Patents

Literature

246results about "Iodine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method for bittern

InactiveCN101691239ARealize closed loopSimple process controlCalcium/strontium/barium carbonatesIodineSimple componentChemistry

The invention relates to a comprehensive utilization method for bittern, which belongs to the technical field of salt chemical engineering. The bittern is a liquid mineral product, and is rich in multiple elements such as potassium, sodium, lithium, boron, bromine, iodine and the like; and at present, in the prior domestic bittern development and utilization, some simple components or components with high additional value in the elements are extracted, and the un-extracted components are discharged along with old bittern to be abandoned so as to cause serious waste of resources and pollute the environment. Through reasonable combination of processes of removing H2S from the bittern, settling magnesium, settling calcium and preparing calcium carbonate, preparing potassium-sodium mixed saltthrough primary salt preparation and secondary salt preparation, extracting potassium chloride through flotation, extracting boron, iodine, bromine, rubidium and cesium through acidification, preparing rubidium chloride and cesium chloride, extracting lithium and the like, the method implements step-by-step ordered extraction of main components; the toil yield of several main components reaches over 95 percent; and the method has the advantages of mutually exclusive loss in component extraction, implementation of closed cycle of processes, no mother liquor discharge, simple process control, low cost, high yield, environmental protection and the like.

Owner:DAZHOU HENGCHENG ENERGY GROUP

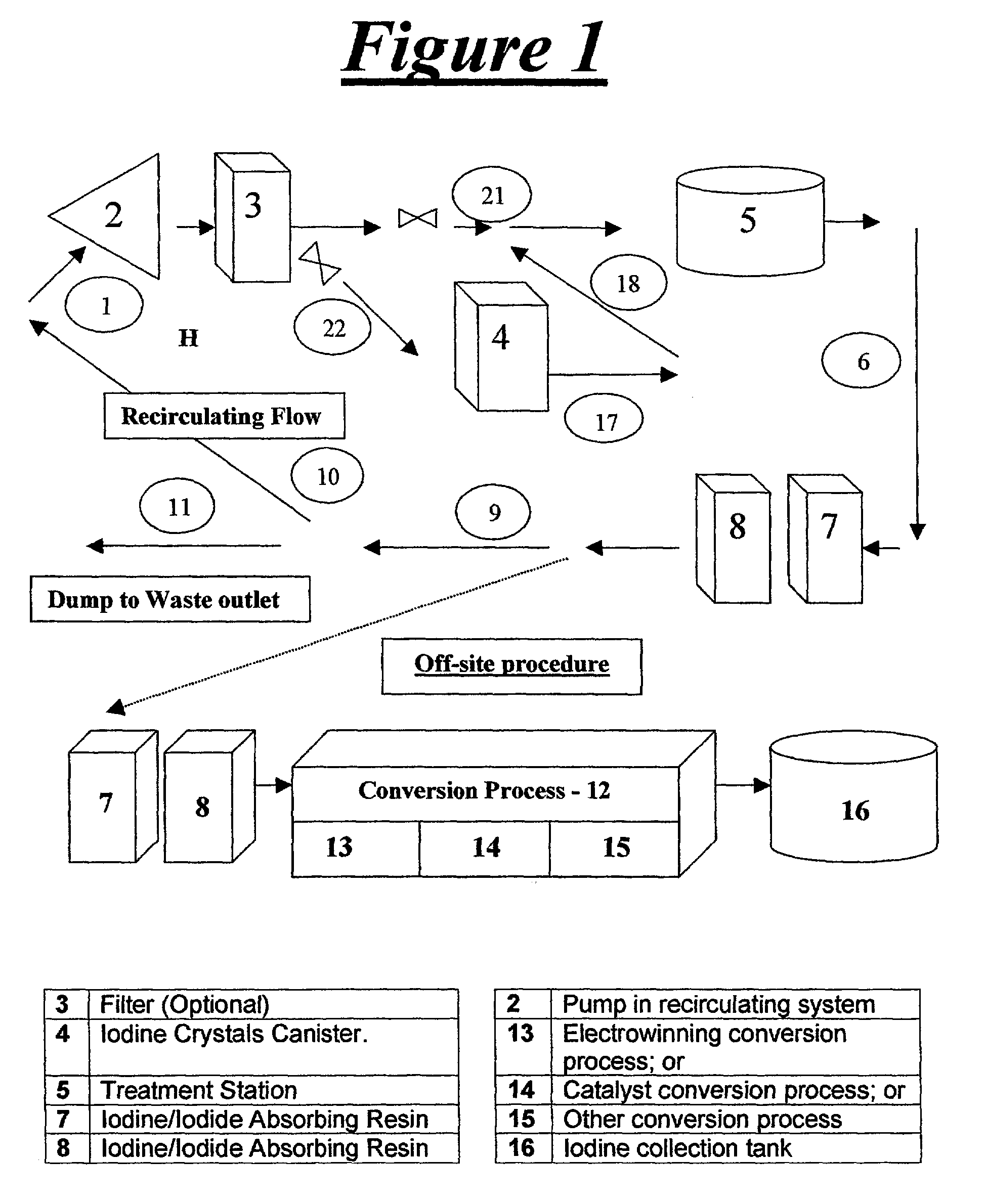

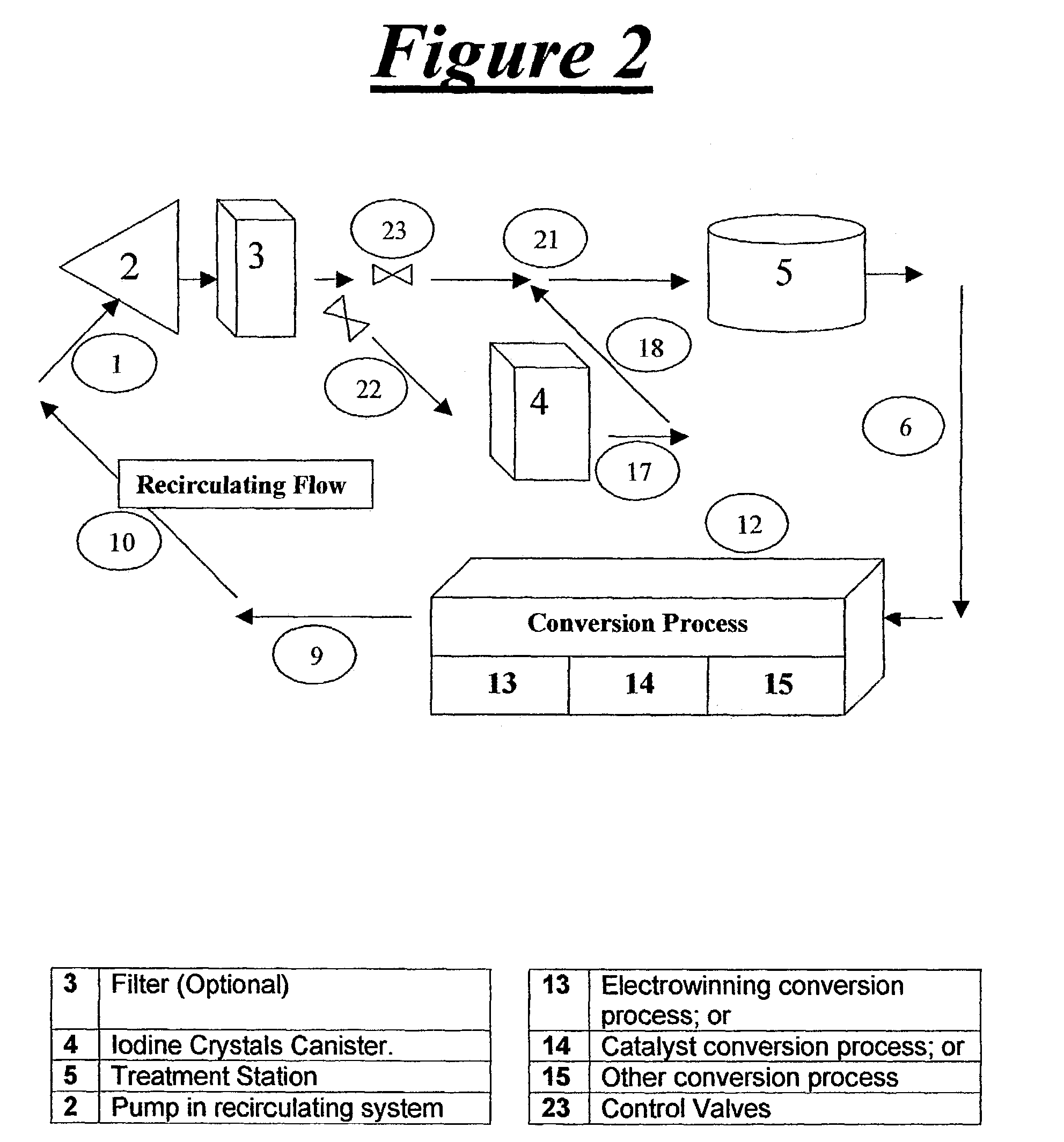

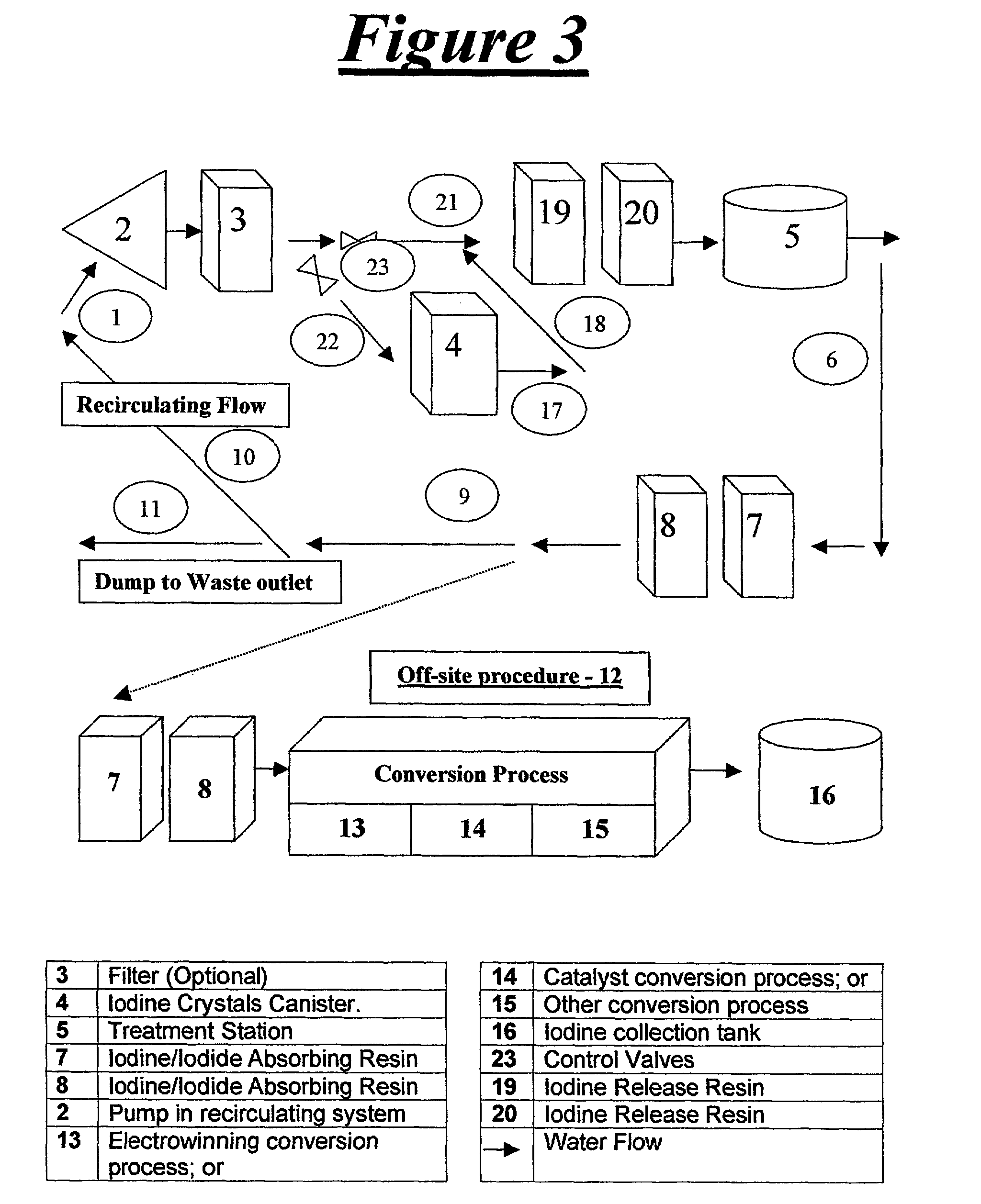

Methods and processes for iodine disinfection

InactiveUS7033509B2Accurate methodMaintain optimum levelIodineWater/sewage treatment by substance additionIodineChemistry

An iodine purification process comprising; a source of fluid; means for delivery of iodine to the source of fluid for use in the purification process; the process further comprising means for recovery of the iodine and / or iodine and / or other iodine species derived from the iodine, from said fluid.

Owner:PETERS HLDG PTY LTD

Method for preparing radioactive <124>I ions

ActiveCN103771341ANo leaksImprove radiation effectIodineAlkali metal iodidesAngle of incidenceDistillation

The invention discloses a method for preparing radioactive <124>I ions. The preparation method comprises the following steps: a, taking aluminium oxide powder and tellurium dioxide powder in a mass ratio of 1:18-22, uniformly mixing the powder, and pressing the obtained mixture into a tellurium target with a thickness of 50-60 mg / cm<2>; b, placing the prepared tellurium target in a circular accelerator, and irradiating the tellurium target 2-3 h by Te (p, n) <124>I, wherein the incident p particle beam intensity is 18-20 mu A, the energy is 18.5-20 MeV, and the angle of incidence is 6-10 DEG; meanwhile, cooling the tellurium target by using water in the process of irradiating, and after the irradiating is completed, placing the tellurium target to cool 4-6 h; c, placing the tellurium target in a quartz distillation tube of a destructive distillation device to distill, meanwhile, controlling the temperature to 750 DEG C so as to heat the tellurium target, so that radioactive <124>I ions are escaped, and collecting the radioactive <124>I ions. The problems that radionuclide <124>I prepared in the prior art is low in yield and low in recovery rate are solved.

Owner:MITRO BIOTECH CO LTD

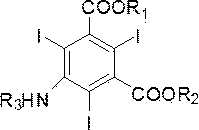

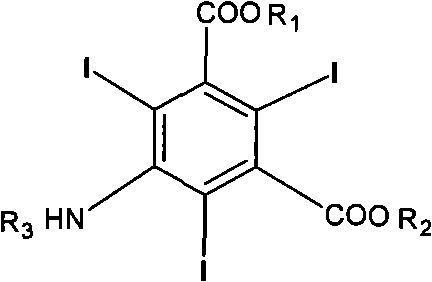

Method for recycling iodine from production waste liquid of X-CT series contrast agents

A method for recycling iodine from production waste liquid of X-CT series contrast agents comprises the following steps: firstly, converting iodine in iodinated organic compounds in organic waste liquid into inorganic iodide; secondly, concentrating, oxidizing the concentrated liquid by using a complex oxidizing agent, oxidizing the iodide anions into elementary iodine, and separating out elementary iodine by filtering; finally, extracting the residual elementary iodine from the filtrate by using an organic solvent so as to completely recycle the low-concentration elementary iodine. The iodine recycling method is applicable to treatment of iodine-containing waste liquid with diverse existing forms of iodine and high iodine content, thus solving the environment pollution problem caused by discharge of the iodine-containing waste liquid in the production process of the X-CT series iodine contrast agents and achieving the recycling of the iodine.

Owner:SICHUAN UNIV

Method for reclaiming iodine from concentrated phosphoric acid from wet method phosphoric acid production

The invention discloses a method for recovering iodine from concentrated phosphoric acid which is produced by wet-process phosphoric acid; the method comprises the following steps of: extracting the iodine from the concentrated phosphoric acid produced in the production process of phosphorous ore which contains iodine, wherein, the concentrated phosphoric acid contains 50 to 110 mg / L of the iodine and 40 percent to 52 percent of P2O5; adding 27 percent to 35 percent of hydrogen peroxide water solution into the phosphoric acid as an oxidizing agent for reaction; using air to blow out the molecular iodine of the phosphoric acid; then absorbing the molecular iodine by acid solution containing liquid SO2 with the PH value of the absorbing solution ranging from 1 to 6; adding hydrogen peroxide and leading the iodine to be precipitated; carrying out filtering and separation and obtaining the finished iodine. The applicant finds that the iodine is extracted from the concentrated phosphoric acid after the diluted phosphoric acid is concentrated into the concentrated phosphoric acid; as the material liquid is concentrated, the concentration of the material iodine is high, the solution impurity is little and the content of the reducible matter and the organic matter is low, therefore, the usage of the oxidizing agent can be reduced; the method of the invention has the advantages of high concentration of the material iodine, little usage of the oxidizing agent, easy extraction, high recovery rate and low production cost.

Owner:WENGFU (GRP) CO LTD +1

Method for recycling iodine from diluted phosphoric acid for phosphoric acid manufacture with wet-process

The invention discloses a method for recovering iodine from dilute phosphoric acid in phosphoric acid production with a wet method; iodine is extracted from the dilute phosphoric acid generated in the iodine-containing phosphorus ore production process, wherein, the content of iodine in the dilute phosphoric acid is 50-110mg / L, the concentration of P2O5 in the dilute phosphoric is 25-30%, compound oxidant is added into the phosphoric acid for oxidation reaction, air is used for blowing molecular iodine out, then SO2-containing acidic solution is used for absorbing, the pH value of absorption liquid is between 1-6, then hydrogen peroxide is added to separate iodine out and filtration and separation are carried out to obtain finished iodine. The compound oxidant obtained from the tests conducted by the applicant can improve the efficiency of oxidant and reduce the dosage of oxidant. Proved by the tests performed by the applicant, after the hydrogen peroxide is added with vanadic oxide, the dosage of oxidant can be reduced by 30%; at present, the actual amount of the hydrogen peroxide used for producing 1 ton iodine is 20 tons.

Owner:WENGFU (GRP) CO LTD

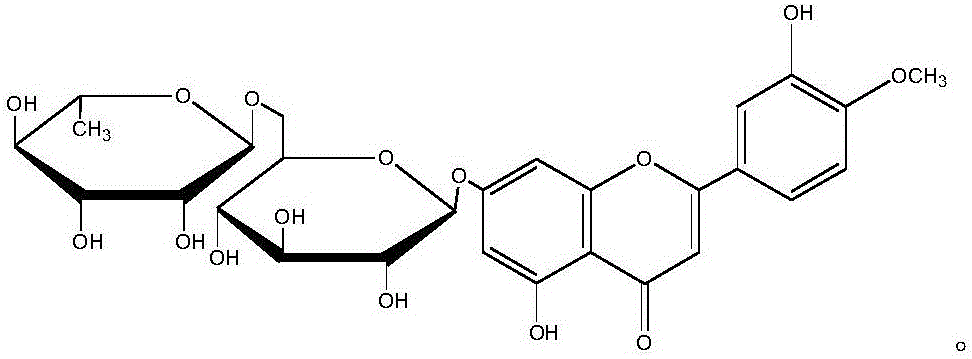

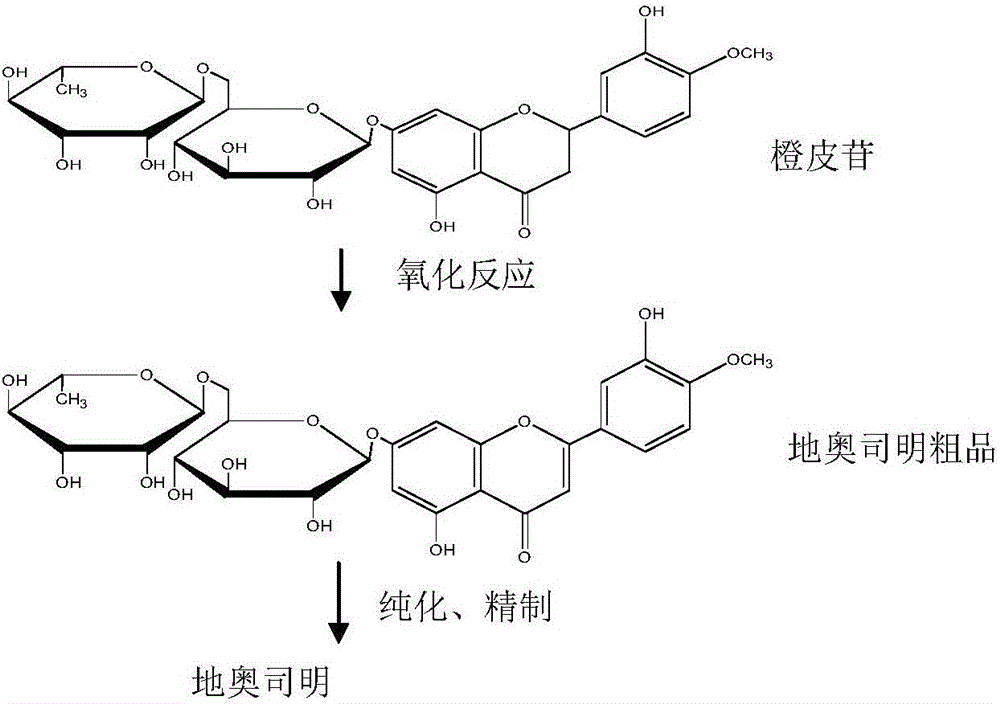

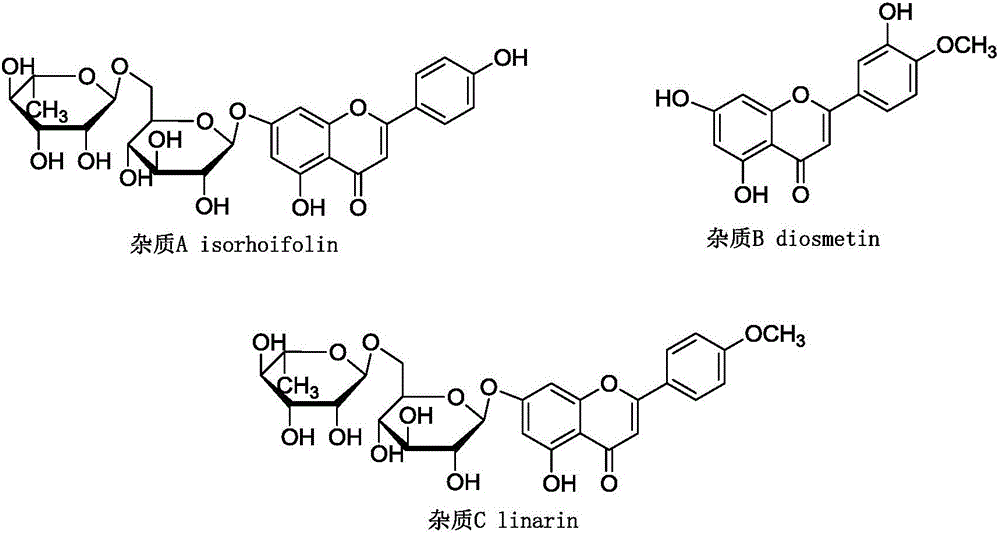

Method for preparing green and economic diosmin

ActiveCN105732744AReduce high temperature impurity contentHigh recovery rateSugar derivativesIodineDiosminIodine

The invention discloses a method for preparing green and economic diosmin. The method comprises three main steps of preparation, recycling and refining. Compared with a conventional method, the method thoroughly avoids use of pyridine and inorganic base, the production environment is greatly improved, the aftertreatment is simple, iodine and solvents can be recycled, the reaction conditions are gentle, the production cost is low, and meanwhile in the method, a crude product is not refined in a classic alkali solution acidification mode instead of a mode that diosmin is separated out, then the purity of a finished product can be up to 99%, the product quality can be improved, and moreover the method is simple and convenient to operate and applicable to industrial production.

Owner:NANJING CHIA TAI TIANQING PHARMA

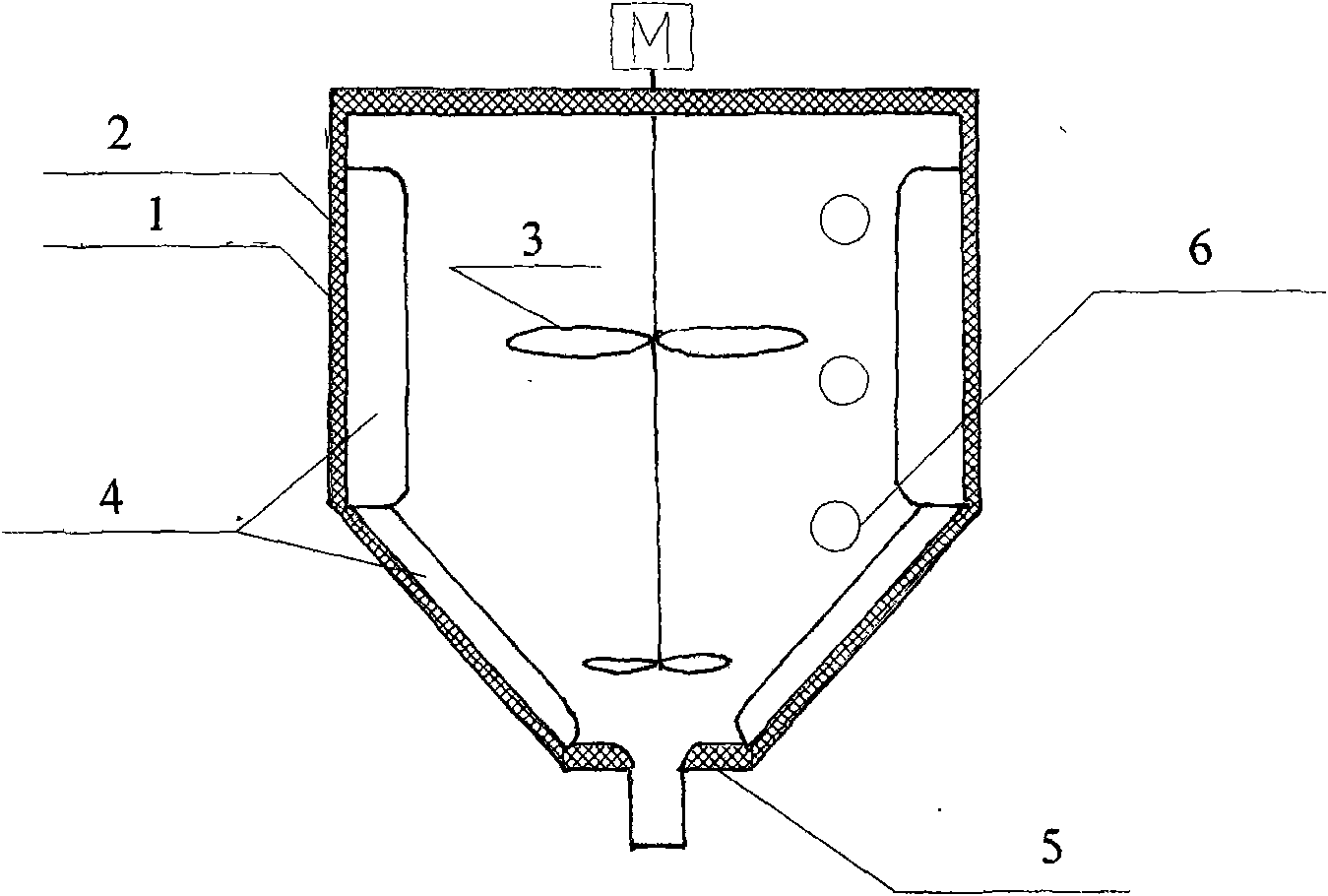

Iodine crystallizer

InactiveCN101670189APromote productionAvoid corrosionIodineSolution crystallizationFrequency conversionIodine

The invention relates to an iodine crystallizer which is characterized in that: (1) a steel net PO is take as a lining in the crystallizer; (2) a small platform is added at the cone bottom of the crystallizer; (3) the crystallizer is provided with a plurality of oxidant adding points; (4) a stirrer of the crystallizer is a frequency-conversion adjusting mode and the frequency of the mixer can be changed according to the characteristic during the formation process of the crystals; (5) the wall of the crystallizer is provided with a viewing hole; (6) the crystallizer is internally provided witha baffle plate so that the collision occurs between crystals or between the crystals and the wall, the stirrer and the like, thus generating minute crystals to induce the secondary nucleation, therebyleading the crystals forming the specified crystal shape. The steel net PO of the lining in the crystallizer has very good performances of iodine-resistance and oxidant-corrosion resistance, thus avoiding the phenomenon of blocking a liquid drain pipe in the crystallization; and adjusting the shapes of the crystals by adjusting the speed of the stirrer, thus obtaining the product with the good shape of the crystal and obvious metallic luster.

Owner:WENGFU (GRP) CO LTD

Method for extracting iodine from iodine-containing fluosilicic acid

The invention discloses a method for extracting iodine from fluosilicic acid containing the iodine; the method comprises the following steps of: extracting the iodine from the fluosilicic acid solution produced in the production process of the phosphoric acid, wherein, the fluosilicic acid contains 50 to 110 mg / L of the iodine and the total acidity of the fluosilicic acid is 15 percent to 25 percent; adding a compound oxidizing agent into the fluosilicic acid and oxidizing the ion iodine in the solution into molecular iodine; using air to blow out the molecular iodine; absorbing the moleculariodine by using the acid solution containing SO2 with the PH value of the absorbing liquid ranging from 1 to 6; adding hydrogen peroxide and leading the iodine to be precipitated; carrying out filtering and separation and obtaining the finished iodine. The raw material for extracting the iodine by the invention is fluosilicic acid, in which the content of the iodine is usually below 100mg / L. The method and the compound oxidizing agent obtained by the applicant by experiments can carry out extraction to the iodine with low content. The invention expands the selecting range of extracting the material of the iodine.

Owner:WENGFU (GRP) CO LTD +1

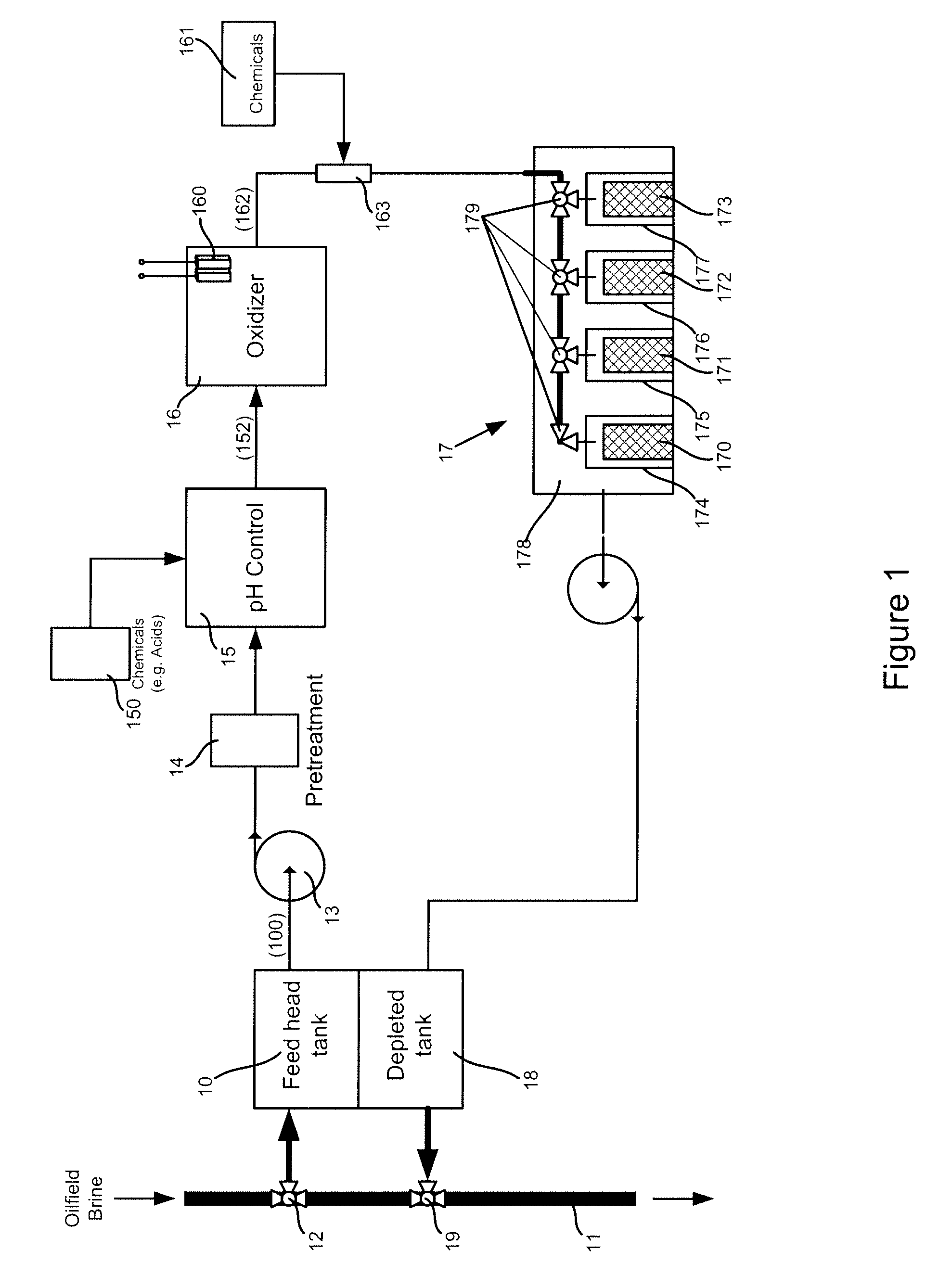

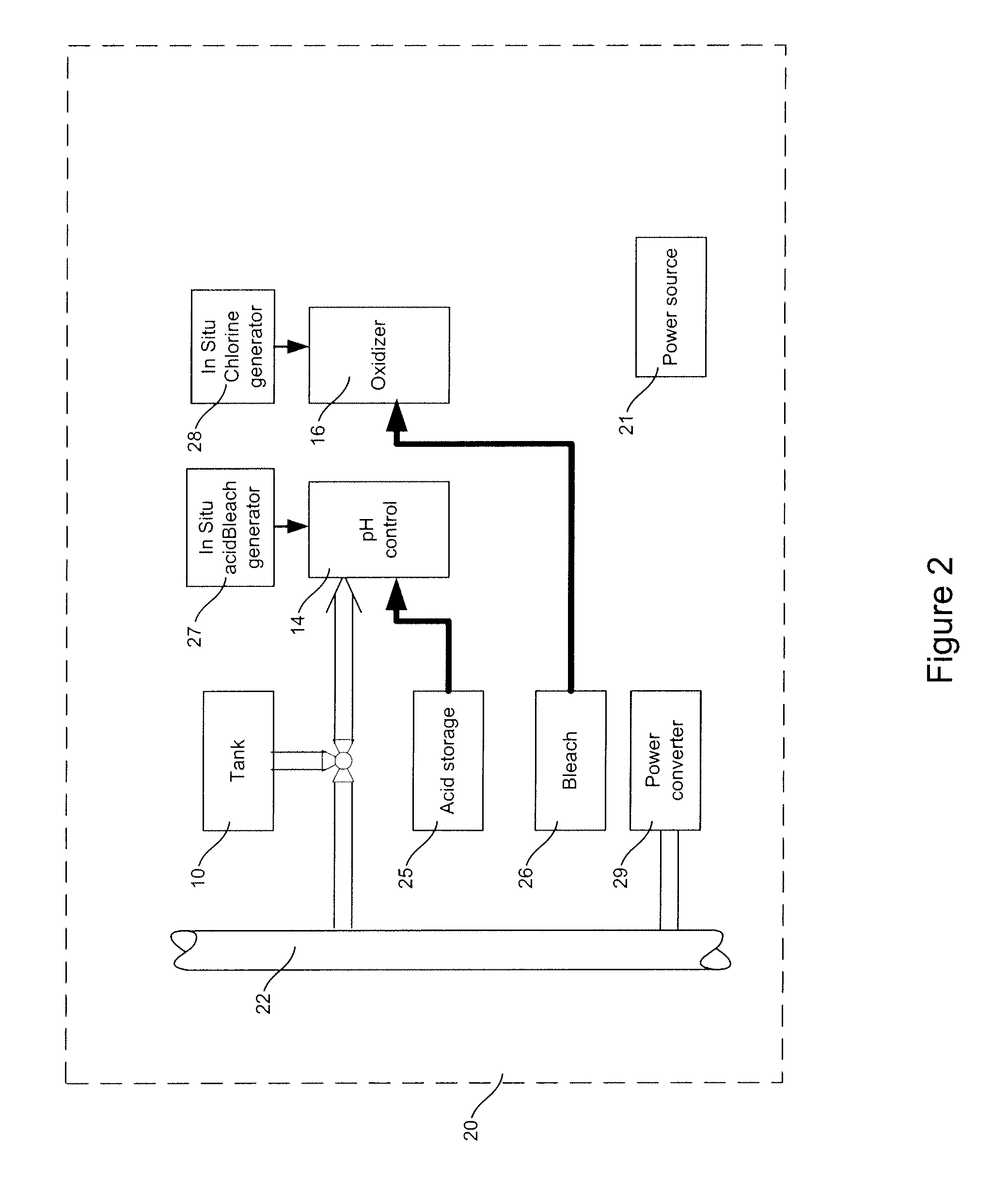

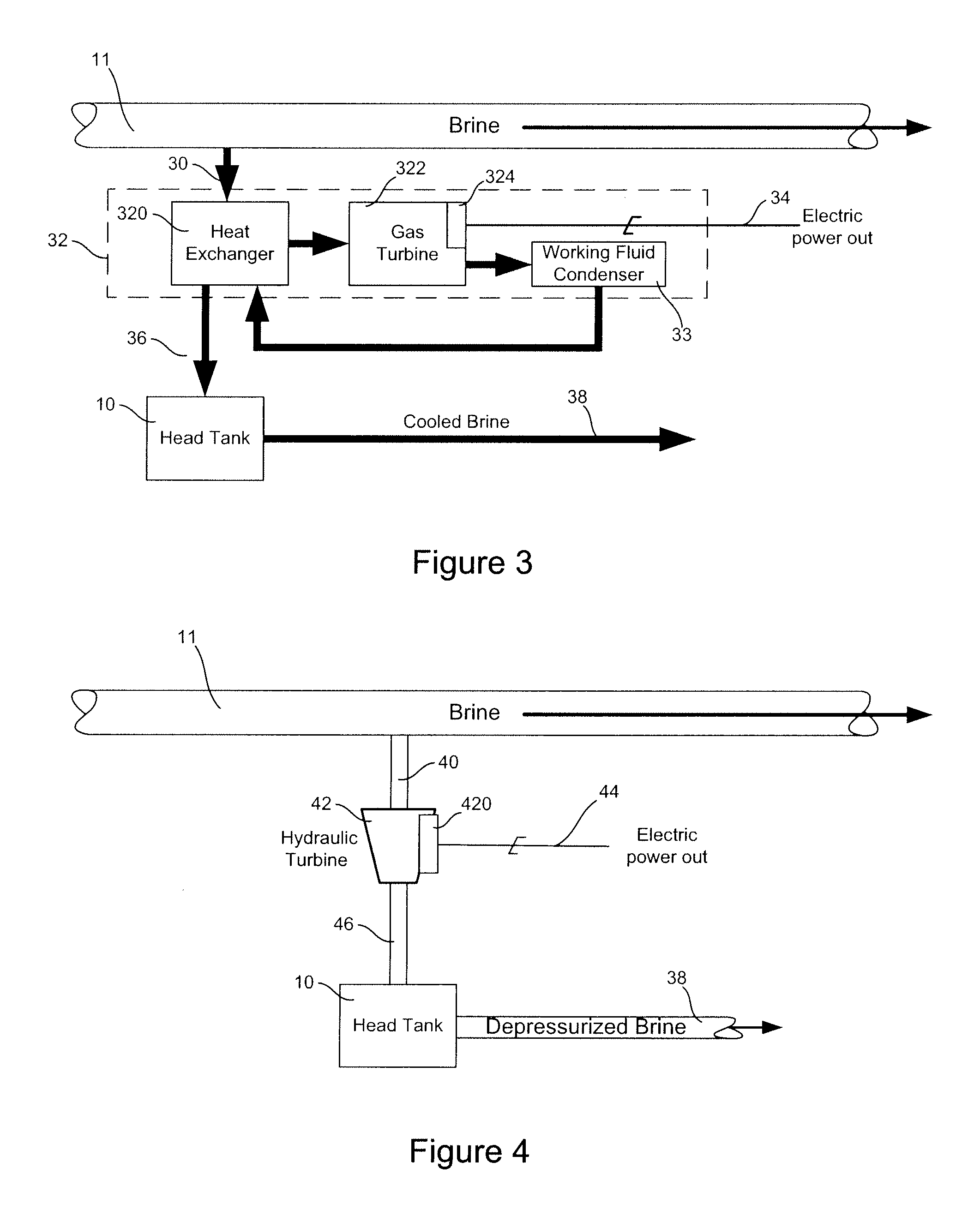

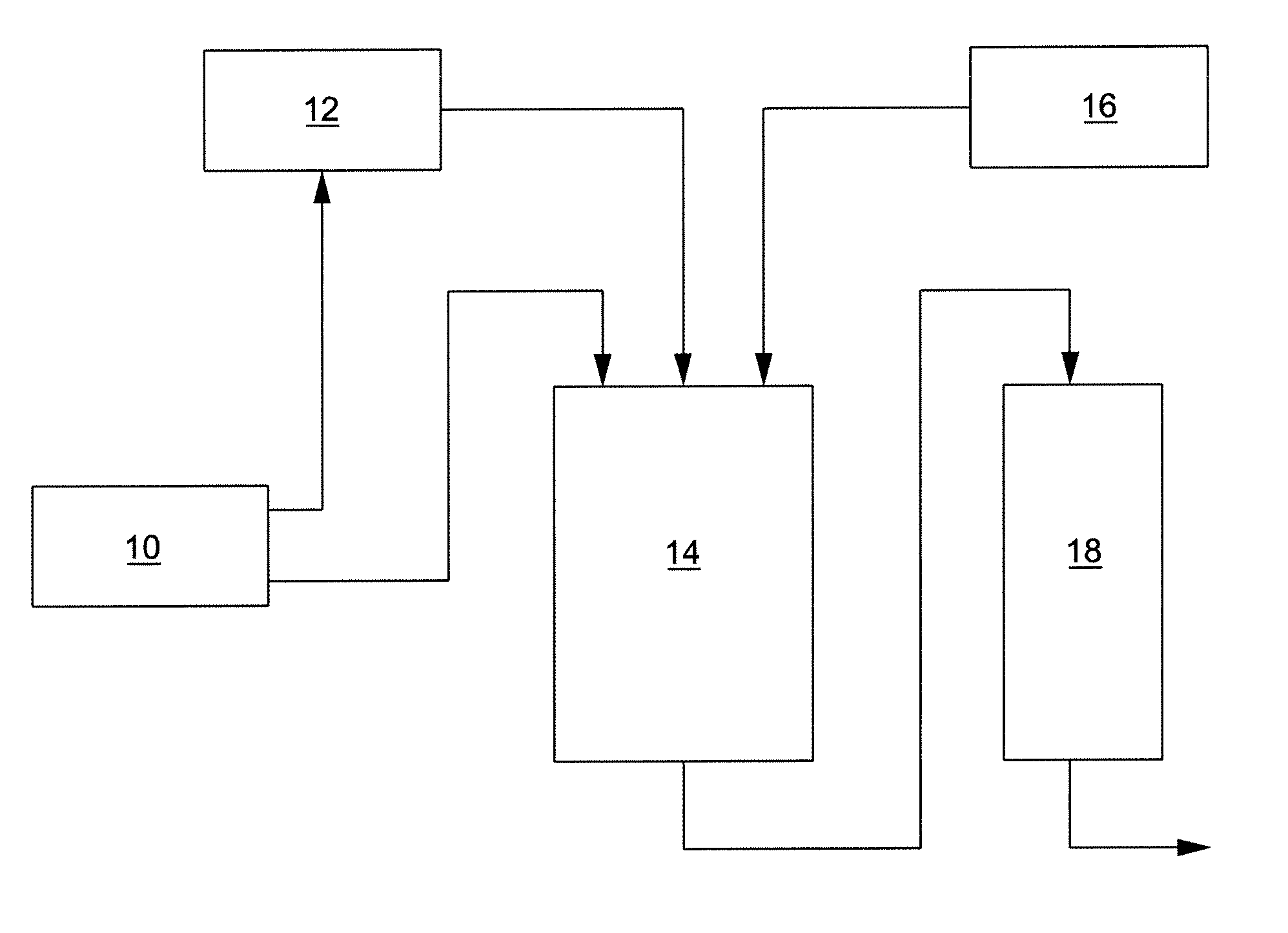

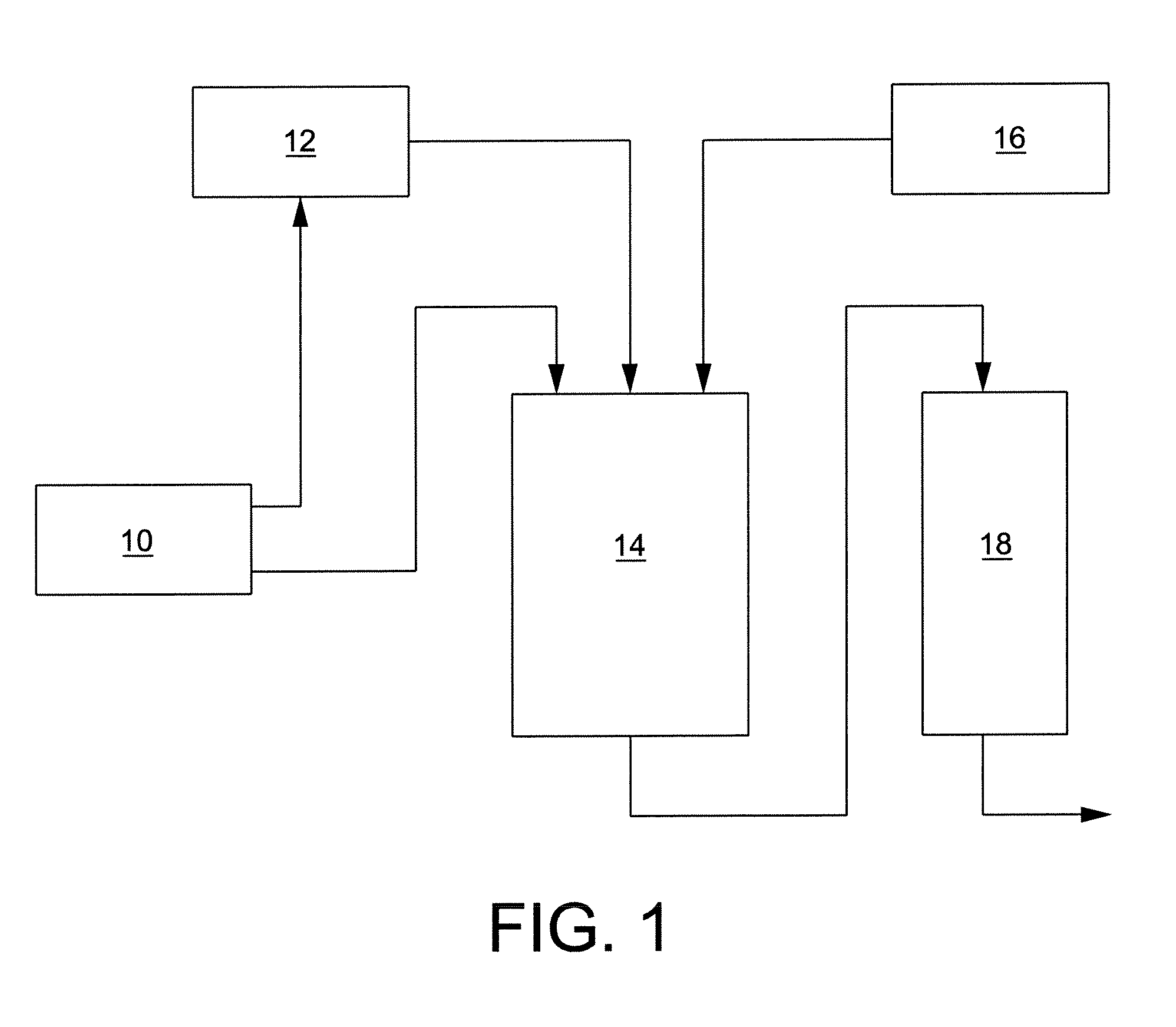

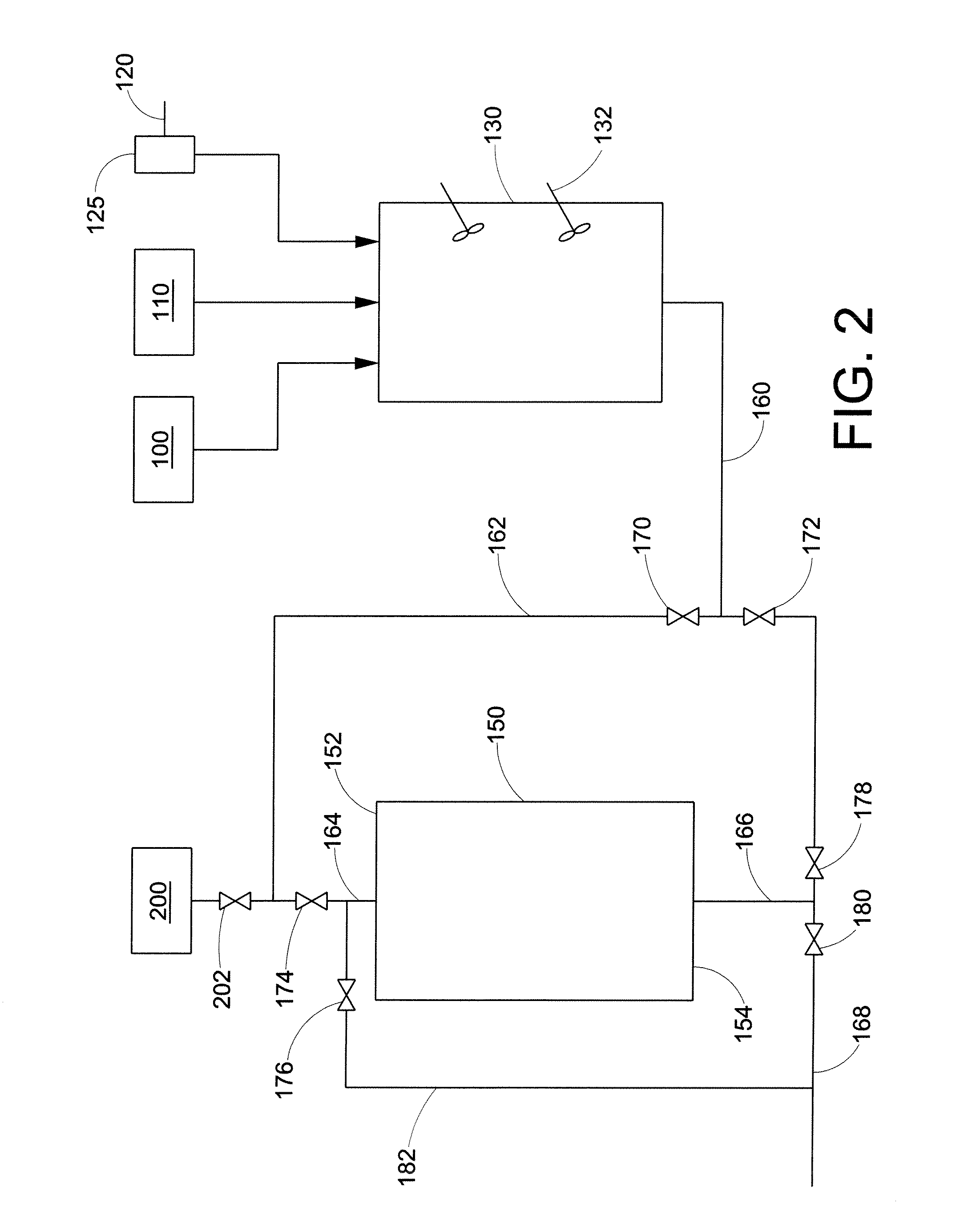

Iodine recovery systems and methods

Systems and methods for the recovery of iodine are described. In particular, recovery systems and methods produce an iodine complex from an aqueous brine containing iodide. A head tank for maintains a supply of the brine, a pH controller acidifies brine received from the head tank and an oxidizer converts iodide in the acidified brine to elemental iodine. At least one activated carbon contactor module is removably inserted into a stream of the oxidized brine provided by the oxidizer and binds the molecular iodine to form the iodine complex. A container may enclose the head tank, the pH controller and the oxidizer in order to facilitate transportation of the system and performance of the methods and processes in proximity to a brine source. The brine may be employed or associated with oilfield operations.

Owner:IOFINA RESOURCES INC

Method for recovering iodine in production waste liquid of X-CT series contrast media

ActiveCN101554994AAvoid wastingSolve pollutionIodineMultistage water/sewage treatmentLiquid wasteFiltration

The invention relates to a method for recovering iodine in production waste liquid of X-CT series contrast media. The method comprises the following steps: stewing and refluxing the waste liquid first to recover most of dissociated elementary substance iodine, reducing most of high hypervalent iodine into elementary substance iodine for precipitation; conducting filtration and separation, oxidizing the filtrate to oxidize most of iodine negative ions into elementary substance iodine for precipitation, conducting filtration and separation; and finally conducting active carbon absorption and sublimation and crystallization on filtrate to recover the low-concentration dissociated elementary substance iodine completely. The method for recovering iodine is suitable for treating the iodine-containing waste liquid that has strong acidity, high iodine content and multiple existing forms of iodine, and not only solves the problem that the discharge of iodine-containing waste liquid pollutes environment in the production process of X-CT series contrast media, but also realizes the recovery of iodine as well as the cyclic utilization of production waste liquid.

Owner:山西新天源药业有限公司

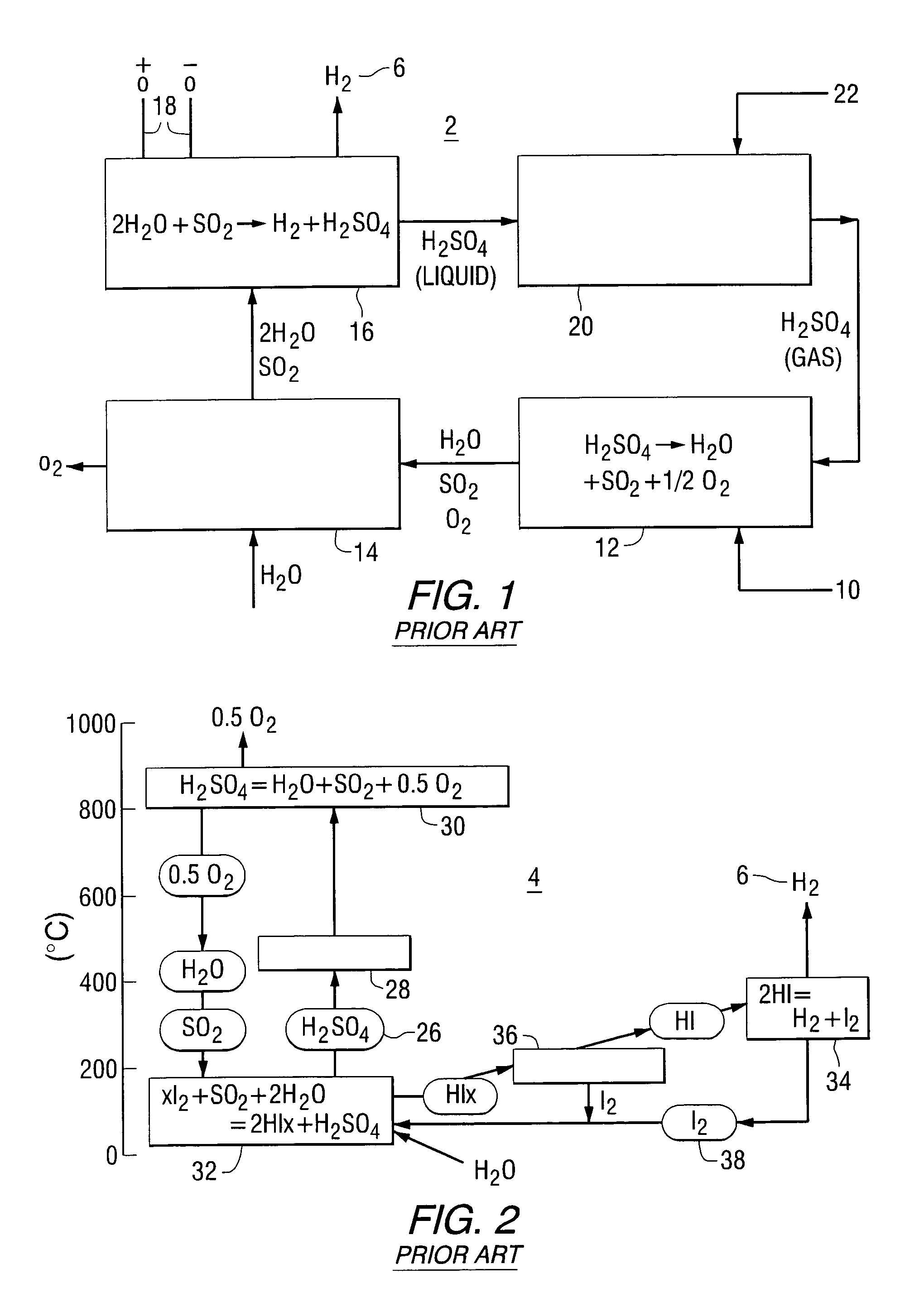

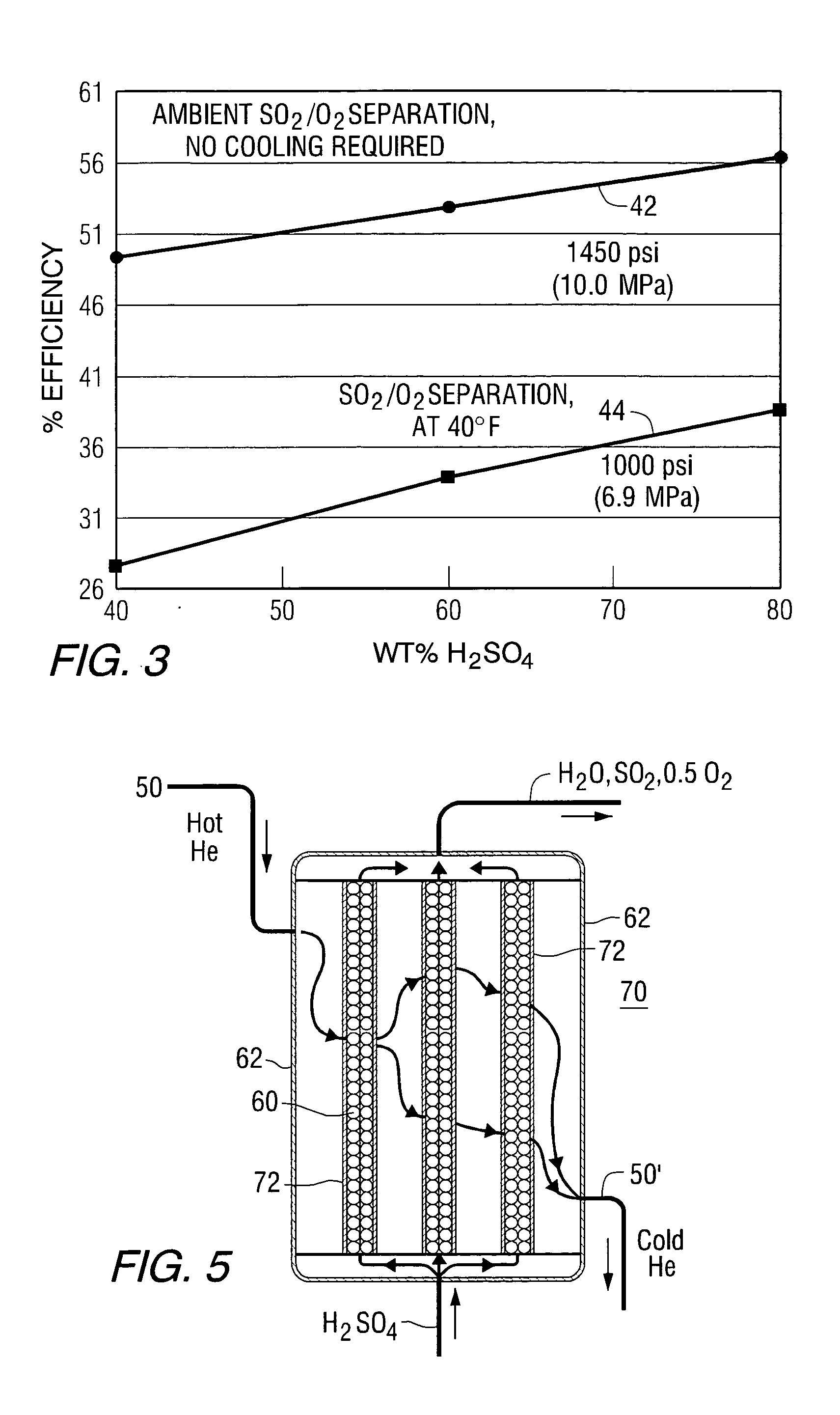

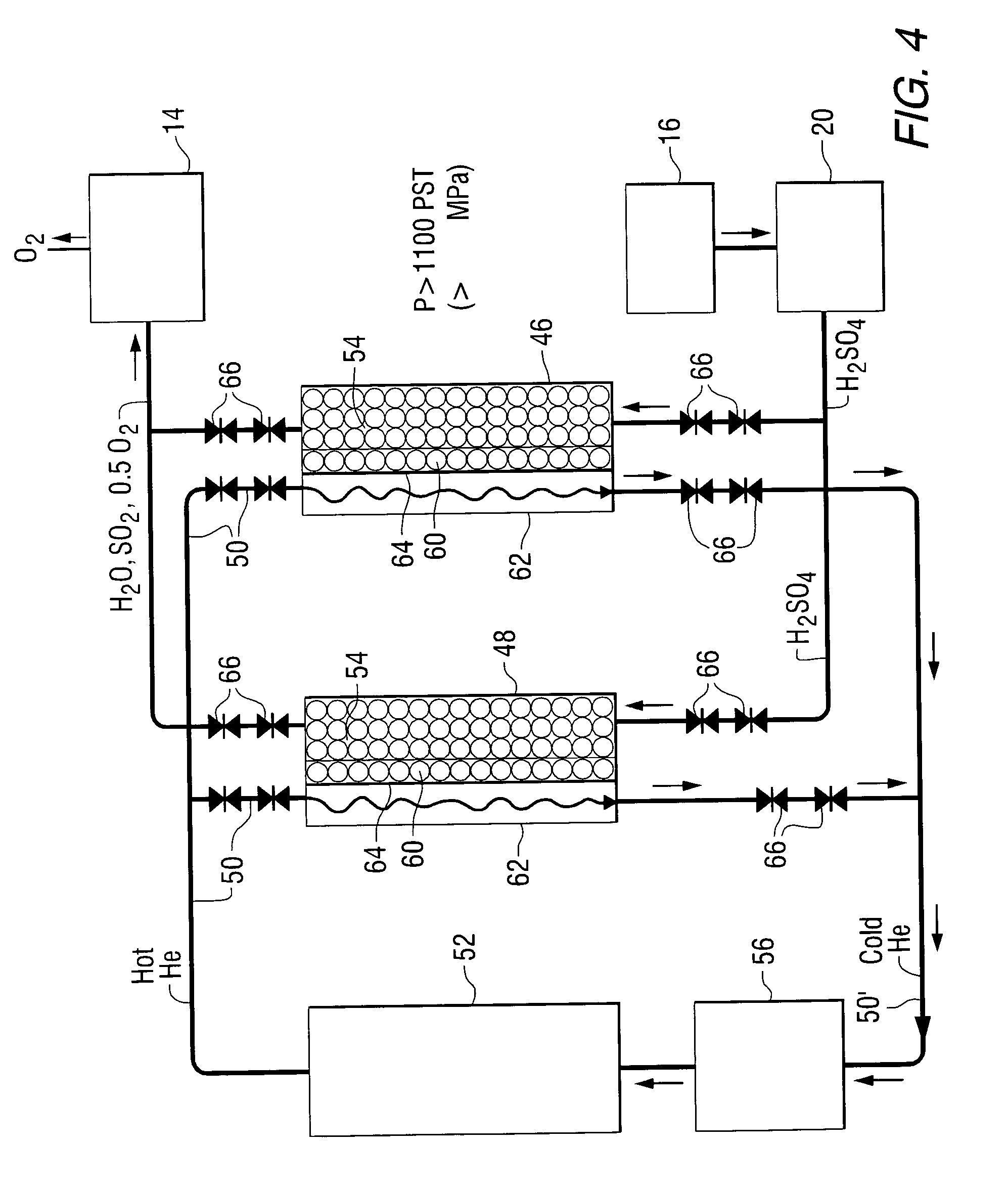

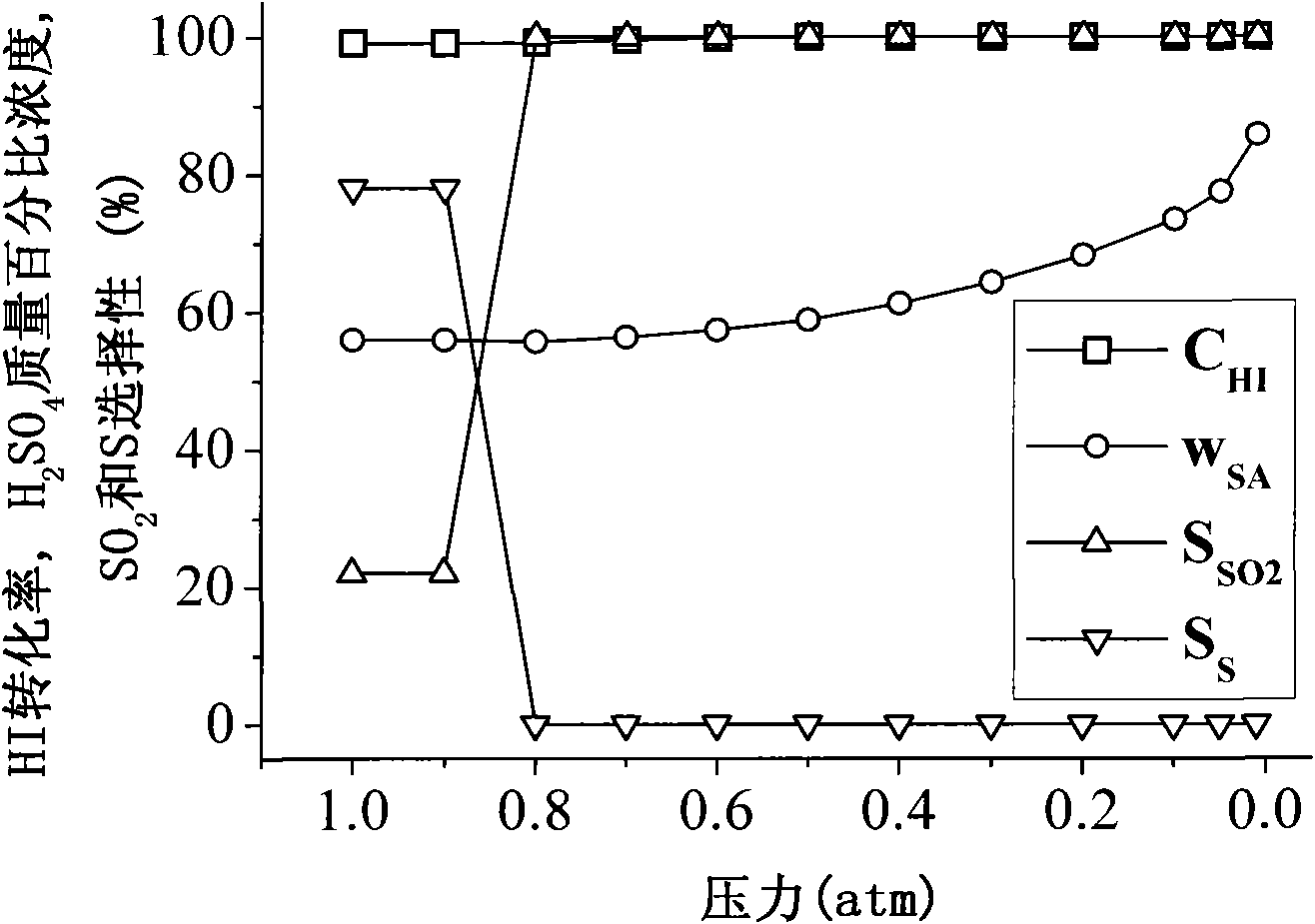

Sulfuric acid process

InactiveUS20060002845A1Reduce in quantityOxygen/ozone/oxide/hydroxideHydrogen iodideDecompositionSulfur

A method of operating the standard Westinghouse Sulfur Process (2) or the standard Iodine Sulfur Process (4) both having the common initial reaction of H2SO4⇄SO2+H2O+O.5O2, where over 760° C. of heat is required for the decomposition, and where the final reaction provides H2 (6), where all the reactions proceed at an elevated pressure greater than 1100 psi (7.88 MPa) to allow recovery of SO2 from H2SO4 decomposition at temperatures above 4.4° C.

Owner:WESTINGHOUSE ELECTRIC CORP

Method for recovering iodine

The invention discloses a method for recovering iodine, which is coupled with the electrochemical method to control the redox level, and recovers the inorganic iodine in liquid waste. A sodium hypochlorite solution is used for oxidizing and recovering organic iodine. The iodide ion content of the recovered liquid waste is about 0.3%. The iodine in the recovered liquid waste is gathered and recovered by using strong basicity anion exchange resin. The iodate ion is reduced to iodine by the method in one step. The complicated operations of reducing iodate ions into iodide ions firstly and then oxidizing into iodine are prevented. The usage amount of the oxidizing and reducing agents is reduced. Therefore, the cost is reduced, and the method for recovering iodine can bring high economic benefit to industrial production.

Owner:施一飞

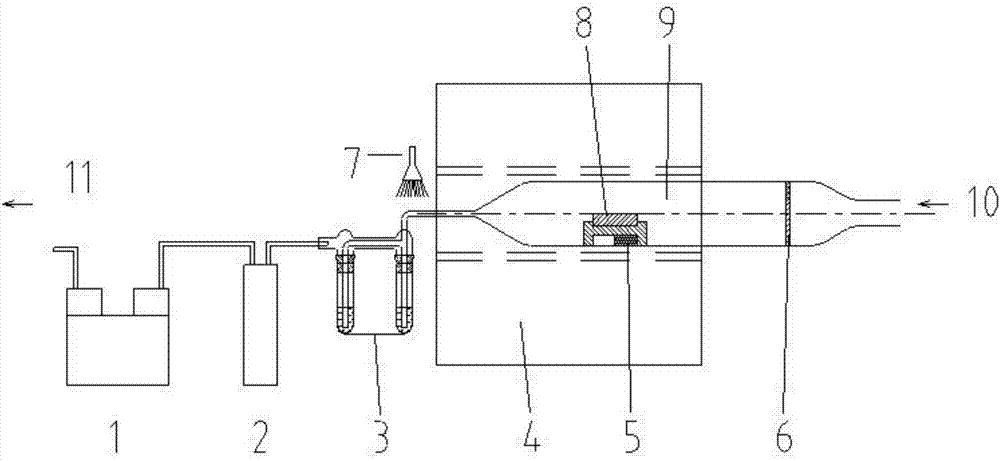

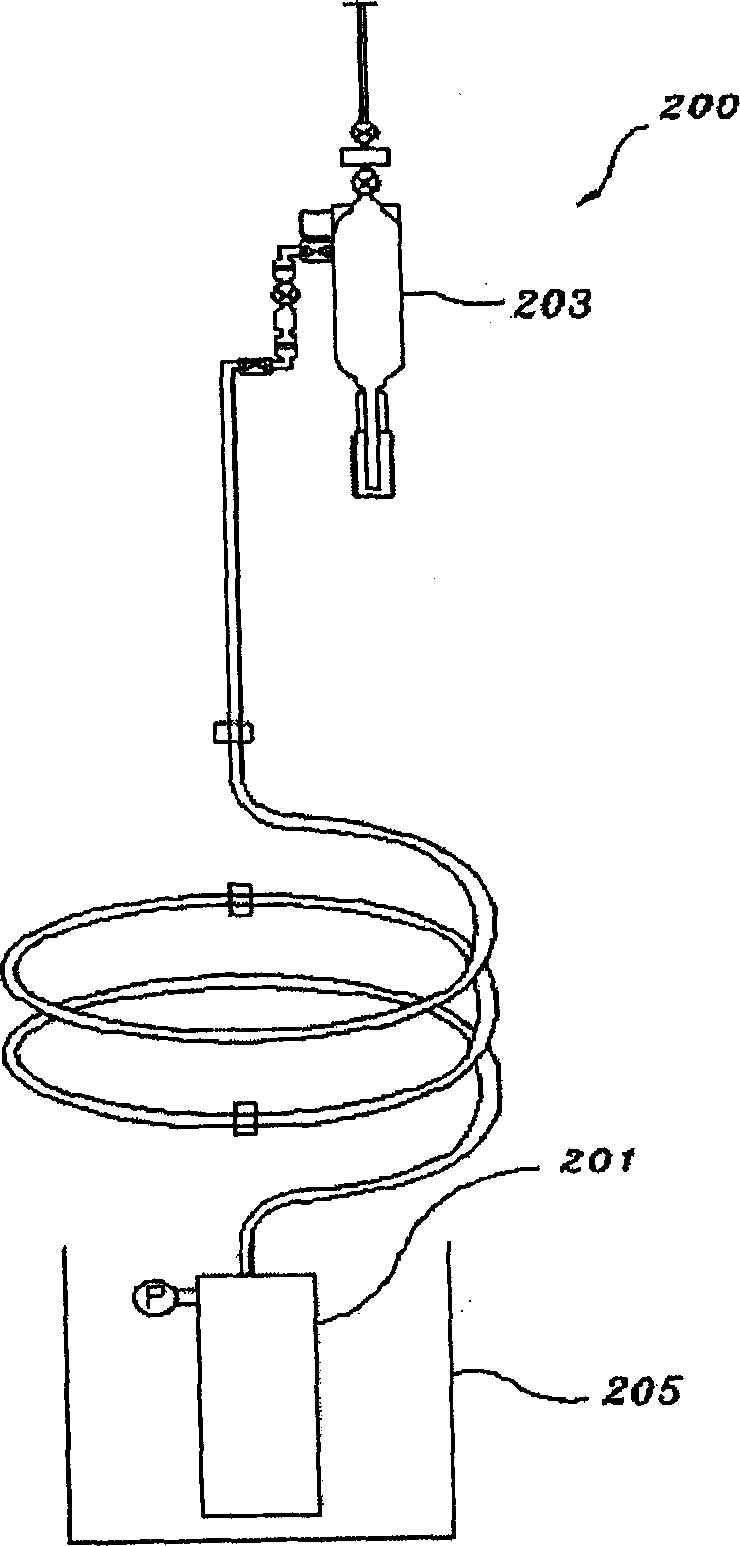

Apparatus for recycling iodine from diluted phosphoric acid for phosphoric acid manufacture with wet-process

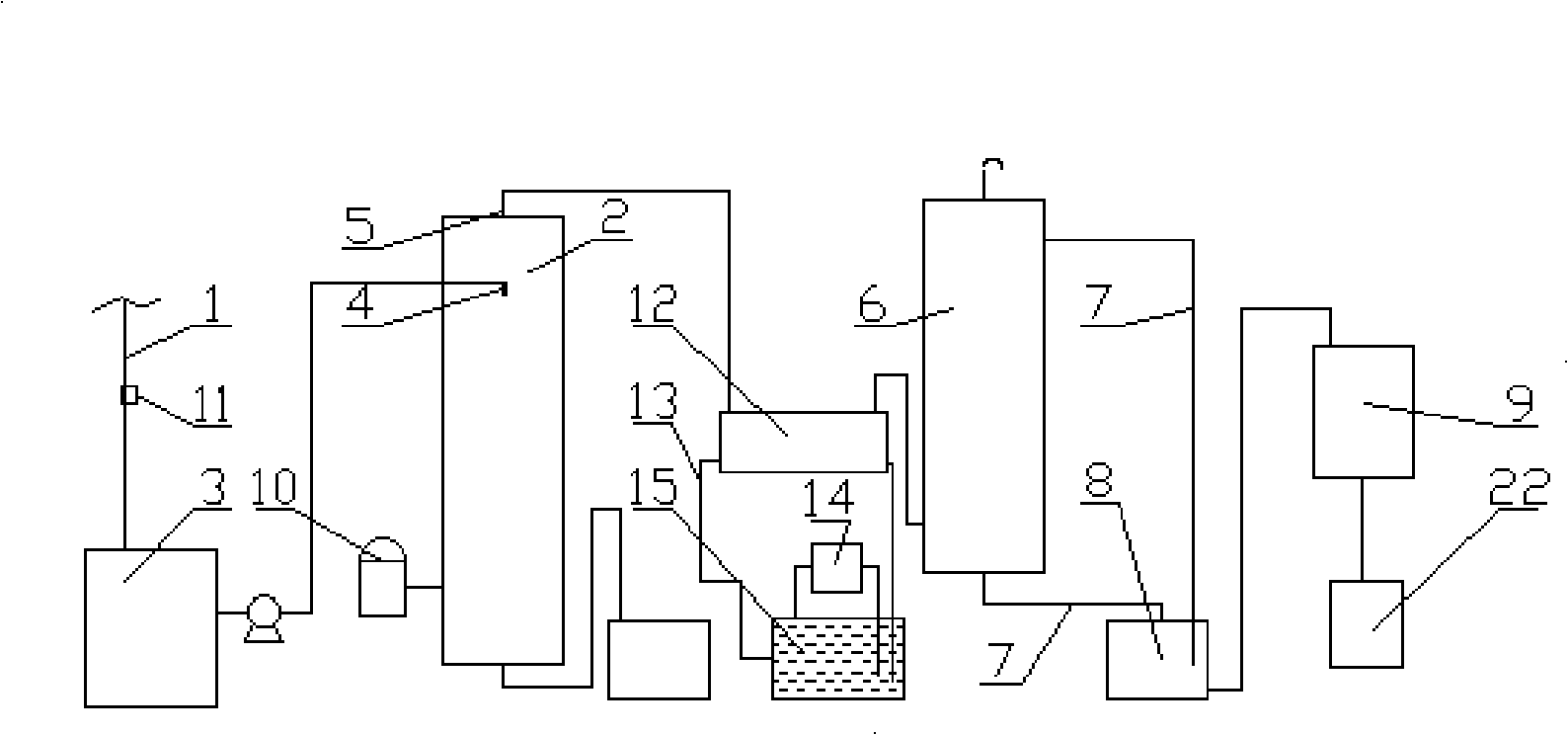

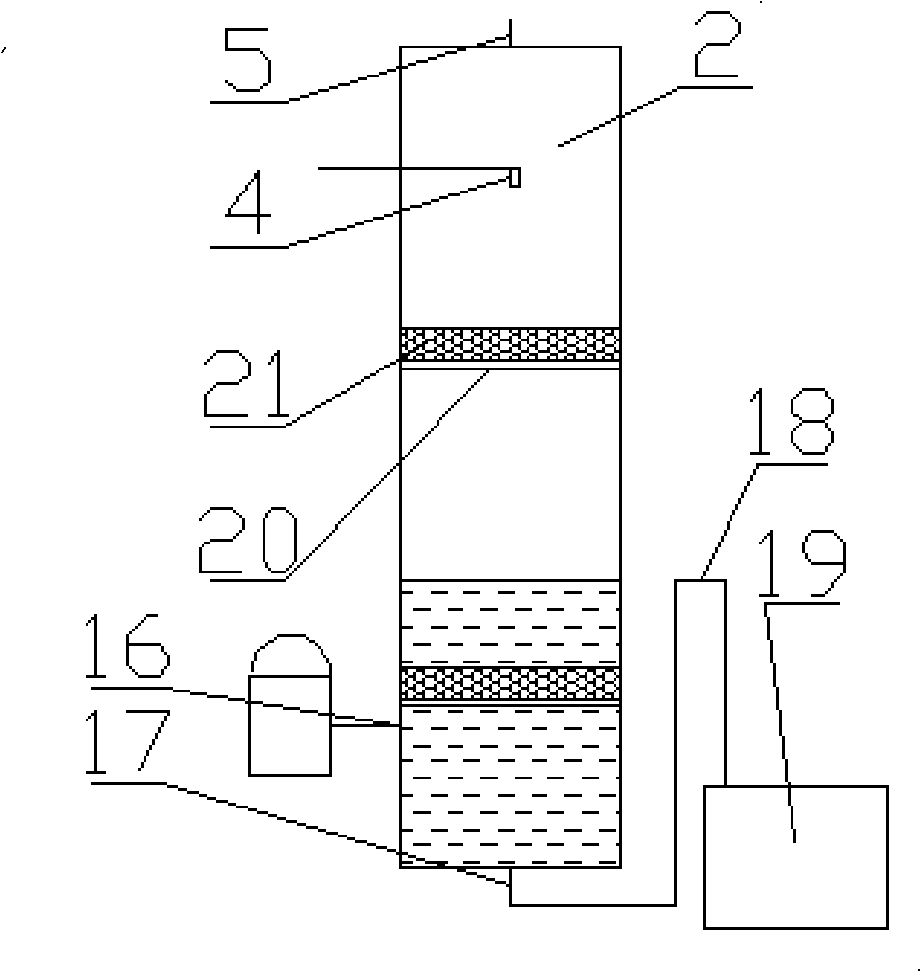

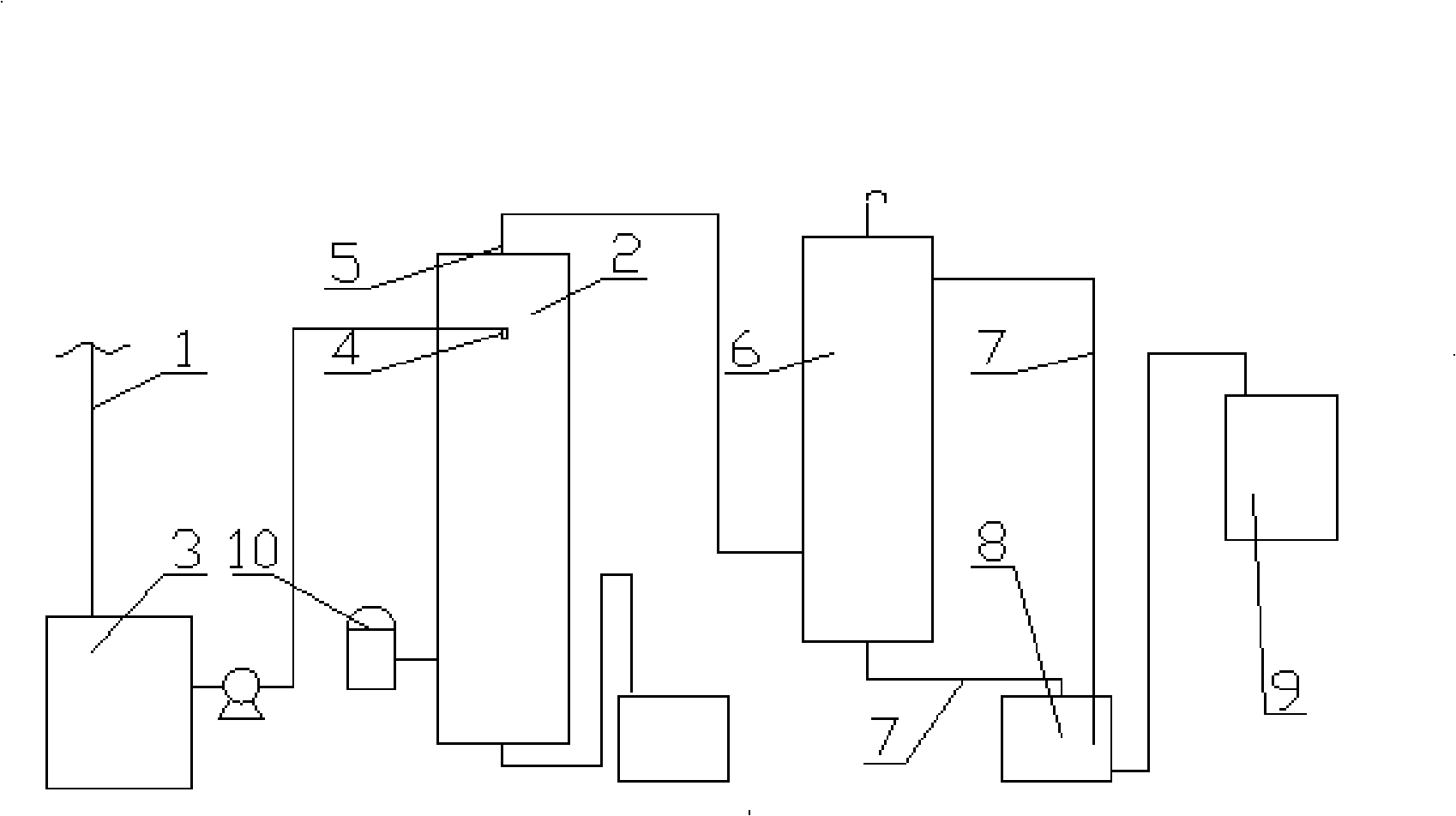

The invention discloses a device for recovering iodine from dilute phosphoric acid in phosphoric acid production with a wet method, comprising a pipeline (1) for leading in the dilute phosphoric acid; the pipeline (1) is connected with an oxidation tank (3), the oxidation tank (3) is connected to a shower (4) above an extracting tower (2) by the pipeline, the lower part of the extracting tower (2) is connected with a blast blower (10), an air outlet (5) of the extracting tower (2) is connected with a packing absorbing column (6), an absorption liquid pipeline (7) of the packing absorbing column (6) is connected with a receiving tank (8) which is connected with an iodine separating tank (9). Proved by a series of industrial tests and researches conducted by the applicant in a phosphorus chemical factory, the device of the invention can realize mass industrial production for extracting iodine, and the device is obtained by optimization through a plurality of tests.

Owner:WENGFU (GRP) CO LTD

Medical iodine-131 carbon microspheres and preparation method thereof

The invention discloses medical iodine-131 carbon microspheres for tumor radiotherapy or tumor early-stage imaging diagnosis and a preparation method thereof. The medical iodine-131 carbon microspheres are prepared in the manner that molecular iodine (I2) generated by a reaction of a medical Na131I solution and an oxidizing agent like hydrogen peroxide is adsorbed with carbon microspheres, and then curing treatment is carried out; or, the medical iodine-131 carbon microspheres are prepared in the manner that carbon microspheres are treated with an Ag(NO3) solution and then react with a medical Na131I solution to generate Ag131I, and Ag131I is deposited in the carbon microspheres and cured. The adsorption or curing efficiency of the medical iodine-131 carbon microspheres on iodine-131 nuclides is higher than 99%, the 131I release rate of the medical iodine-131 carbon microspheres subjected to further curing treatment is lower than 0.01%, and the medical iodine-131 carbon microspheres are good in biocompatibility and applicable to in-vivo tumor radiotherapy or tumor early-stage imaging diagnosis.

Owner:CHENGDU NEW RADIOMEDICINE TECH CO LTD

Method for extracting iodine from iodine containing circulation water of yellow phosphorus factory

The invention discloses a method for extracting iodine from the iodine-containing recycled water of a yellow phosphorus plant; the iodine is extracted from the recycled water generated from yellow phosphorus production process, wherein, the content of iodine in the recycled water is 80-140mg / L, the content of phosphorus in the recycled water is 100-400mg / L, compound oxidant is added into the recycled water for oxidation reaction, ionic iodine is oxidized into molecular iodine, air is used for blowing molecular iodine out, then SO2-containing acidic solution is used for absorbing, the pH value of absorption liquid is between 1-6, then hydrogen peroxide is added to separate iodine out and filtration and separation are carried out to obtain finished iodine. The recycled water from the yellow phosphorus plant with iodine content of below 140 mg / L is usually selected as raw material for extracting iodine; the method and the compound oxidant proposed by the applicant after tests can extract the iodine with low content in the recycled water and can expand the select range of the raw material for extracting iodine, and optimum compound oxidant proportion and production technique are also provided by the tests.

Owner:WENGFU (GRP) CO LTD

Method for refining industrial coarse iodine

ActiveCN101274748ASublimation is goodReduce the content of volatile impuritiesIodineSocial benefitsIodine

The invention relates to a method for refining industrial crude iodine. The method comprises the steps that the industrial crude iodine with the iodine content accounting for 70 to 95 percent is adopted as material to be added into a sublimator which is provided with concentrated sulfuric acid, a temperature measurement device and a gas blowing-out device; the ambient temperature of a crystallization device is controlled to be 20 DEG C, the sublimator is first heated to 60 to 90 DEG C and the sublimated iodine is caused to flow into a crystallizer by using the gas with the flow rate of 8 to 15L / min; after being maintained for 40 to 60 min, the temperature of the sublimator is heated to 160 to 200 DEG C and the gas-flow rate is adjusted to 1 to 1.5L / min so as to continue to collect the remaining iodine. By adopting the refining method, the content of volatile impurities in iodine products can be effectively reduced; multi-level crystallization devices are adopted to be connected in series to prevent the loss of the iodine and improve the working efficiency of the iodine sublimator. The obtained refined iodine products have neat appearance, large particle size and low impurity content. In addition, the refining method of the invention has the advantages of easy industrialization, low investment, high recovery rate and cleanness without pollution, etc., and can also increase the added value of the iodine products as well as generate relatively high economic and social benefits.

Owner:WENGFU (GRP) CO LTD

Method for extracting iodine from dehydrate wet method diluted phosphoric acid reaction iodic waste gas

InactiveCN103011084AEfficient recyclingImprove efficiencyDispersed particle separationIodineIodinePhosphoric acid

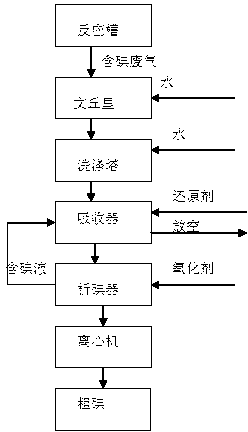

The invention discloses a method for extracting iodine from a dehydrate wet method diluted phosphoric acid reaction iodic waste gas. The method comprises the following steps: (1) collecting an iodic waste gas, and scrubbing in water by using a venturi scrubber and a scrubbing tower; (2) feeding the iodic waste gas subjected to defluorination into an iodine absorbing tower filled with materials, wherein a sealing tank is installed at the lower part of the tower and is filled with water and added with absorbent; (3) pumping the liquid in the sealing tank by using a washing circulation pump into the absorbing tower to be washed in circulation; (4) discharging the washed waste gas into the atmosphere through a fan; (5) after the concentration of the iodine in the liquid in the sealing tank achieves 50g / L, pumping the iodic liquid into an iodine precipitation tank, and adding hydrogen peroxide so as to precipitate the iodine in a crystal mode; and (6) filtering the liquid of iodic crystal, feeding back the liquid into the sealing tank of the absorbing tower, and obtaining 90% of crude iodine in a centrifugal mode. By utilizing the method, the iodine in the dehydrate wet method phosphoric acid reaction waste gas is effectively recycled, so that larger benefits are brought to enterprises, and meanwhile the on-site atmosphere environment is improved with good environmental-protection effect.

Owner:WENGFU (GRP) CO LTD

Semi-synthesis method of phenolic hydroxyl flavonoid compounds and iodine recycling method

The invention discloses a semi-synthesis method of phenolic hydroxyl flavonoid compounds and an iodine recycling method, relating to two ways A and B and iodine recycling, wherein in the way A, flavone is easily dissolved in a pyridine solvent of ethylene glycol or glycerin, and with iodine as a dehydrogenating agent, flavone is generated by heating and dehydration; in the way B, flavanone or flavone is not dissolved in pyridine of alcohol, the complexing of trivalent aluminum and flavanone is adopted, the solubility of the complexing and dehydrogenation products is high in alcohol, flavone is separated from the aluminum complex by use of phosphoric acid and the like, and flavone insoluble in water is separated out and obtained by filtering. The method disclosed by the invention is a universal method for preparing flavonoid compounds through dehydrogenation of phenolic hydroxyl dihydro flavonoids, the dosage of the reagents such as pyridine and the like is very small, and the treatment is simple, so that the method is suitable for industrial production. Take the diosmin preparation using hesperidin as an example, compared with the existing documents and patents, in the method disclosed by the invention, the dosage of organic solvents such as pyridine and the like is the least, the treatment is the simplest, the yield is the highest, and the method is environment-friendly (iodides can be oxidized by hydrogen peroxide, the recycling process is simple, and the yield is relatively high), and industrial production is easy to realize.

Owner:迁西县板栗产业研究发展中心

Iodine extraction processes

ActiveUS20110108486A1Process economyFlexible for changingWater contaminantsSolid sorbent liquid separationActivated carbonIodide

Processes for extracting iodine from an aqueous solution, such as brine, are disclosed. Activated coconut carbon particles are mixed with the solution to adsorb iodide through pores in the activated carbon particles. The activated carbon particles are then treated with sulfur dioxide gas and water to form hydrogen iodide. The hydrogen iodide is then reacted with chloride to obtain elemental iodine (I2).

Owner:IOFINA CHEM

Method for extracting iodine from blanching waste water of fresh kelp

A method for extracting iodine from blanching waste water of fresh kelp comprises the steps as follows: adjusting the pH value of the blanching waste water, adding an oxidant into the blanching waste water, blowing out the iodine in the blanching waste water by using air, absorbing the iodine in the blown out air by using a solution, analyzing the iodine in the absorption solution, and removing residual oxidant in iodine waste water. The invention overcomes the defects that cannot be overcome in the traditional kelp ion-exchange iodine extraction process through the adoption of the air blowing method, and solves the heating problems in the traditional air blowing method in virtue of the characteristic of high temperature of the blanching waste water of fresh kelp, reduces process cost, realizes economical and efficient extraction of iodine from the blanching waste water of fresh kelp, and achieves the iodine extraction rate above 80 percent. The invention discloses a reduction acidification oxidation method to solve the speed problem of iodine analysis adopting a NaOH solution as an absorption solution and improve quality. Besides, the invention adopts a quantitative reaction method and removes the residual oxidant NaNO2 in the waste water after iodine extraction, thereby solving the problem of environmental pollution caused by the oxidant in the traditional process.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

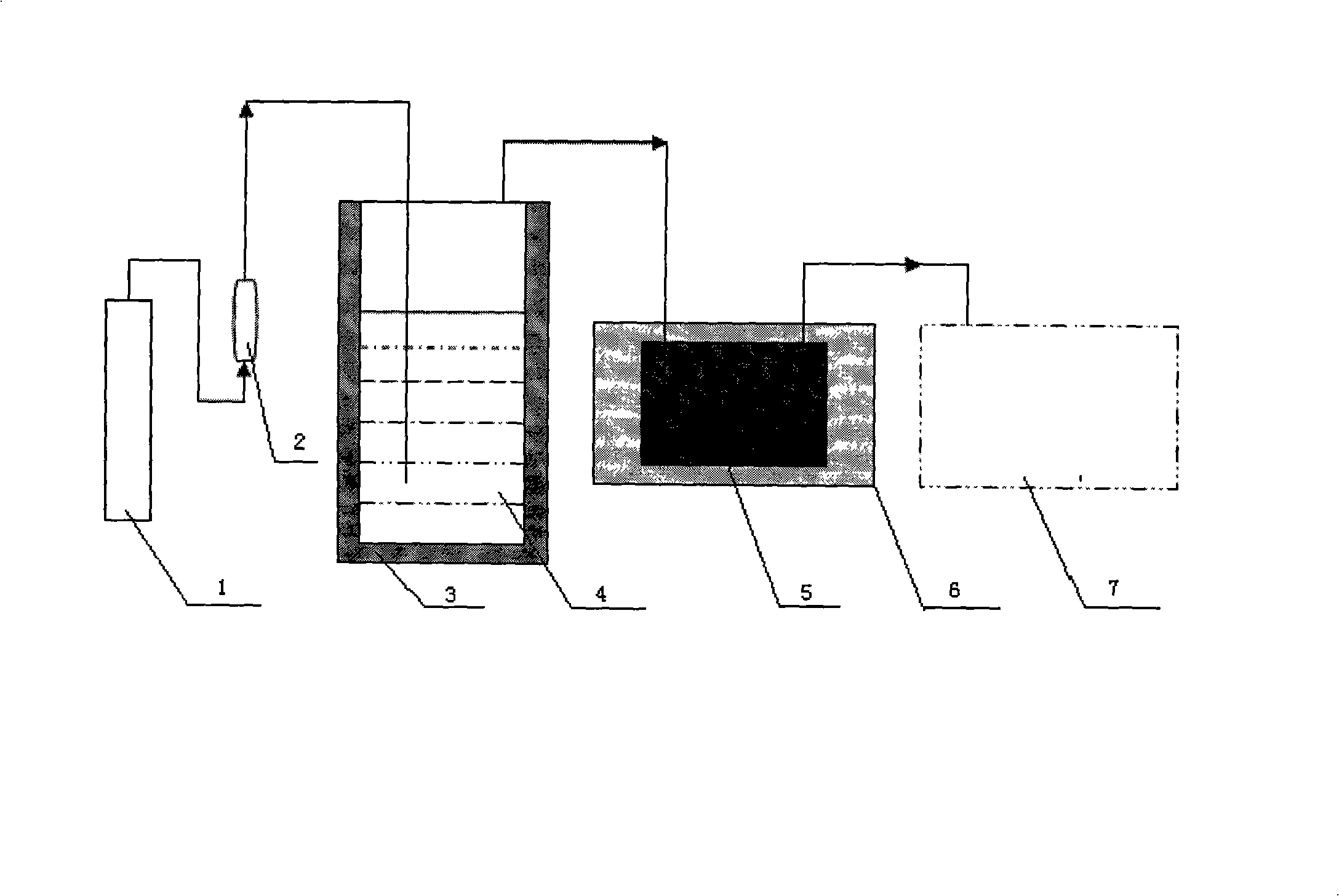

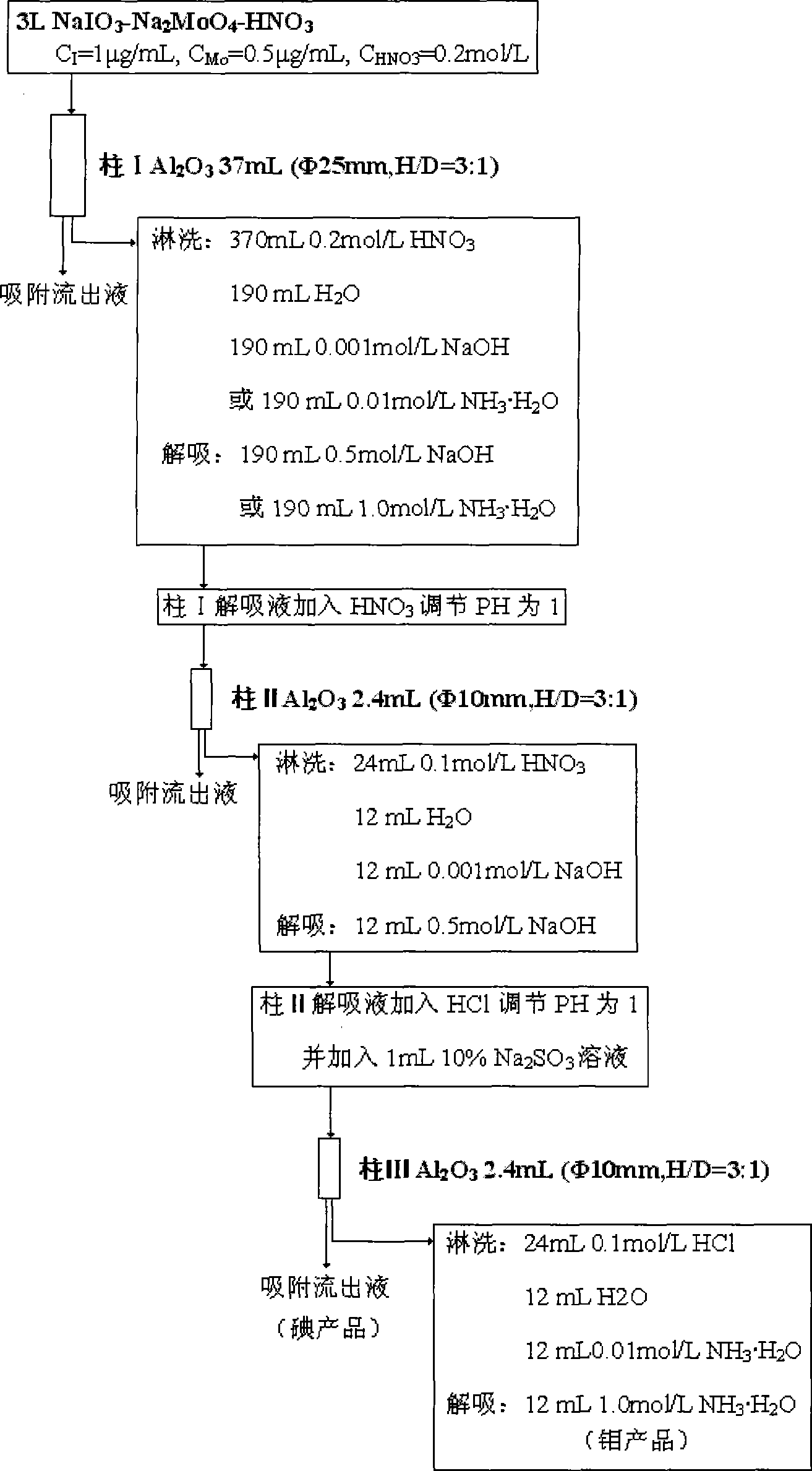

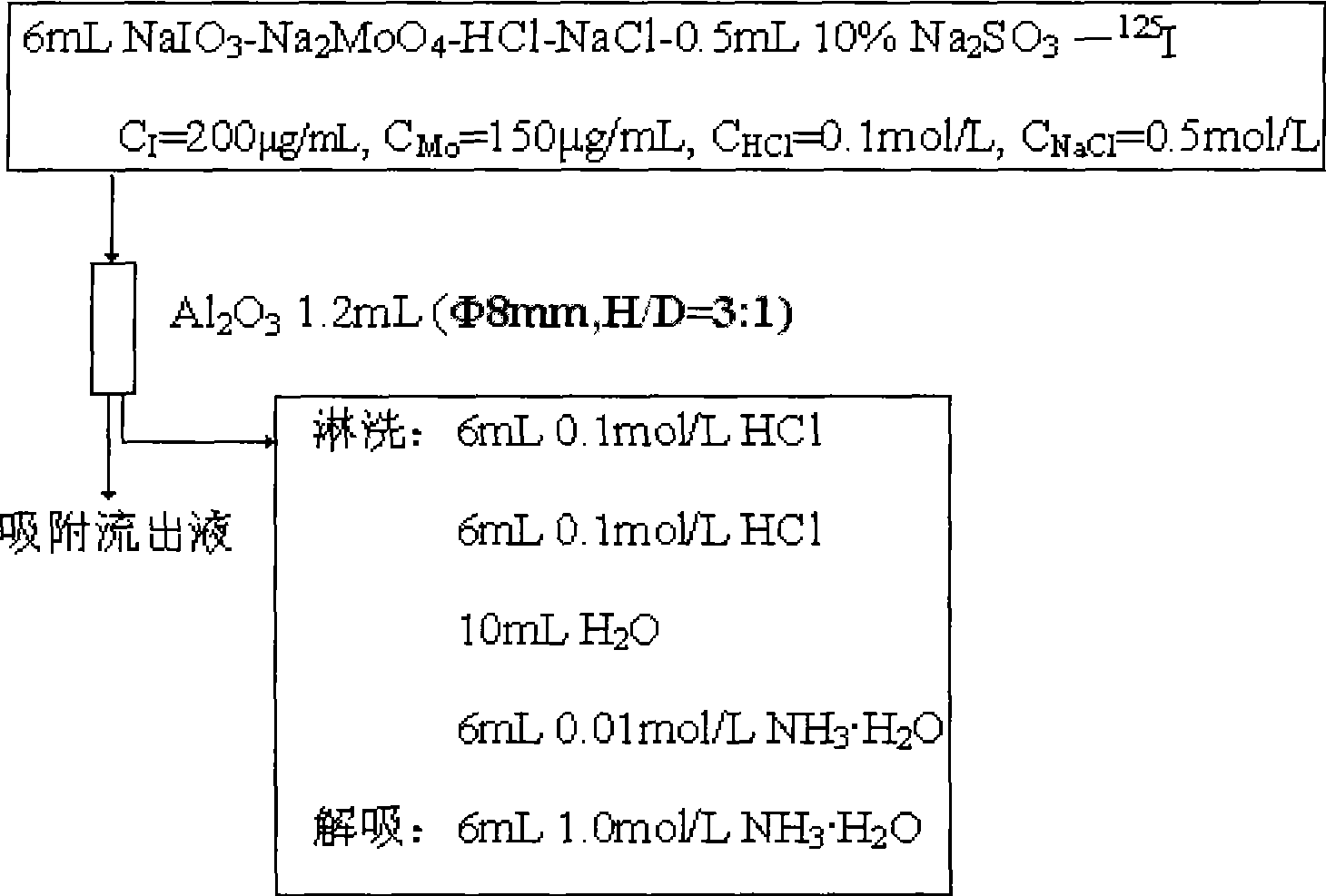

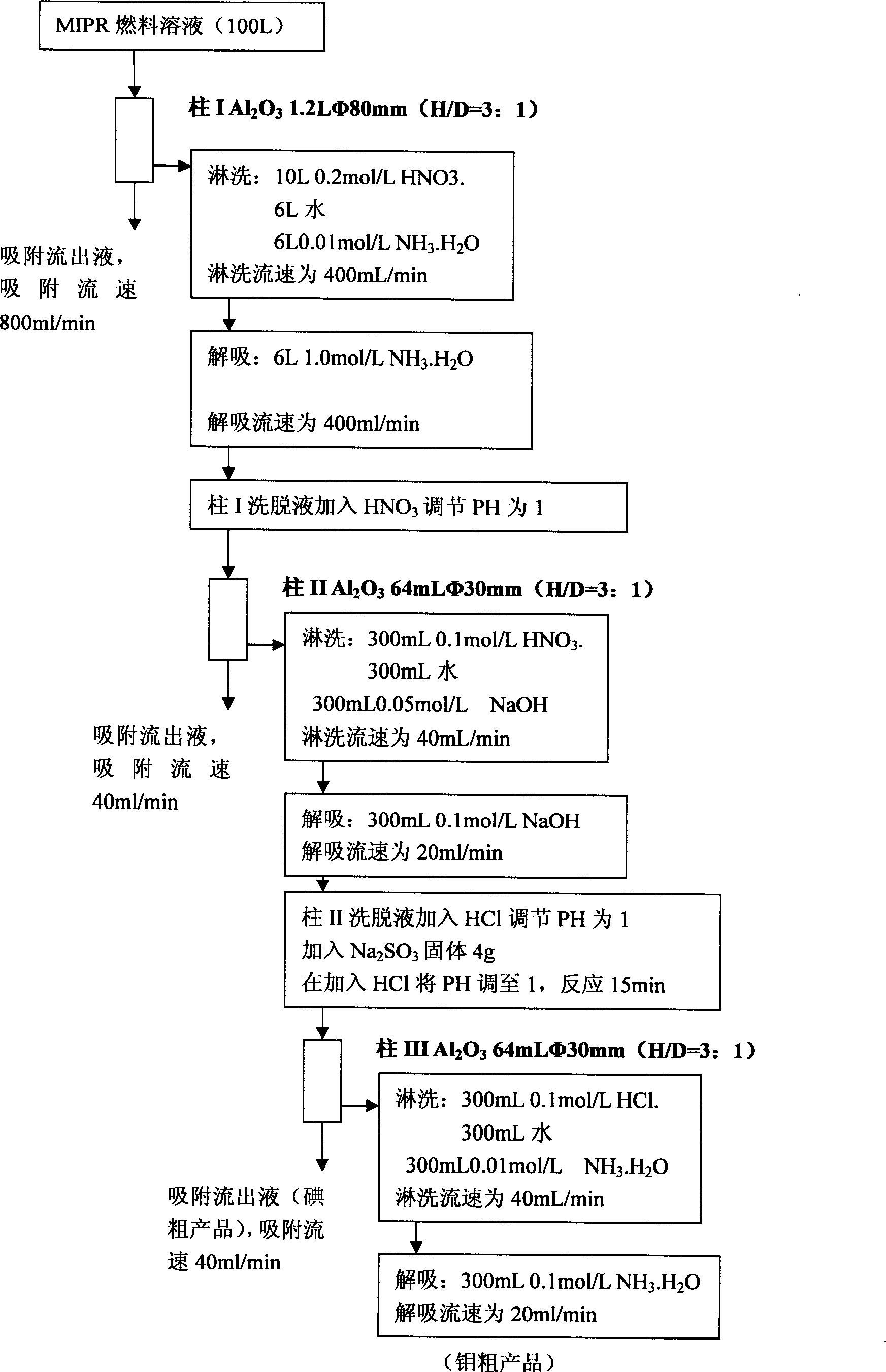

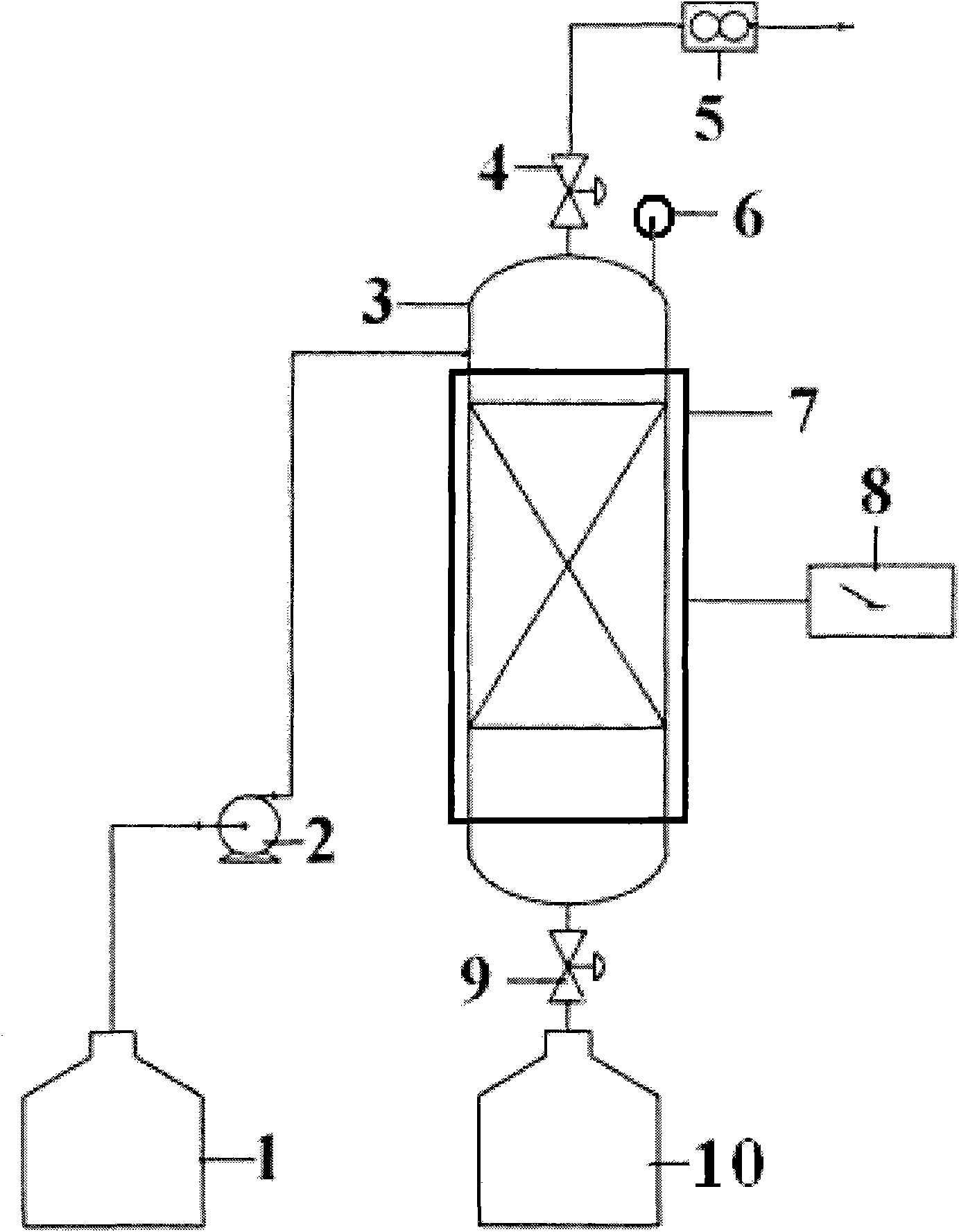

Extraction and purification technique for producing iodine-131 using homogeneous solution-type reactor

ActiveCN101468791AImprove the purification effectHigh recovery rateIodineIsotope separationNuclear reactorIodide-131

The invention belongs to technology of producing medical radioactive nuclide, and in particular relates to a process for extracting and purifying iodine-131 through a homogeneous aqueous solution nuclear reactor. The process comprises the following steps: adsorbing iodine-131 is from a bulk fuel solution after the reactor operates by an aluminum oxide extraction column or a hydrous zirconium oxide extraction column; and then cleaning the extraction column by using diluted HNO3, H20, NH3.H20; desorbing the iodine-131 on the extraction column by an NH3.H20 or NaOH solution; and finally, separating and purifying the desorbed iodine-131. The yield of the I obtained by the process is more than 50 percent, and purity of the I meets the requirement of a medical NaI solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

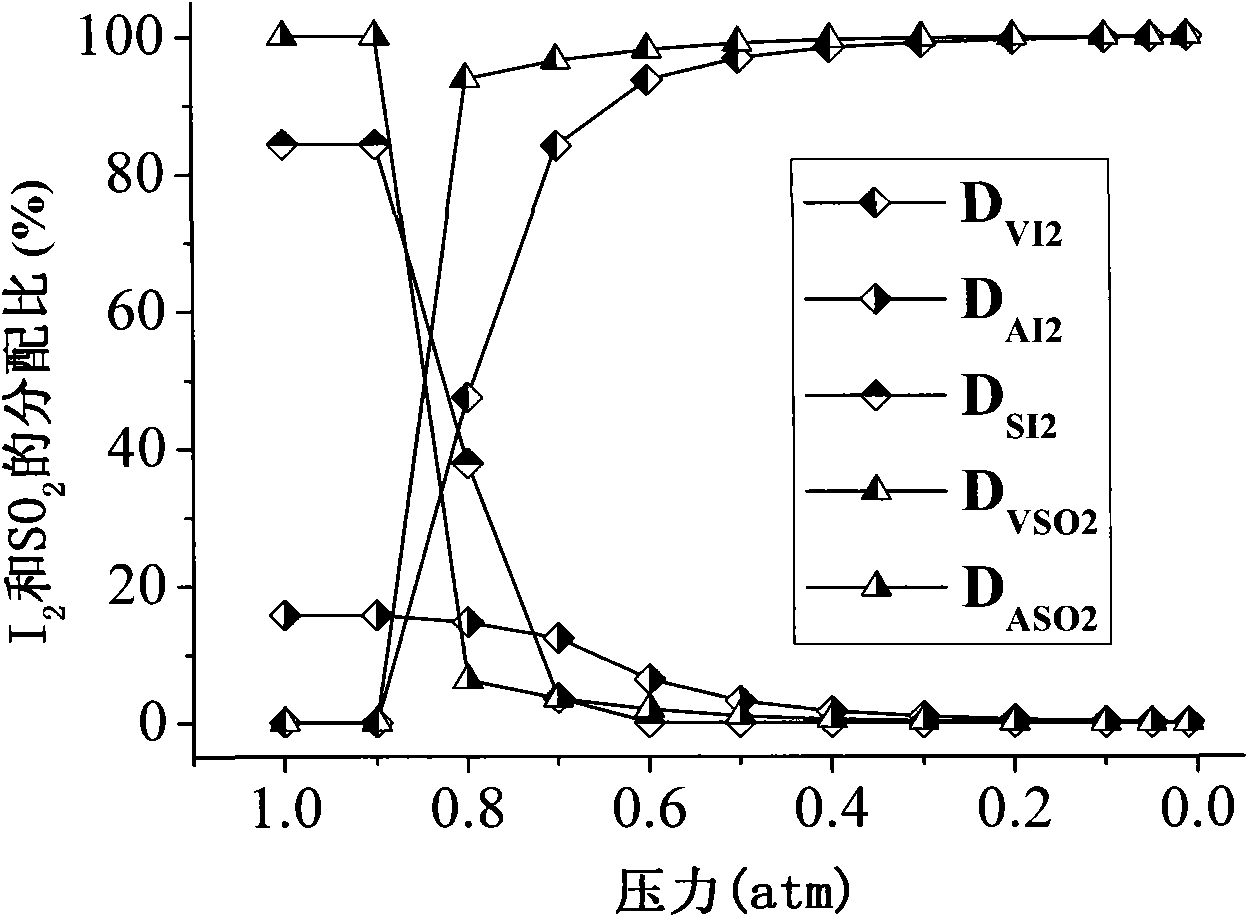

Process and device for purifying sulfuric acid phase in iodine and sulfur cycle under low pressure

ActiveCN101857204AOvercome costsOvercoming complexityIodineSulfur-trioxide/sulfuric-acidSulfur cycleNitrogen gas

The invention relates to a process and a device for purifying a sulfuric acid phase in the iodine and sulfur cycle under low pressure and belongs to the technical field of hydrogen production of the iodine and sulfur thermochemical cycle. The process for purifying the sulfuric acid phase is carried out under the condition of lower than normal pressure, i.e. under the condition of a purification temperature between 50 and 200 DEG C, a pressure P of a purifying and concentrating tower is controlled in the range that P is more than or equal to 0.01atm and less than 1atm. Compared with the conventional sulfuric acid phase purification process which adopts a nitrogen purging mode under normal pressure, the process has the characteristics of low purification temperature, simple process and low cost and can realize purification and concentration of the sulfuric acid phase in one step so as to effectively improve the purifying efficiency and reduce the purifying and concentrating cost.

Owner:TSINGHUA UNIV

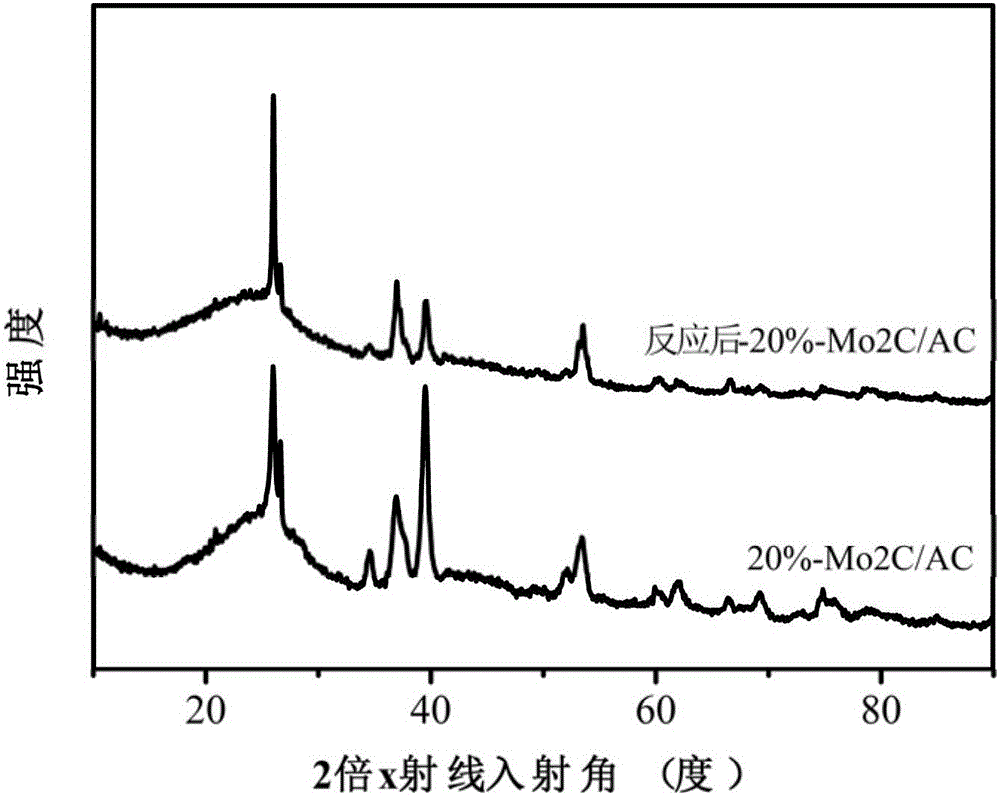

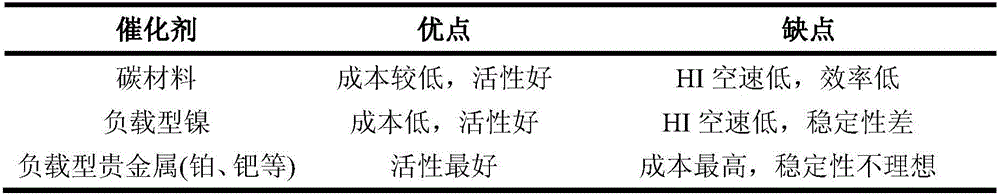

Method for preparing hydrogen through hydrogen iodide catalysis and decomposition

ActiveCN105836702AImprove economyHigh decomposition conversion ratePhysical/chemical process catalystsIodineDecompositionReaction temperature

The invention provides a method for preparing hydrogen through hydrogen iodide catalysis and decomposition and belongs to the technical field of catalysis reaction .According to the method, molybdenum-based carbide or molybdenum-based nitride is adopted as hydrogen iodide decomposition catalyst, reaction temperature is 350-850 DEG C, and normal pressure is -40 atm .The molybdenum-based carbide comprises pure molybdenum carbide and supported molybdenum carbide .The molybdenum-based nitride comprises pure molybdenum nitride and supported molybdenum nitride .The mass percentage of molybdenum in a supported molybdenum carbide and molybdenum nitride catalyst is 0.5-30% .The method for preparing hydrogen through hydrogen iodide catalysis and decomposition has the advantages of being low in catalyst cost, high in activity and good in stability .Reaction for producing hydrogen through hydrogen iodide catalysis and decomposition can be efficiently and stably conducted through the method.

Owner:TSINGHUA UNIV

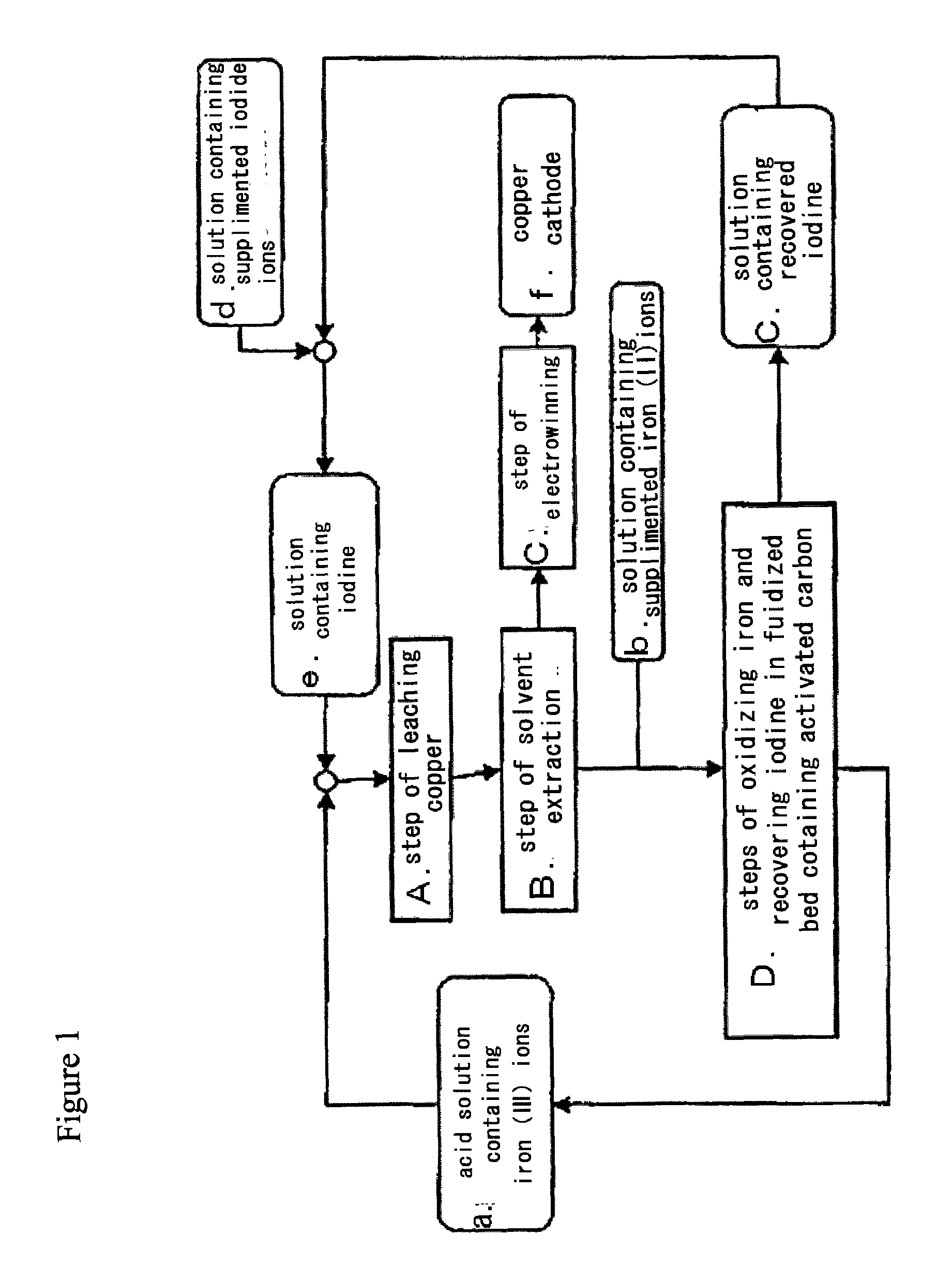

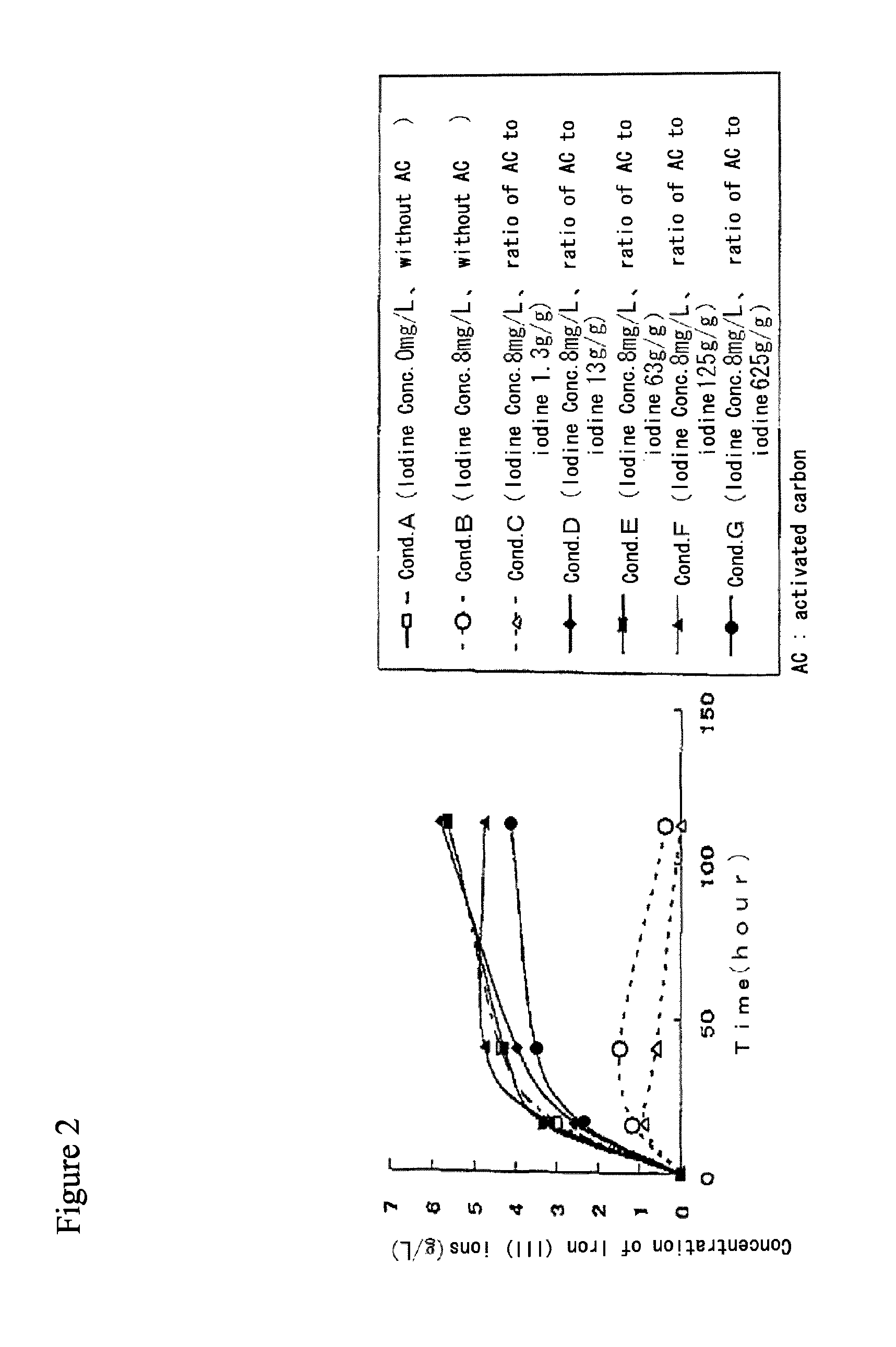

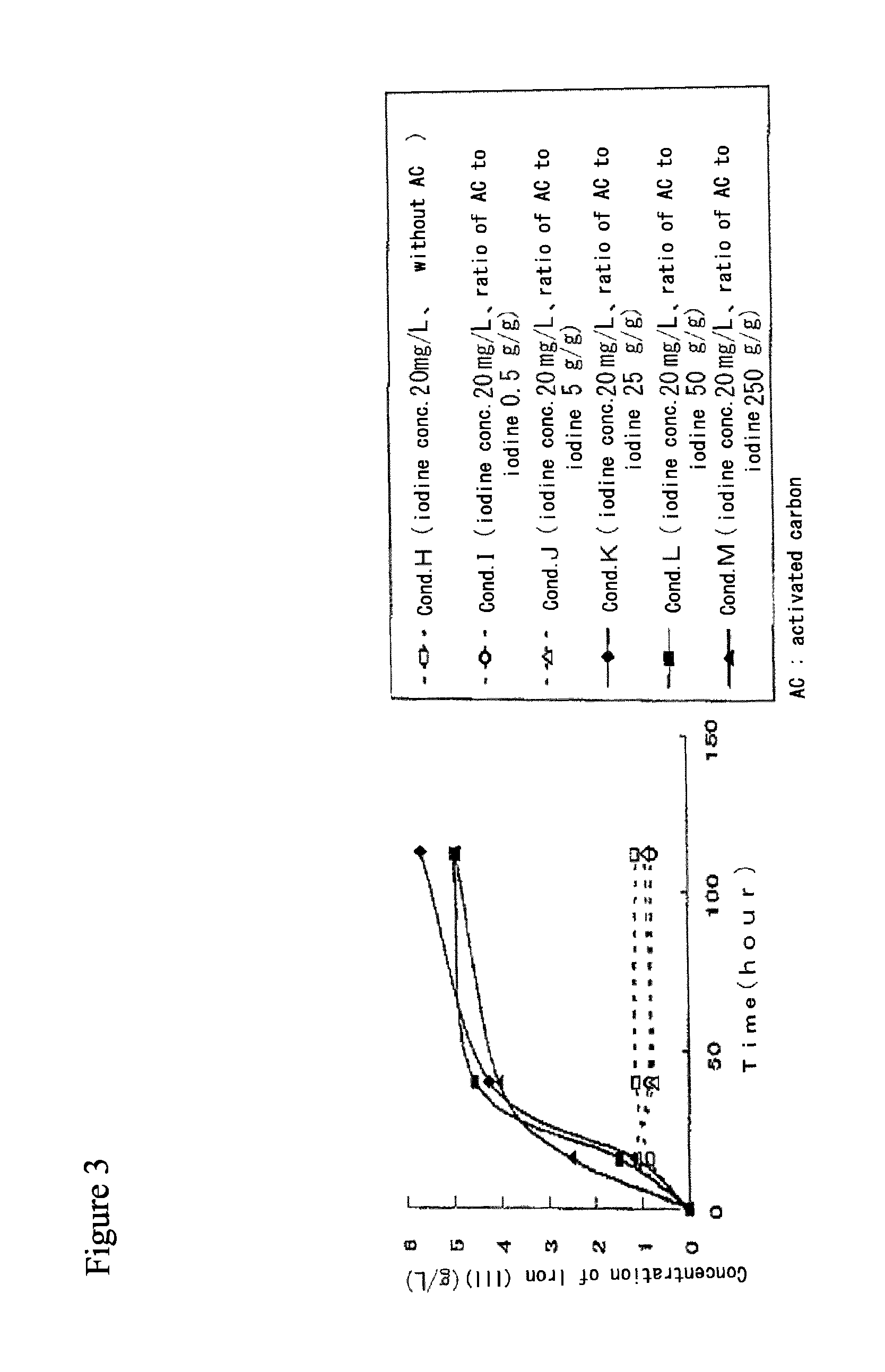

Method for processing acidic solution that contains iodide ions and iron ions

ActiveUS8865119B2Efficient regenerationModerate toxicitySolvent extractionIodineActivated carbonMicroorganism

Owner:JX NIPPON MINING & METALS CORP

Methods and Compositions For Treating Feline Hyperthyroidism

Methods for treating feline hyperthyroidism comprising (1) administering to a feline an antithyroid agent in conjunction with feeding the feline a composition comprising from about 0.1 to less than about 1 mg / kg iodine or (2) feeding the feline a composition comprising from about 0.1 to less than about 1 mg / kg selenium on a dry matter basis.

Owner:HILLS PET NUTRITION INC

Method for extracting iodine from iodine-containing solution

The invention discloses a method for extracting iodine from an iodine-containing solution. The method comprises the following steps: adjusting the pH of the iodine-containing solution; adding an oxidant into the iodine-containing solution to be oxidized for certain time and adding an extracting agent into the oxidized solution; heating and stirring for certain time; adding a reverse extraction agent into a loaded organic phase to be subjected to reverse extraction; after the reverse extraction, carrying out water washing treatment on the organic phase; and acidifying a water phase after the reverse extraction to separate crude iodine. According to the method disclosed by the invention, an oxidization-extraction method is adopted so that the method has the advantages of high extraction rate, simple equipment, low energy consumption and the like. The extraction rate of the iodine is more than 93 percent and the extraction agent can be repeatedly used.

Owner:HARBIN INST OF TECH AT WEIHAI

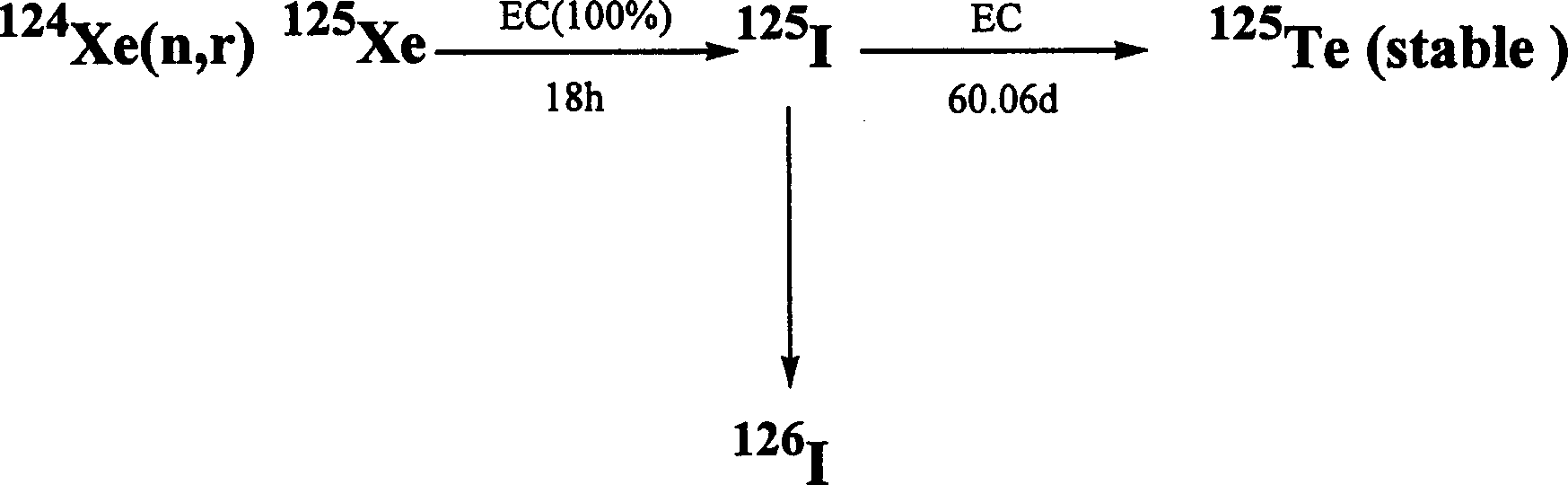

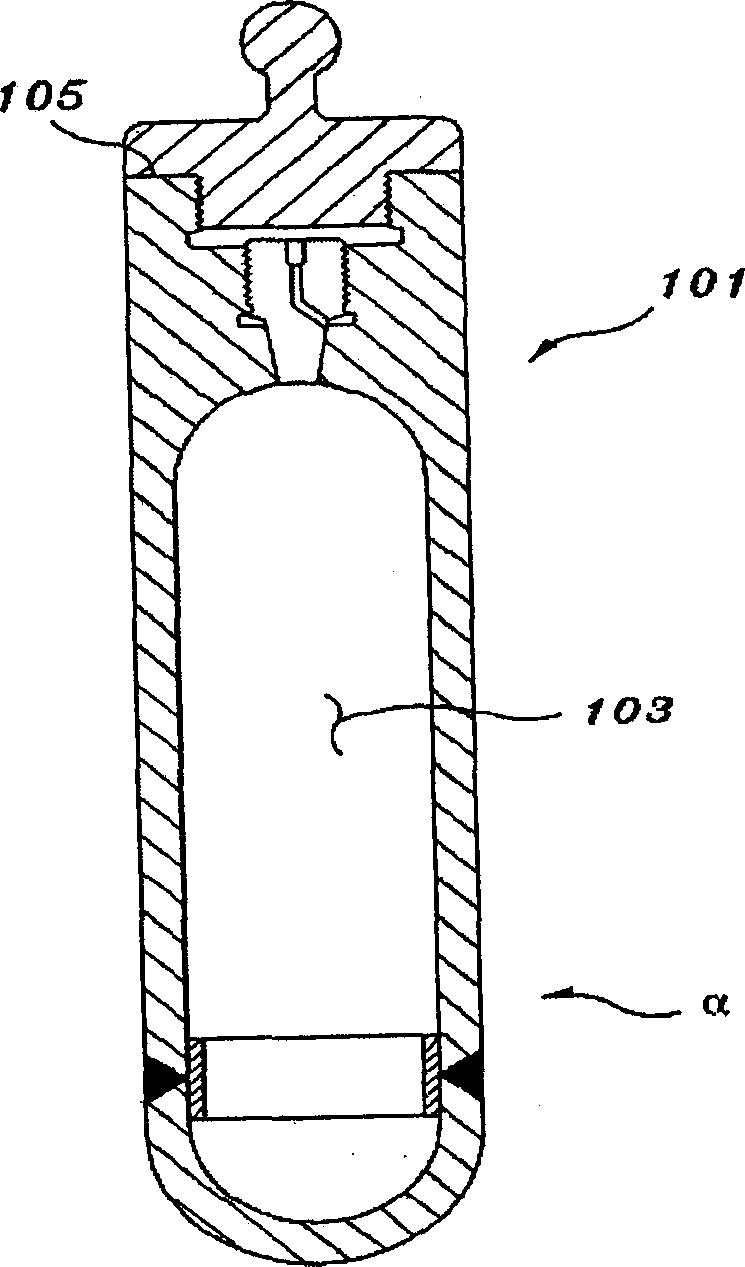

Internal circulating irradiation capsule for iodine-125 and method of producing iodine-125 using same

InactiveCN1794360AConversion outside reactor/acceleratorsNuclear energy generationIodineDirect radiation

The invention provides an inner circulation irradiation box which can be used to produce iodine-125 and a related production method. An irradiation box filled with xenon gas has a lower irradiation section and an upper irradiation section, and a neutron control member. The lower irradiation part is inserted into the irradiation hole of the reactor core and directly irradiated with a large amount of neutrons. Iodine-125 is produced from xenon gas when neutrons are irradiated to xenon gas. The upper irradiated portion protrudes from the irradiated hole, and iodine-125 is transported to the upper irradiated portion by convection and cured in the upper portion. The neutron control component reduces neutrons in the upper section to mass produce highly pure and highly radioactive iodine-125.

Owner:KOREA ATOMIC ENERGY RES INST

Method for recovering iodine from wastewater in medicine production

The invention discloses a method for recovery iodine from wastewater in medicine production. The method comprises the following steps: acidifying the wastewater in the medicine production with an acid, then reducing inorganic iodine with a reductant, adding a composite oxidant for oxidizing organic iodine, continuously dropwise adding hydrogen peroxide to oxidize iodine negative ions, and simultaneously introducing water vapor to heat and bubble, such that elementary iodine overflows in purple haze; continuously heating till no purple haze overflows, introducing the purple haze to an absorption container, reducing the elementary iodine with a reducible absorption solution, oxidizing the absorption solution with hydrogen peroxide, and filtering and separating to obtain coarse iodine. The acid for acidifying is any one of sulfuric acid, hydrochloric acid or nitric acid; the reductant is one or any two of or a mixture of iron powder, zinc powder, sodium hydrogen sulfite, sodium sulfite or sodium thiosulfate; the composite oxidant is one of C / Fe<2+> or Fe / Fe<3+> in a mixture; the reducible absorption solution is any one of a sulphurous acid solution, a sodium hydrogen sulfite solution or a sodium sulfite solution.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD +1

Method for extracting iodine from iodine containing underground bittern

The invention discloses a method for extracting iodine from iodine-containing subsurface brine; the content of iodine in the subsurface brine is 20-30mg / L, compound oxidant is added in the subsurface brine as oxidant for oxidation reaction, air is used for blowing molecular iodine out, then SO2 acidic solution is used for absorbing, the pH value of absorption liquid is between 1-6, then hydrogen peroxide is added to separate iodine out and filtration and separation are carried out to obtain finished iodine. The subsurface brine with iodine content of 20-30 mg / L is usually selected as raw material for extracting iodine; the compound oxidant of the invention can improve the efficiency of oxidant; proved by tests, after the hydrogen peroxide is added with vanadic oxide, the dosage of oxidant can be reduced by 30%. Therefore, the method and the compound oxidant proposed by the applicant after tests can extract the iodine with low content and can expand the select range of the raw materials for extracting iodine.

Owner:WENGFU (GRP) CO LTD

Popular searches

Rubidium/caesium/francium compounds Bromine/hydrogen-bromide Alkali metal chlorides Boron-oxygen compounds Lithium carbonates/bicarbonates Water/sewage treatment using germicide/oligodynamic-process Chemicals Water/sewage treatment by oxidation Water treatment parameter control Specific water treatment objectives

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com