Patents

Literature

49 results about "Sulfur cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sulfur cycle is the collection of processes by which sulfur moves between rocks, waterways and living systems. Such biogeochemical cycles are important in geology because they affect many minerals. Biochemical cycles are also important for life because sulfur is an essential element, being a constituent of many proteins and cofactors, and sulfur compounds can be used as oxidants or reductants in microbial respiration. The global sulfur cycle involves the transformations of sulfur species through different oxidation states, which play an important role in both geological and biological processes.

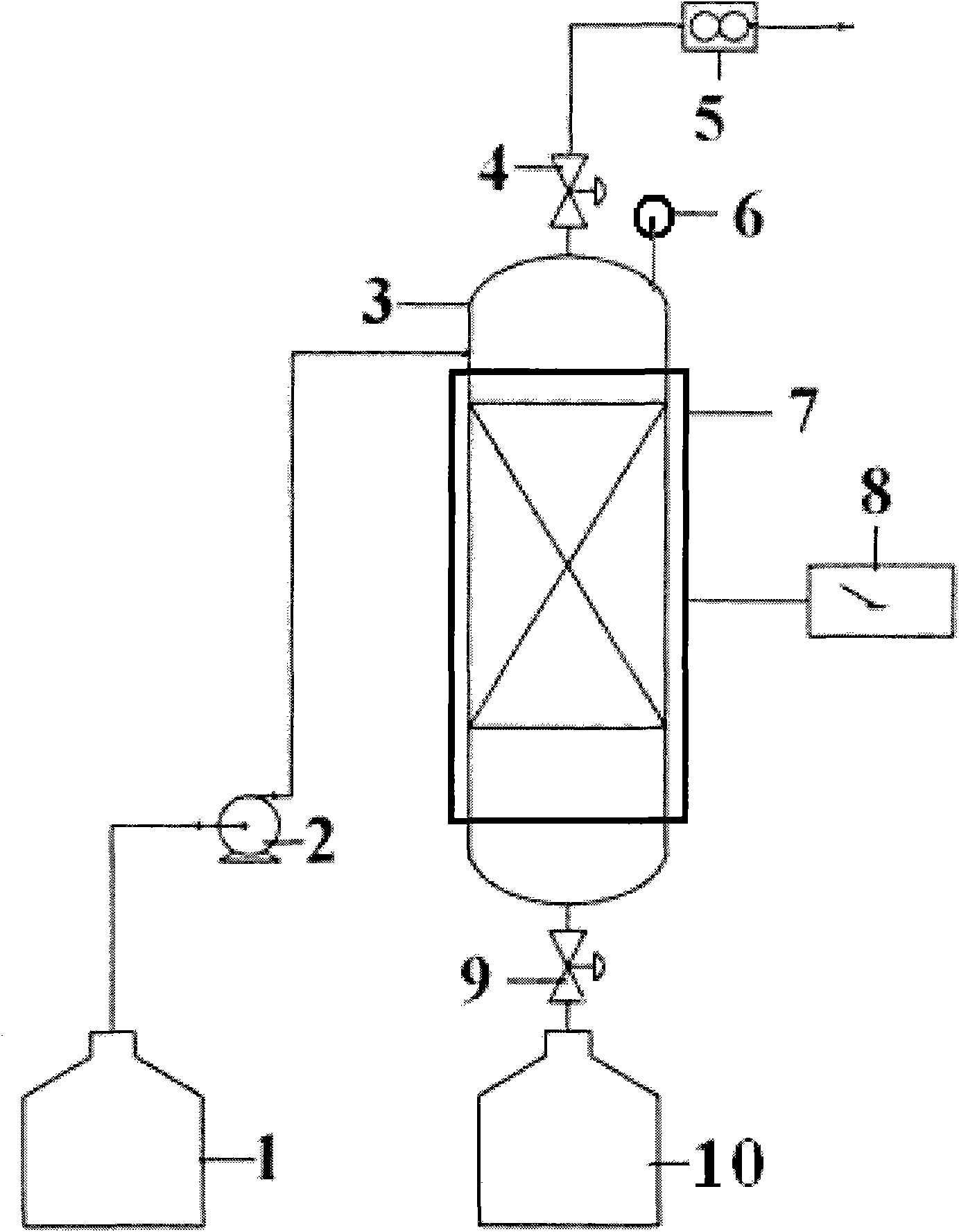

Process for purifying sulfuric acid phase and hydriodic acid phase in iodine-sulfur cycle

InactiveCN101830443AAchieve purificationSuppress generationIodine/hydrogen-iodideSulfur-trioxide/sulfuric-acidThermochemical cycleSulfur cycle

The invention relates to a process for purifying a sulfuric acid phase and a hydriodic acid phase in an iodine-sulfur cycle, which belongs to the technical field related to hydrogen production through an iodine-sulfur thermochemical cycle. The sulfuric acid phase and the hydriodic acid phase obtained through a Benson reaction in the iodine-sulfur cycle respectively contain a small amount of HI and a small amount of H2SO4, and a traditional purification process comprises the following steps of: using nitrogen gas as sweep gas, heating to promote the occurrence of the reverse reaction of the Benson reaction: 2HI+H2SO4=SO2+I2+2H2O, and removing impurity acid. The traditional purification process can consume main acid, and a side reaction often occurs together. In order to overcome the defect, the invention provides a two-phase purification process using the mixed gas of oxygen and inert gas as active sweep gas, and as for the purification of the sulfuric acid phase, the reaction principle is 4HI+O2=2I2+2H2O, sulfuric acid is not lost, and the reaction temperature is lower; and as for the purification of the hydriodic acid phase, the active sweep gas can inhabit the generation of S and H2S and promote the selectivity enhancement of converting H2SO4 into SO2.

Owner:TSINGHUA UNIV

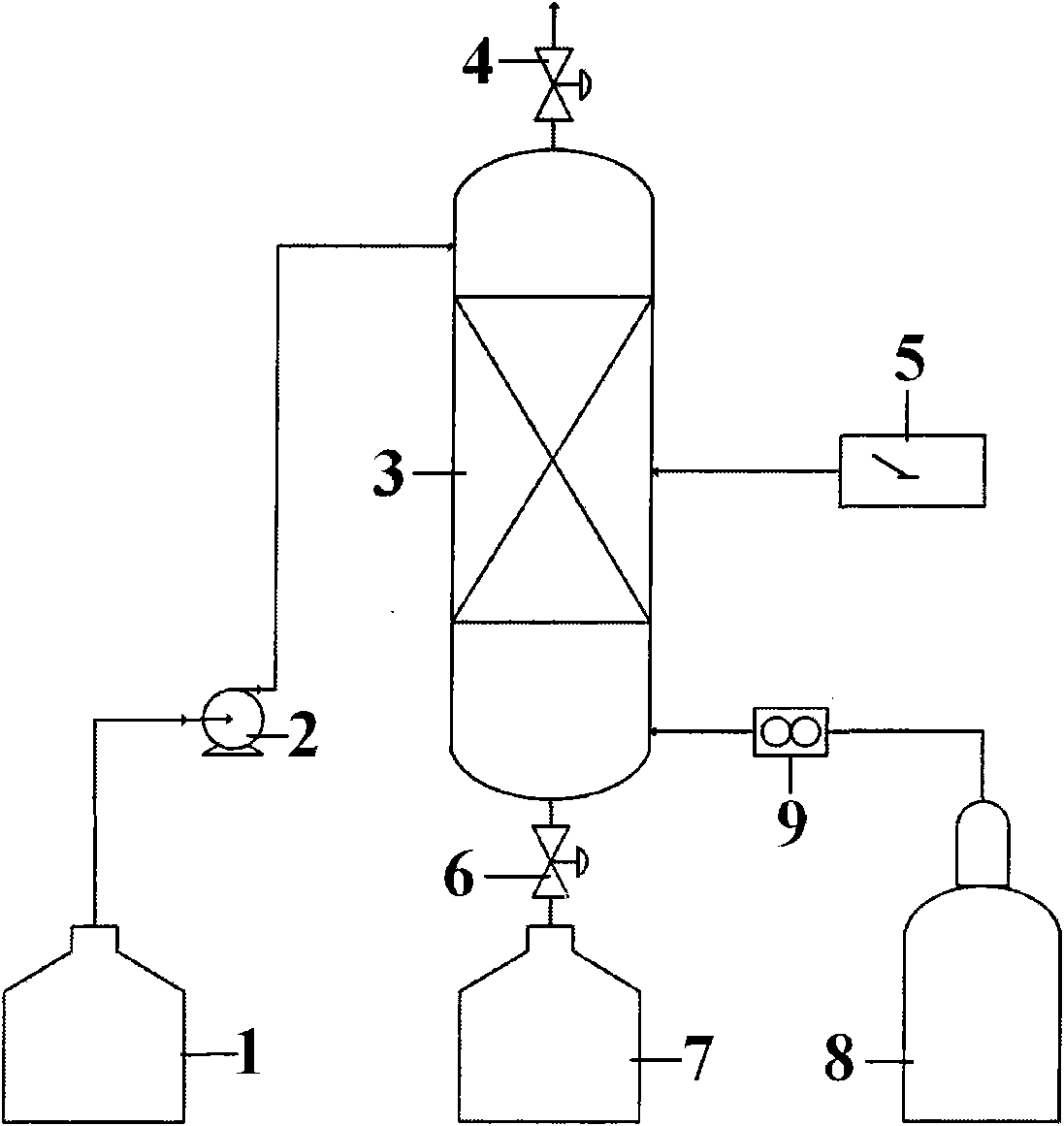

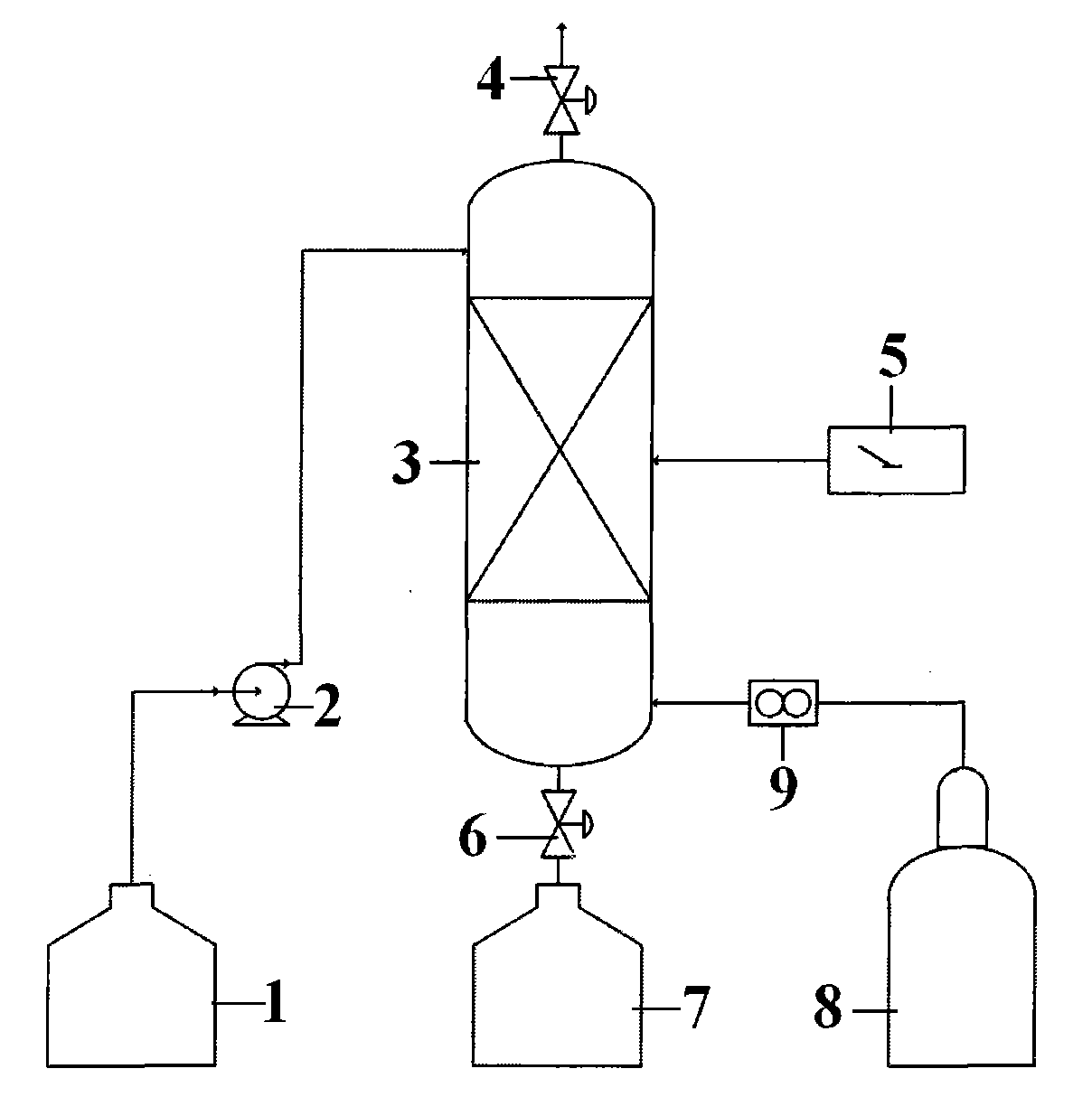

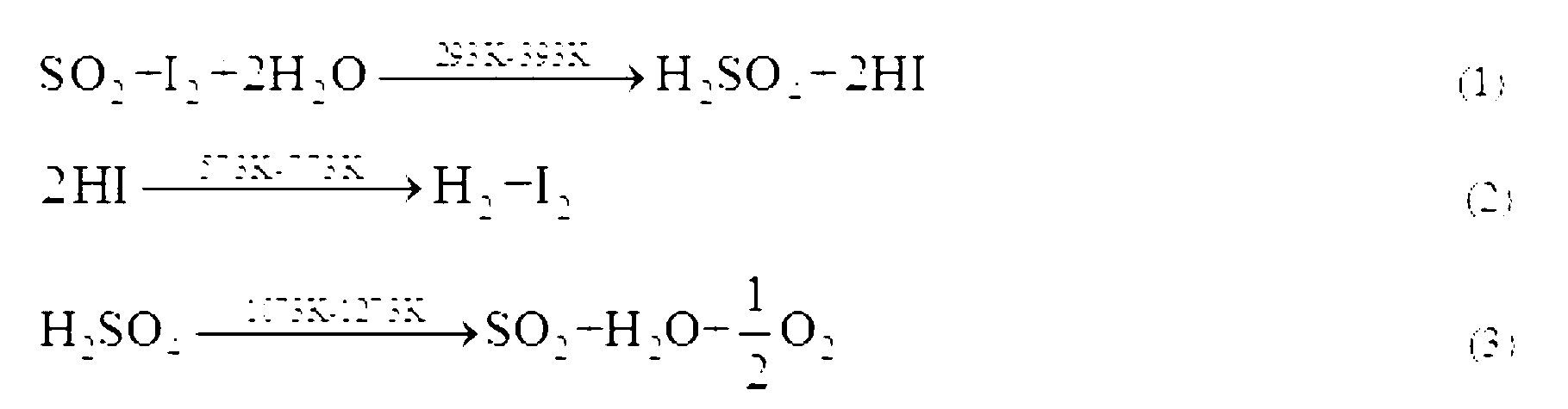

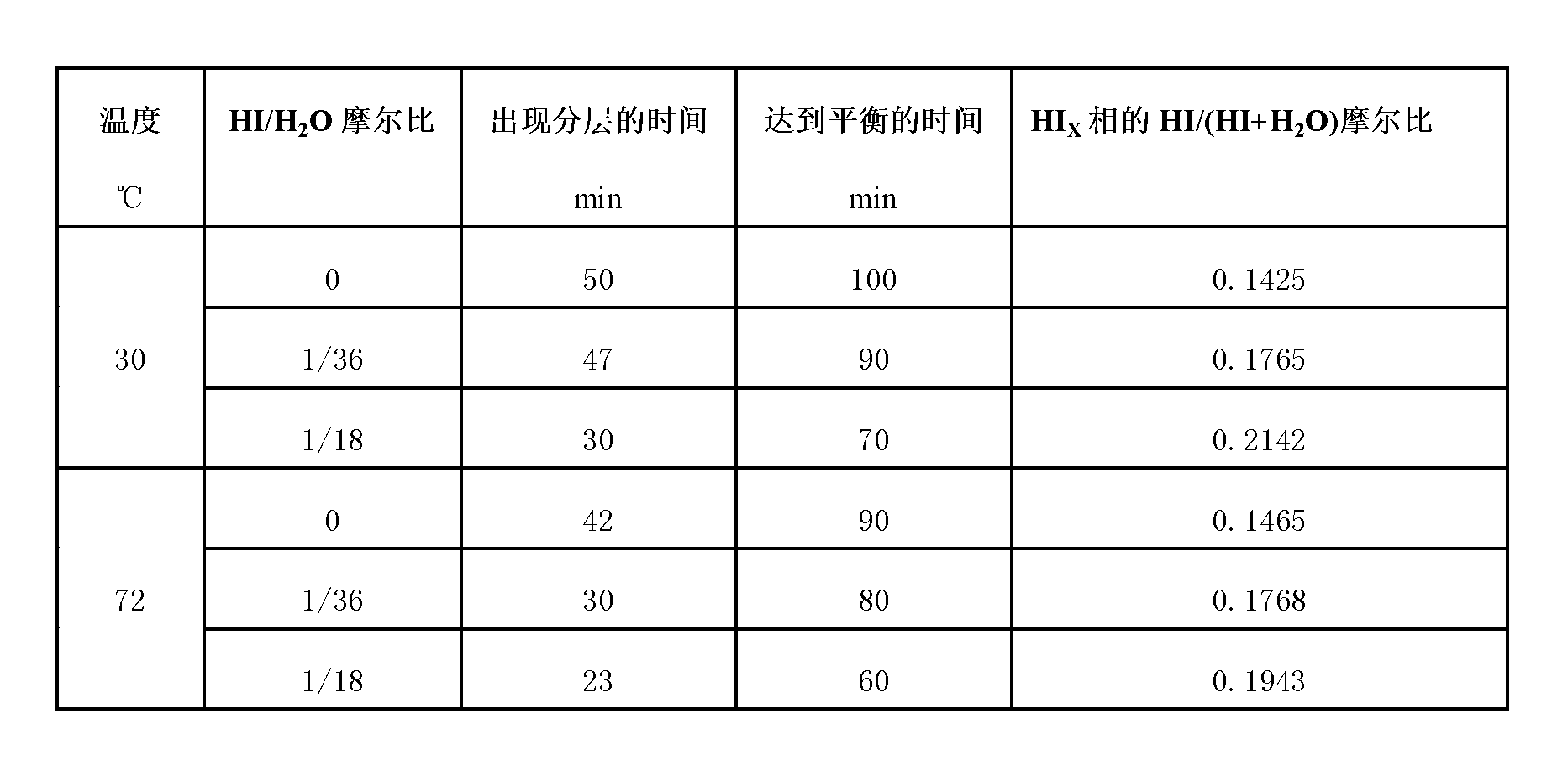

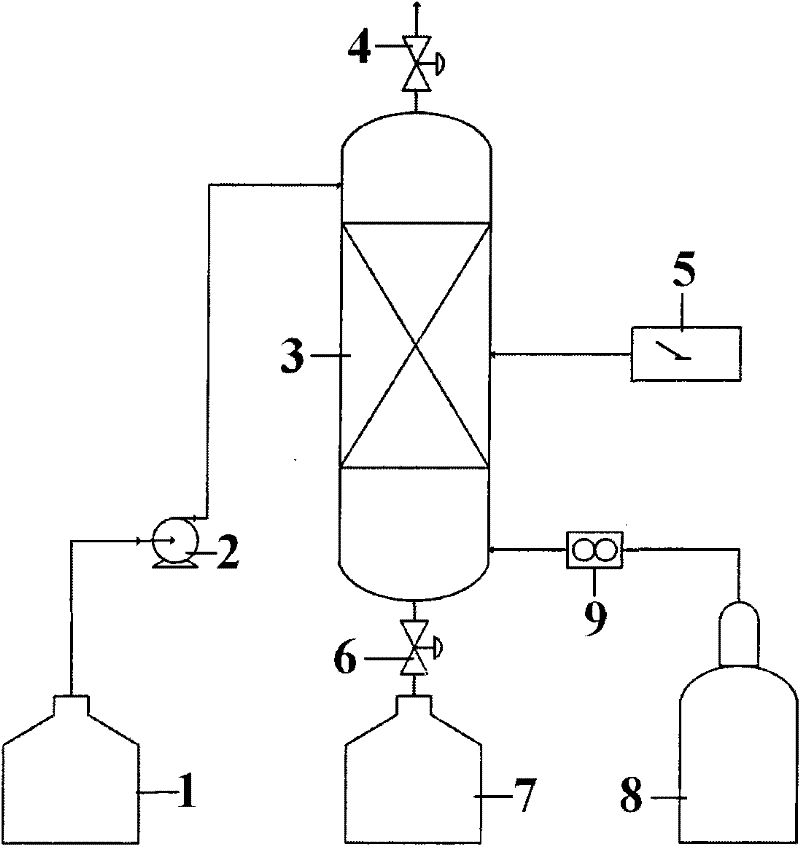

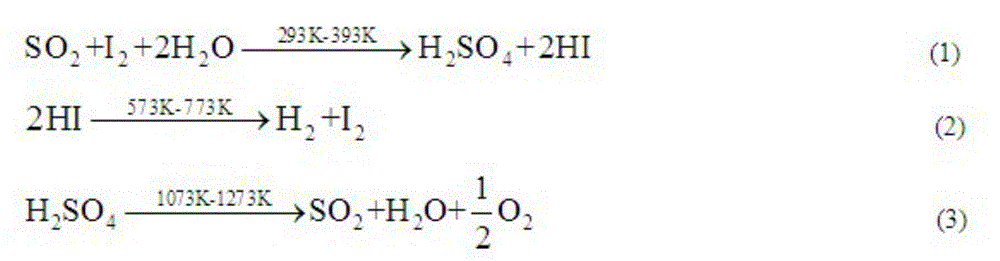

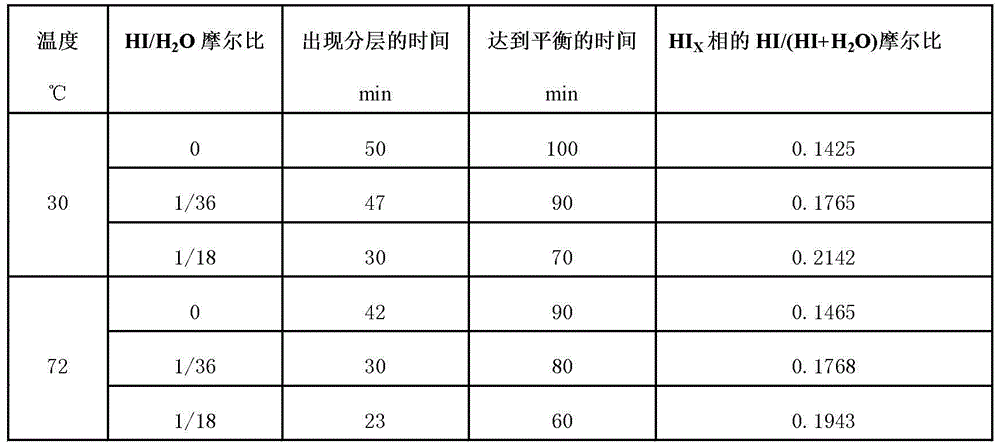

Method for promoting Bunsen reaction in thermochemical iodine-sulfur cycle for hydrogen manufacturing

ActiveCN103213945AOmit the concentration stepIncreased reaction kinetic rateHydrogen productionMass ratioDistillation

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

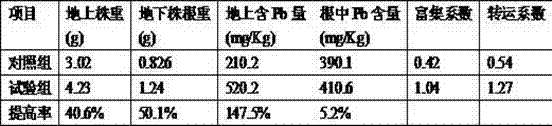

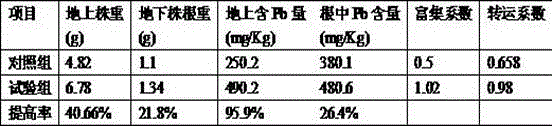

Compound photosynthetic bacteria preparation for enhancing phytoremediation for heavy metal pollution of soil and preparation method thereof

InactiveCN104707864AIncrease nutritionActivation activityContaminated soil reclamationPlant growthChemistry

The invention provides a compound photosynthetic bacteria preparation for enhancing the phytoremediation for heavy metal pollution of soil and a preparation method thereof. The high concentration compound photosynthetic bacteria preparation of thiocapsa roseopersicina and rhodopseudomonas capsulata is adopted through the step that thiocapsa roseopersicina cultures in purple sulfur photosynthetic bacteria and rhodopseudomonas capsulate cultures in purple non-sulfur photosynthetic bacteria are subjected to such culture steps as seed activation, seed culture and anaerobic fermentor irradiation culture. The compound photosynthetic bacteria preparation is used for enhancing the phytoremediation for heavy metal pollution of soil, thiocapsa roseopersicina as sulfur-oxidizing bacteria can be used for oxidizing relatively stable sulfides with heavy metals, thereby promoting sulfur cycle of soil, reducing the PH value of soil and improving the activity of heavy metals; the thiocapsa roseopersicina and rhodopseudomonas capsulata as bacterial manure can promote the conversion of soil substances, improve the soil structure and soil fertility, promote plant growth and improve the biomass of plants enriched with heavy metals, thereby enhancing the efficiency of phytoremediation for heavy metals in soil.

Owner:北京聚益成广科技有限公司

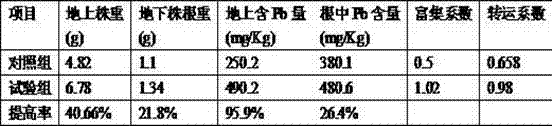

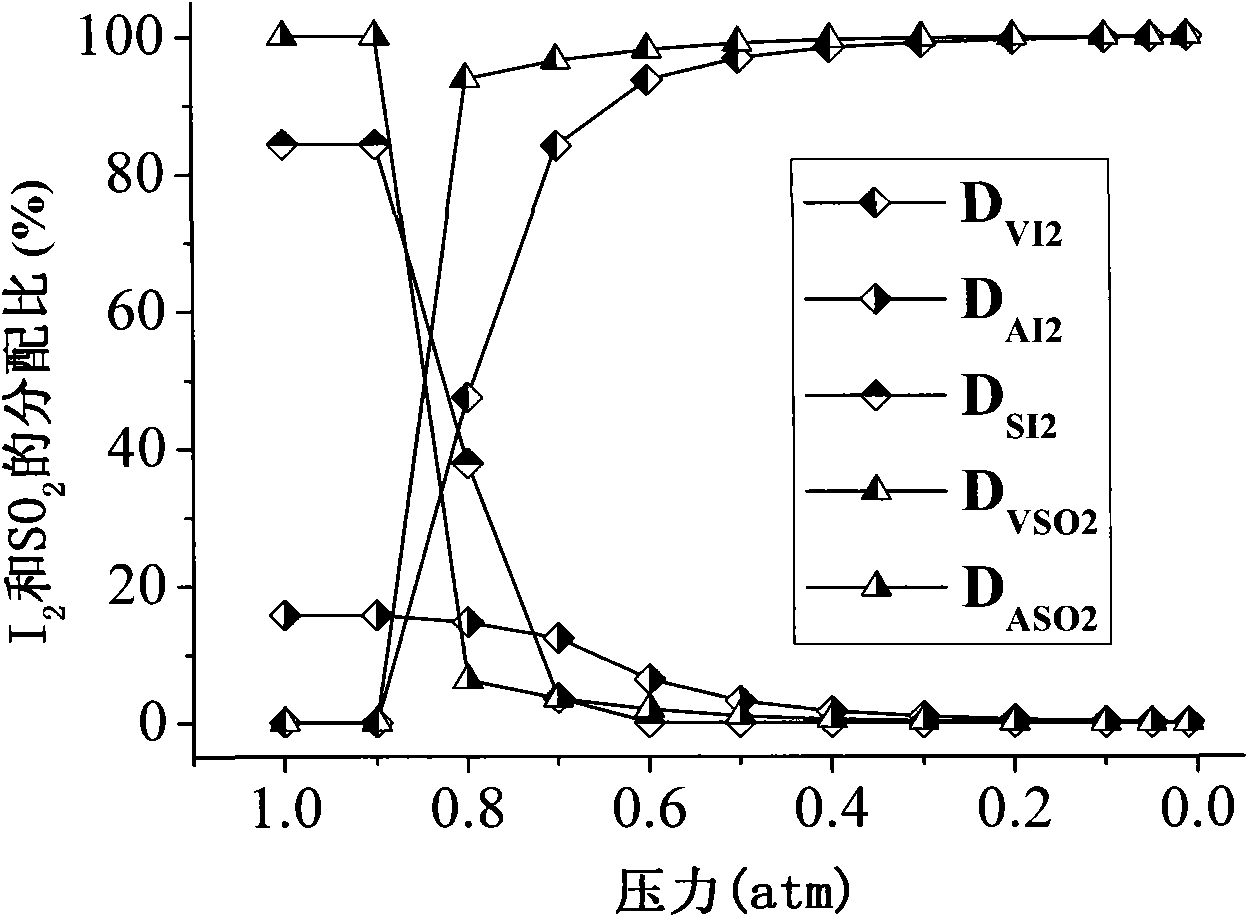

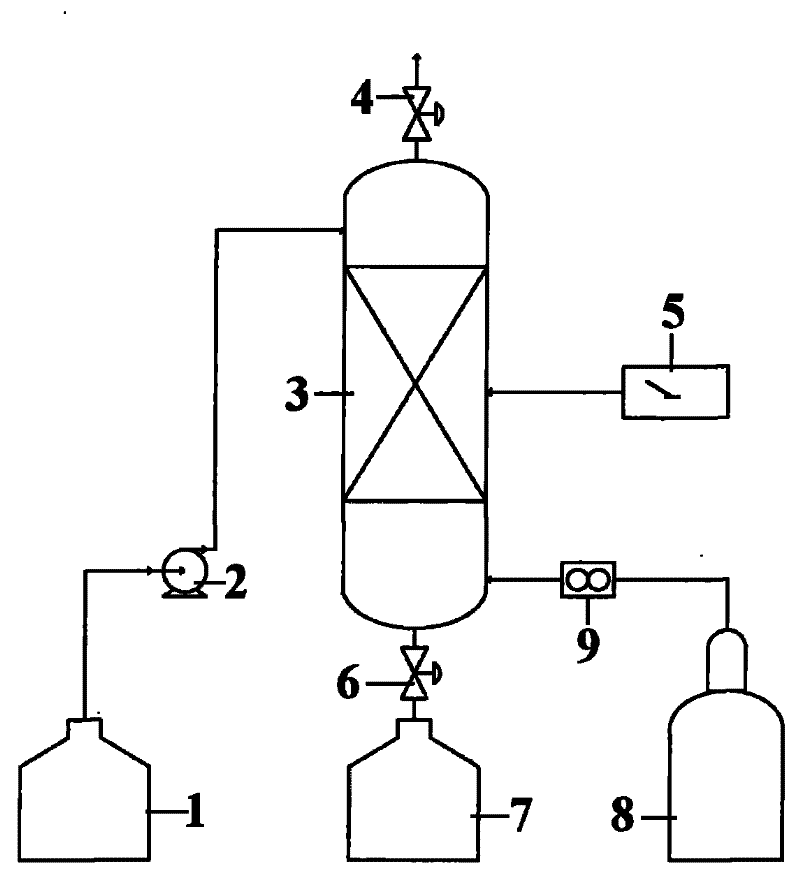

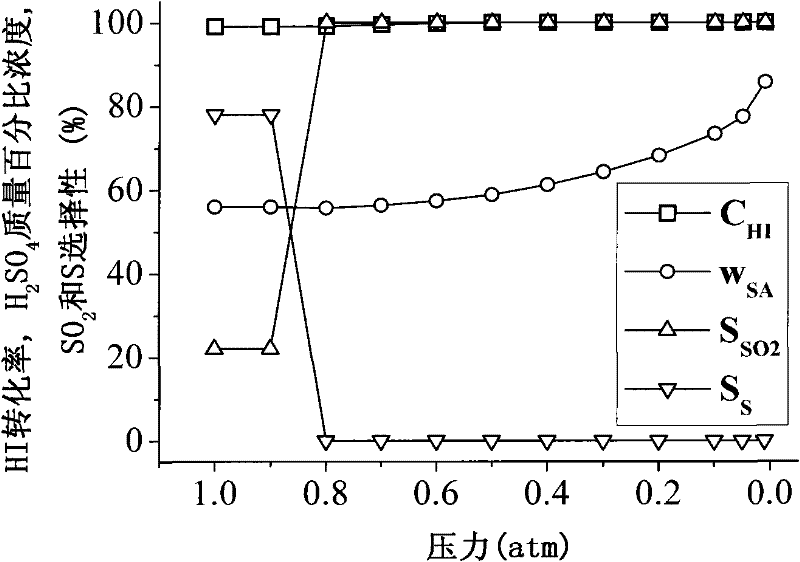

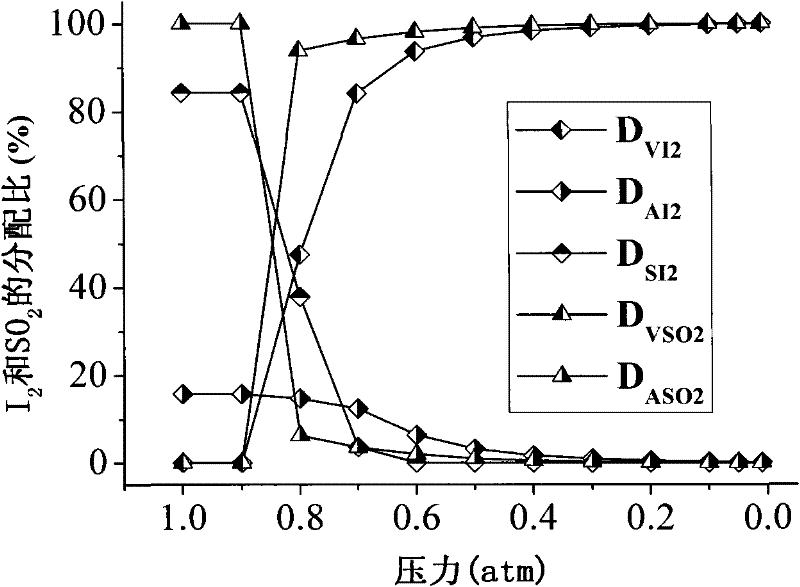

Process and device for purifying sulfuric acid phase in iodine and sulfur cycle under low pressure

ActiveCN101857204AOvercome costsOvercoming complexityIodineSulfur-trioxide/sulfuric-acidSulfur cycleNitrogen gas

The invention relates to a process and a device for purifying a sulfuric acid phase in the iodine and sulfur cycle under low pressure and belongs to the technical field of hydrogen production of the iodine and sulfur thermochemical cycle. The process for purifying the sulfuric acid phase is carried out under the condition of lower than normal pressure, i.e. under the condition of a purification temperature between 50 and 200 DEG C, a pressure P of a purifying and concentrating tower is controlled in the range that P is more than or equal to 0.01atm and less than 1atm. Compared with the conventional sulfuric acid phase purification process which adopts a nitrogen purging mode under normal pressure, the process has the characteristics of low purification temperature, simple process and low cost and can realize purification and concentration of the sulfuric acid phase in one step so as to effectively improve the purifying efficiency and reduce the purifying and concentrating cost.

Owner:TSINGHUA UNIV

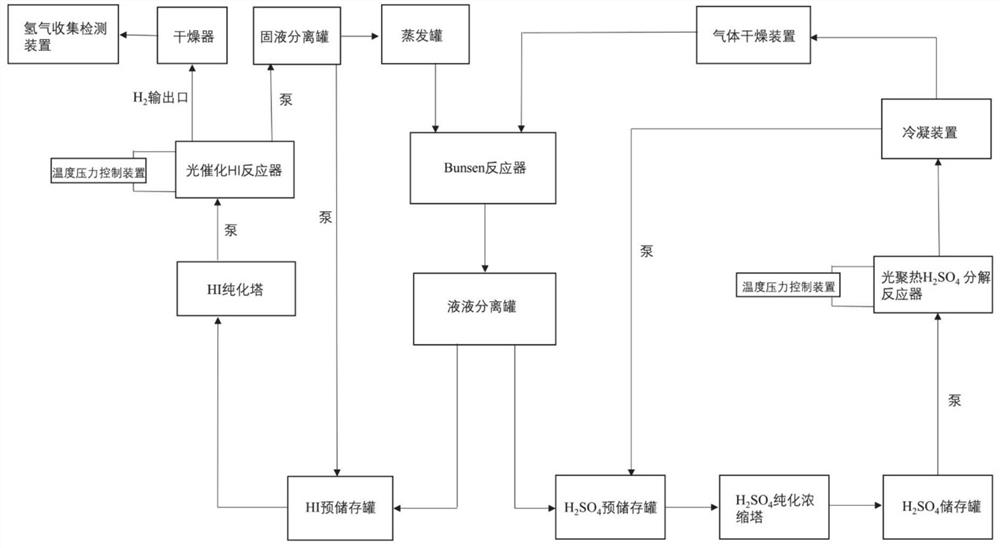

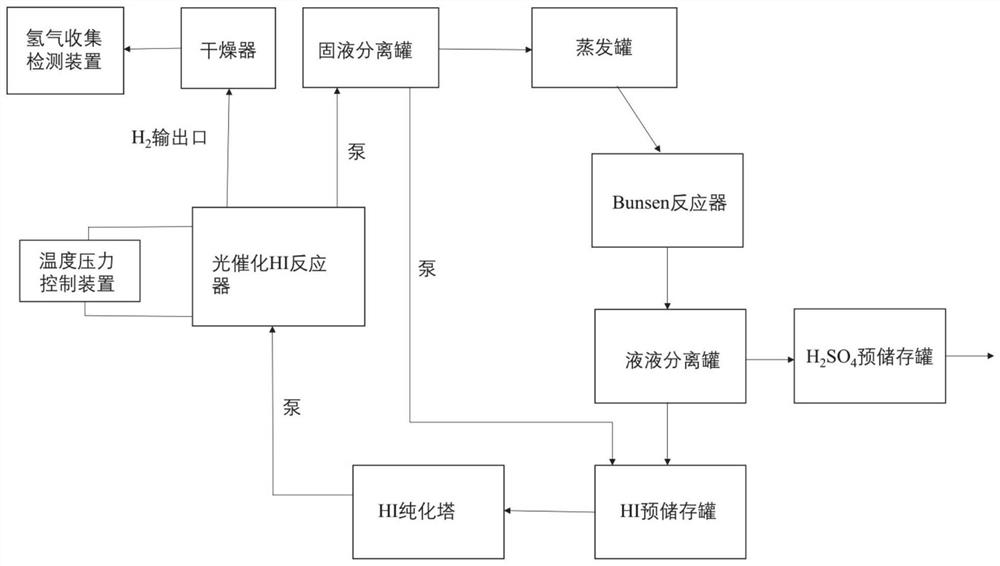

Iodine-sulfur cyclic hydrogen production method and system based on efficient light energy utilization

PendingCN112142001ARealize the combination of cycle hydrogen productionAchieve decompositionEnergy inputHydrogen productionPtru catalystLight energy

The invention discloses an iodine-sulfur cycle hydrogen production method and system based on high-efficiency light energy utilization. The method comprises the steps: carrying out photocatalytic decomposition on an HI solution through solar illumination to obtain hydrogen, carrying out solid-liquid separation on the remaining material after photocatalytic decomposition to obtain elemental iodine,and carrying out a Bunsen reaction on the elemental iodine, sulfur dioxide and water to obtain HI and H2SO4, wherein HI prepared from Bunsen is used as a raw material for photocatalytic decomposition, H2SO4 generated by the Bunsen reaction is decomposed to generate SO2 under the condition of sunlight light heat gathering and heating, SO2 generated by decomposition of H2SO4 is used as a raw material for the Bunsen reaction, and the catalyst for photocatalytic decomposition is a catalyst based on methyl amino lead iodide. According to the method, solar energy can be used for replacing heat energy consumed in the circulation process, so that the reaction cost can be reduced to a great extent, and the method has a certain industrial application prospect.

Owner:SHANDONG UNIV

Ammonia-process desulfurization and decarbonization integrated device and method

PendingCN113262625AWaste water treatment from gaseous effluentsAmmonium salt fertilisersAmmonium sulfateDecarburization

The invention is applied to desulfurization and decarburization of process gas containing sulfur oxides and CO2, and belongs to the field of environmental protection, ammonia is used as a desulfurization and decarbonization agent, the gas firstly enters a desulfurization device for desulfurization to generate ammonium sulfate fertilizer, the desulfurized gas enters a decarbonization device to remove carbon dioxide in the gas to generate ammonium bicarbonate fertilizer, the decarbonized gas contains free ammonia, is washed with a desulfurization circulating solution and then is washed with water, and the washing solution returns to a desulfurization tower and is used as an absorbent for desulfurization. A desulfurization unit is provided with a cooling device for cooling the flue gas, so that the subsequent decarburization requirement is met. Condensate water generated in the desulfurization cooling process is used as ammonia washing replenishing water or used for other purposes after being subjected to film separation and purification, concentrated water returns to a desulfurization area, and no waste water is generated. According to the technology, decarburization and desulfurization technologies are organically integrated, ammonia washing efficiency is high by adopting acidic desulfurization circulating liquid to wash ammonia, the problem of ammonia escape in the decarburization process is successfully solved, the process is simpler, investment and operation cost is low, by-products of ammonium sulfate and ammonium bicarbonate fertilizer are produced, CO2 does not need to be reinjected underground for storage, by-product ammonia water can be used, and the purposes of treating waste with waste and recycling economy are really achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

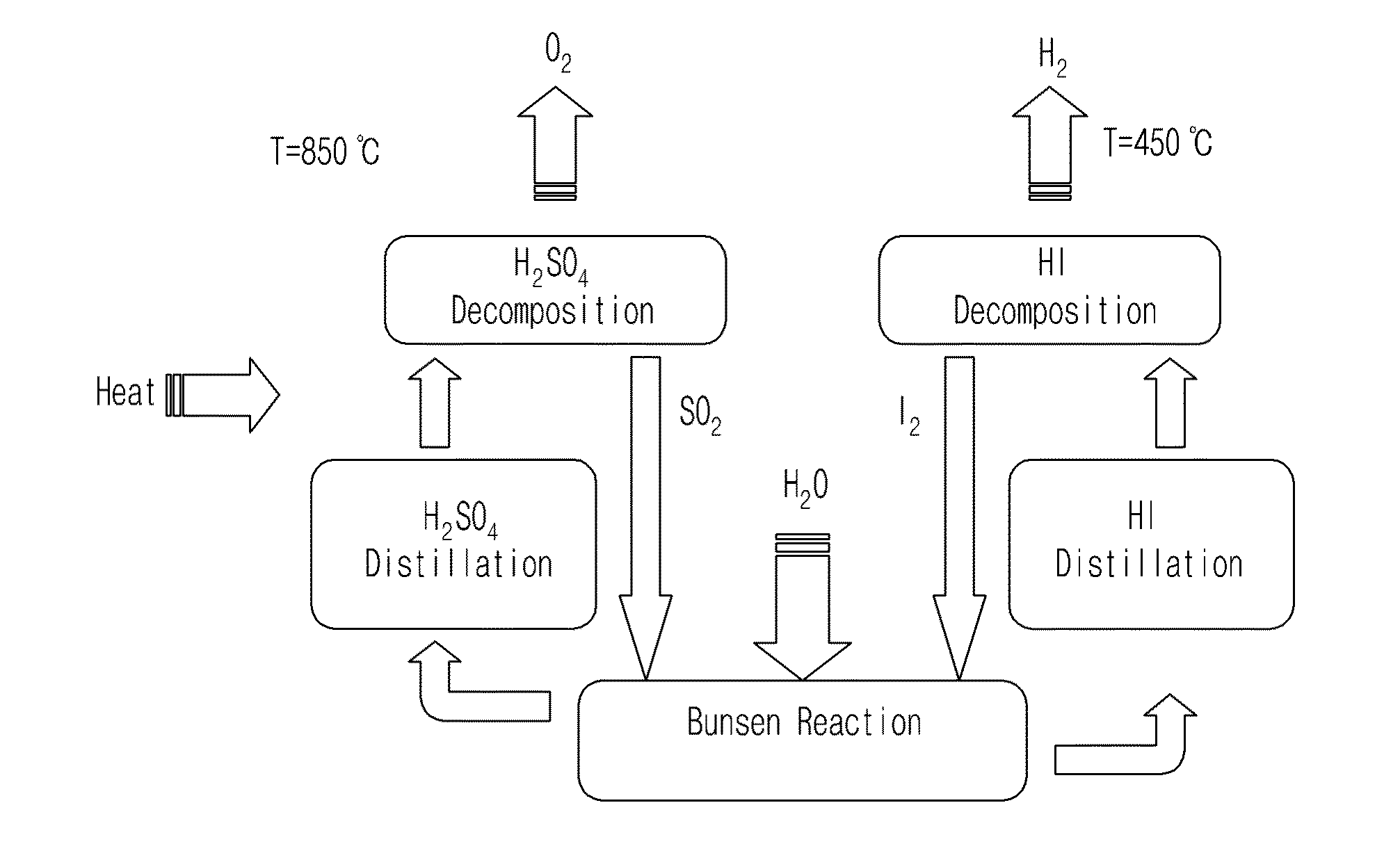

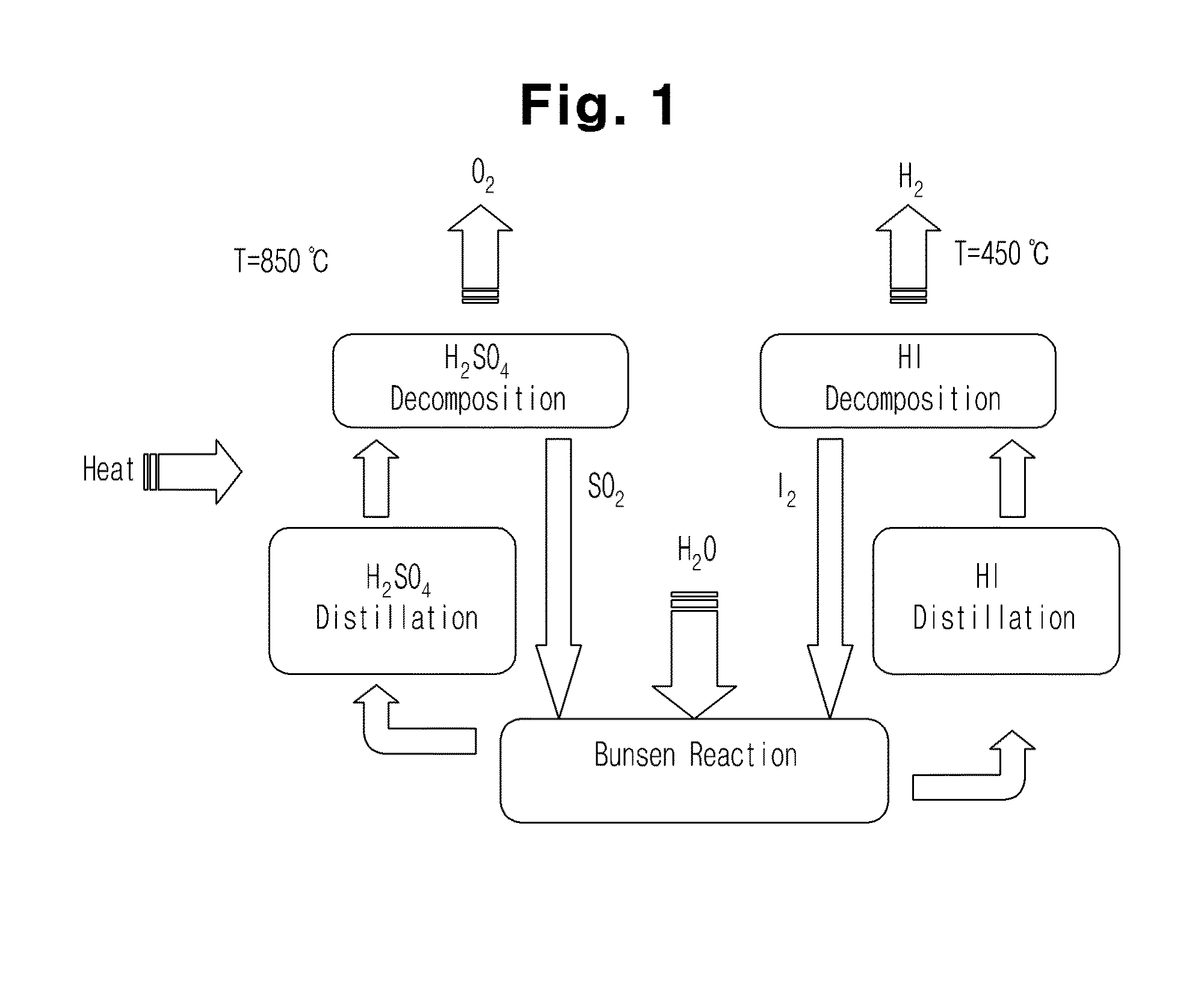

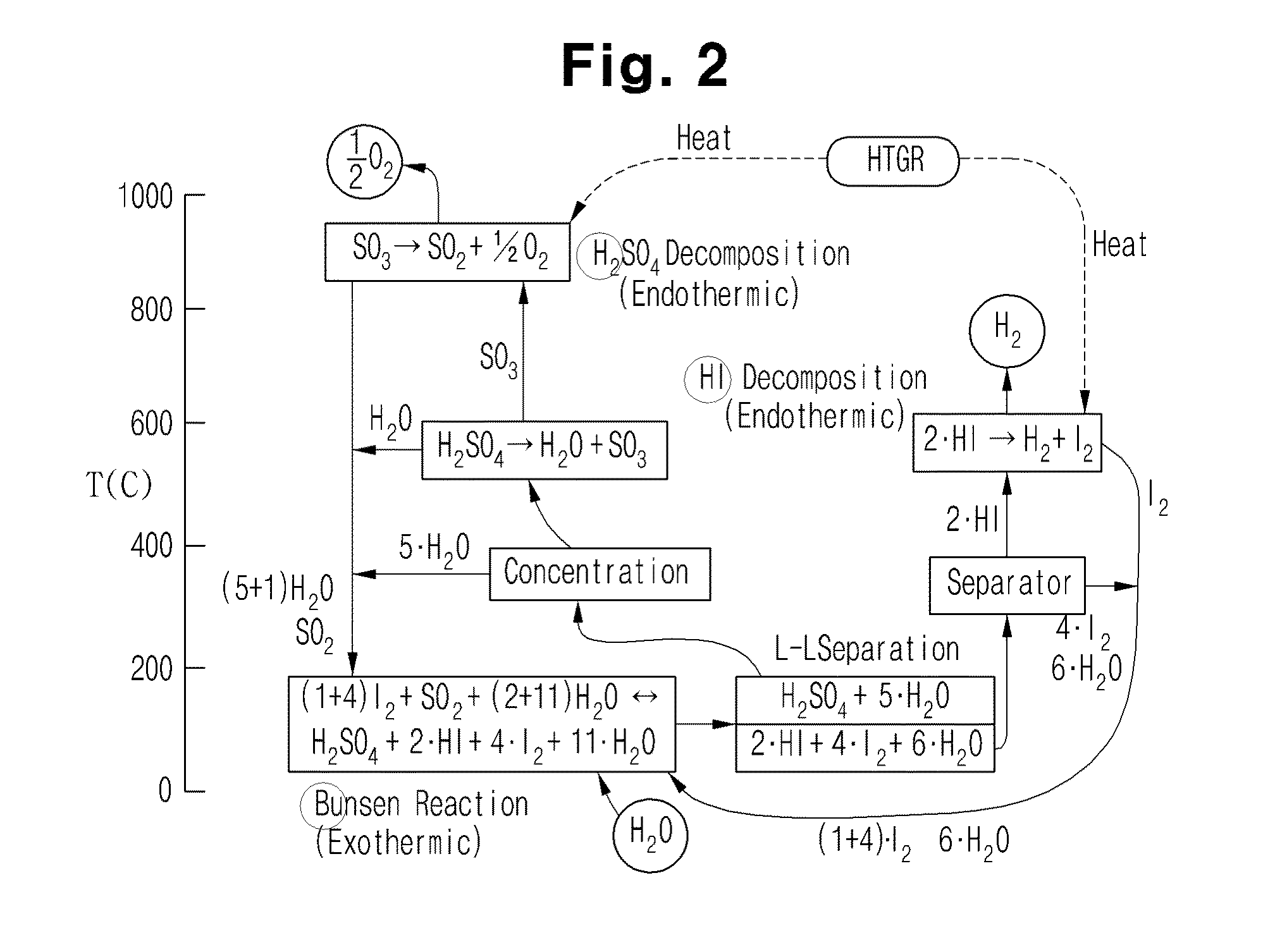

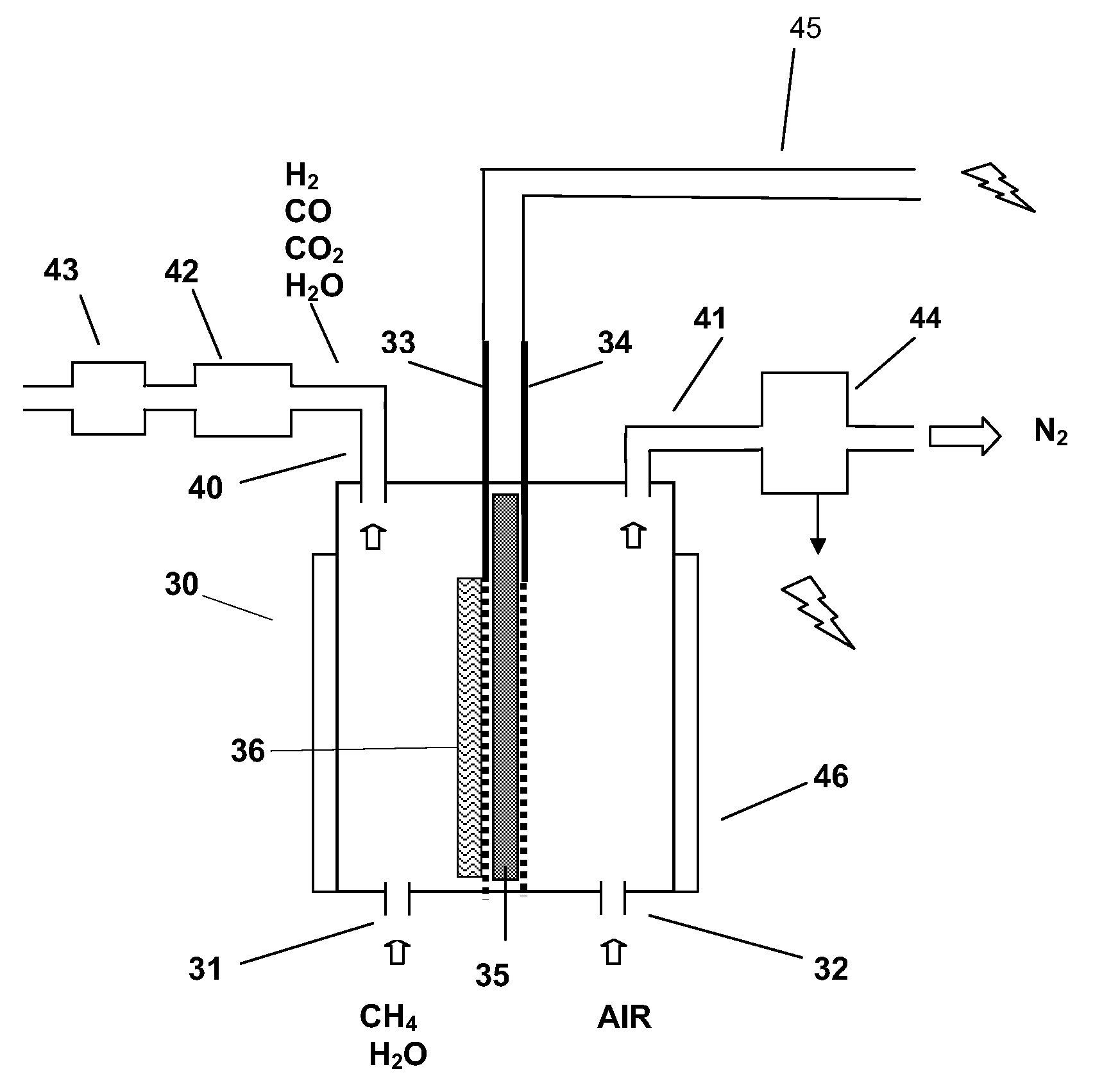

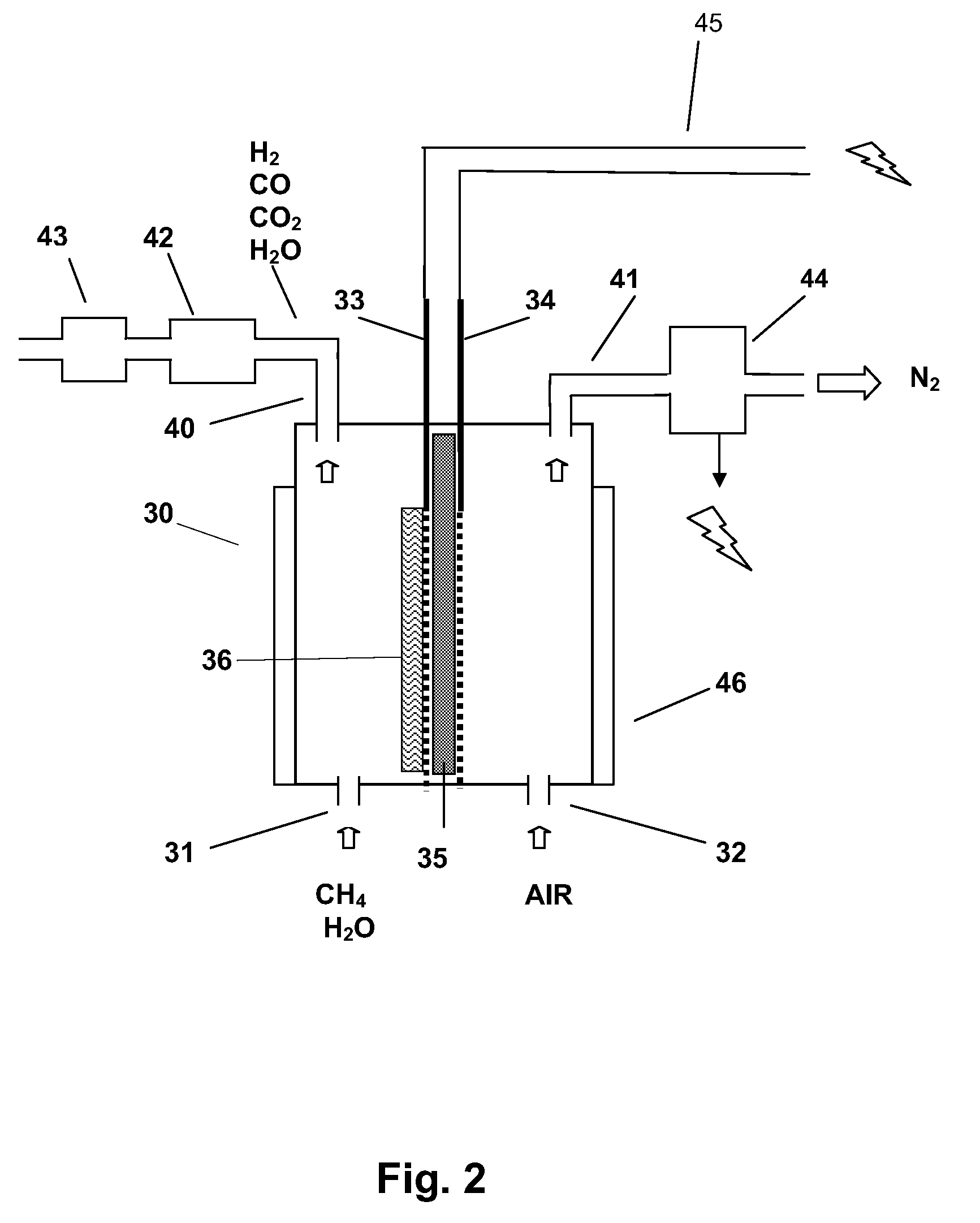

Iodine-sulfur cycle for nuclear hydrogen production with improved thermo-chemical efficiency

InactiveUS20130195749A1Reduce corrosionImprove thermo-chemical efficiencyChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxideThermal energyCyclic process

Disclosed herein is an iodine-sulfur cycle for nuclear hydrogen production, which can improve thermochemical efficiency. The iodine-sulfur cycle is advantageous in that the amount of excess water and iodine supplied to a Bunsen reaction process is minimized, thus minimizing the amount of thermal energy consumed in the recovery and recirculation process thereof, in that sulfuric acid having stronger hydrophilicity than hydrogen iodide absorbs excess water in large quantities in a spontaneous liquid-liquid phase separation process, so that, after the spontaneous liquid-liquid phase separation process, the concentration of hydrogen iodide in a hydrogen iodide solution exceeds a concentration at an azeotropic point without conducting an additional concentration process, with the result that highly-concentrated hydrogen iodide gas can be obtained only through a flashing process, thereby decreasing energy consumption and simplifying the process and thus improving economical efficiency, and in that process temperature and pressure can be decreased, thus greatly deceasing the corrosivity in an operational environment. Therefore, the iodine-sulfur cycle according to the present invention can be usefully used for high-efficient and environmentally-friendly nuclear hydrogen production.

Owner:KOREA ADVANCED INST OF SCI & TECH

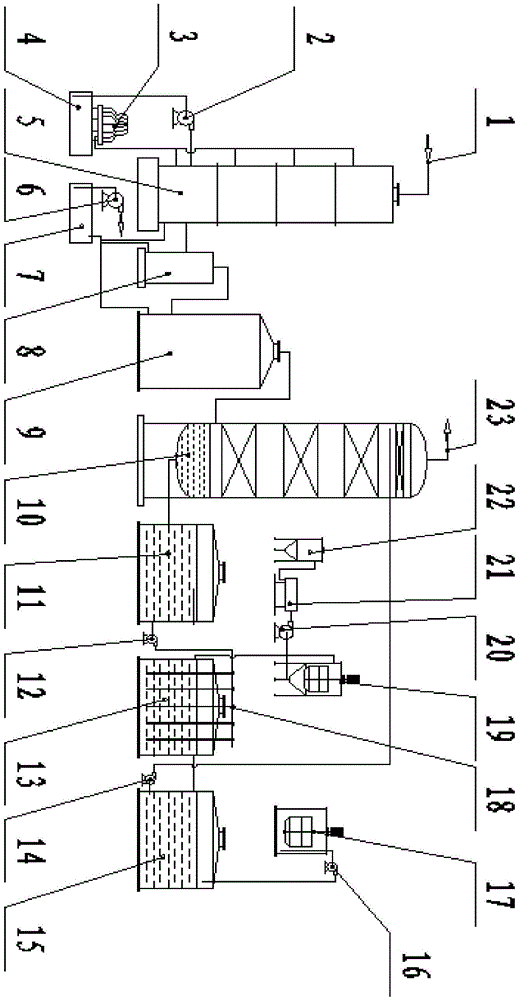

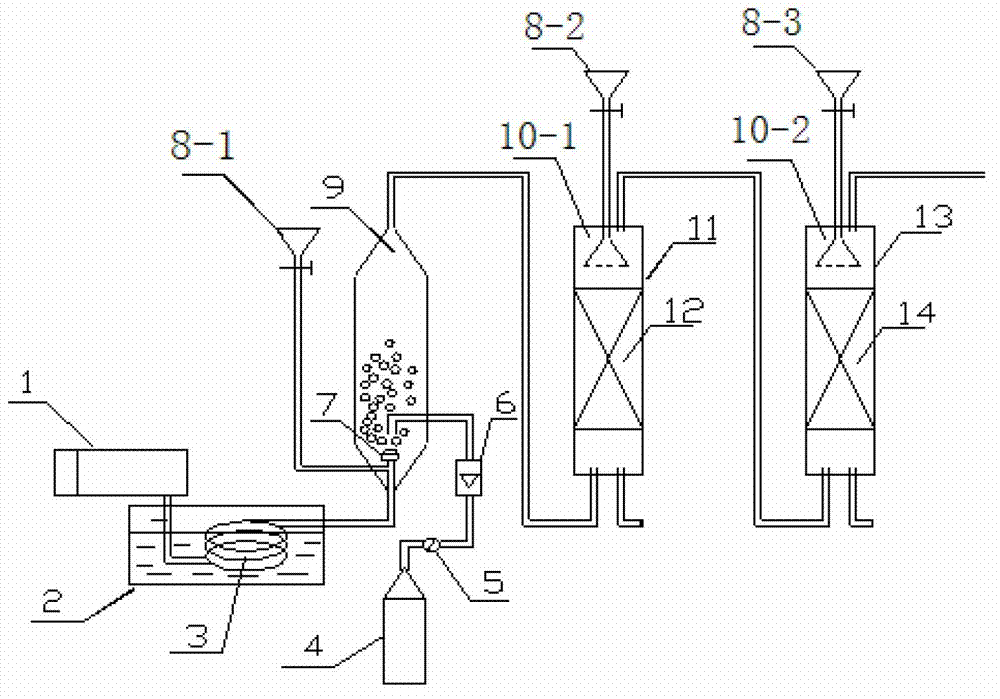

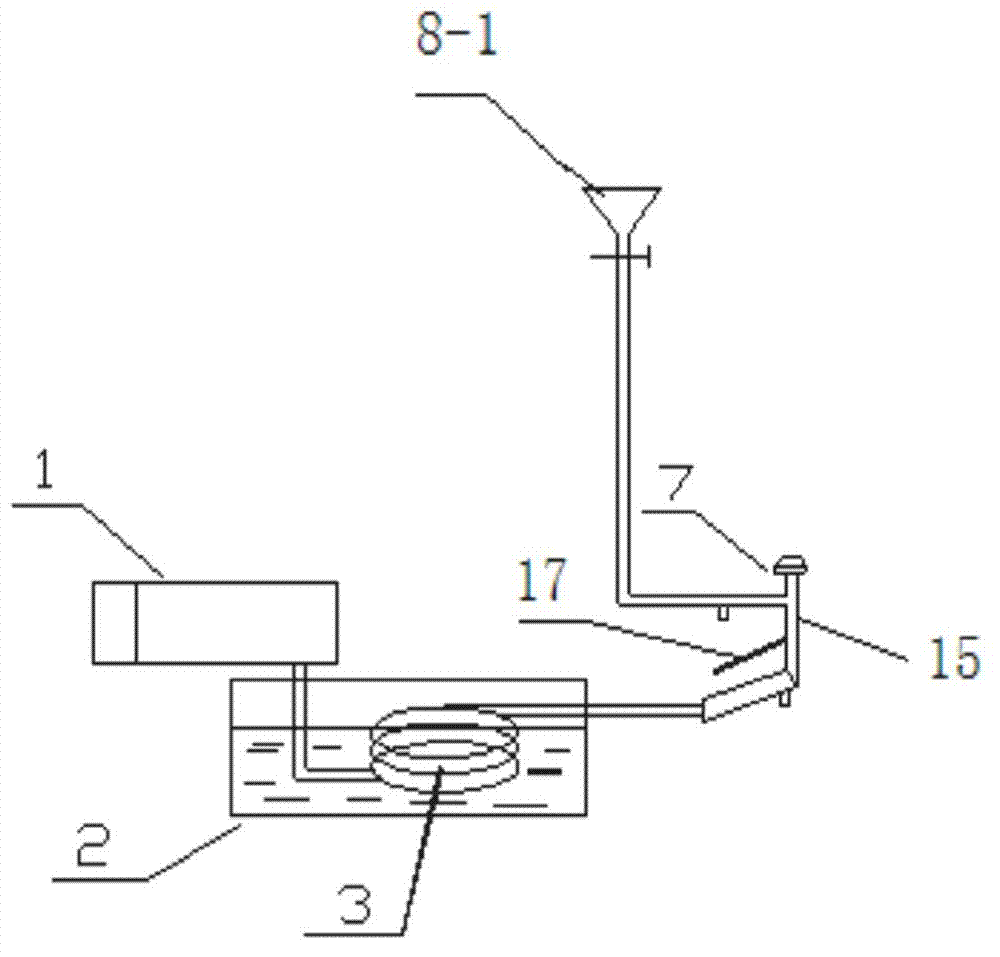

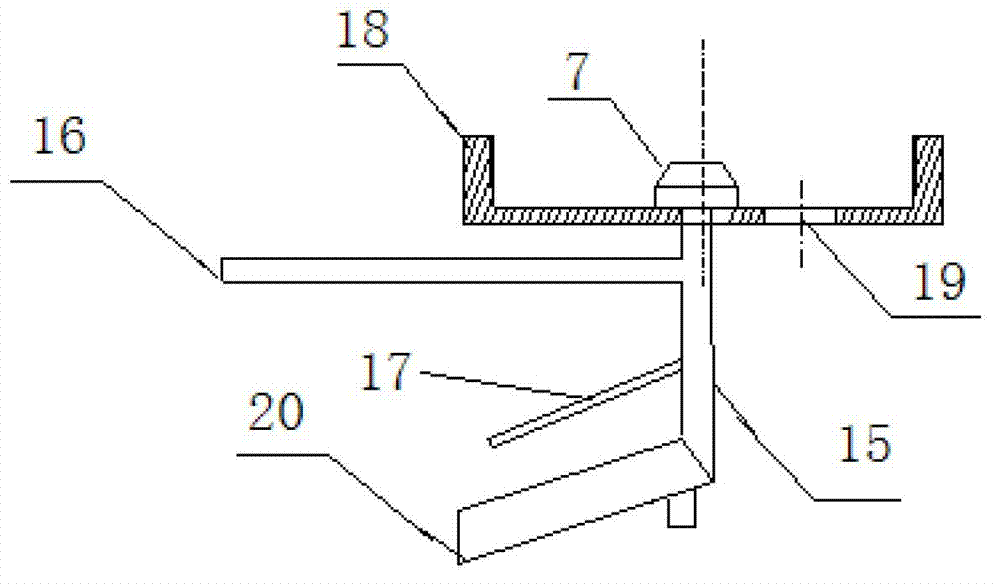

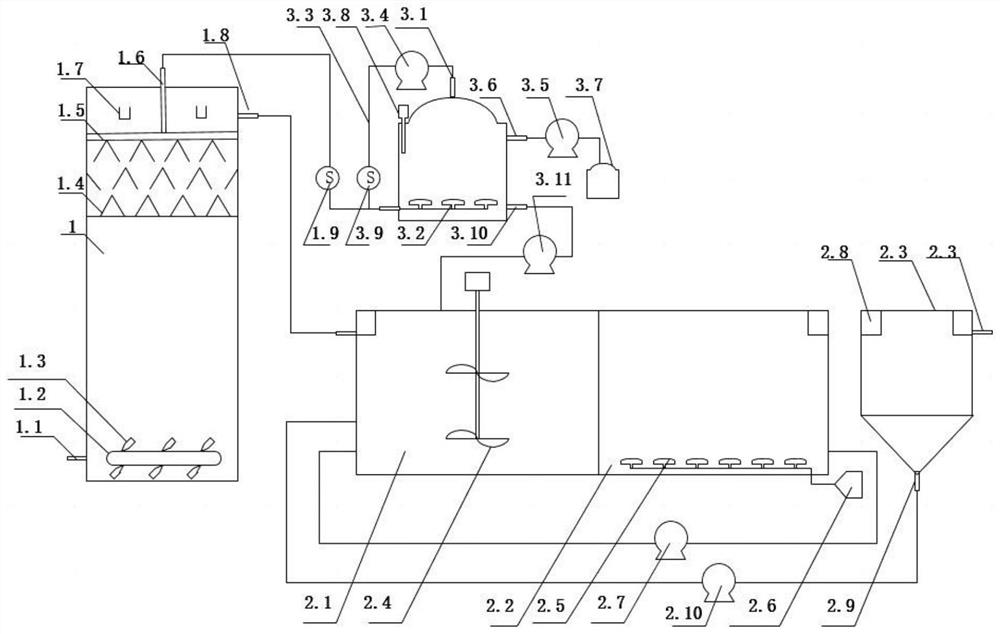

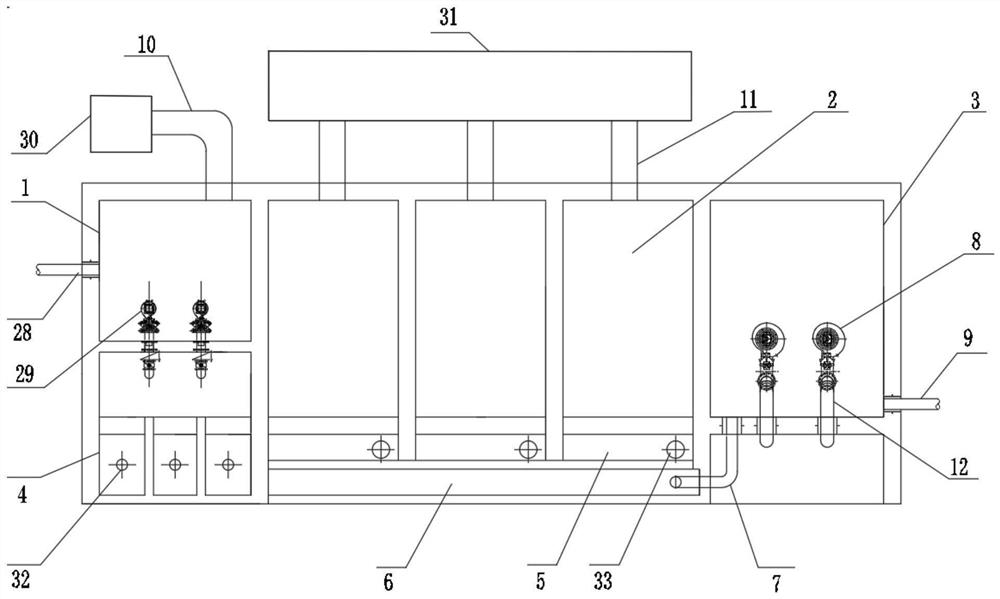

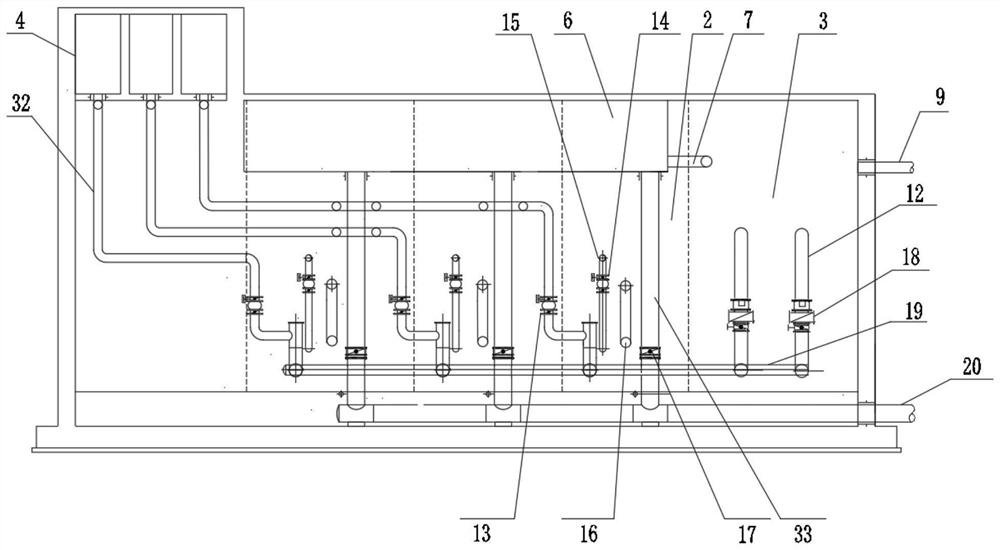

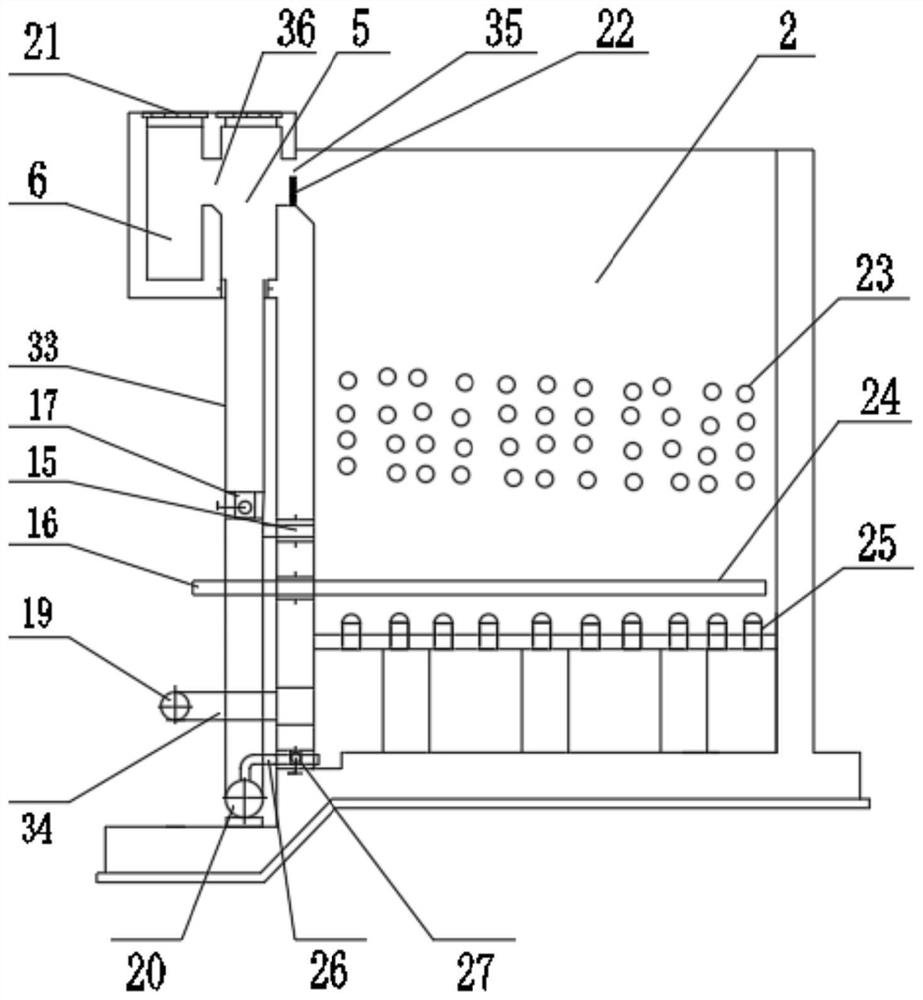

Integrated process and device for semicoke coal gas

InactiveCN105542874AHigh puritySolve pollutionChemical industrySulfur preparation/purificationSulfideProcess engineering

The invention discloses an integrated process and device for semicoke coal gas. The integrated device sequentially comprises a coal gas pretreatment system, a desulfuration circulating system and a sulfur recovery system, wherein the coal gas pretreatment system comprises a cooler, a drop catcher and an electrostatic detarrer which are sequentially connected, an inlet of the coal gas pretreatment system is connected with a coal gas input conduit, an outlet of the coal gas pretreatment system is connected with the desulfuration circulating system, a coal gas outlet of the desulfuration circulating system is connected with a coal gas output conduit, and a circulating liquid outlet of the bottom of the desulfuration circulating system is connected with the sulfur recovery system. By adopting the process and the device, the temperature of the semicoke coal gas can be dropped, coal tar and sulfides are removed from the semicoke coal gas, valuable substances are recovered, and the quality of the semicoke coal gas is improved; the process and the device have the advantages that the investment is small, the stability is good, the routine maintenance is simple, the operating cost is low, and the like.

Owner:陕西华祥能源科技集团有限公司

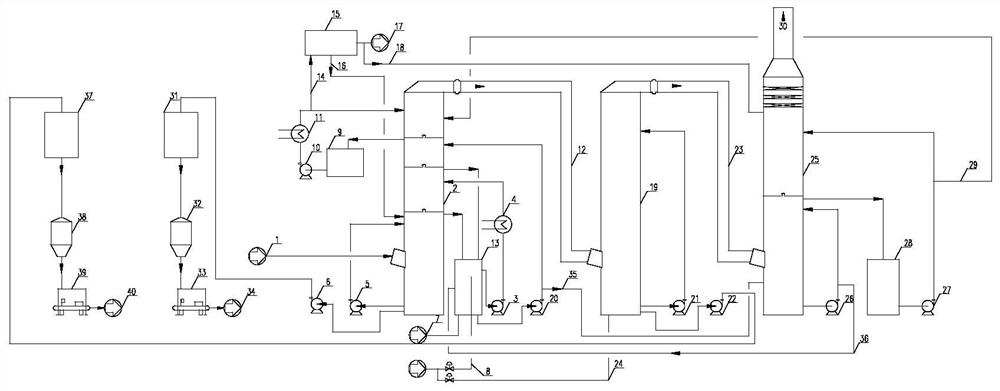

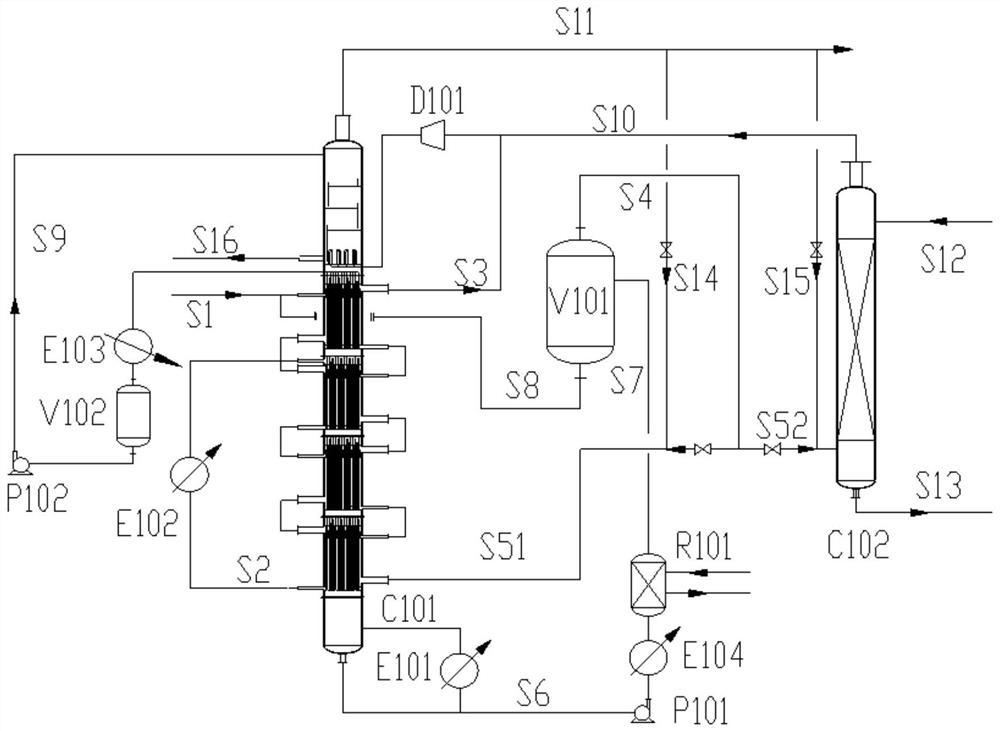

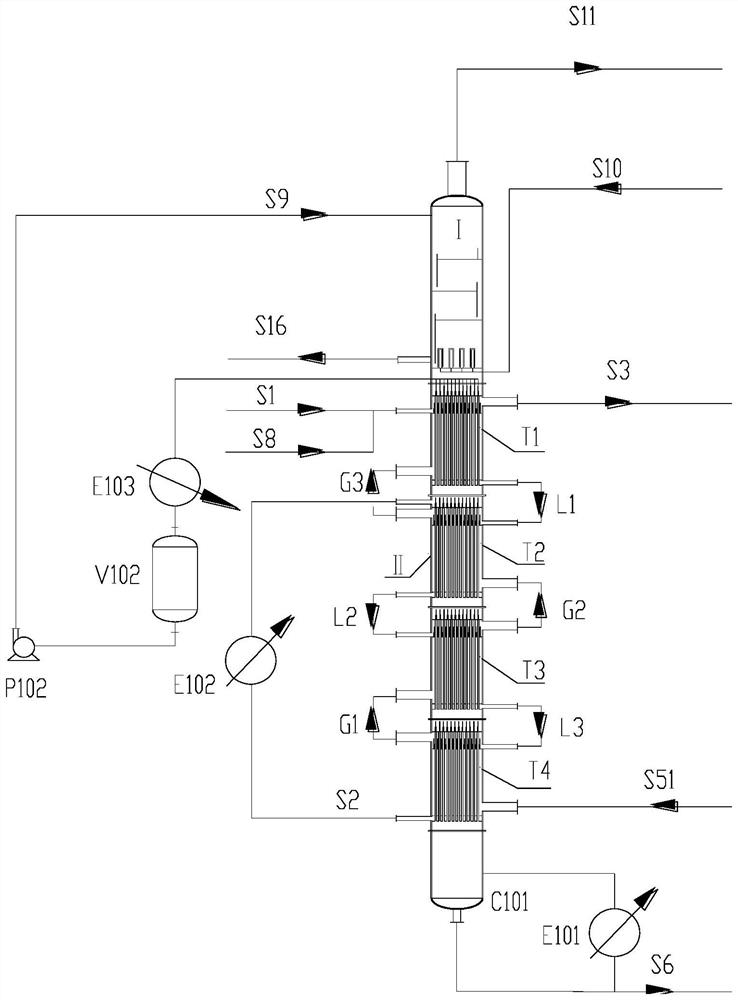

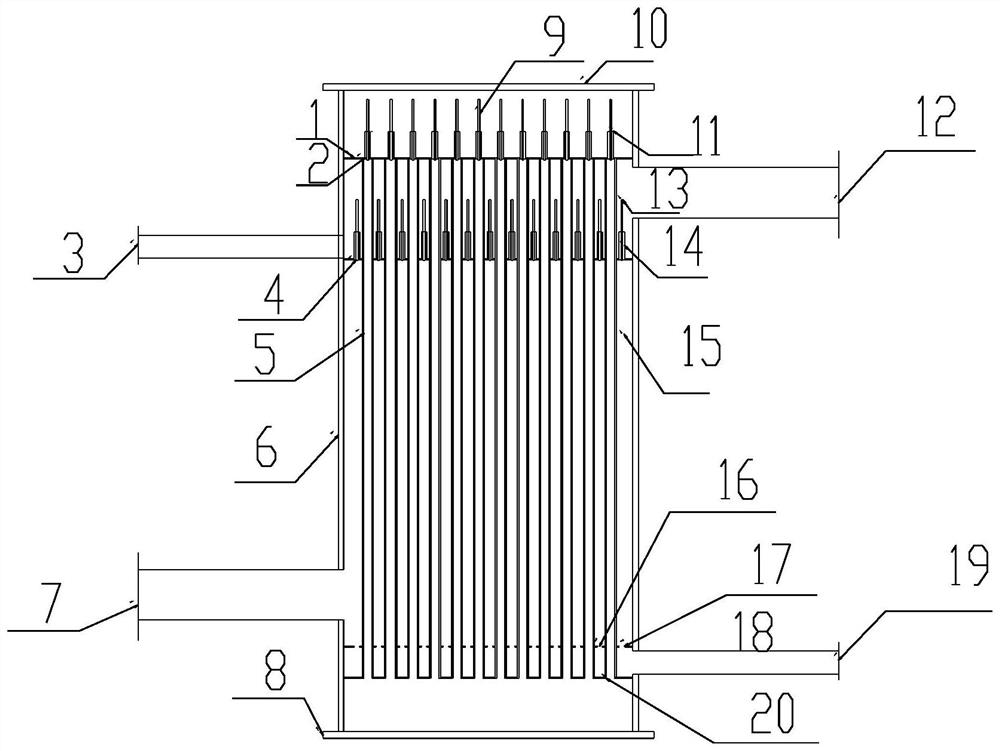

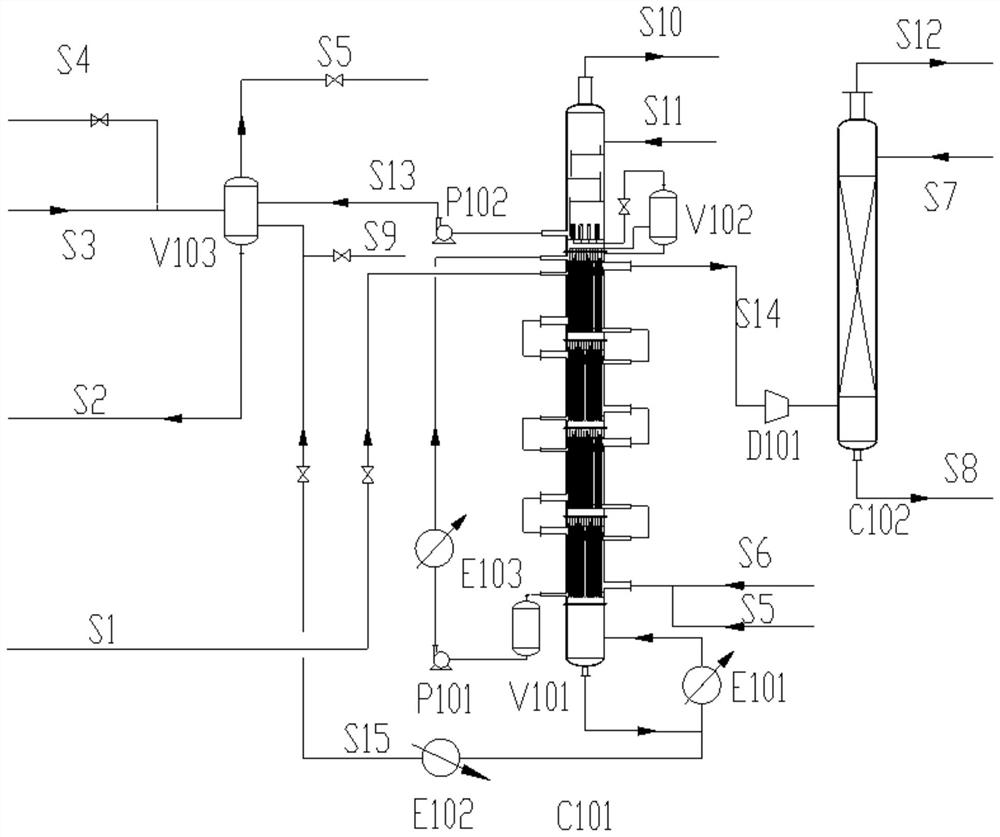

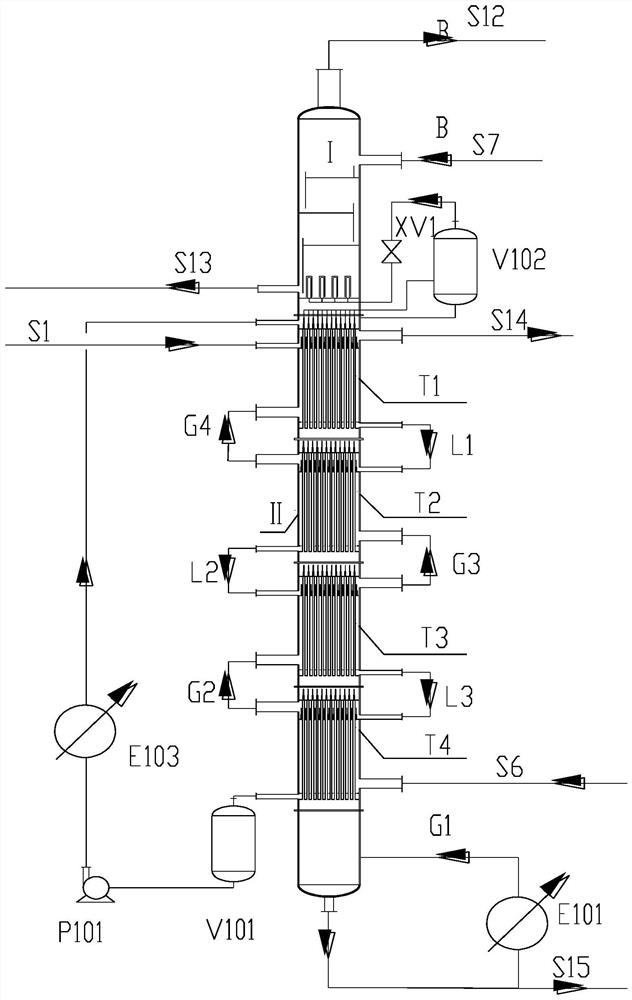

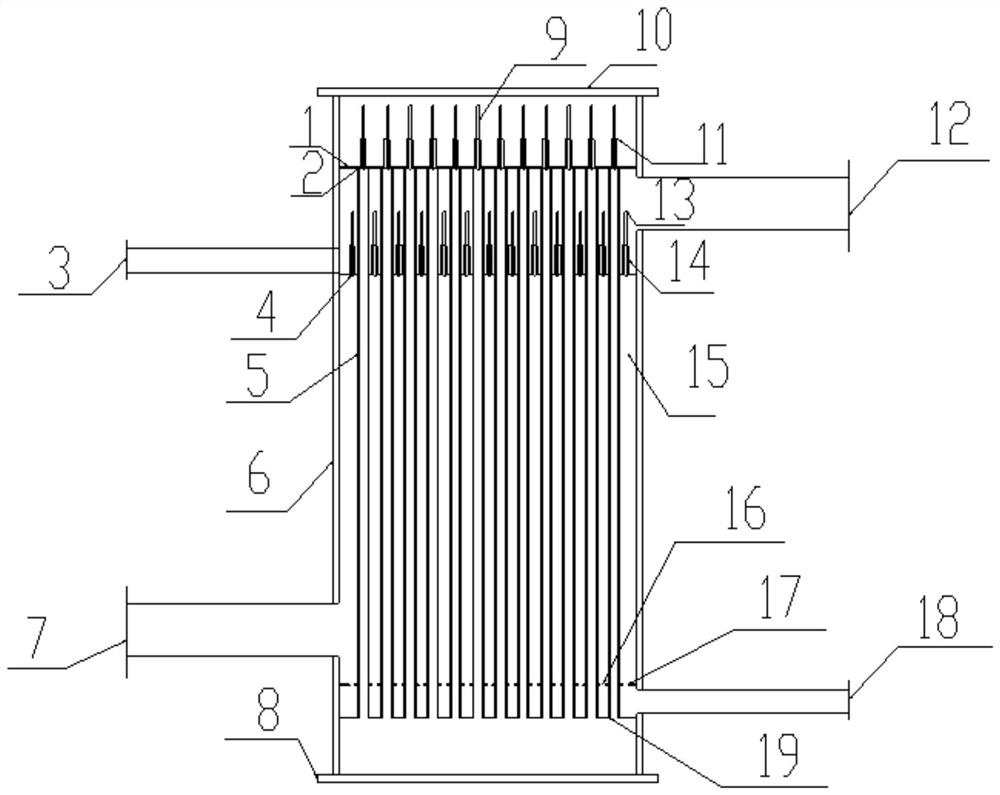

Process and device for preparing oxygen through thermal decomposition of sulfuric acid phase in iodine-sulfur circulation

ActiveCN113274755AHigh recovery rateAvoid gasDistillation separationOxygen preparationSulfur cycleThermochemical cycle

The invention provides a process and a device for preparing oxygen through thermal decomposition of a sulfuric acid phase in iodine-sulfur circulation, and belongs to the related technical field of hydrogen preparation through thermal chemical circulation. The process comprises a sulfuric acid phase steam stripping purification section, a rectification concentration section, a washing section and a sulfuric acid thermal decomposition and mixed gas blending process and device. According to the invention, a shell pass and a tube pass of a novel shell-and-tube heat integration composite tower are filled with a 1# filler and a 2# filler respectively, N tower sections of a composite section are coaxially connected in a sealed mode, and a sulfuric acid phase steam stripping purification section, a reaction rectification section and a washing section are coupled together, so that gradient utilization of energy is achieved; a process gas containing O2 and SO2 decomposed by sulfuric acid is blended with O2 extracted by a system, and the blended gas is used as a steam stripping purification gas which respectively enters the steam stripping purification section of the shell pass of the composite tower and an HIX steam stripping purification tower; and compared with a traditional process for preparing oxygen through sulfuric acid phase thermal decomposition, the process of the invention has the advantages that the quality and the energy utilization rate of the system are improved, the purification efficiency is improved, and the energy consumption and the production cost are reduced.

Owner:DALIAN UNIV OF TECH

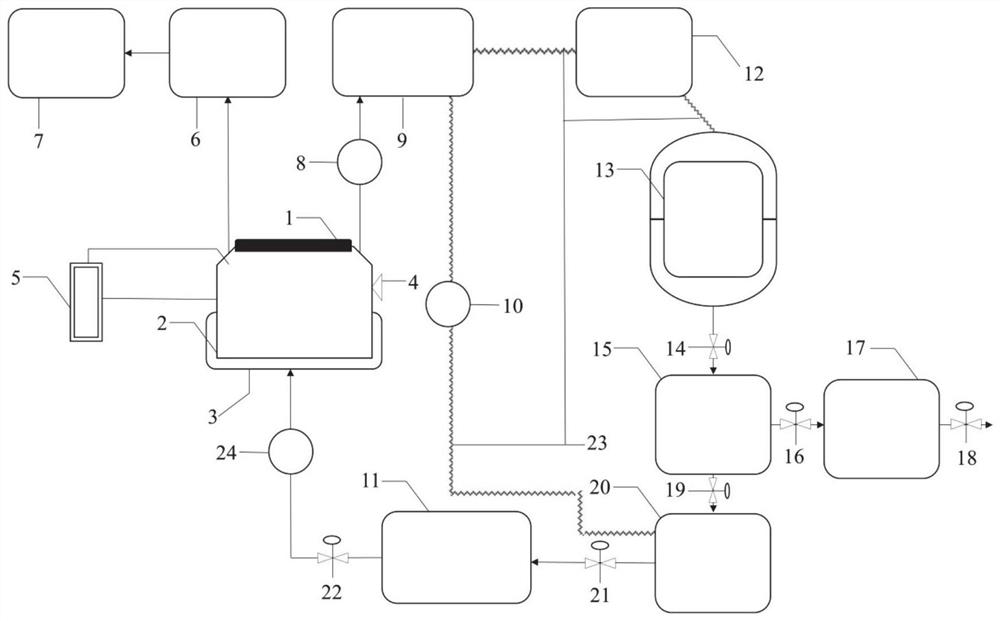

Process and device for preparing hydrogen from hydrogen iodide in iodine-sulfur circulation

ActiveCN113233415AEnhanced mass transferImprove heat transfer performanceHydrogen iodideEnergy inputThermochemical cycleSulfur cycle

The invention belongs to the related technical field of hydrogen preparation through thermochemical circulation, and provides a process and a device for preparing hydrogen from hydrogen iodide in iodine-sulfur circulation. The device comprises an HIX steam stripping section, a reaction rectifying section, a reaction gas washing section and a steam stripping gas washing process and device. A shell pass and a tube pass of a novel shell-and-tube heat integration composite tower are filled with a 1# filler and a 2# filler respectively, N tower sections of a composite section are coaxially and hermetically connected, and the HIX steam stripping section, the reaction rectifying section and a water washing section are coupled together, so that gradient utilization of energy is realized; the system mixed gas containing O2 and SO2 is used as the circulating stripping gas of the stripping section of the composite tower, so that the generation of S, H2S and a small amount of H2SO4 mingled in an HIX system is inhibited, and the recovery rate of SO2 in HIX is improved; and the tower bottom material liquid of the reaction section of the heat integration composite tower and the acidic water of the washing section and the stripping gas washing tower are returned to the front mixing tank of the Bensen reactor, so that the quality utilization rate of the system is improved.

Owner:DALIAN UNIV OF TECH

Process for purifying sulfuric acid phase and hydriodic acid phase in iodine-sulfur cycle

InactiveCN101830443BAchieve purificationSuppress generationIodine/hydrogen-iodideHydrogen productionThermochemical cycleSulfur cycle

The invention relates to a process for purifying a sulfuric acid phase and a hydriodic acid phase in an iodine-sulfur cycle, which belongs to the technical field related to hydrogen production through an iodine-sulfur thermochemical cycle. The sulfuric acid phase and the hydriodic acid phase obtained through a Benson reaction in the iodine-sulfur cycle respectively contain a small amount of HI and a small amount of H2SO4, and a traditional purification process comprises the following steps of: using nitrogen gas as sweep gas, heating to promote the occurrence of the reverse reaction of the Benson reaction: 2HI+H2SO4=SO2+I2+2H2O, and removing impurity acid. The traditional purification process can consume main acid, and a side reaction often occurs together. In order to overcome the defect, the invention provides a two-phase purification process using the mixed gas of oxygen and inert gas as active sweep gas, and as for the purification of the sulfuric acid phase, the reaction principle is 4HI+O2=2I2+2H2O, sulfuric acid is not lost, and the reaction temperature is lower; and as for the purification of the hydriodic acid phase, the active sweep gas can inhabit the generation of S and H2S and promote the selectivity enhancement of converting H2SO4 into SO2.

Owner:TSINGHUA UNIV

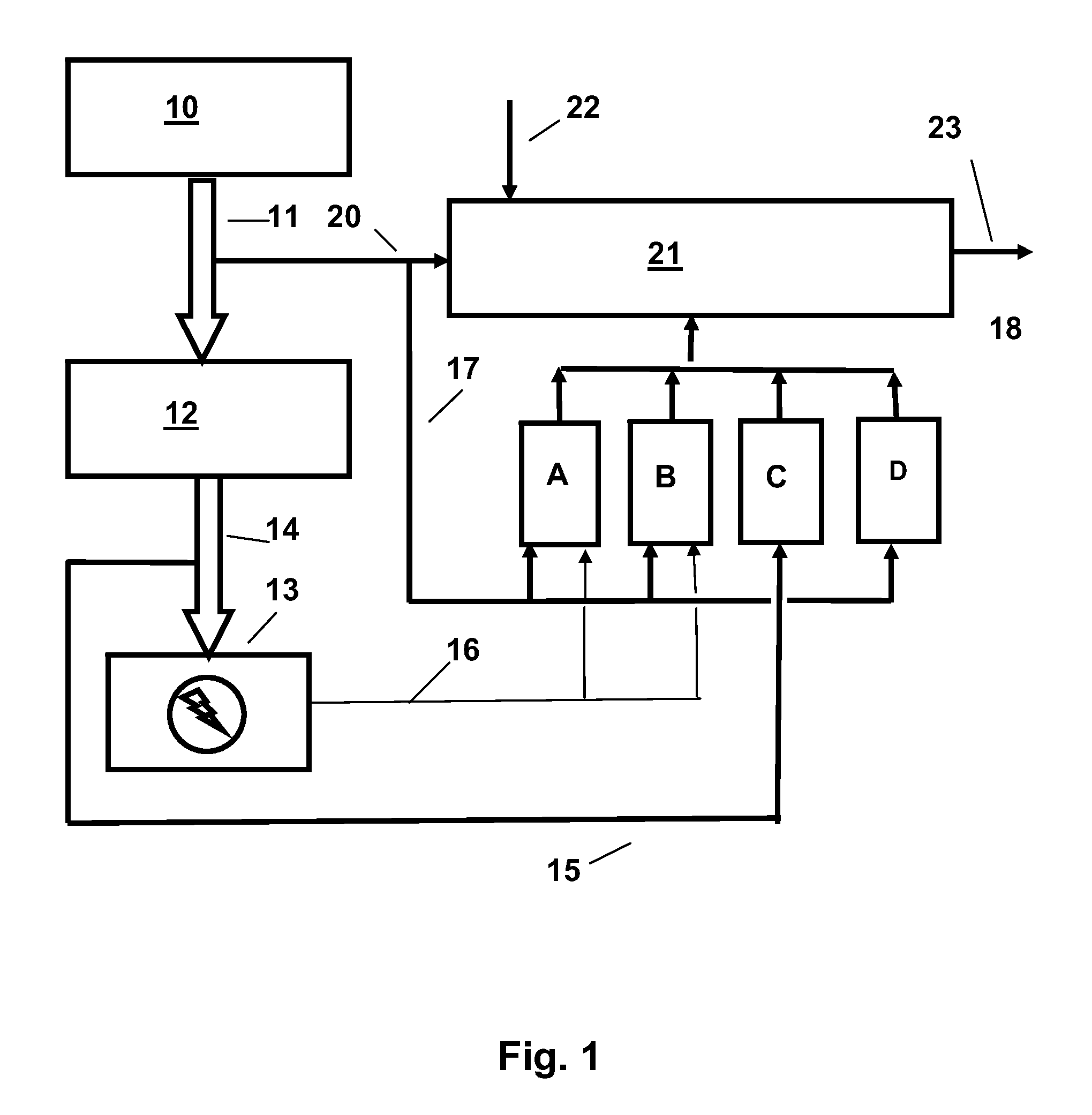

High temperature hydropyrolysis of carbonaceous materials

InactiveUS20100320120A1Significant carbon emissionEfficient use ofMolecular sieve catalystsLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesPetroleum oil

Heat from nuclear reactor as a source of thermal energy is applied to the conversion of carbonaceous materials such as heavy petroleum crude oils, coals and biomass to liquid hydrocarbons. The heat is applied to provide at least a portion of the process heat used in the high temperature, short contact time hydropyrolysis of the carbonaceous material which is supplied with hydrogen generated by a high temperature process such as high temperature steam electrolysis, the sulfur-iodine cycle, the hybrid sulfur cycle, the zinc-zinc oxide cycle, a solid oxide fuel cell or by methane steam cracking. The heat from the nuclear reactor may be used to generate electricity to operate high temperature steam electrolysis used in generation of the hydrogen. By the use of nuclear thermal energy, hydrocarbon resource utilization for process heat is eliminated along with carbon dioxide evolution associated with burning of the hydrocarbon resource to generate process heat. The substitution of zero carbon emission sources therefore offers the potential for significant carbon emission reductions in refinery operations where external process heat can be applied and effectively utilized.

Owner:EXXON RES & ENG CO

Device and operation method for removing malodorous gas such as methyl mercaptan by chlorine dioxide

InactiveCN103157366ALow running costReduce equipment investmentDispersed particle separationLiquid wasteSulfur cycle

The invention discloses a device and an operation method for removing malodorous gas such as methyl mercaptan by chlorine dioxide. The device mainly comprises a chlorine dioxide atomization device, a malodorous gas reactor, an alkali absorption tower and a tail gas absorption tower. The bottom of the malodorous gas reactor is provided with the chlorine dioxide atomization device and is connected to a methyl mercaptan standard gas cylinder by a pipe. The top of the malodorous gas reactor is connected to the bottom of the alkali absorption tower by a pipe. The top of the alkali absorption tower is connected to an absorption liquid separating funnel and is connected to the bottom of the tail gas absorption tower. The top of the tail gas absorption tower is connected to an anhydrous ethanol separating funnel and a gas discharge pipe. The operation method comprises that chlorine dioxide and malodorous gas such as methyl mercaptan undergo a reaction in the malodorous gas reactor; and the reaction product passes through the alkali absorption tower and is absorbed by the tail gas absorption tower so that malodorous gas removal is realized. The alkali absorption waste liquid can be fed back to a sulfur cycle process of a sulfate pulping factory so that the waste is changed into values and current green papermaking requirements are satisfied.

Owner:GUANGXI UNIV

Process and device for purifying sulfuric acid phase in iodine and sulfur cycle under low pressure

ActiveCN101857204BLower the purification temperatureImprove purification efficiencyIodineSulfur-trioxide/sulfuric-acidSulfur cycleThermochemical cycle

The invention relates to a process and a device for purifying a sulfuric acid phase in the iodine and sulfur cycle under low pressure and belongs to the technical field of hydrogen production of the iodine and sulfur thermochemical cycle. The process for purifying the sulfuric acid phase is carried out under the condition of lower than normal pressure, i.e. under the condition of a purification temperature between 50 and 200 DEG C, a pressure P of a purifying and concentrating tower is controlled in the range that P is more than or equal to 0.01atm and less than 1atm. Compared with the conventional sulfuric acid phase purification process which adopts a nitrogen purging mode under normal pressure, the process has the characteristics of low purification temperature, simple process and low cost and can realize purification and concentration of the sulfuric acid phase in one step so as to effectively improve the purifying efficiency and reduce the purifying and concentrating cost.

Owner:TSINGHUA UNIV

Polyphosphate-containing composite corrosion and scale inhibitor, application thereof and method for inhibiting corrosion of sulfur-containing circulating cooling water

ActiveCN110803781AAvoid corrosionLow running costSpecific water treatment objectivesScale removal and water softeningAqueous corrosionMeth-

The invention relates to the field of sulfur-containing circulating cooling water corrosion, and discloses a polyphosphate-containing composite corrosion and scale inhibitor, an application thereof and a method for inhibiting corrosion of sulfur-containing circulating cooling water. The composite corrosion and scale inhibitor contains polyphosphates, organic phosphonic acid, a copolymer of acrylicacid, 2-acrylamido-2-methylpropanesulfonic acid and hydroxypropyl acrylate and a copolymer of acrylic acid and hydroxypropyl acrylate, wherein the weight ratio of the polyphosphates to the organic phosphonic acid to the copolymer of acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and hydroxypropyl acrylate to the copolymer of acrylic acid and hydroxypropyl acrylate is 1:(1.2-1.8):(1.5-3):(1.5-3). The method provided by the invention is more suitable for low-hardness low-alkali sulfur-containing circulating cooling water after the pH value of sulfur-containing circulating cooling wateris adjusted to be 9.5-10 and the concentration of calcium ions is adjusted to be 200-300 mg / L, and a good corrosion and scale inhibition effect can be obtained. Through the method, corrosion of sulfides in the sulfur-containing circulating cooling water to water cooling equipment can be effectively inhibited without using a large amount of reagents and fresh water.

Owner:CHINA PETROLEUM & CHEM CORP +1

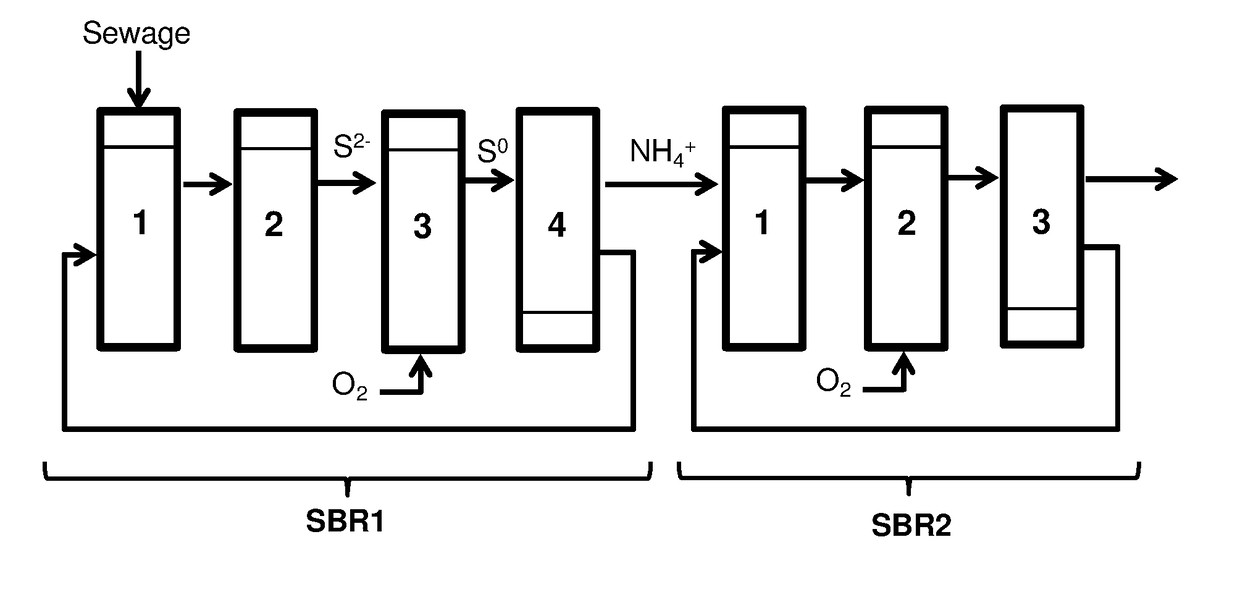

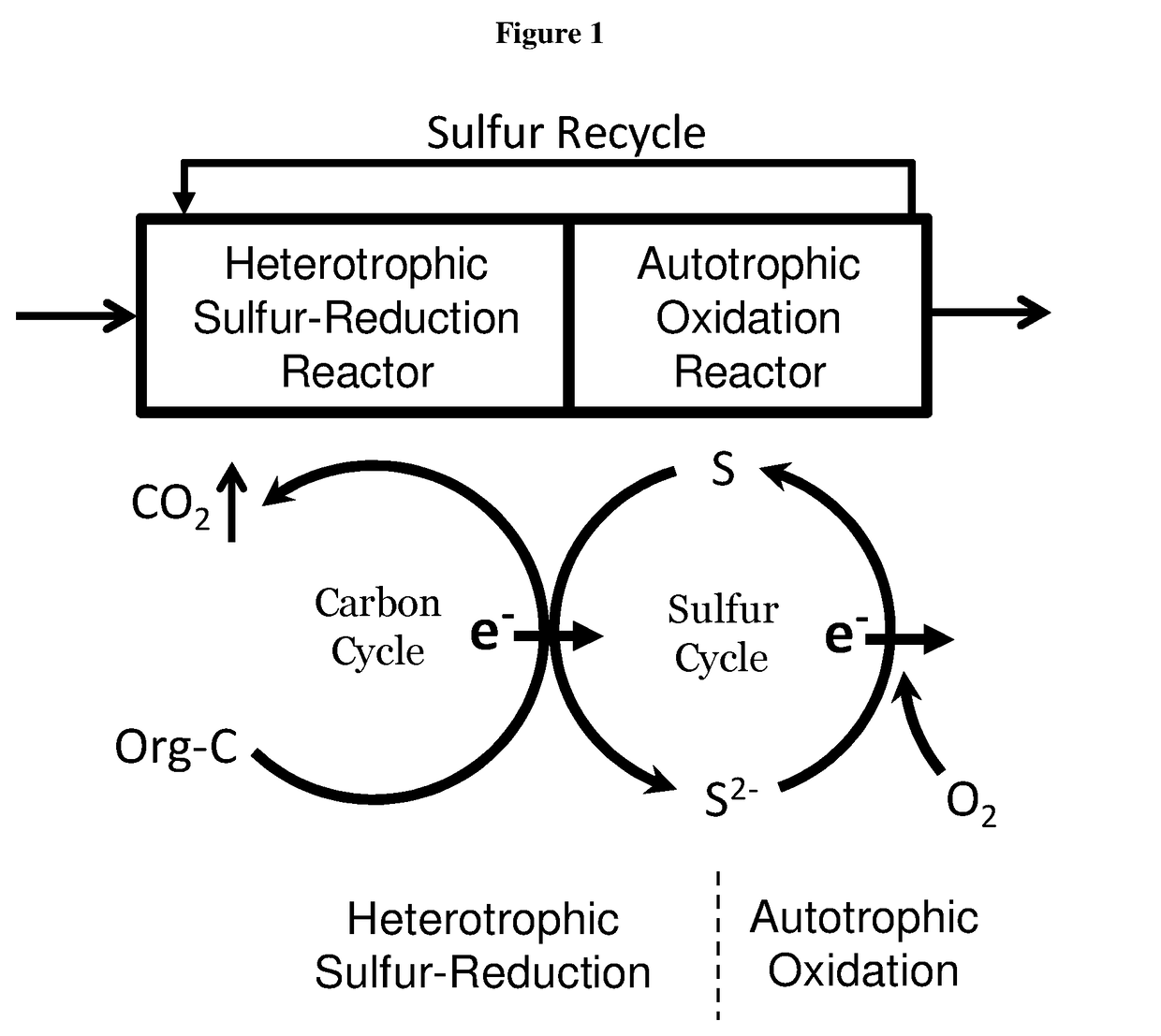

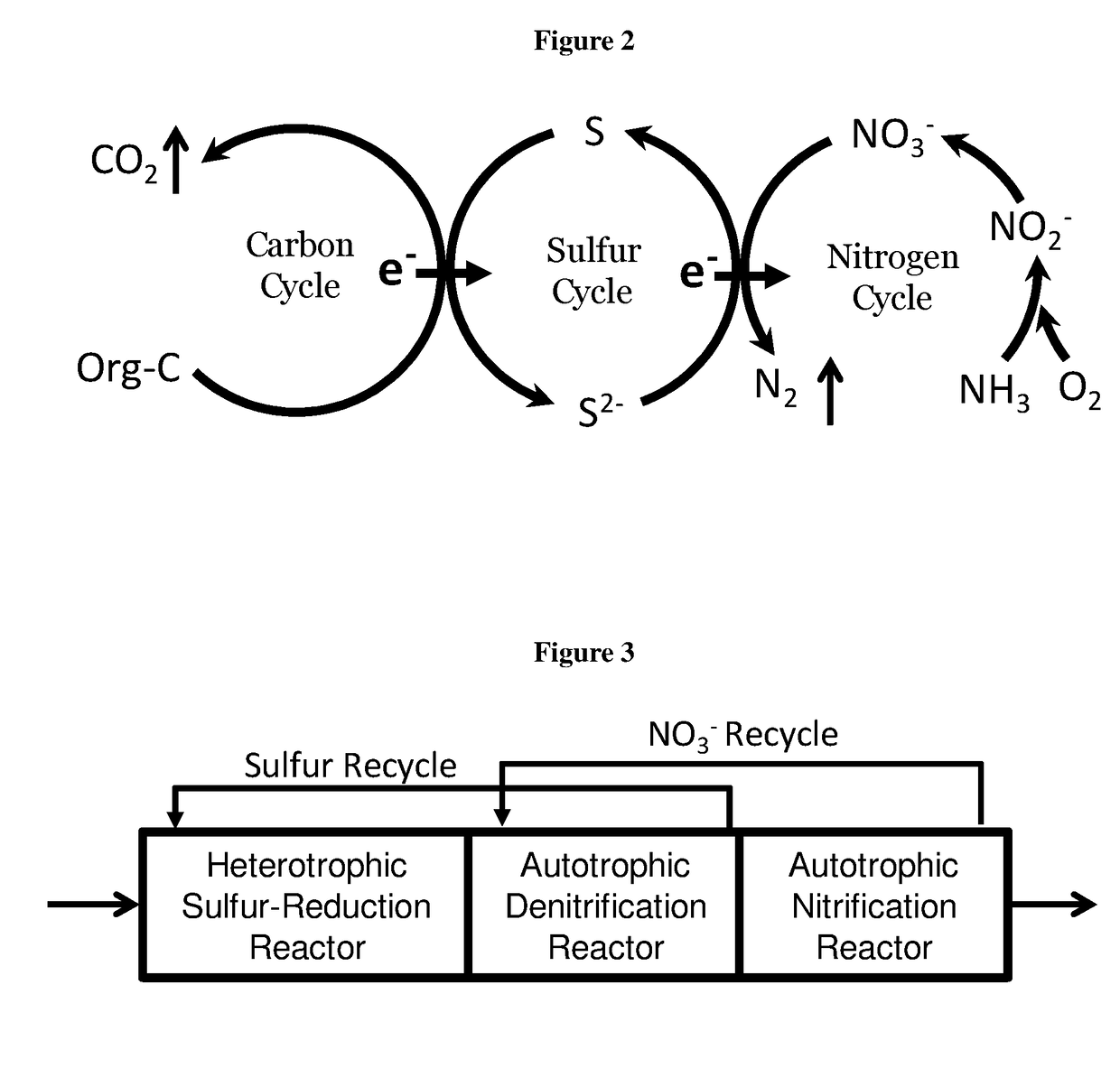

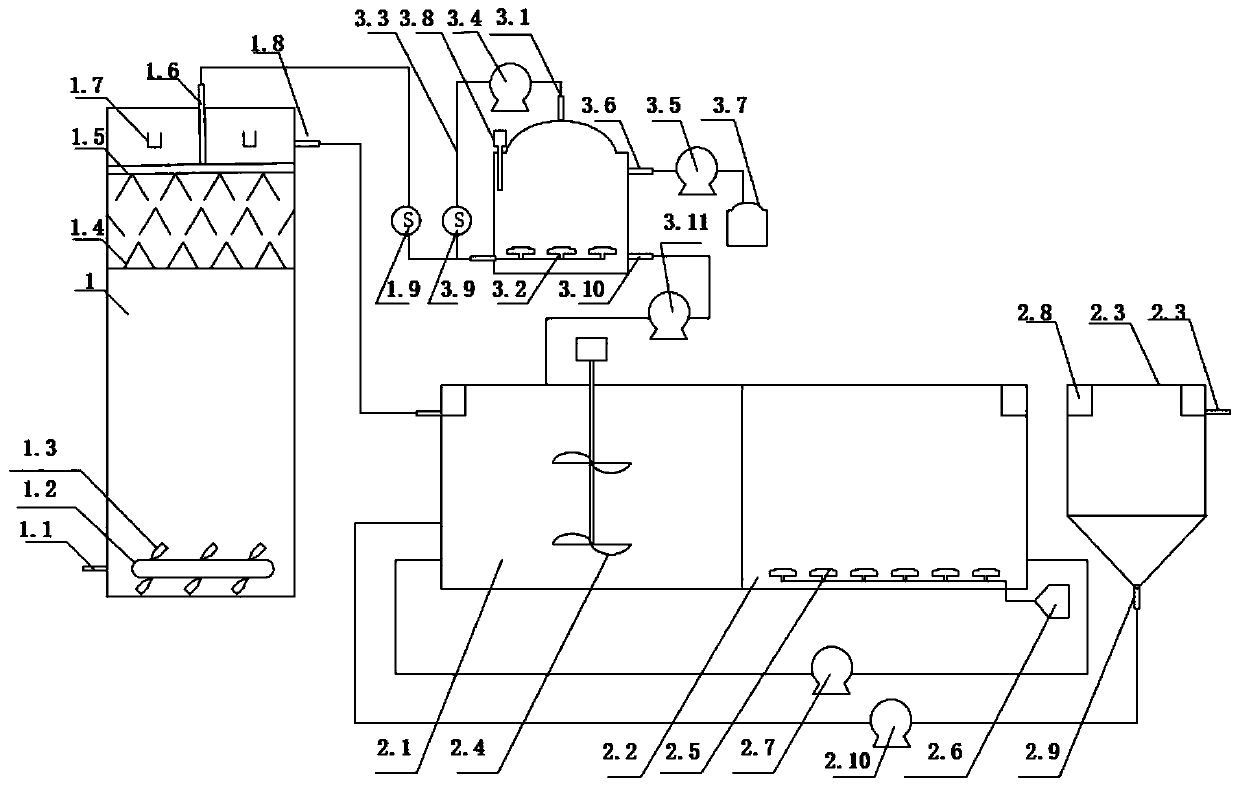

Internal sulfur cycling sani (isc-sani) process for biological wastewater treatment

ActiveUS20170369350A1Water treatment parameter controlTreatment using aerobic processesSulfur cycleNitrate salts

A method of removing organic carbon in biological wastewater treatment includes the steps of:(a) oxidizing organic carbon to carbon dioxide with elemental sulfur as an electron carrier, and reducing the elemental sulfur to sulfide;(b) oxidizing the sulfide to elemental sulfur by recycled nitrate through controlling one or more of a recycling ratio to maintain an oxidation reduction potential (ORP) within the range of −360 my to −420 mv, using an auto ORP controller; (c) recycling the elemental sulfur formed during oxidation of the sulfide back to the oxidation of the organic carbon; and(d) oxidizing ammonium to nitrate then partially recycled back for sulfide oxidation.

Owner:THE HONG KONG UNIV OF SCI & TECH

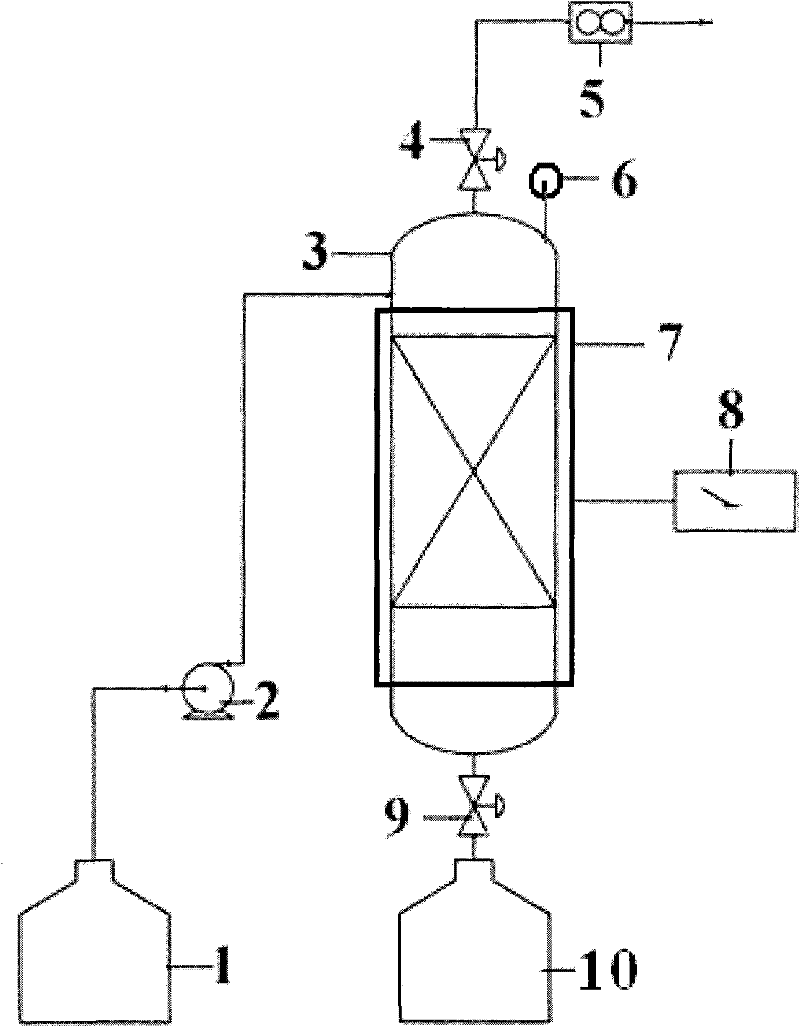

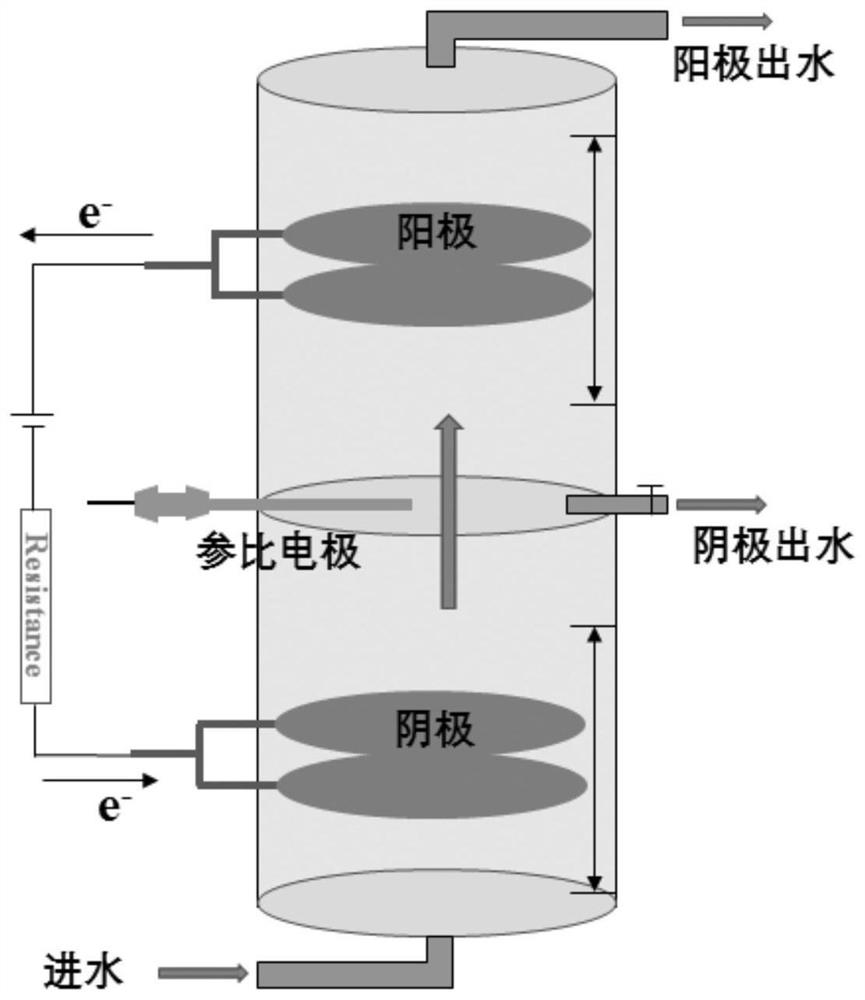

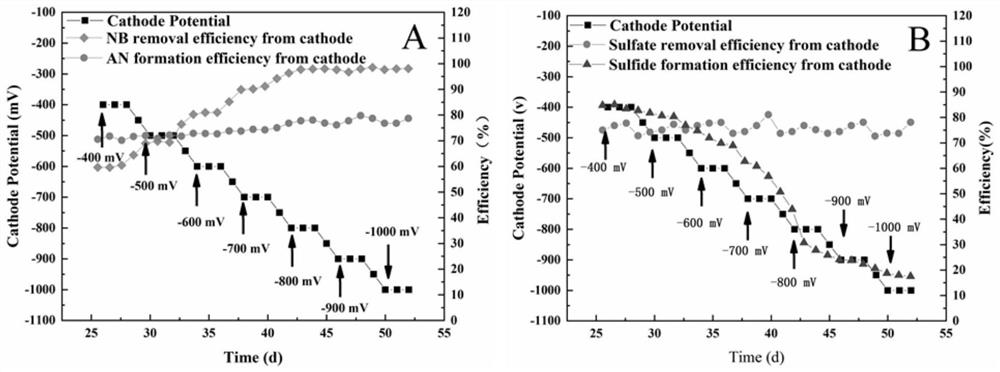

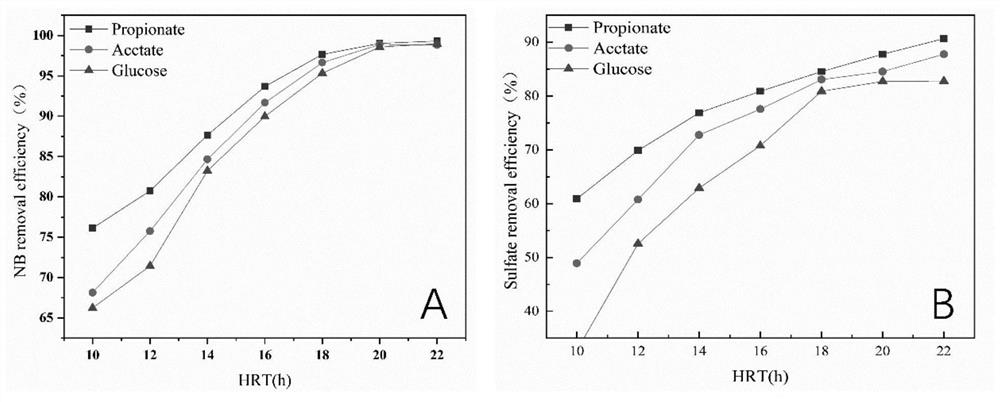

Method for strengthening anaerobic reduction of nitrobenzene by electrochemically regulating sulfur circulation

ActiveCN113003702APromote reductionEnhanced reduction conversionWater treatment parameter controlTreatment by combined electrochemical biological processesNitrobenzeneSulfide compound

The invention belongs to the technical field of industrial wastewater treatment, and discloses a method for strengthening anaerobic reduction of nitrobenzene by electrochemically regulating sulfur circulation. According to the invention, an electric field regulation and control technology is introduced into a traditional anaerobic reduction system, a diaphragm-free up-flow bioelectrochemical reactor is constructed, real-time conversion of sulfate reduction product sulfides is realized through regulation and control of cathode potential, electrons are synchronously released, reduction of nitrobenzene and sulfate in a cathode region is further promoted, the toxicity inhibition of H2S is effectively reduced, the consumption of an external carbon source is reduced, and the system stability is improved. Compared with an existing treatment process, the reduction conversion rate of NB is remarkably increased in a bioelectrochemical system with sulfur metabolism conversion, and the method has a wide application prospect in wastewater treatment.

Owner:NANJING UNIV OF SCI & TECH

Autotrophic-heterotrophic coupled deep denitrification device and method for sewage based on sulfur circulation

ActiveCN111422986AReduce processGood removal effectWater treatment parameter controlGas treatmentNitrationSulfide

The invention provides an autotrophic-heterotrophic coupled deep denitrification device and method for sewage based on sulfur circulation, belonging to the technical field of sewage treatment. According to the invention, alkali liquor is adopted for a unit which generates hydrogen sulfide in the process of sewage treatment to absorb hydrogen sulfide; the absorbed sulfide is lifted to an anoxic tank, and nitrate nitrogen in the anoxic tank is removed through sulfur autotrophic denitrification; heterotrophic denitrification is conducted on residual organic matters of an anaerobic methanogenesisreaction in an anoxic tank, an anoxic unit carries out both sulfur autotrophic nitrogen removal and organic matter heterotrophic nitrogen removal, and removal of nitrate nitrogen is reinforced throughcoupling of sulfur autotrophic nitrogen removal and heterotrophic nitrogen removal; and a biogas desulfurization process system only absorbs hydrogen sulfide, and the absorbed sulfide is utilized inan anoxic system, so recovery and utilization of elemental sulfur are realized.

Owner:BEIJING JIAOTONG UNIV

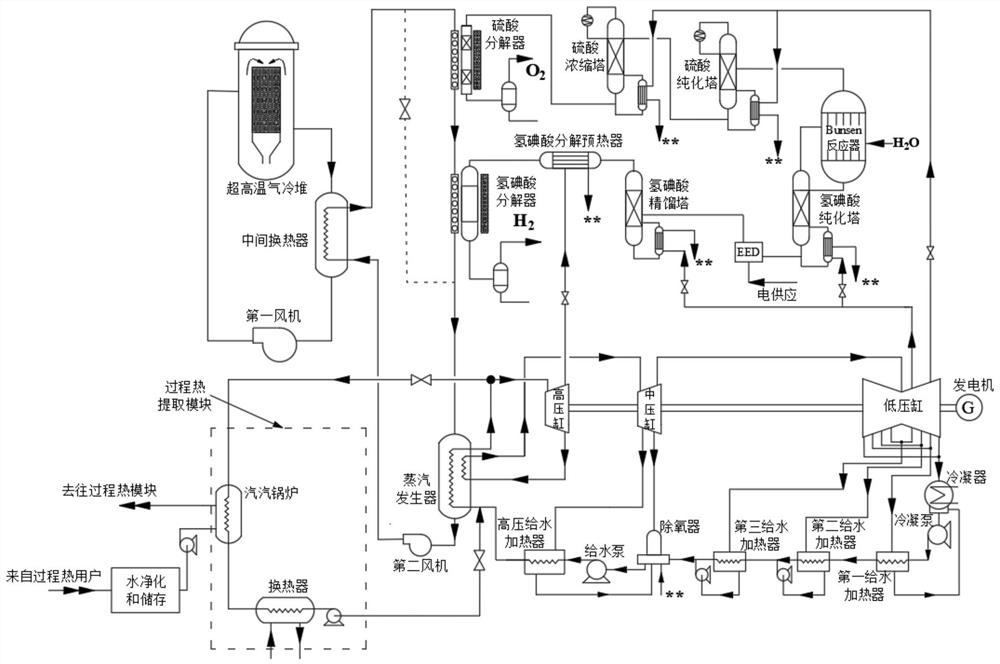

Combined heat, electricity and hydrogen production system with ultrahigh-temperature gas cooled reactor coupled with iodine-sulfur circulation

ActiveCN114517714AMeet multi-level energy needsImprove energy efficiencyLiquid degasificationFeed water supplySulfur cycleIntermediate heat exchanger

The invention discloses an ultrahigh-temperature gas cooled reactor coupled iodine-sulfur circulation thermoelectric hydrogen cogeneration system which comprises an iodine-sulfur circulation hydrogen production module, a process heat extraction module, a power generation loop, an ultrahigh-temperature gas cooled reactor and an intermediate heat exchanger, the power generation loop comprises a steam generator, a high-pressure cylinder, an intermediate-pressure cylinder and a low-pressure cylinder, the high-pressure cylinder exhausts steam to supply heat to a hydroiodic acid decomposition preheater, and the intermediate-pressure cylinder exhausts steam to supply heat to a hydroiodic acid decomposition preheater; and steam extracted by the low-pressure cylinder supplies heat to the sulfuric acid purification tower, the sulfuric acid concentration tower, the hydriodic acid purification tower and the hydriodic acid rectification tower. High-temperature helium at an outlet of the ultrahigh-temperature gas cooled reactor transfers heat to secondary side helium through the intermediate heat exchanger, and the secondary side helium supplies heat to the sulfuric acid decomposer, the hydriodic acid decomposer and the steam generator. The ultrahigh-temperature gas cooled reactor and the iodine-sulfur cycle are coupled in the combined heat, power and hydrogen production system, heat, power and hydrogen can be produced at the same time, gradient utilization of energy of the ultrahigh-temperature gas cooled reactor is achieved, multi-level energy requirements are met, the overall energy utilization rate of the system is increased, and a basis is provided for design of a process heat utilization system of the ultrahigh-temperature gas cooled reactor.

Owner:TSINGHUA UNIV

Method for promoting bunsen reaction in thermochemical sulfur-iodide cycle hydrogen production

ActiveCN103213945BOmit the concentration stepIncreased reaction kinetic rateHydrogen productionDistillationKinetic rate

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

Titanium sheet with surface modified sulfur doped titanium dioxide nanoflakes as well as preparation method and application of titanium sheet

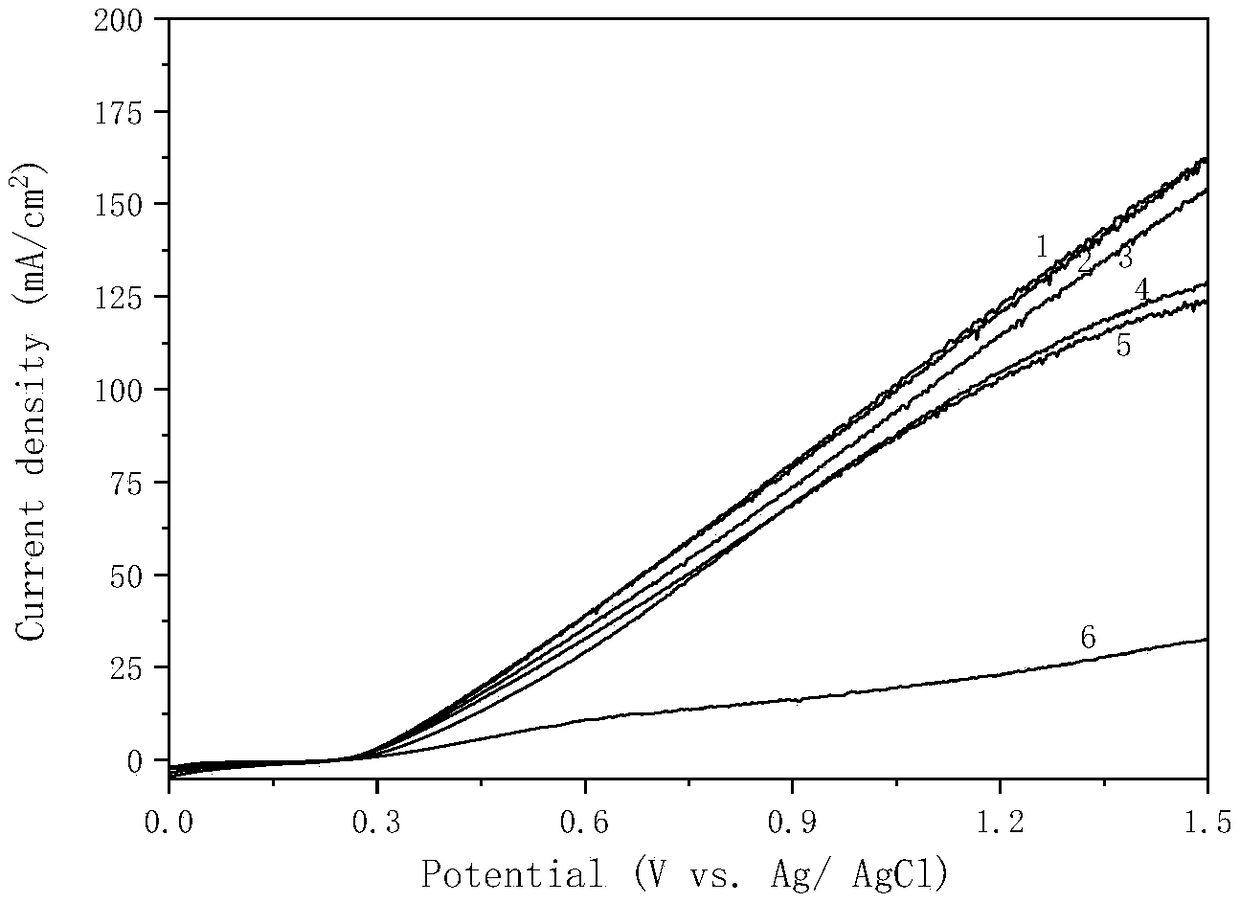

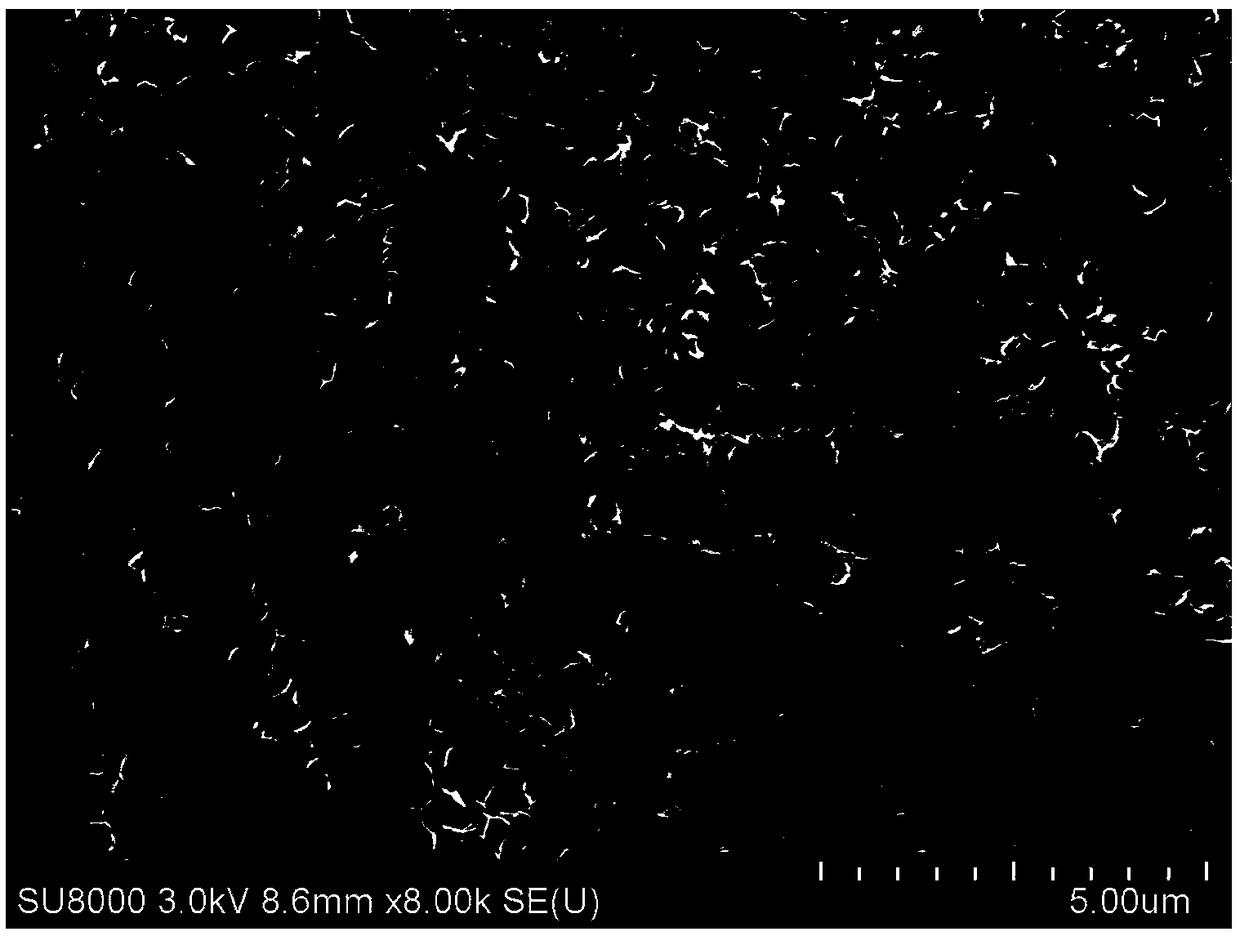

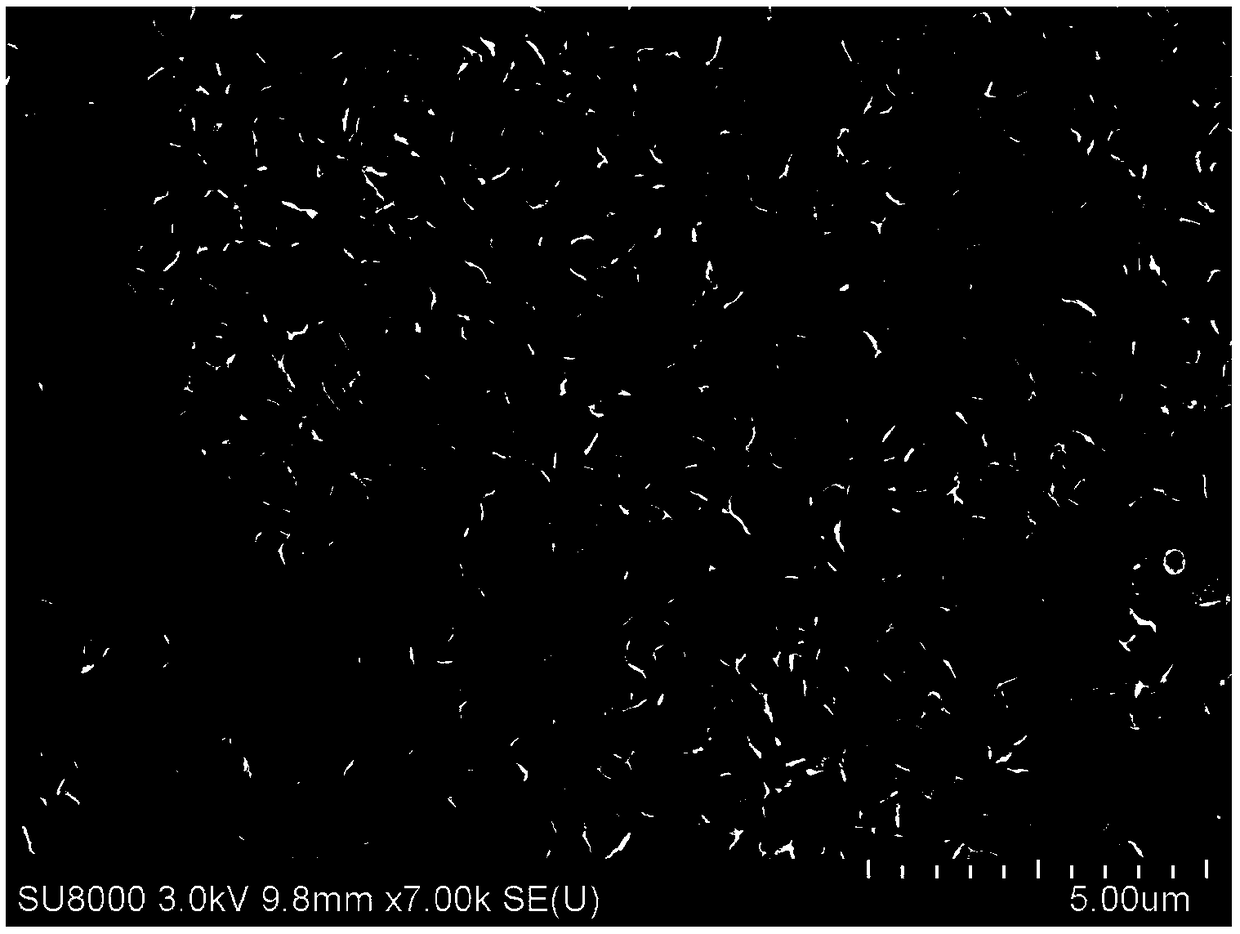

ActiveCN108855139AImprove conductivityImprove electrocatalytic performancePhysical/chemical process catalystsElectrodesElectrolysisHydroiodic acid

The invention discloses a titanium sheet with surface modified sulfur doped titanium dioxide nanoflakes as well as a preparation method and application of the titanium sheet, and belongs to the technical field of inorganic chemical synthesis. The preparation method comprises the following steps: by taking the titanium sheet as a substrate material, urea as an alkali source and thioacetamine (TAA)as a sulfur source, reacting in a mixed solution of water and ethanol for 12 to 72 hours under the hydrothermal condition of 115 to 125 DEG C; washing and naturally drying a product to obtain the titanium sheet modified by the sulfur doped titanium dioxide nanoflakes. The surface of the titanium sheet obtained by reaction is uniformly modified by the sulfur doped titanium dioxide nanoflakes. The electrochemical performance of the obtained product is tested; the product has excellent catalytic property as an anode for producing hydrogen by hydroiodic acid electrolysis in the iodine-sulfur cycle; in addition, with high acid resistance and good electrocatalytic stability, the titanium sheet can be applied to the fields of hydrogen production by the hydroiodic acid electrolysis in the iodine-sulfur cycle and the like.

Owner:JILIN UNIV

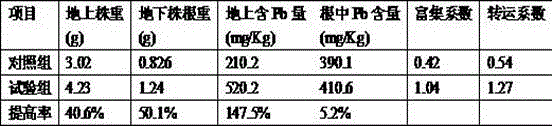

Photosynthetic bacteria preparation for strengthening phytoremediation of soil heavy metal pollution and preparation method thereof

InactiveCN104707864BMaintain water holding capacityContaminated soil reclamationBacteroidesRhodopseudomonas capsulata

The invention provides a compound photosynthetic bacteria preparation for enhancing the phytoremediation for heavy metal pollution of soil and a preparation method thereof. The high concentration compound photosynthetic bacteria preparation of thiocapsa roseopersicina and rhodopseudomonas capsulata is adopted through the step that thiocapsa roseopersicina cultures in purple sulfur photosynthetic bacteria and rhodopseudomonas capsulate cultures in purple non-sulfur photosynthetic bacteria are subjected to such culture steps as seed activation, seed culture and anaerobic fermentor irradiation culture. The compound photosynthetic bacteria preparation is used for enhancing the phytoremediation for heavy metal pollution of soil, thiocapsa roseopersicina as sulfur-oxidizing bacteria can be used for oxidizing relatively stable sulfides with heavy metals, thereby promoting sulfur cycle of soil, reducing the PH value of soil and improving the activity of heavy metals; the thiocapsa roseopersicina and rhodopseudomonas capsulata as bacterial manure can promote the conversion of soil substances, improve the soil structure and soil fertility, promote plant growth and improve the biomass of plants enriched with heavy metals, thereby enhancing the efficiency of phytoremediation for heavy metals in soil.

Owner:北京聚益成广科技有限公司

Urotropine-containing composite corrosion and scale inhibitor, application thereof and method for inhibiting corrosion of sulfur-containing circulating cooling water

ActiveCN110803785AAvoid corrosionLow running costSpecific water treatment objectivesNature of treatment waterAqueous corrosionHexamethylenetetramine

The invention relates to the field of corrosion of sulfur-containing circulating cooling water, and discloses an urotropine-containing composite corrosion and scale inhibitor, an application thereof and a method for inhibiting corrosion of sulfur-containing circulating cooling water. The composite corrosion and scale inhibitor comprises a zinc salt, hydroxyethylidene diphosphonic acid, 2-hydroxyphosphonoacetic acid, a sulfonate copolymer and urotropine, wherein the weight ratio of the zinc salt to the hydroxyethylidene diphosphonic acid to the 2-hydroxyphosphonoacetic acid to the sulfonate copolymer to the urotropine is 1:(2-5):(2-5):(4-10):(125-250), wherein the weight of the zinc salt is based on zinc ions. According to the method provided by the invention, after the pH value of the sulfur-containing circulating cooling water is adjusted to be 8-9, the composite corrosion and scale inhibitor can be used, and a good corrosion and scale inhibition effect can be obtained. According to the method, corrosion of sulfides in the sulfur-containing circulating cooling water to water cooling equipment can be effectively inhibited without using a large amount of reagents and fresh water, and operation cost can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite corrosion and scale inhibitor containing zinc salt and application thereof and method for inhibiting corrosion of sulfur-containing circulating cooling water

InactiveCN110803780AAvoid corrosionLow running costSpecific water treatment objectivesScale removal and water softeningAqueous corrosionSulfonate

The invention relates to the field of corrosion of sulfur-containing circulating cooling water, and discloses a composite corrosion and scale inhibitor containing a zinc salt and an application thereof and a method for inhibiting corrosion of sulfur-containing circulating cooling water. The composite corrosion and scale inhibitor contains the zinc salt, hydrolyzed polymaleic anhydride, a sulfonatecopolymer and urotropine, wherein a weight ratio ofthe zinc saltto the hydrolyzed polymaleic anhydrideto the sulfonate copolymer tourotropine is 1:3-6:4-10:125-250, and the weight of the zinc salt iscalculated by zinc ions. According to the method provided by the invention, the pH value of the sulfur-containing circulating cooling water is adjusted to 8-9, and then the composite corrosion and scale inhibitor is used, so that the relatively good corrosion and scale inhibition effects can be obtained. The method can effectively inhibit corrosion of water-coolingequipment by sulfides in the sulfur-containing circulating cooling water without using a large amount of chemicals and fresh water, and the operating cost can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite corrosion and scale inhibitor and application thereof and method for inhibiting corrosion of sulfur-containing circulating cooling water

InactiveCN110803786AAvoid corrosionLow running costSpecific water treatment objectivesScale removal and water softeningAqueous corrosionAcyl group

The invention relates to the field of corrosion of sulfur-containing circulating cooling water, and discloses a composite corrosion and scale inhibitor and an application thereof and a method for inhibiting corrosion of sulfur-containing circulating cooling water. The composite corrosion and scale inhibitor contains a zinc salt, hydroxyethylidene diphosphonic acid, 2-hydroxyphosphonoacetic acid and a sulfonate copolymer, wherein a weight ratio ofthe zinc saltto hydroxyethylidene diphosphonic acidto 2-hydroxyphosphonoacetic acid tothe sulfonate copolymer is 1:2.5-4:2.5-4:4-9, and the weight ofthe zinc salt is calculated by zinc ions. According to the method provided by the invention, the composite corrosion and scale inhibitor and a complex of a ferric salt and nitrilotriacetic acid are used in combination to obtain relatively good corrosion and scale inhibition effects. The method can effectively inhibit corrosion of water-coolingequipment by sulfides in the sulfur-containing circulating cooling water without using a large amount of chemicals and fresh water, and the operating cost can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

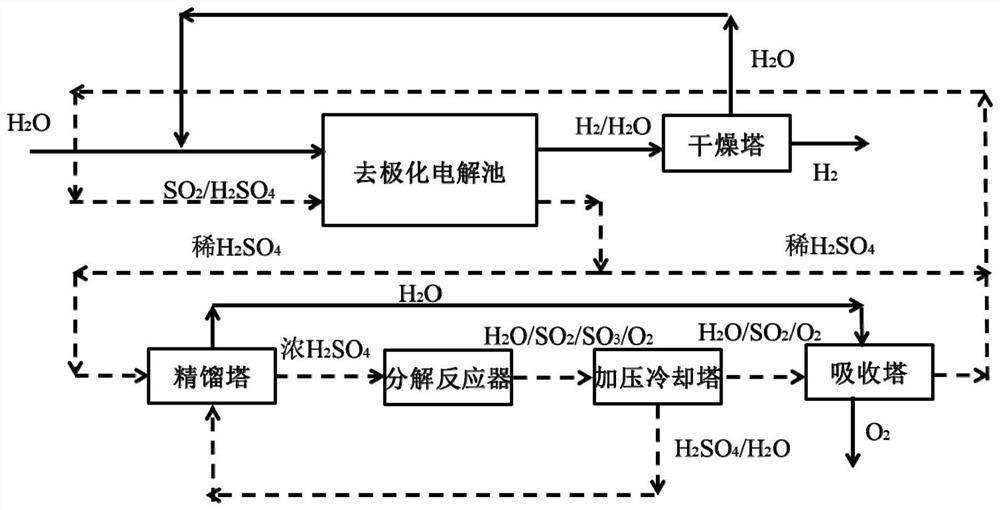

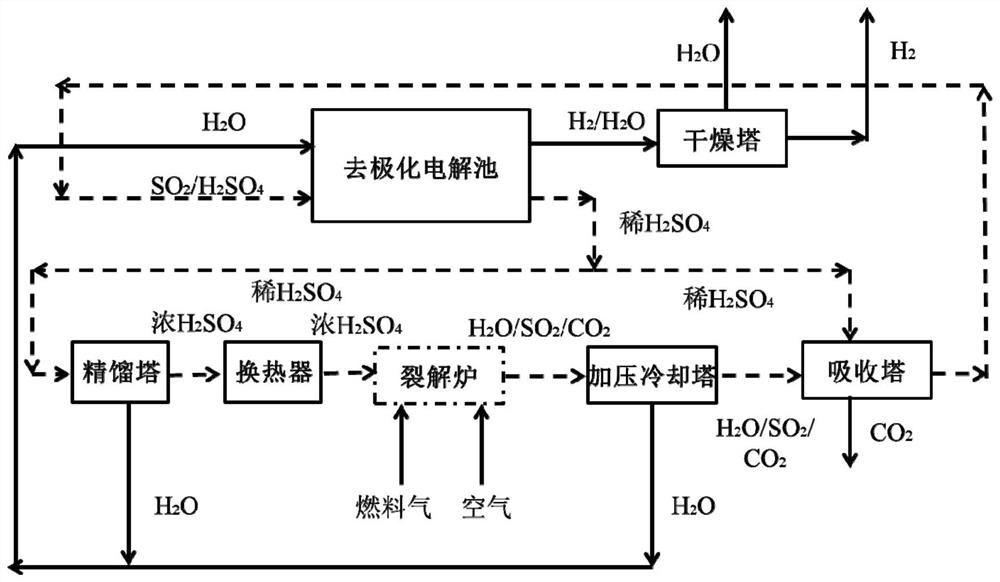

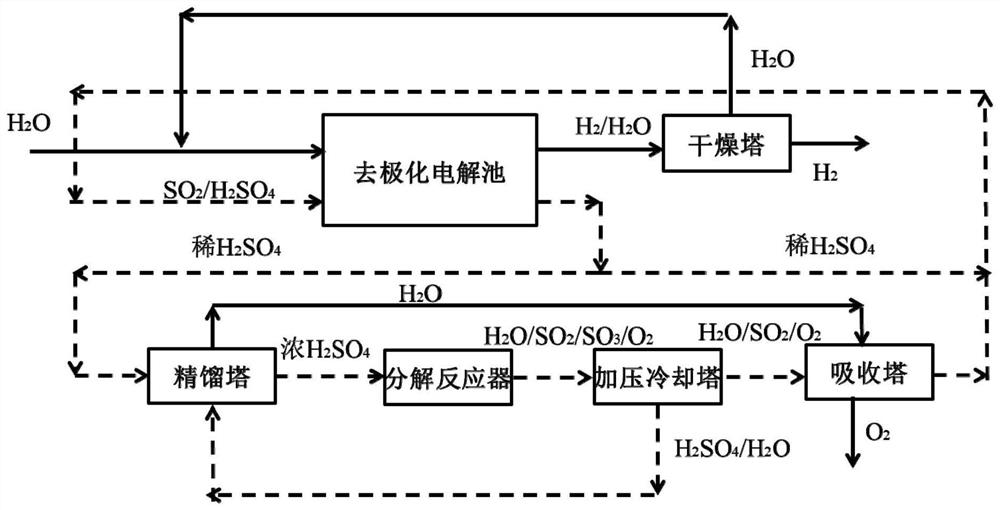

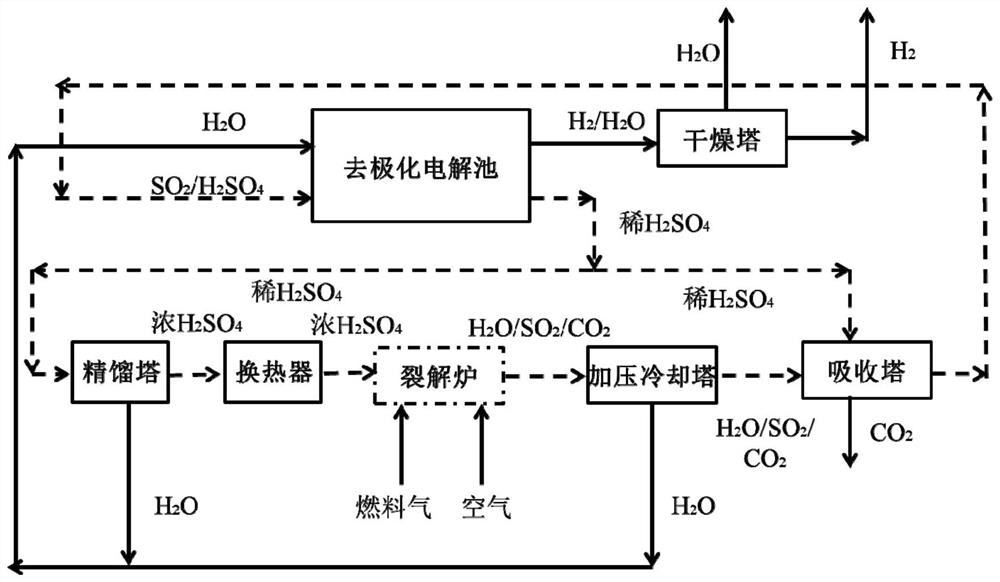

Mixed sulfur circulating hydrogen production method

ActiveCN112030178AMeet the needs of high-grade heatAlleviate the problem of high water consumptionElectrolysis componentsEngineeringMixed gas

The invention discloses a mixed sulfur circulating hydrogen production method, and belongs to the technical field of thermochemical circulating hydrogen production. The method comprises the followingsteps: concentrating and preheating dilute sulfuric acid in a rectifying tower, feeding the concentrated and preheated dilute sulfuric acid into a cracking furnace to be mixed with fuel gas and air, feeding mixed gas generated by cracking into a depolarization electrolytic tank for electrolysis, acquiring a dilute sulfuric acid solution in the anode area, dividing into two parts, sending one partto a rectifying tower, sending the other part to an absorption tower to absorb sulfur dioxide, and in a cathode region of an electrolytic cell, producing a hydrogen product. High-grade steam is used for concentrating and preheating dilute sulfuric acid, and industrial byproduct fuel gas is used for cracking concentrated sulfuric acid at high temperature. Compared with traditional mixed sulfur cycle hydrogen production, the method makes full use of industrial by-product gas, and meets the large-scale requirements of the fields of hydrogen-rich metallurgy, petroleum processing and the like for hydrogen. Meanwhile, fuel gas combustion byproduct water used in the sulfuric acid high-temperature cracking process can be recycled, more water is saved compared with other water decomposition hydrogen production processes, and the process is a hydrogen production process with high industrial application potential.

Owner:TSINGHUA UNIV

Device and method for deep denitrification of sewage based on autotrophic and heterotrophic coupling of sulfur cycle

ActiveCN111422986BReduce processGood removal effectWater treatment parameter controlGas treatmentNitrationEngineering

The invention provides an autotrophic and heterotrophic coupled sewage deep denitrification device and method based on sulfur cycle, belonging to the technical field of sewage treatment. The unit for generating hydrogen sulfide in the sewage treatment process of the present invention uses lye to absorb hydrogen sulfide; lifts the absorbed sulfide to an anoxic pool, and the anoxic pool removes nitrate nitrogen through sulfur autotrophic denitrification; anaerobic methane production The remaining organic matter undergoes heterotrophic denitrification in the anoxic tank, and the anoxic unit performs the combination of sulfur autotrophic denitrification and organic matter heterotrophic denitrification. The biogas desulfurization process system only absorbs hydrogen sulfide, and the absorbed sulfide is utilized in the anoxic system to realize the recovery and utilization of sulfur element.

Owner:BEIJING JIAOTONG UNIV

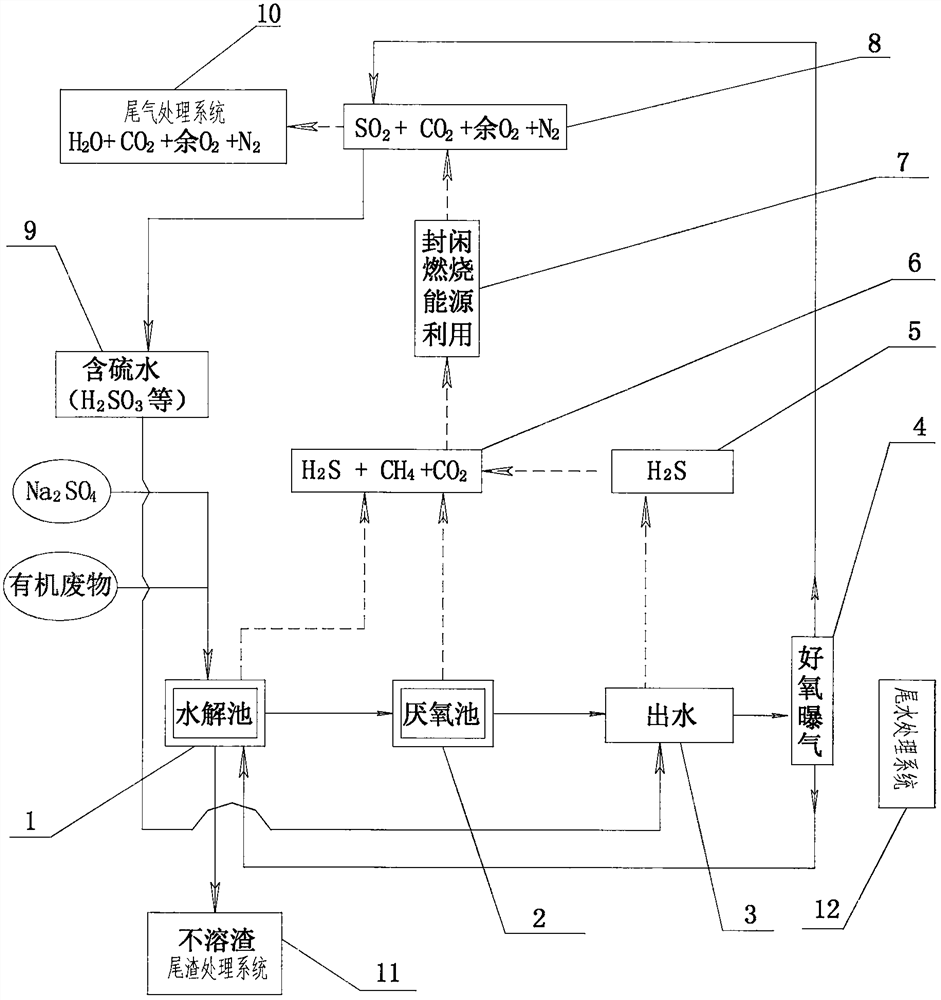

An energy system with the aid of the sulfur cycle

ActiveCN108192807BBioreactor/fermenter combinationsBiological substance pretreatmentsMethanobacterSulfide

The invention discloses an energy system with the help of sulfur cycle. For those conditions that are not conducive to the growth of methanogens, the sulfur cycle can be used, that is, sulfate / sulfite is reduced to sulfide by sulfate-reducing bacteria, and the After the sulfide is acidified into hydrogen sulfide, it is closed and burned to obtain energy. Sulfur dioxide generated after hydrogen sulfide combustion is washed with water to generate sulfurous acid, which enters the anaerobic system, and then is reduced by sulfate-reducing bacteria to form a cycle and continuously obtain energy.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

A method for hydrogen production by mixed sulfur cycle

ActiveCN112030178BMeet the needs of high-grade heatAlleviate the problem of high water consumptionElectrolysis componentsMixed gasSulfur dioxide

The invention discloses a hydrogen production method with mixed sulfur circulation, which belongs to the technical field of thermochemical circulation hydrogen production. In this method, dilute sulfuric acid is concentrated in a rectification tower first, and after preheating, it enters a cracking furnace and mixes with fuel gas and air. It is divided into two streams, one of which is sent to the rectification tower, and the other is sent to the absorption tower to absorb sulfur dioxide; the cathode area of the electrolytic cell produces hydrogen products. The invention uses high-grade steam to concentrate and preheat dilute sulfuric acid, and uses industrial by-product fuel gas to crack concentrated sulfuric acid at high temperature. Compared with the traditional mixed sulfur cycle hydrogen production, this method makes full use of industrial by-product gas and meets the large-scale demand for hydrogen in hydrogen-rich metallurgy, petroleum processing and other fields. At the same time, the fuel gas combustion by-product water used in the sulfuric acid pyrolysis process can be recycled, which is more water-saving than other water splitting hydrogen production processes, and is a hydrogen production process with strong industrial application potential.

Owner:TSINGHUA UNIV

Denitrification biological filter for deeply removing total nitrogen

PendingCN113816567AGood removal effectImprove denitrification effectWater treatment compoundsSpecific water treatment objectivesBiological filterTotal nitrogen

The invention relates to a denitrification biological filter, in particular to a denitrification biological filter for deeply removing total nitrogen. The invention aims to overcome the problem that the total nitrogen removal effect of a denitrification filter is poor. The denitrification biological filter consists of a midway lifting pump tank, a biological filter, a clean water tank, a reservoir, a backwashing drainage channel, a drainage channel, a chemical adding device and a biological agent and electron acceptor adding device. On the basis of an existing denitrification biofilter, the removal of total nitrogen in wastewater is deeply enhanced; the biodegradability of the wastewater and the bioavailability of the denitrification biofilter are improved by utilizing the pretreatment of the midway lifting pump tank; and a sulfur circulation autotrophic denitrification system is constructed by adding a biological complex microbial inoculant and an electron acceptor into the denitrification biological filter, so the removal of total nitrogen in the wastewater is enhanced. The denitrification biological filter is suitable for urban sewage treatment.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com