Iodine-sulfur cycle for nuclear hydrogen production with improved thermo-chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

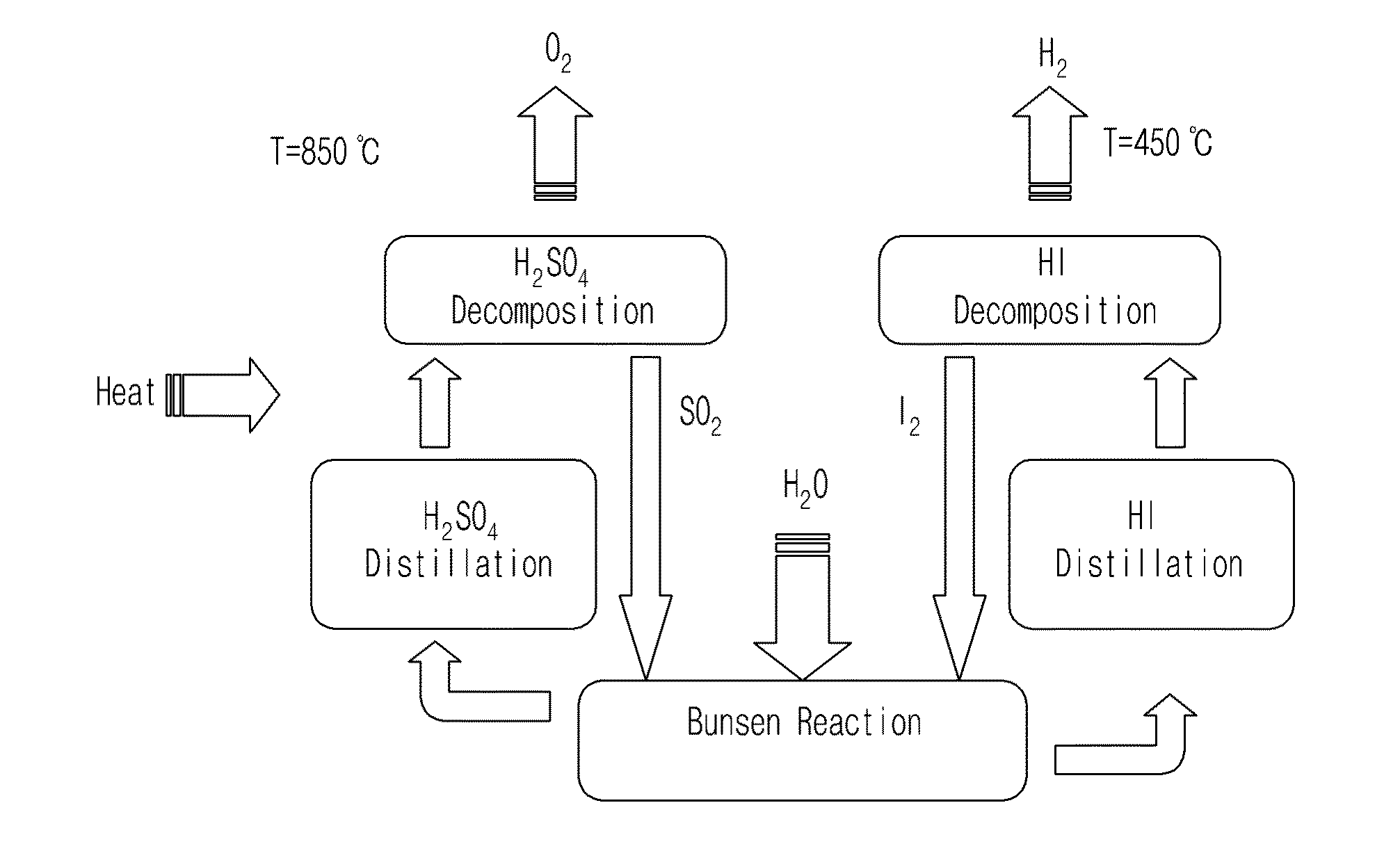

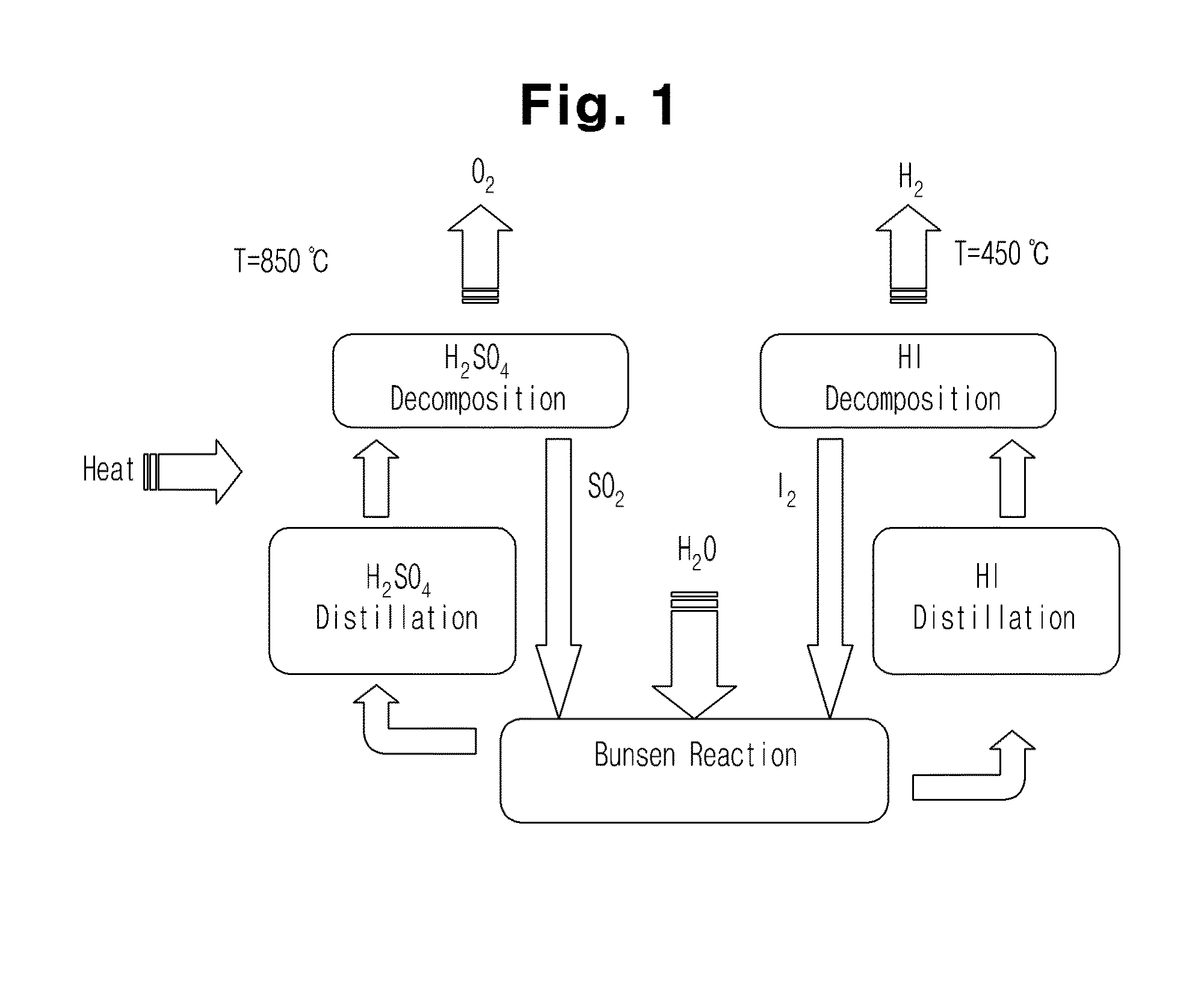

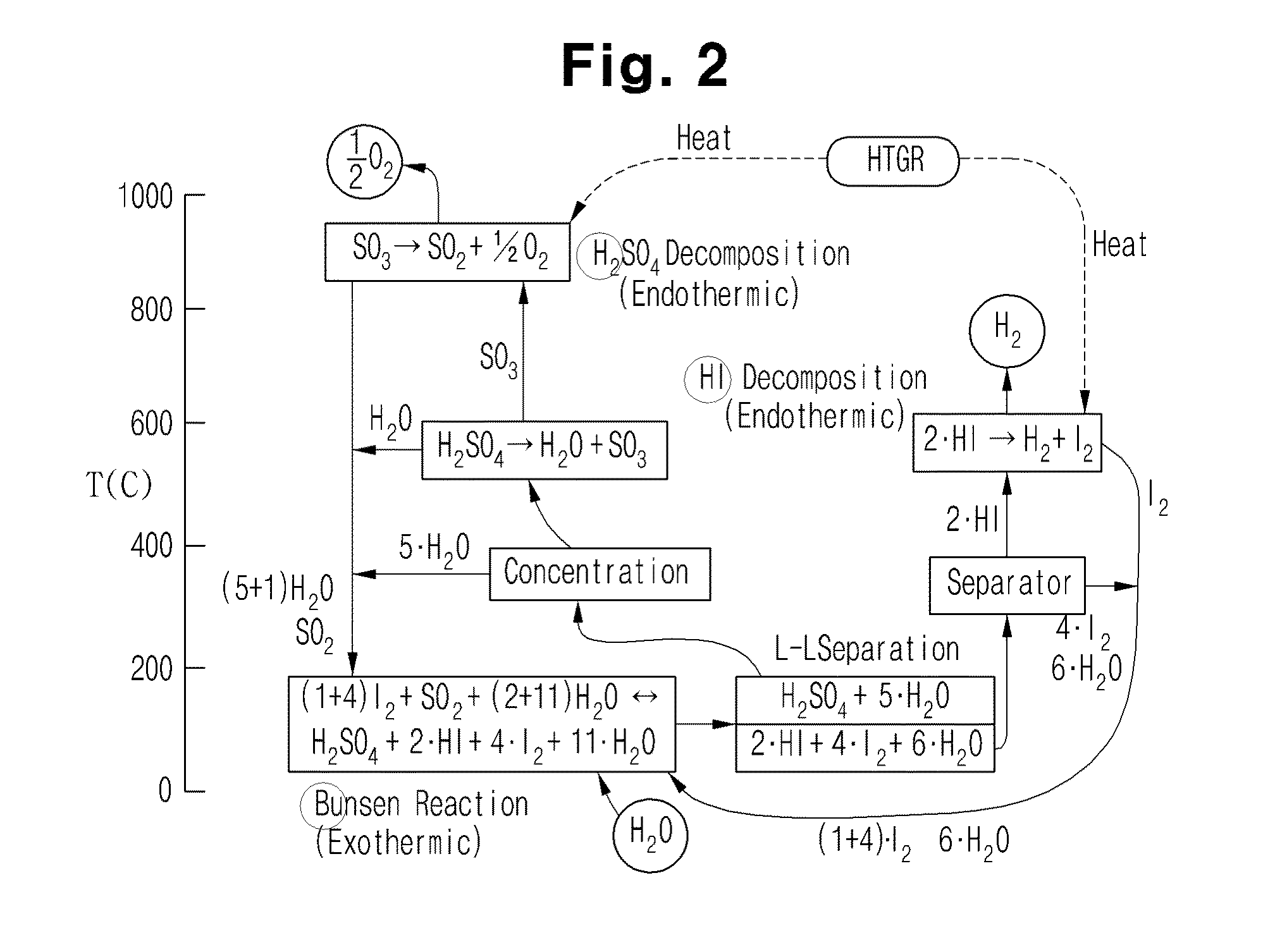

[0034]Hereinafter, certain embodiments of the present invention will be described in detail with reference to the attached drawings.

[0035]The present invention provides an iodine-sulfur cycle for nuclear hydrogen production, including a Bunsen reaction process including a liquid-liquid phase separation process, a hydrogen iodide decomposition process and a sulfuric acid decomposition process, wherein sulfur dioxide, iodine, and water, which are reactants necessarily used to conduct the Bunsen reaction process, mix with excess water and excess iodine and then react with each other at an operating temperature of 330˜350K (57˜77° C.) as represented by the following Reaction Formula 1.

(5˜7)·I2+SO2+(13˜15)·H2O[2HI+4·I2+(6˜8)·H2O]+[H2SO4+5·H2O] [Reaction Formula 1]

[0036]In the Reaction Formula 1, based on the composition ratio of reactants at an optimal operating point at which the minimum amount of excess water required to be supplied such that the Bunsen reaction smoothly proceeds in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com