Method for recovering iodide from isophorone cracking material

A technology of isophorone and pyrolysis materials, applied in the direction of alkali metal iodide, etc., can solve the problems of non-conformity with green environmental protection technology, direct recovery of sodium iodide solids, etc., to reduce the risk of frequent operations, continuous and stable operation of the production process , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

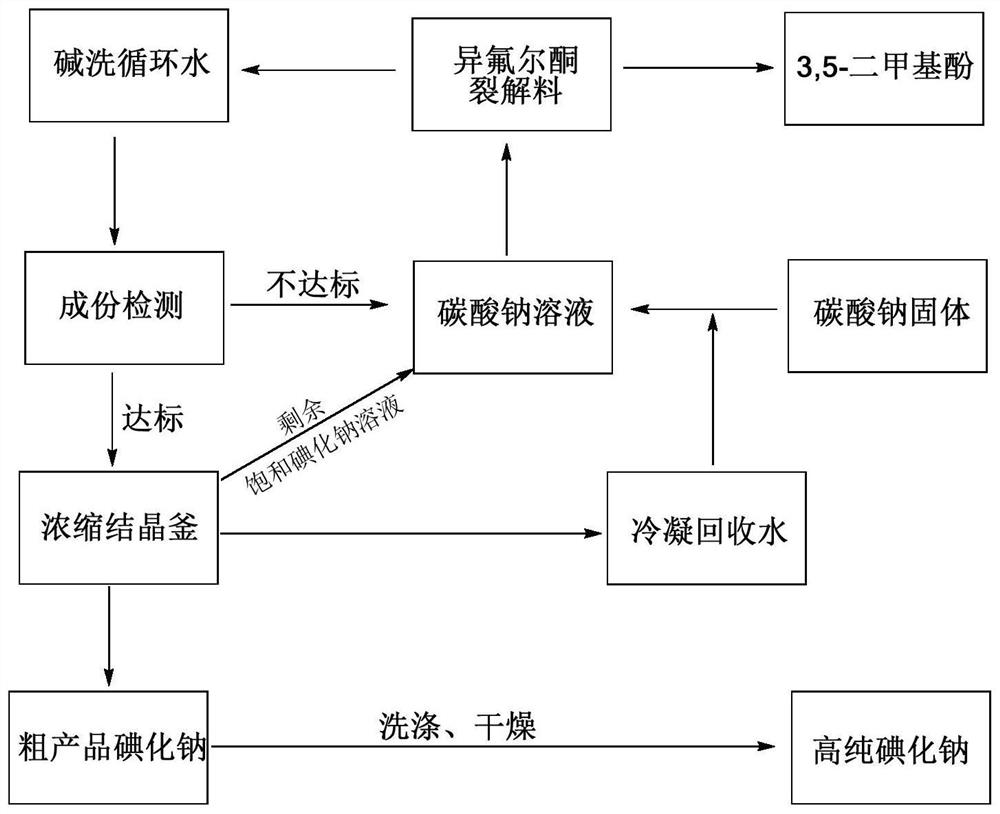

[0040] See attached figure 1 The implementation of the process of the present invention mainly includes four parts: alkali washing system, concentration and recrystallization system, washing and drying system, and recycling system.

[0041] (1) Alkali washing system: the pyrolysis material produced by isophorone high-temperature cracking and aromatization is washed with sodium carbonate solution, and the iodide ion in the pyrolysis material is fully converted into sodium iodide. After standing still, 3,5 dimethylphenol was separated from the upper layer, and alkaline washing water was separated from the lower layer. Utilize the titration method to detect the iodide ion concentration in the alkali washing water, if the iodide ion concentration is lower than 40% (by weight), then the alkali washing water is recycled repeatedly to increase the iodide ion concentration in the water. When the sodium iodide concentration reaches 40% (by weight), the salinity of the alkali washing w...

Embodiment 2

[0051] 1000 Kg aromatization process is produced 3,5 xylenol cracking material is processed, and the iodide ion (converted from methyl iodide) that contains 5.8kg is contained in the cracking material, washes repeatedly with 100 Kg saturated sodium carbonate solution, will cracking The iodide ions in the material are fully converted into sodium iodide; after standing still, 670 Kg of 3,5 dimethylphenol is separated from the upper layer, and the alkali washing water is separated from the lower layer; the alkali washing water is recycled, when the concentration of sodium iodide When it reaches 40% (by weight), it is sent to an evaporation concentration kettle for concentration under reduced pressure, so that the concentration of sodium iodide is increased to 80% (by weight). The hot supersaturated sodium iodide solution was slowly cooled down to 25°C, and 5.55 Kg of sodium iodide crystals were precipitated. The sodium iodide crystals were washed with tetrachlorethylene to remove...

Embodiment 3

[0055] 1000Kg aromatization process is produced 3,5 xylenol cracking material is processed, and the iodide ion (converting out from methyl iodide) that contains 5.8kg is contained in the cracking material, washes with 100Kg saturated sodium hydroxide solution, will crack in the material The iodide ion is fully converted into sodium iodide; after leaving standstill, separate the 3,5 dimethylphenols of 310Kg from the upper layer, and separate the alkali washing water from the lower floor; the concentration of sodium iodide reaches 40% (by weight), Sent to the evaporation and concentration tank for concentration under reduced pressure, so that the concentration of sodium iodide was increased to 80% (by weight). The hot supersaturated sodium iodide solution was slowly cooled down to 25°C, and 5.10Kg of sodium iodide crystals were crystallized. The sodium iodide crystals were washed with tetrachloroethylene to remove impurities, and then evaporated by vacuum distillation to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com