Process for purifying sulfuric acid phase and hydriodic acid phase in iodine-sulfur cycle

A technology of hydroiodic acid and sulfuric acid, applied in the production of sulfur trioxide/sulfuric acid, hydrogen, iodine/hydrogen iodide, etc., can solve the problem of main acid consumption and achieve the effect of increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

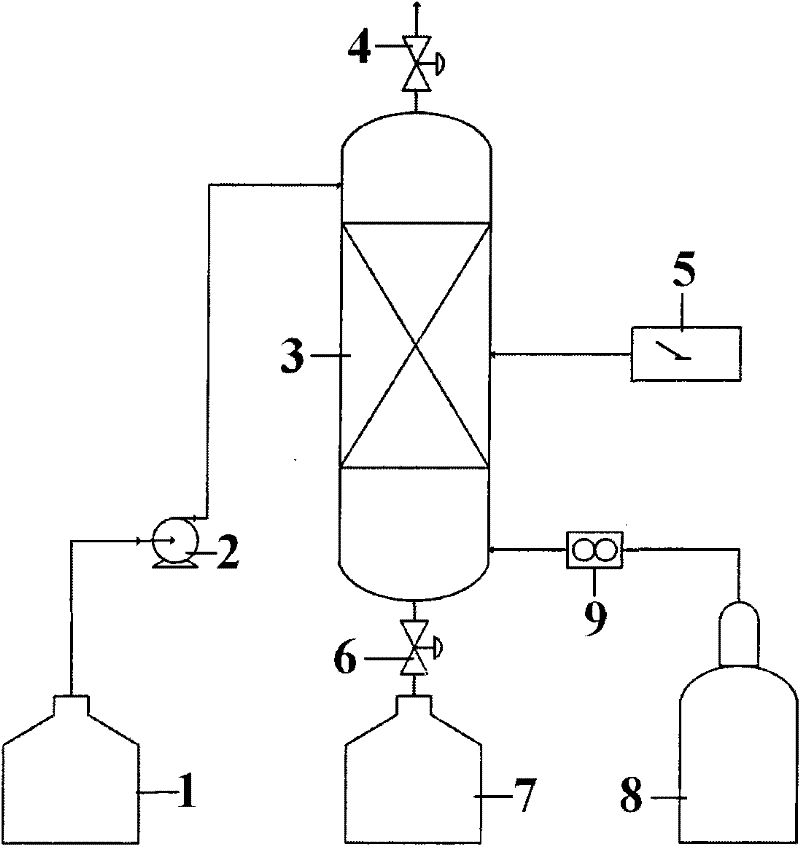

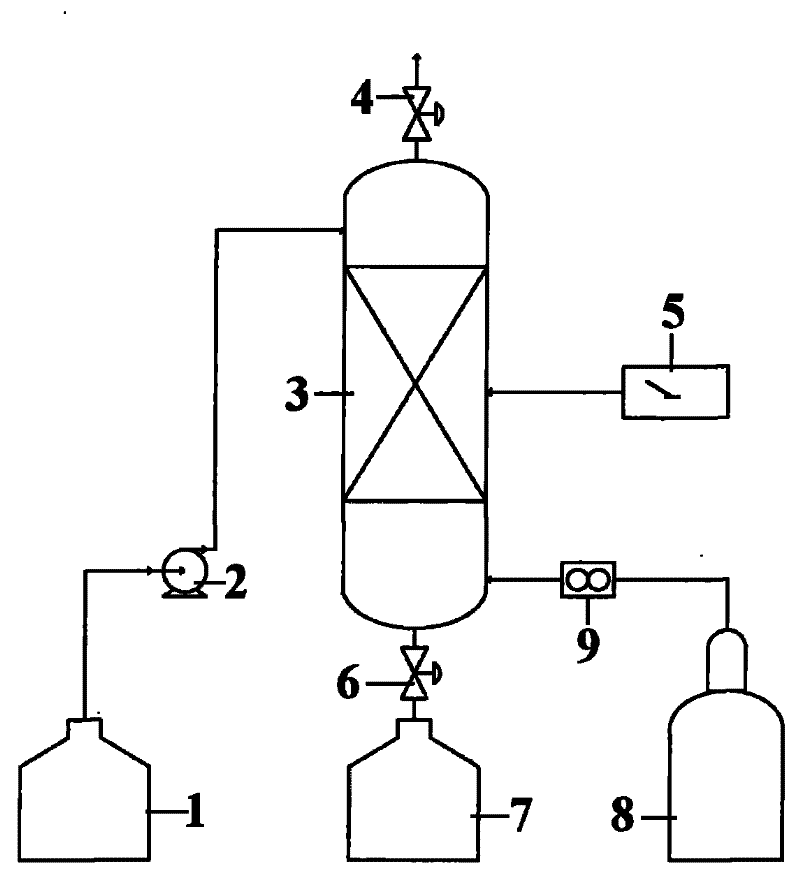

[0042] First, the purification tower (such as figure 1 Shown) heating up to 90°C, 100°C, 110°C respectively, and the composition is converted into H through the liquid flow control pump 2 SO 4 +0.1HI+4H 2 O (ie molar ratio H 2 SO 4 :HI:H 2 (0=1: 0.1: 4) the sulfuric acid phase, imports from the feed inlet on the upper part of the purification tower, and the control sulfuric acid phase liquid flow rate is 183g / h, simultaneously will be mixed gas by nitrogen oxygen (molar ratio 0 2 :N 2 =1:20) the active purge gas that forms is passed into from the gas inlet of purification tower bottom, and purge gas flow rate is 11.8L / h, and the molar flow rate of oxygen in the active purge gas and the molar flow rate ratio of impurity acid HI this moment The ratio is 1:4, the sulfuric acid phase flows through the temperature-controlled purification tower under the purging of the active purge gas, a small amount of hydroiodic acid in the sulfuric acid phase and the oxygen in the active p...

Embodiment 2

[0044] First, the purification tower (such as figure 1 Shown) heated up to 200 ° C, through the liquid flow control pump to convert the composition into H 2 SO 4 +0.15HI+0.03I 2 +5H 2 O (ie molar ratio H 2 SO 4 :HI:I 2 :H 2 (0=1: 0.15: 0.03: 5) sulfuric acid phase, input from the upper feed port of the purification tower, the control sulfuric acid phase liquid flow velocity is 215g / h, simultaneously will be mixed gas by oxygen argon (molar ratio 0 2 : Ar=50: 1) the active purge gas that forms is passed into from the gas inlet of purification tower lower part, and purge gas flow rate is 6.9L / h, and the molar flow of oxygen in the active purge gas and the mole flow rate of impurity acid HI this moment The flow ratio is 2:1, the sulfuric acid phase flows through the temperature-controlled purification tower under the condition of purging the active purge gas, and is purified, and the purified liquid flows out from the liquid outlet at the lower end of the purification towe...

Embodiment 3

[0046] First, the purification tower (such as figure 1 Shown) heated to 80 ℃, through the liquid flow control pump to form H 2 SO 4 +0.05HI+4H 2 O (ie molar ratio H 2 SO 4 :HI:H 2 (0=1: 0.05: 4) sulfuric acid phase, input from the upper feed port of the purification tower, the control sulfuric acid phase liquid flow velocity is 177g / h, simultaneously will be by nitrogen oxygen mixed gas (mol ratio 0 2 :N 2 =1:50) the active purge gas that forms is passed into from the gas inlet of purification tower lower part, and purge gas flow velocity is 28.6L / h, and the molar flow rate of oxygen in the active purge gas and the molar flow rate ratio of impurity acid HI this moment The ratio is 1:2, the sulfuric acid phase flows through the temperature-controlled purification tower under the condition of purging the active purge gas, that is, it is purified, and the purified liquid flows out from the liquid outlet at the lower end of the purification tower. The gas after the purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com