Process and device for preparing oxygen through thermal decomposition of sulfuric acid phase in iodine-sulfur circulation

A technology of thermal decomposition and sulfuric acid, applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, separation methods, etc., can solve the problems of increased system cost, high cost, consumption of main acid HI, etc., to improve the recovery rate , investment and energy consumption reduction, the effect of improving quality and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

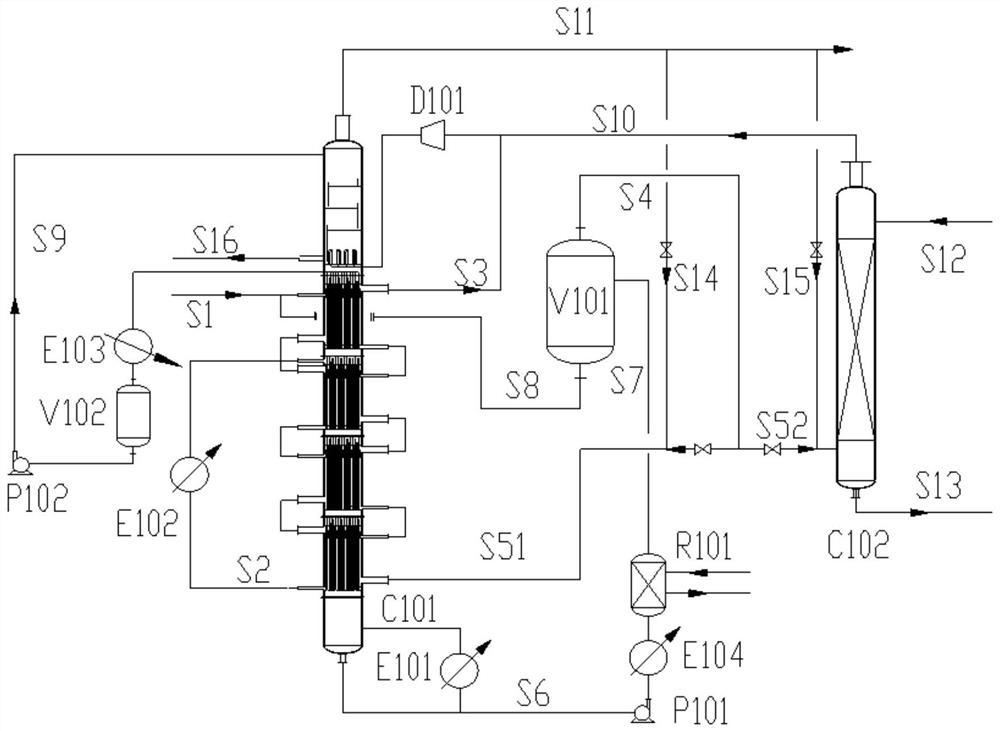

Method used

Image

Examples

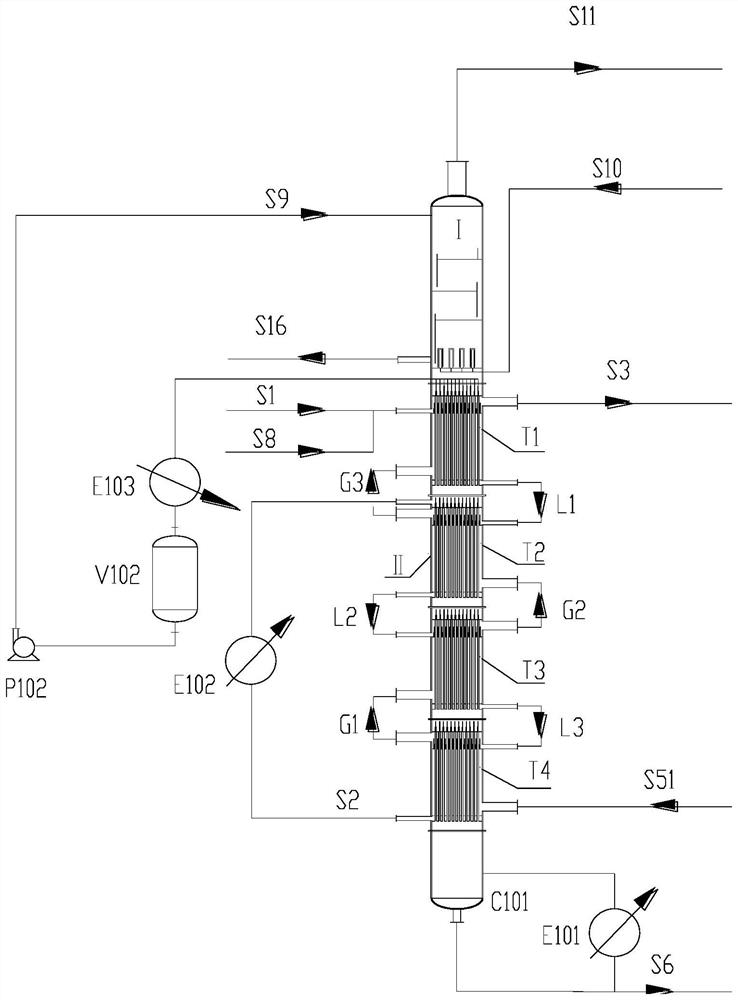

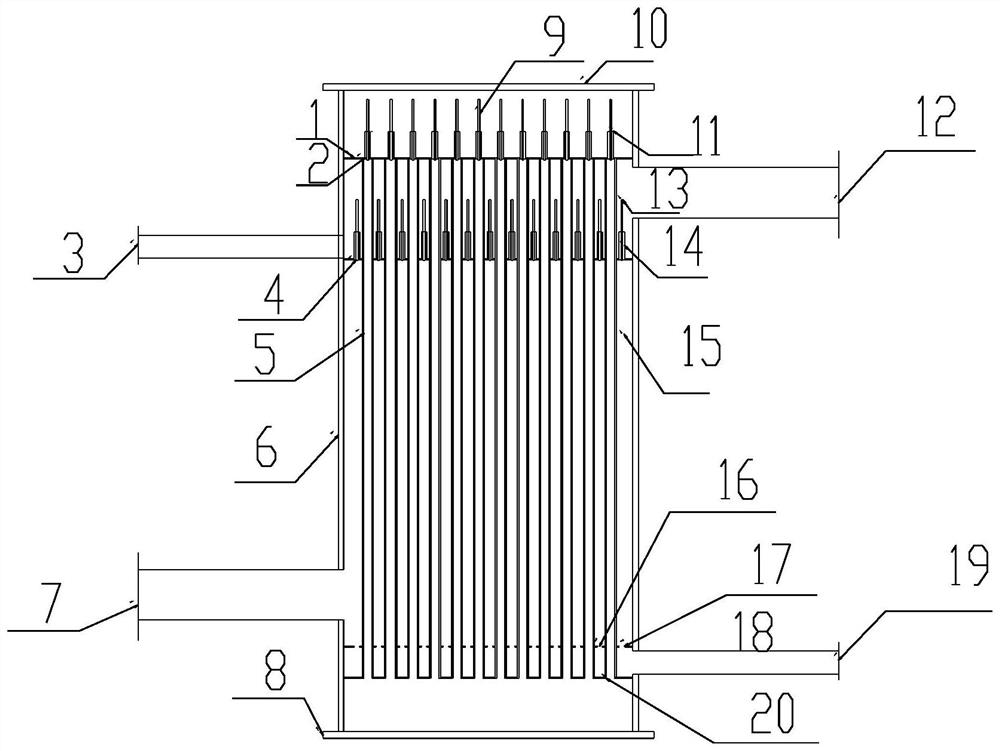

Embodiment 1

[0089] Using the process described in the present invention, SA enters the C101 heat-integrated composite tower. The outer diameter of the new composite tower is 250mm, the height of the composite tower section is 650mm, and the material of the composite tower is corrosion-resistant and high-temperature-resistant stainless steel. The stripping and purification section and the rectification and concentration section of C101 heat integrated composite tower are 8 trays respectively, and the water washing section contains 10 trays. The pressure of the stripping purification section is 1 bar, and the temperature of the stripping tower is 120°C. The pressure of the rectification and concentration section is 1 bar, the feed position is the fourth plate, the feed temperature is 125°C, the tower top temperature is 55°C, and the tower bottom temperature is 330°C. The pressure of the washing section is 7 bar and the temperature is 110°C. The C102 column contains 8 trays, the pressure is...

Embodiment 2

[0101] Using the process described in the present invention, the structure and process parameters are the same as in Example 1.

[0102] Stream label and attachment of sulfuric acid phase thermal decomposition oxygen production unit in iodine-sulfur cycle figure 1 Consistent, the material property is as shown in S1 in embodiment 2 table 2: S1 is the composite tower stripping purification section SA feed, and total flow is 9.507kmol / h, and the C101 stripping section stripping gas S51 through reconciling contains 0.866kmol / hSO 2 and 0.820kmol / h of O 2 , C101 stripping section stripping gas purified stripping gas S3, containing 0.832kmol / h of SO 2 and 0.630kmol / h of O 2 . Harmonized C102 stripping section stripping gas S52, containing 0.866kmol / h of SO 2 and 0.490 kmol / h of O 2, the stripping gas S10 purified by the C102 stripper, containing 0.899kmol / h of SO 2 and 0.320kmol / h of O 2 . After being washed by the C10 water washing section, the composition of the acidic wa...

Embodiment 3

[0106] Using the process described in the present invention, SA enters the C101 thermal integration composite tower. The outer diameter of the new composite tower is 300mm, the height of the composite tower section is 680mm, and the material of the composite tower is corrosion-resistant and high-temperature-resistant stainless steel. The stripping and purification section and the rectification and concentration section of C101 heat integrated composite tower are 8 trays respectively, and the water washing section contains 8 trays. The pressure of the stripping purification section is 1 bar, and the temperature of the stripping tower is 120°C. The pressure of the rectification and concentration section is 1 bar, the feed position is the fourth plate, the feed temperature is 125°C, the tower top temperature is 55°C, and the tower bottom temperature is 330°C. The pressure of the washing section is 7 bar and the temperature is 110°C. The C102 column contains 10 trays, the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com