Process for recovering iodine from industrial tail liquid and preparing polarization liquid and potassium iodide from recovered iodine

A preparation process and iodine recovery technology, which is applied in the direction of iodine/hydrogen iodide, alkali metal iodide, iodine, etc., can solve the problems of high cost, waste of resources, failure to meet emission standards, etc., and achieve high utilization rate, large Economic benefit, effect of reducing reinvestment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

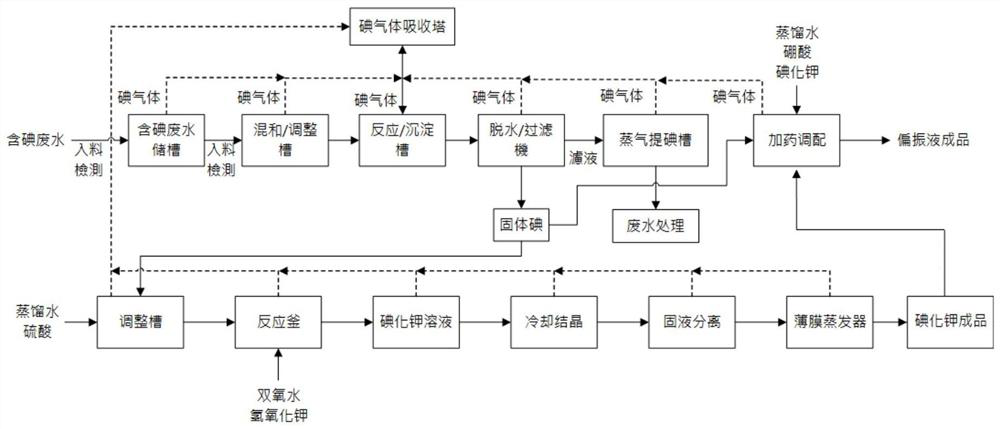

[0042] A kind of industrial tail liquid reclaims iodine and prepares the preparation technology of polarizing liquid and potassium iodide with reclaiming iodine, and concrete process step is:

[0043](1) Pretreatment and classification of iodine-containing wastewater to be extracted

[0044] Test the iodine concentration and PH value of the iodine-containing wastewater in the iodine-containing wastewater storage tank, and store it in a classified manner. Pump the wastewater with similar test results and the regularly generated backwash water into the reaction sedimentation tank, and put the mixed solution into acid and alkali. Adjust the PH, mix evenly, generate a part of iodine gas and acid mist gas, and transport it to the iodine gas absorption tower through the pipeline;

[0045] (2) react to generate solid iodine

[0046] Sampling the remaining mixed solution to detect the iodine concentration, adding antioxidants, chelating agents, and hydrogen peroxide, reacting, iodine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com