Process and device for preparing hydrogen from hydrogen iodide in iodine-sulfur circulation

A hydrogen iodide and process technology, which is applied in the field of hydrogen iodide production process and equipment in the iodine-sulfur cycle, can solve the problems of reduced hydrogen production efficiency, increased hydrogen production cost, and high energy consumption for electrochemical decomposition, achieving improved The effect of recovery rate, investment and energy consumption reduction, improvement of quality and energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

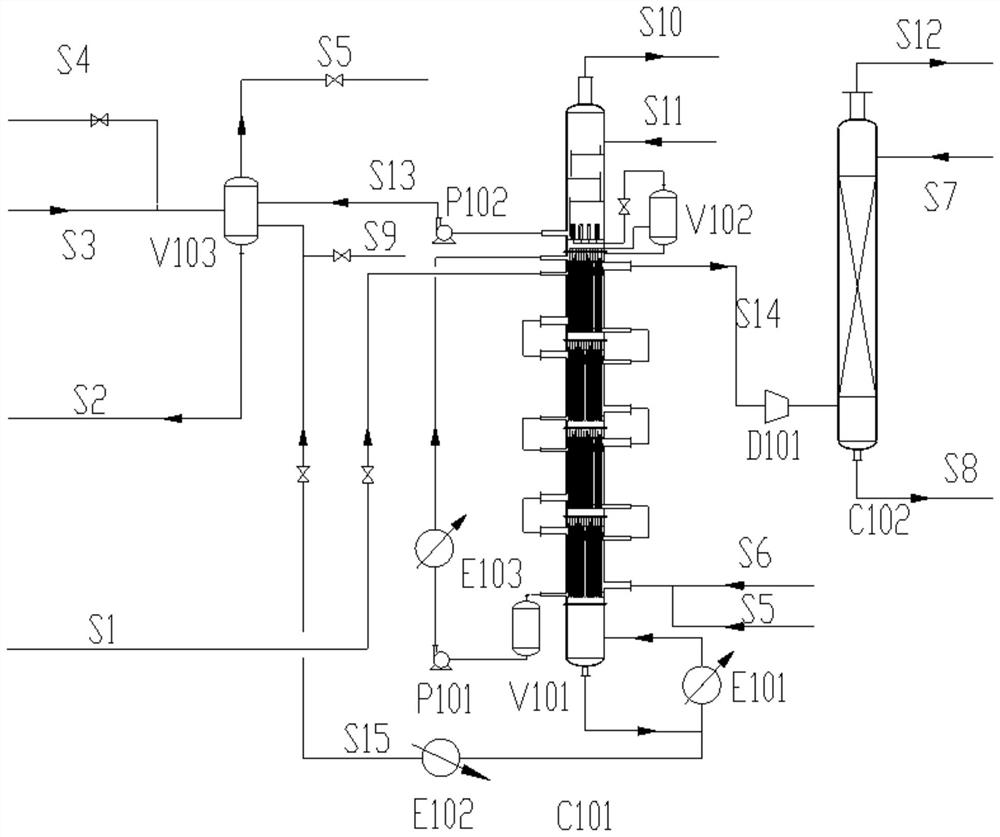

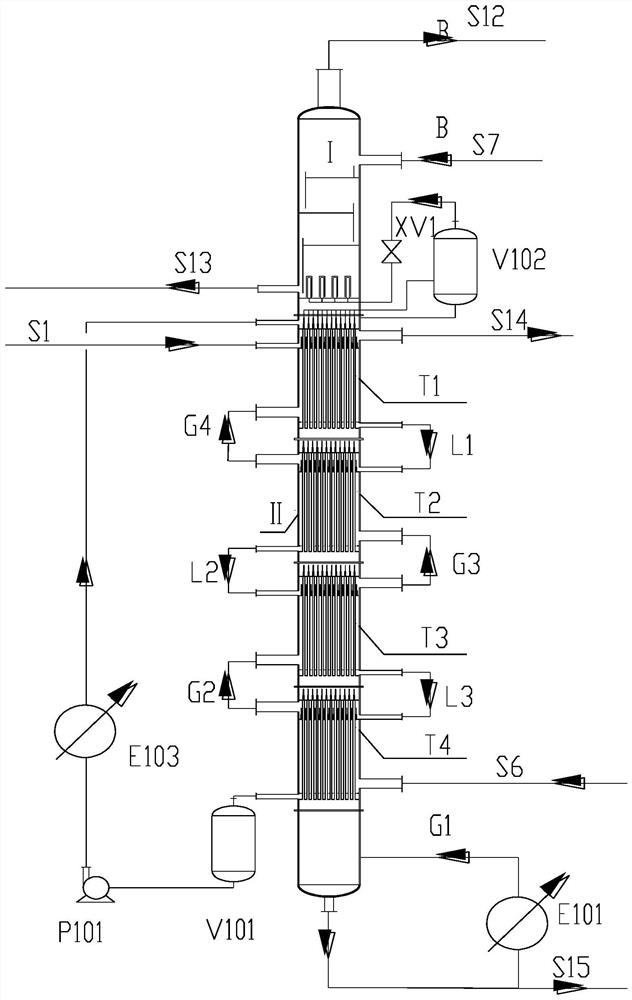

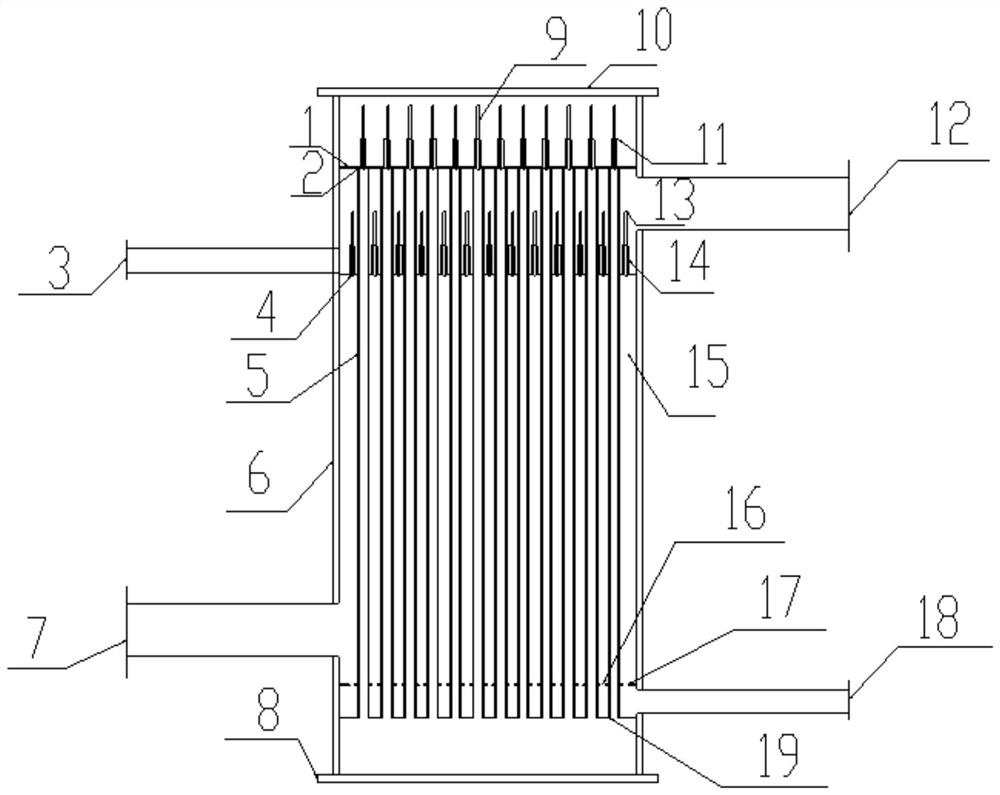

Embodiment 1

[0081] Using the process described in the present invention, HIX enters the thermal integration composite tower C101. The outer diameter of the new composite tower is 250mm, the height of the composite tower section is 680mm, and the material of the composite tower is corrosion-resistant and high-temperature-resistant stainless steel. The stripping section and the reaction section of heat integrated composite tower C101 are 8 trays respectively, and the water washing section contains 6 trays. The pressure of the stripping section is 1 bar, and the temperature of the stripping tower is 120°C. The pressure in the reaction section is 10 bar, the feed position is the second plate, the feed temperature is 447°C, the tower top temperature is 207°C, the tower bottom temperature is 477°C, and the reflux ratio is 3. The pressure of the washing section is 1 bar, the washing water enters the washing section at the top of the tower, and the water temperature is 5°C. o 2 Washing tower C1...

Embodiment 2

[0090] Using the process described in the present invention, HIX enters the thermal integration composite tower C101. The outer diameter of the new composite tower is 250mm, the height of the composite tower section is 680mm, and the material of the composite tower is corrosion-resistant and high-temperature-resistant stainless steel. The stripping section and the reaction section of heat integrated composite tower C101 are 8 trays respectively, and the water washing section contains 6 trays. The pressure of the stripping section is 1 bar, and the temperature of the stripping tower is 120°C. The pressure in the reaction section is 10 bar, the feed position is the second plate, the feed temperature is 447°C, the tower top temperature is 207°C, the tower bottom temperature is 477°C, and the reflux ratio is 3. The pressure of the washing section is 1 bar, the washing water enters the washing section at the top of the tower, and the water temperature is 5°C. o 2 Washing tower C102...

Embodiment 3

[0095] Using the process described in the present invention, HIX enters the thermal integration composite tower C101. The outer diameter of the new composite tower is 250mm, the height of the composite tower section is 680mm, and the material of the composite tower is corrosion-resistant and high-temperature-resistant stainless steel. The stripping section and the reaction section of heat integrated composite tower C101 are 8 trays respectively, and the water washing section contains 6 trays. The pressure of the stripping section is 1 bar, and the temperature of the stripping tower is 120°C. The pressure in the reaction section is 10 bar, the feed position is the second plate, the feed temperature is 447°C, the tower top temperature is 207°C, the tower bottom temperature is 477°C, and the reflux ratio is 3. The pressure of the washing section is 1 bar, the washing water enters the washing section at the top of the tower, and the water temperature is 5°C. o 2 Washing tower C1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com