient to operate, low in cost, high in recyclability, and causing no secondary contamination during the whole process. The method can be used for the direct preparation of analytical pure potassium iodide, thus avoiding the safety problems of iodine storage and iodine vapor.

Owner:WUXI YISHUIYUAN RESOURCE RECYCLING TECH CO LTD

A kind of purification method of potassium iodide and application thereof

InactiveCN102275954AEasy to separateEasy to operateAlkali metal halide purificationAlkali metal iodidesPurification methodsAlcohol

The invention discloses a method for purifying potassium iodide and its application. The method comprises the following steps: (1) taking technical grade potassium iodide, adding alcohol to soak for 0.5-2 hours; then centrifuging to take the precipitate; (2) repeating the precipitate The operations of step (1) are performed 3 to 5 times; (3) the precipitate is added to an alcohol containing potassium hydroxide and soaked for 0.5 to 1 hour; then centrifuged to take the precipitate; and the precipitate is dried to obtain purified potassium iodide. The potassium iodide purification method provided by the invention has the advantages of low energy consumption, low cost and less environmental pollution; simple operation, high yield, high efficiency, and good separation effect on sodium ions; overcoming the low yield of the existing potassium iodide purification method, and the removal of The effect of sodium is not ideal.

Owner:GUANGDONG GUANGSHI REAGENTS TECH

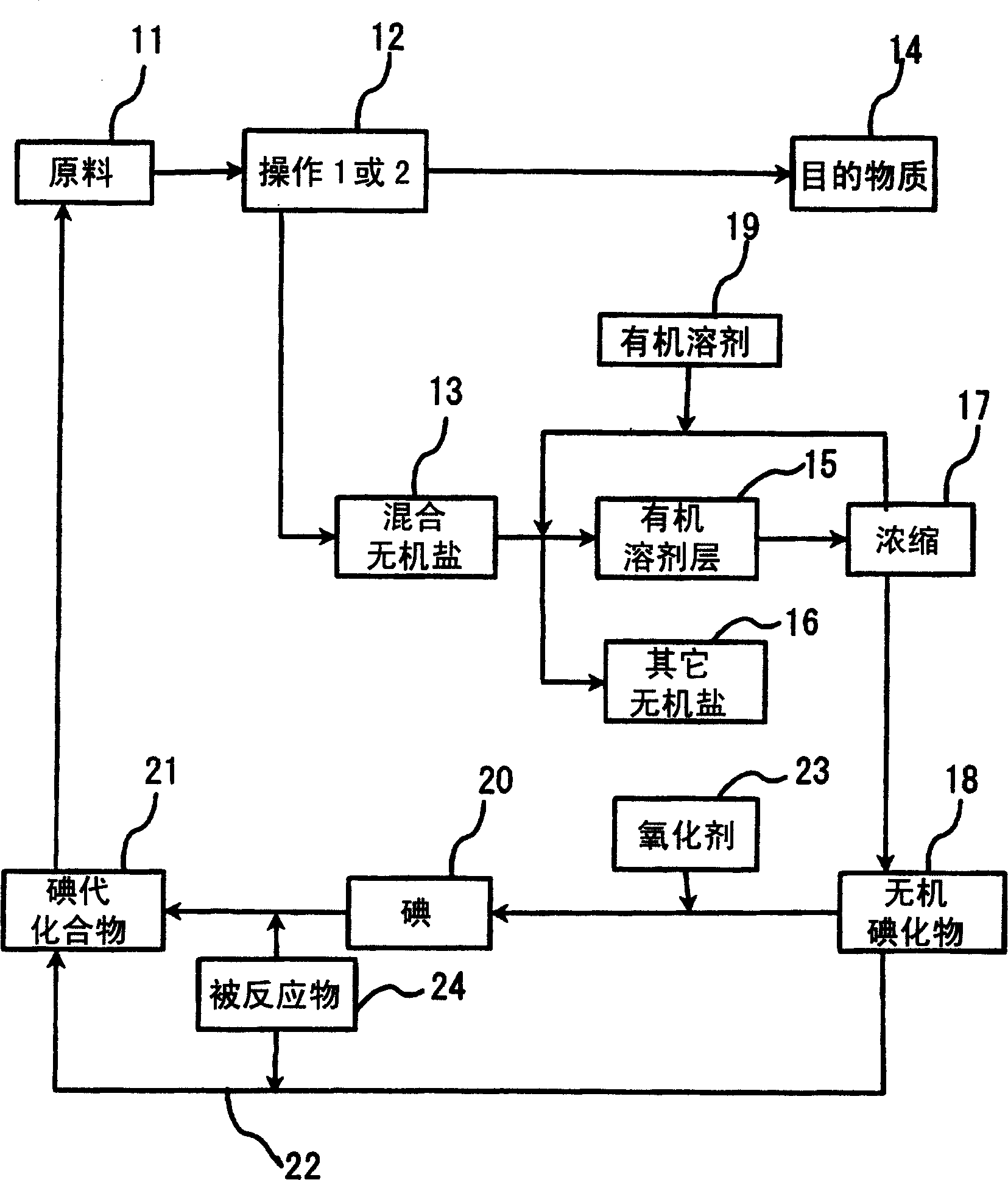

Reclaiming method of inorganic iodide

InactiveCN1689966AHigh yieldEasy to recycleIodide preparationLiquid solutions solvent extractionHigh concentrationInorganic salts

To provide a method for recovering an inorganic iodide, by which the inorganic iodide can be easily recovered in a high concentration from a mixed inorganic salt aqueous solution containing the inorganic iodide without necessitating specific equipment, and to obtain an objective substance at a low cost by recycling the recovered inorganic iodide in an iodine ion-removing reaction.

Owner:FUJIFILM WAKO PURE CHEM CORP

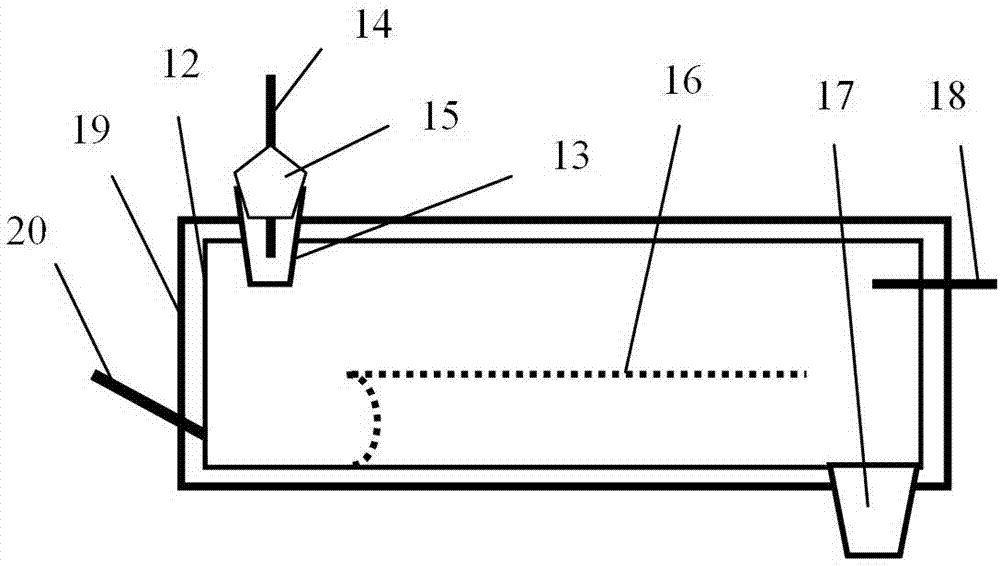

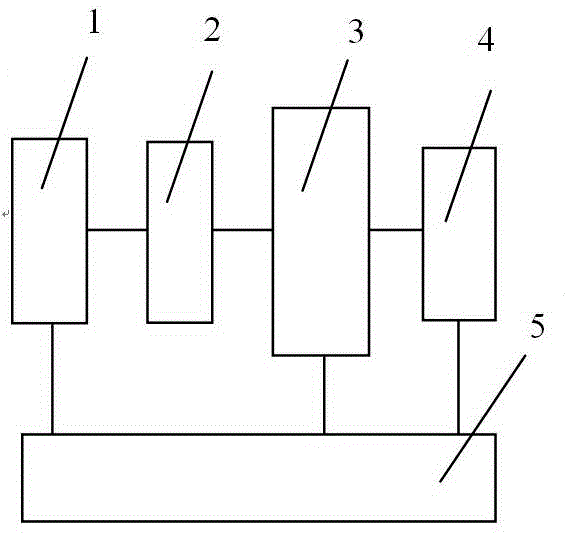

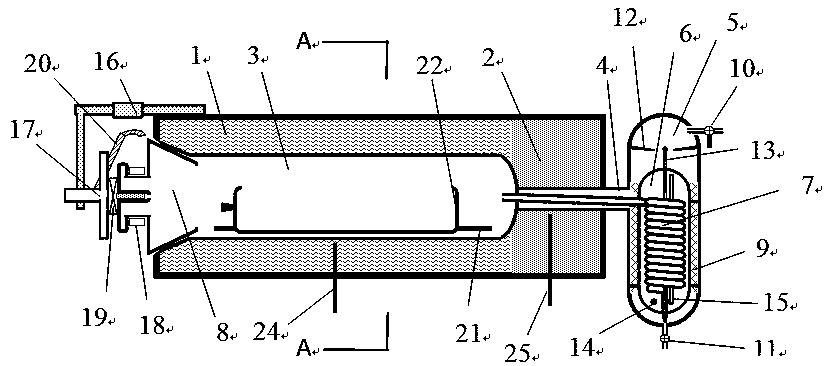

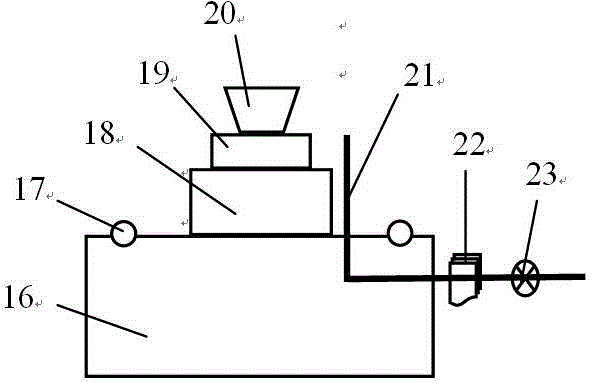

Horizontal high-concentration Na<131>I production device

InactiveCN104512913ARealize mass productionSafeguard storageAlkali metal iodidesHigh concentrationDistillation

The invention provides a horizontal high-concentration Na<131>I production device, which comprises a dryer, a distillation device, a purifier, an iodine-131 trap, an exhaust gas purifier, a vacuum pump and a controller, wherein the dryer, the distillation device, the purifier, the iodine-131 trap, the exhaust gas purifier and the vacuum pump are sequentially connected through a pipeline; the distillation device, the purifier and the iodine-131 trap are electrically connected with the controller respectively. According to the device, iodine-131 steam distilled from activated TeO2 can be efficiently treated, and about 98 percent of iodine-131 can be recovered to obtain a medical Na<131>I solution at concentration of higher than 10Ci / mL. The device is compact, small and convenient to operate.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Method for recovering iodine

InactiveUS20090041655A1Recovering iodine simply and economicallyIodineIncinerator apparatusIodised saltCombustion

An object of the present invention is to provide a method for recovering iodine, which can be carried out simply and economically without practicing mixing processing operation of iodine-containing material, an alkali metal compound and a solvent in advance before introducing to a combustion furnace. The object of the present invention can be attained by a method for recovering iodine which comprises feeding an iodine-containing solution containing iodine and / or iodine compound, a basic alkali metal compound solution and / or a basic alkaline earth metal compound solution separately to a roasting furnace, oxidatively decomposing a combustible material by heat treatment, and absorbing iodine and / or iodine salt contained in a component at heat treatment exit with water or an aqueous solution.

Owner:NIPPON CHEMICALS CO LTD

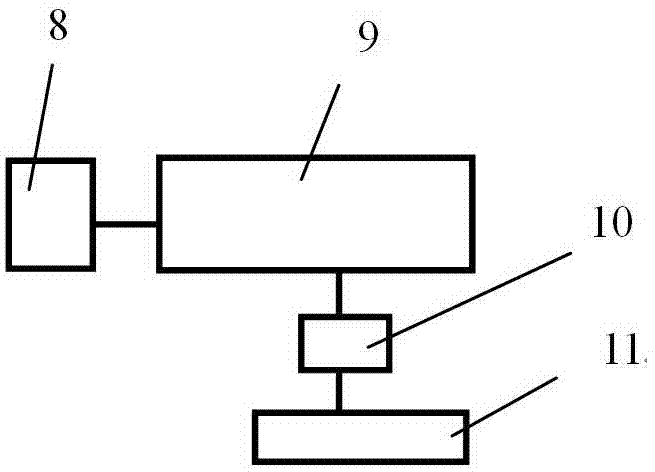

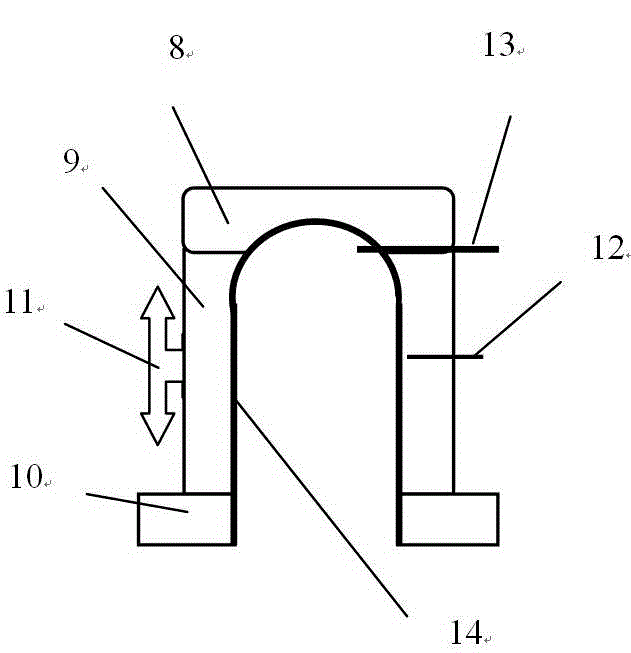

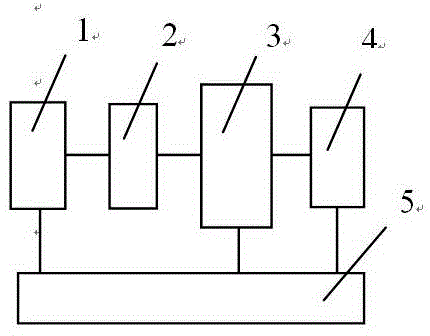

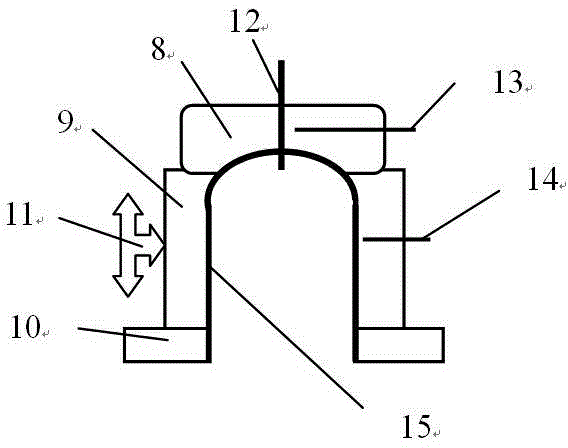

Self discharging vertical type Na131I production device

InactiveCN104700916ASave operating spaceAutomatic unloadingChemical to radiation conversionRadioactive sourcesElectricityCrucible

The invention provides a self discharging vertical type Na131I production device. The self discharging vertical type Na131I production device comprises a motor I, a slide chute, a distillation furnace, an iodine gathering device and a controller, wherein the motor I is fixedly connected with the slide chute, the slide chute is connected with the distillation furnace in slide mode, the distillation furnace is connected with the iodine gathering device through a pipeline, and the controller are respectively connected with the motor I, the distillation furnace and the iodine gathering device in electrical mode. The iodine gathering device of the self discharging vertical type Na131I production device is designed in an integrated structure. The self discharging vertical type Na131I production device has an automatic distillation residue discharging function, can directly place an uncovered target cylinder in a ceramic crucible so as to achieve distillation, significantly improves a yield per unit, reduces radioactive contamination risk, solid waste output and the self size, and is compact in structure, suitable for Na131I destructive distillation production in a shield work box small in effective operation space, and good in operation stability, convenience and safety.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

System and method for producing iodine compound

A system (100) of the present invention for producing an iodine compound includes: a raw material adjusting unit (1) for supplying hydrogen-containing gas to at least one of liquid iodine in an iodine melting pot (4) and gaseous iodine obtained by evaporating liquid iodine so as to obtain a mixture gas; a hydrogen iodide producing unit (10) including a hydrogen iodide producing tower (12) having a catalyst layer (12a) for converting the introduced mixture gas into crude hydrogen iodide gas; a hydrogen iodide refining unit for removing unreacted iodine from the introduced crude hydrogen iodide gas so as to obtain hydrogen iodide gas; and an iodine compound producing unit (30) for producing a target iodine compound from the obtained hydrogen iodide gas and a reaction material. This allows producing an iodine compound with high purity easily, efficiently, and with low cost.

Owner:NIPPON CHEMICALS CO LTD

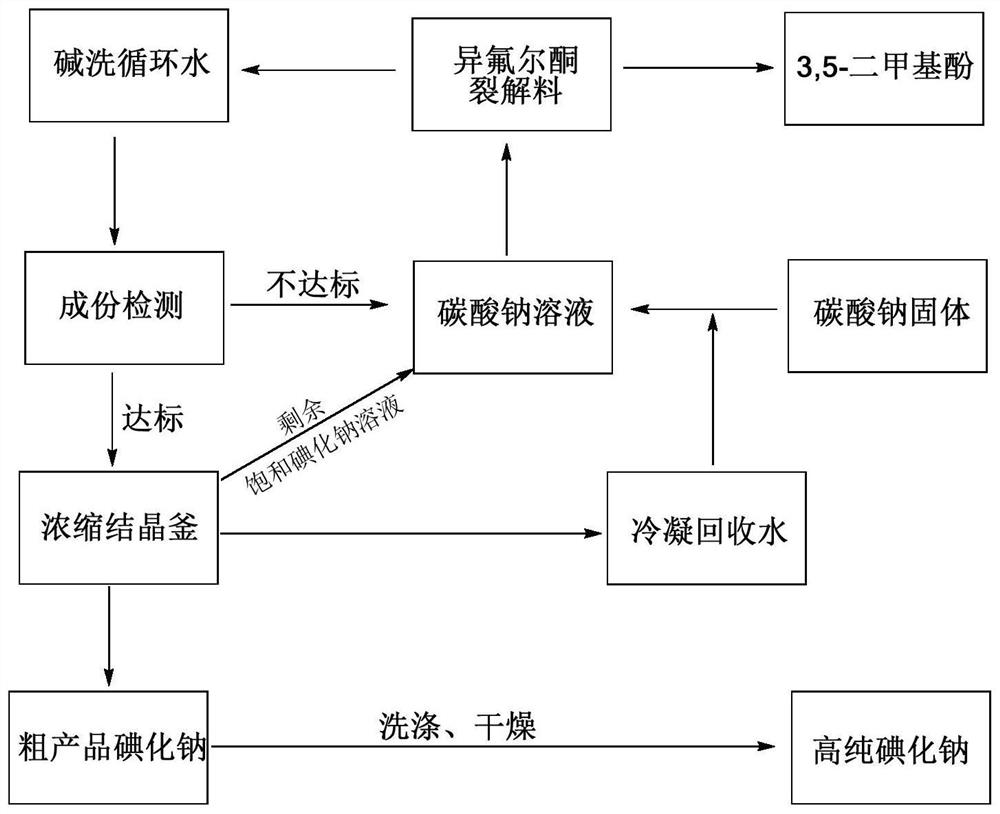

Method for recovering iodide from isophorone cracking material

ActiveCN113120925ADirect separationReduce the risk of frequent operationsAlkali metal iodidesSodium bicarbonateSodium acetate

The invention discloses a method for recovering iodide from an isophorone cracking material, the method comprises the following steps: washing the cracking material for producing 3,5-dimethyl phenol by high-temperature cracking aromatization of isophorone with a metal salt solution, and fully converting iodide ions in the cracking material into iodide; after standing, separating 3, 5-dimethylphenol from the upper layer, and separating alkali washing water from the lower layer; concentrating the alkali washing water, crystallizing, washing and drying to obtain iodide solid; the metal salt solution is sodium carbonate, sodium bicarbonate, sodium acetate, potassium carbonate, lithium carbonate or ammonium carbonate. The whole process is simple and convenient to operate, the production process is continuously and stably operated, the risk of frequent operation of personnel is reduced, the safety is improved, the target product is obtained, the iodine element in the wastewater is recovered to a greater extent, the production cost of an enterprise is reduced, and the method is a green process.

Owner:湖南瑞冠生物化工科技有限公司

Method for purifying potassium iodide from perfluoroalkylethyl acrylate byproduct

ActiveCN110002470AEasy to operateRecycling is possibleOrganic compound preparationCarboxylic acid esters preparationPotassium iodineChemistry

The invention discloses a method for purifying potassium iodide from a perfluoroalkylethyl acrylate byproduct. The method comprises the following steps: washing, centrifugal filtration, and drying forobtaining the finished refined potassium iodide solid. The method for purifying potassium iodide has the advantages of simplicity in process operation, realization of the purity of the purified potassium iodide of 99%, no generation of three wastes in the whole process, safety ensuring and low energy consumption.

Owner:SICHUAN XIAIFU TECH

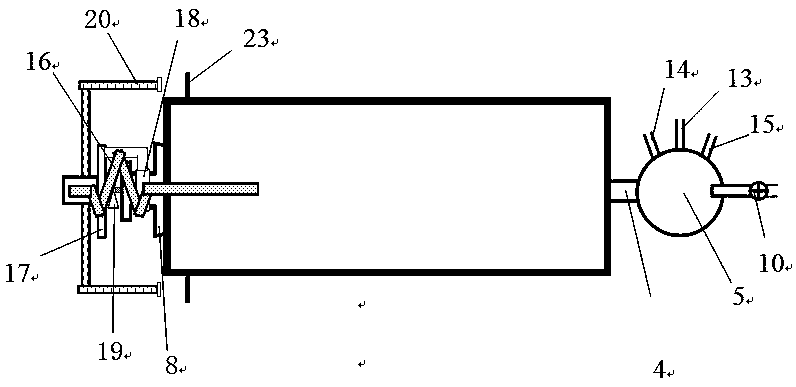

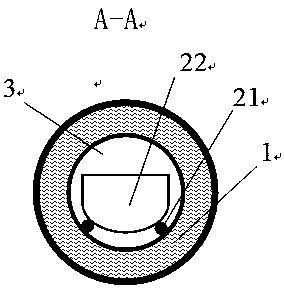

Horizontal double temperature zone I-131 destructive distillation device

ActiveCN108619908AQuick load outEfficient captureIsotope separationAlkali metal iodidesDistillationEngineering

The invention discloses a horizontal double temperature zone I-131 destructive distillation device. The horizontal double temperature zone I-131 destructive distillation device comprises a heating furnace of a horizontal tubular furnace structure, a furnace cover, a distillation absorber, and a telescopic rack; the distillation absorber is arranged in a heating furnace chamber; the furnace cover,and the telescopic rack are arranged on a same end of the heating furnace; one end of the telescopic rack is horizontally fixedly arranged at the top center of the heating furnace, and the other end of the telescopic rack is designed to stretch downward vertically and is connected with the furnace cover on the heating furnace side through slide connection. The horizontal double temperature zone I-131 destructive distillation device is realizing rapid carrying and high efficiency capturing of high temperature molten piled TeO2 distillation high temperature I-131 steam; a low temperature zone isadopted for purifying treatment of distillation carrying gas, and it is beneficial for increasing of Na131I production efficiency and production safety.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:SINOMINE RESOURCE EXPLORATION

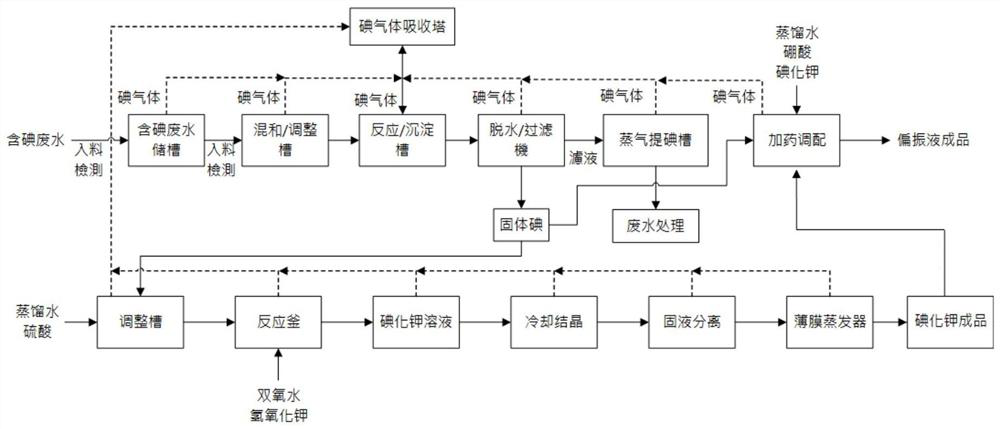

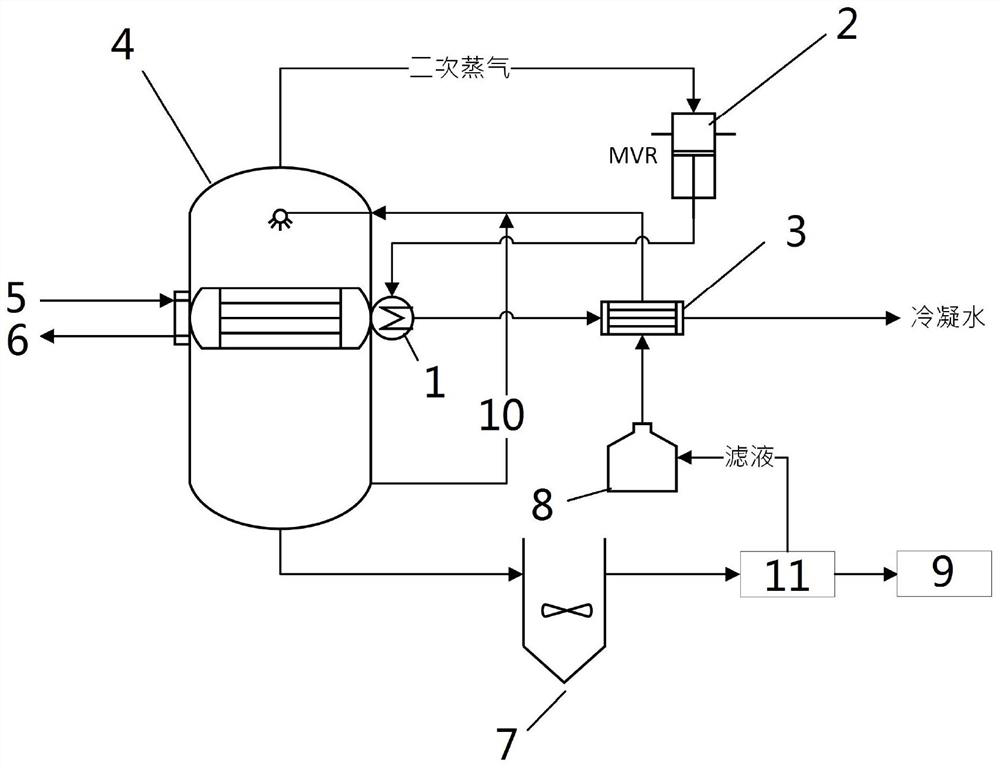

Process for recovering iodine from industrial tail liquid and preparing polarization liquid and potassium iodide from recovered iodine

ActiveCN113716783AHigh purityIncrease profitTreatment involving filtrationIodineNuclear chemistryIodide potassium

The invention provides a preparation process for recovering iodine from industrial tail liquid, preparing polarization liquid from the recovered iodine and producing potassium iodide, wherein the preparation process sequentially comprises the following seven steps: pretreating and classifying iodine-containing wastewater to be extracted, reacting to generate solid iodine, centrifugally dewatering, extracting iodine by steam and recycling, absorbing iodine gas, and preparing the potassium iodide and the polarization liquid. According to the preparation process, the solid iodine can be recovered from iodine-containing wastewater or concentrated iodine liquid in the industrial tail liquid according to the preparation process, the solid iodine can be purified into the electronic-grade iodine, the electronic-grade iodine can be further made into the polarization liquid, and meanwhile, the tail liquid can directly enter a wastewater plant to achieve the emission standard.

Owner:常州睿典材料科技有限公司

Preparation process of high purity anhydrous sodium iodide powder

ActiveCN108726539AReduce manufacturing costSimple processAlkali metal halide purificationAlkali metal iodidesSodium bicarbonateSodium iodide

The invention provides a preparation process of high purity anhydrous sodium iodide powder. The process includes: putting iodine and sodium bicarbonate in water to prepare a mixed solution, then adding hydrazine hydrate, a sodium hydroxide solution, an HI solution and a sodium hydroxide solution into the mixed solution in order for treatment, and then removing impurities and performing concentration, and carrying out centrifugal separation to obtain sodium iodide powder, and finally subjecting hydrogen iodide powder to recrystallization treatment with anhydrous ethanol to obtain the high purity anhydrous sodium iodide powder, which has an impurity K content of less than 2ppm and an apparent density of 2.4-2.6g / mL. The process provided by the invention has the characteristics of unique technology, low cost, high product purity and apparent density, and is suitable for large-scale production.

Owner:涞水县燕南精细化工有限公司

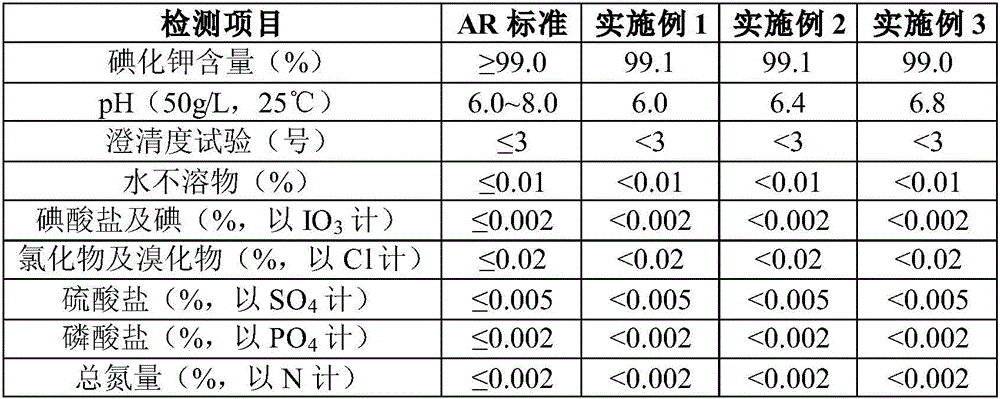

Method for preparing potassium iodide by using micro-channel reactor

ActiveCN106800303AEfficient preparationQuantitative preparationAlkali metal iodidesAfter treatmentWastewater

The invention belongs to the technical field of chemical reagent synthesis and relates to a method for preparing potassium iodide by using a micro-channel reactor. Specifically, the method comprises the following steps of (1) preparing a solution A by using hydroiodic acid and formic acid; (2) preparing a solution B by using potassium hydroxide and water; (3) reacting the two solutions in the micro-channel reactor; and (4) carrying out after-treatment. The method is mild in reaction condition, the high-quality potassium iodide can be efficiently and quantitatively prepared, and no waste gas or wastewater is generated in the whole preparation process; the disadvantages that a traditional technology is unsafe, toxic and multiple in three wastes in after-treatment are overcome; the potassium iodide prepared through the method is safe and reliable; various detection results can meet the requirements of related standards; the application field of a product is expanded; the preparation method is simple and feasible; and the possibility is provided for massive production.

Owner:SHANGHAI WOKAI BIOTECH

Method for recycling fluorine-containing and iodine-containing waste resources

ActiveCN112079364AIncrease profitLow costAlkali metal halide purificationAlkali metal iodidesPotassium fluoridePotassium hydroxide

The invention relates to a method for recycling fluorine-containing and iodine-containing waste resources. The method comprises the following steps: converting organic fluorine into potassium fluorideby using potassium hydroxide, and performing aerobic incineration at a temperature of 600-800 DEG C by using a converter to completely burn out or carbonize organic matters without generating fluorine-containing toxic substances such as hydrofluoric acid, perfluoroisobutylene and the like; removing fluorine ions by using calcium hydroxide, removing excessive calcium hydroxide by using potassium carbonate, adjusting the pH value by using formic acid, and converting potassium formate into potassium iodide by using iodine. Therefore, elemental iodine does not need to be recovered to reproduce potassium iodide, the cost is saved, and the utilization rate of iodine is increased. According to the potassium iodide finished product, the content of potassium iodide is 99% or above, and fluorine ions are smaller than 1 ppm.

Owner:山东博苑医药化学股份有限公司

Vertical type Na131I dry distillation production device

InactiveCN104528653ALow sublimation temperatureSafe transferIodide preparationAlkali metal iodidesElectricityCrucible

The invention provides a vertical type Na131I dry distillation production device which comprises a motor, a sliding chute, a distillation furnace, an iodine catcher and a controller, wherein the motor is fixedly connected with the sliding chute; the sliding chute is slidably connected with the distillation furnace; the distillation furnace is connected with the iodine catcher through a pipeline; and the controller is electrically connected with the motor, the distillation furnace and the iodine catcher respectively. The vertical type Na131I dry distillation production device provided by the invention can be used for producing the medical-grade Na131I from activated TeO2, and can be used for directly placing an uncapped target barrel into a ceramic crucible for distillation, thus obviously enhancing the unit yield of the device and the utilization rate of a raw material and reducing the risk of radioactive pollution and the output of a radioactive solid waste. The vertical type Na131I dry distillation production device provided by the invention is compact in structure, can be suitable for Na131I dry distillation production inside a shielding work box with a small effective operation space and has good stability, convenience and safety in operation.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

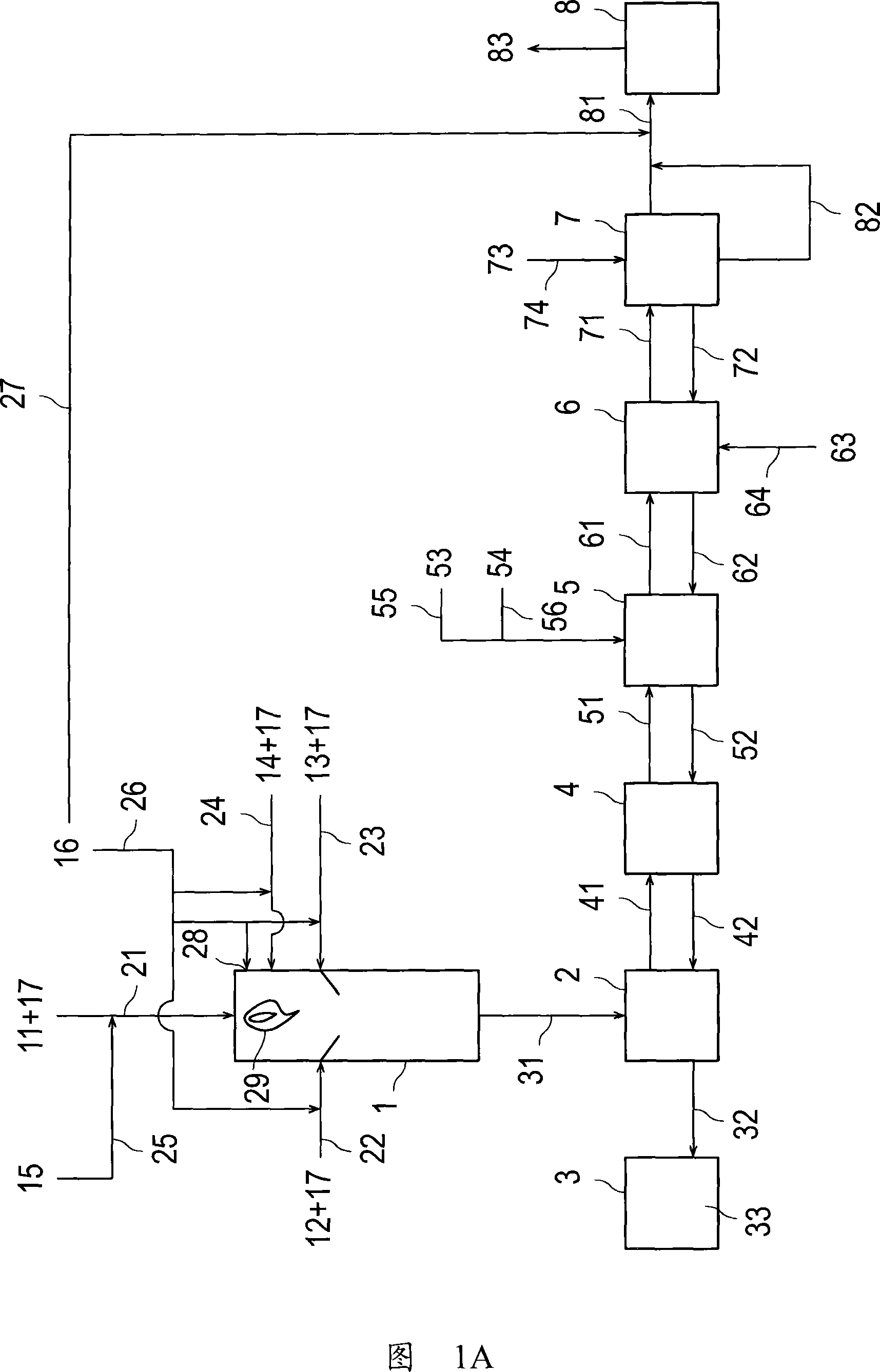

Inorganic iodide, production method thereof, and production system thereof

According to a method for producing an inorganic iodide in accordance with the present invention, it is possible to efficiently produce a highly pure inorganic iodide by reacting a hydrogen iodide gas with an inorganic base compound by bringing the hydrogen iodide gas into contact with the inorganic base compound. As such, it is possible to provide a simple and efficient method for producing an inorganic iodide.

Owner:NIPPON CHEMICALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com