Patents

Literature

39 results about "Bunsen reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

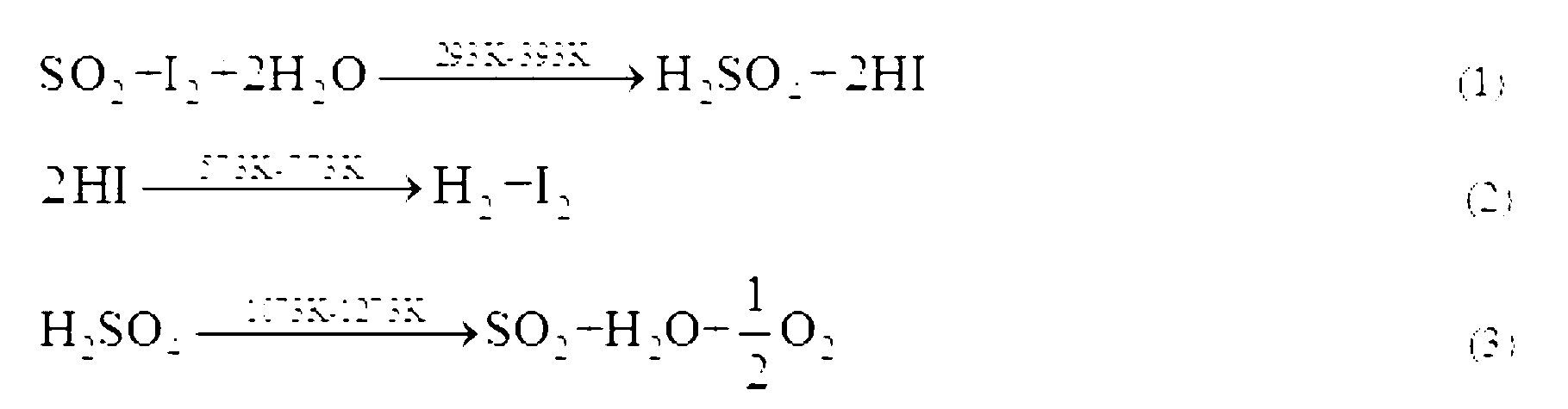

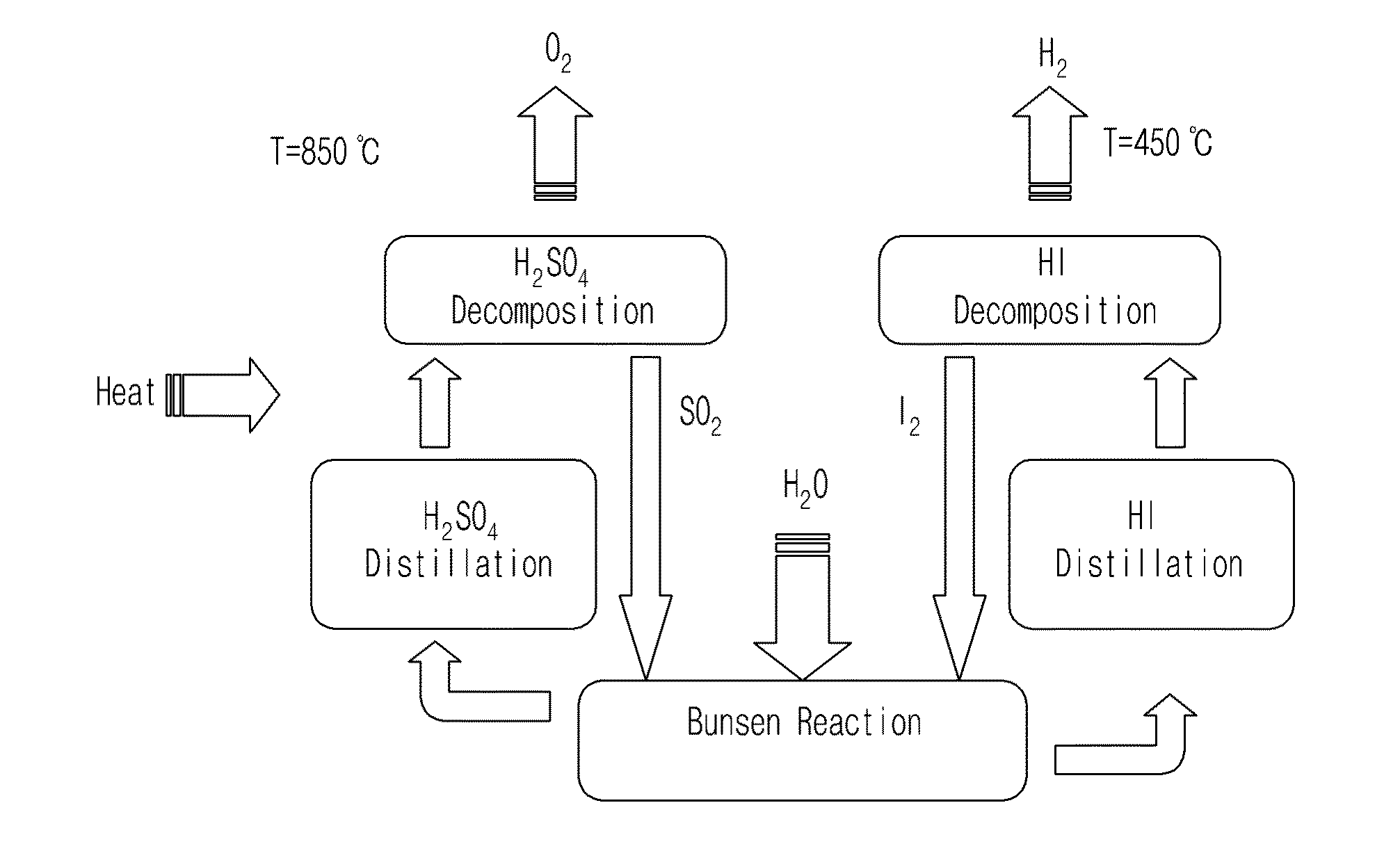

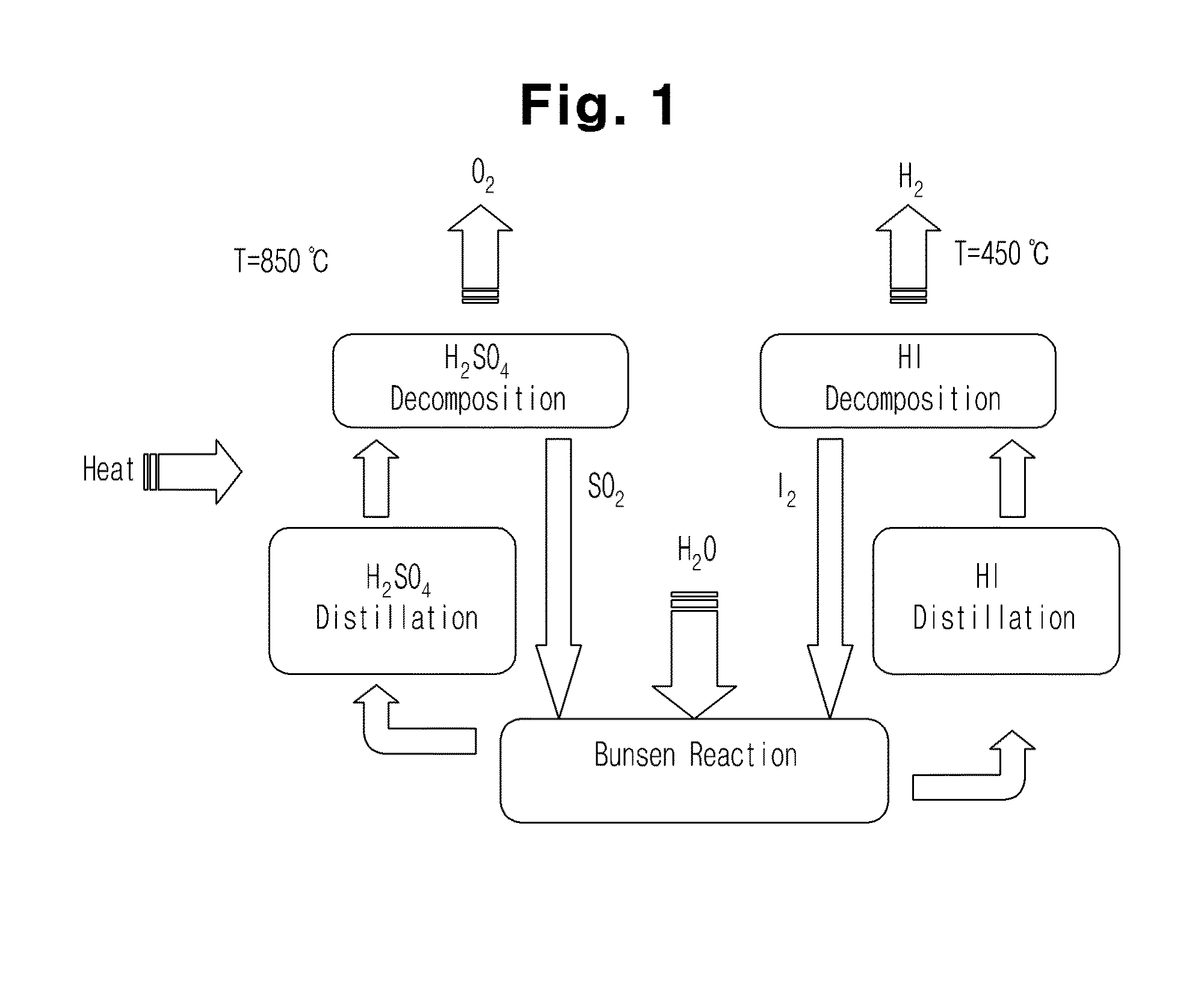

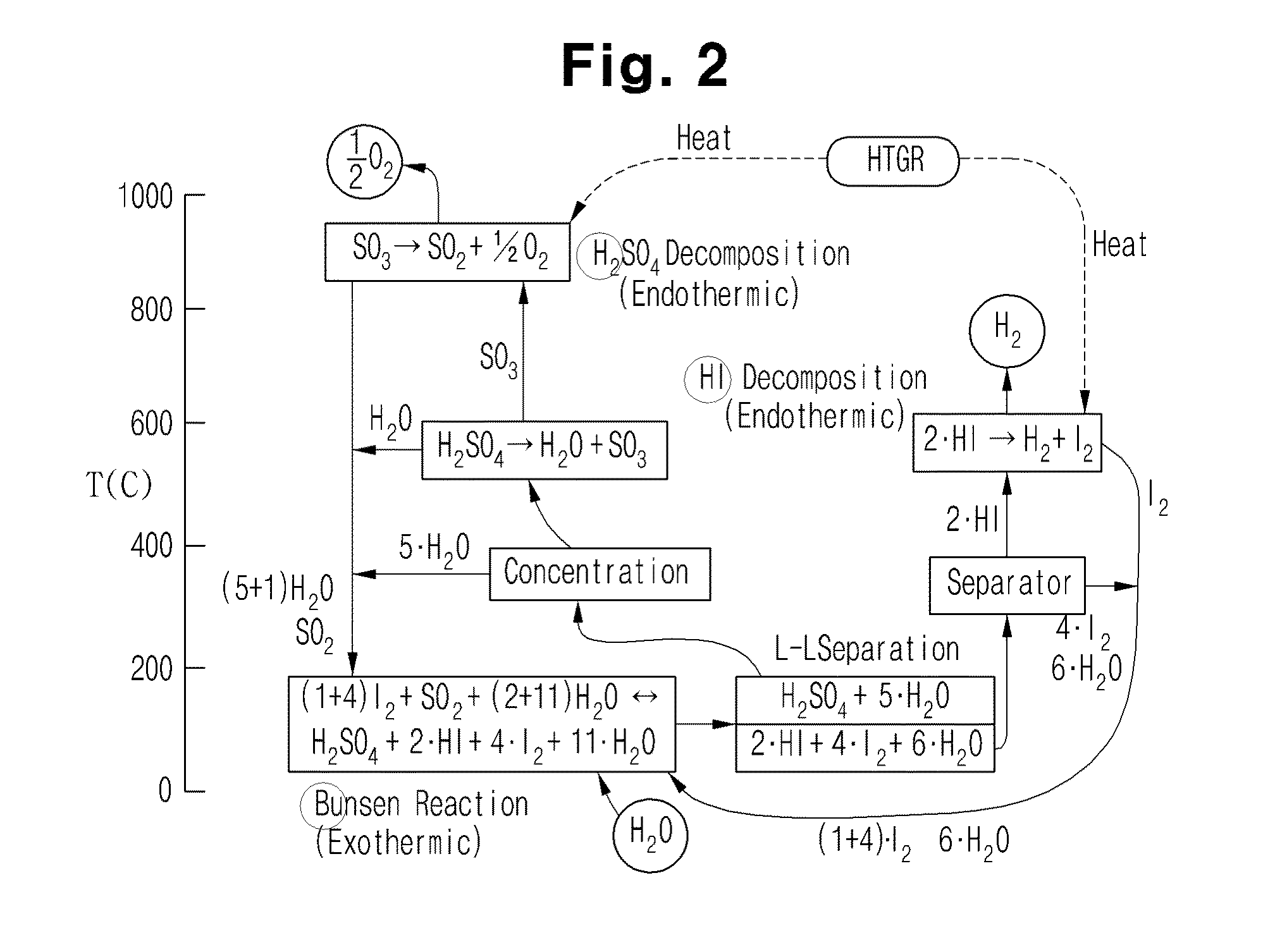

The Bunsen reaction is a chemical reaction that describes water, sulfur dioxide, and iodine reacting to form sulfuric acid and hydrogen iodide...

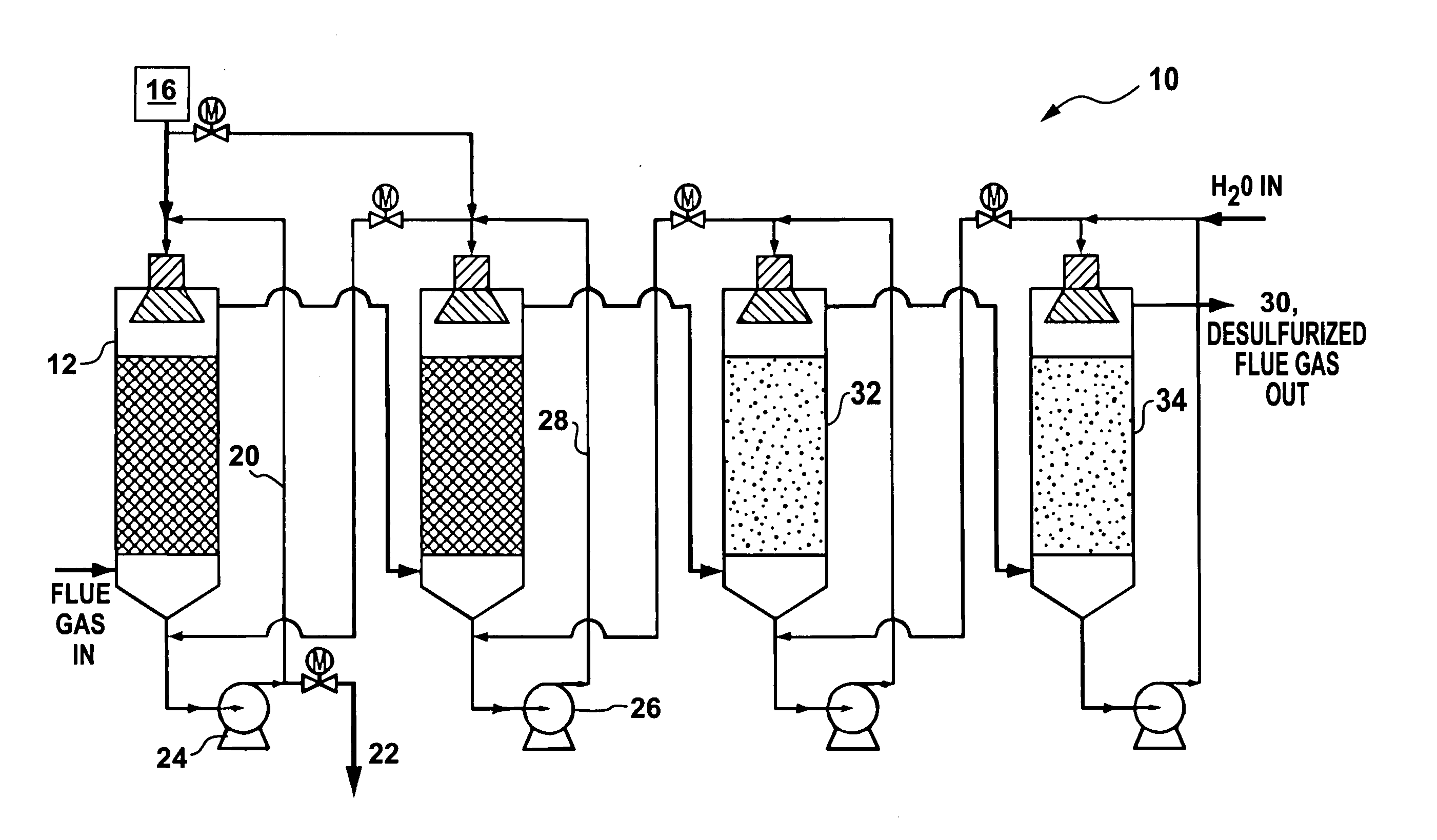

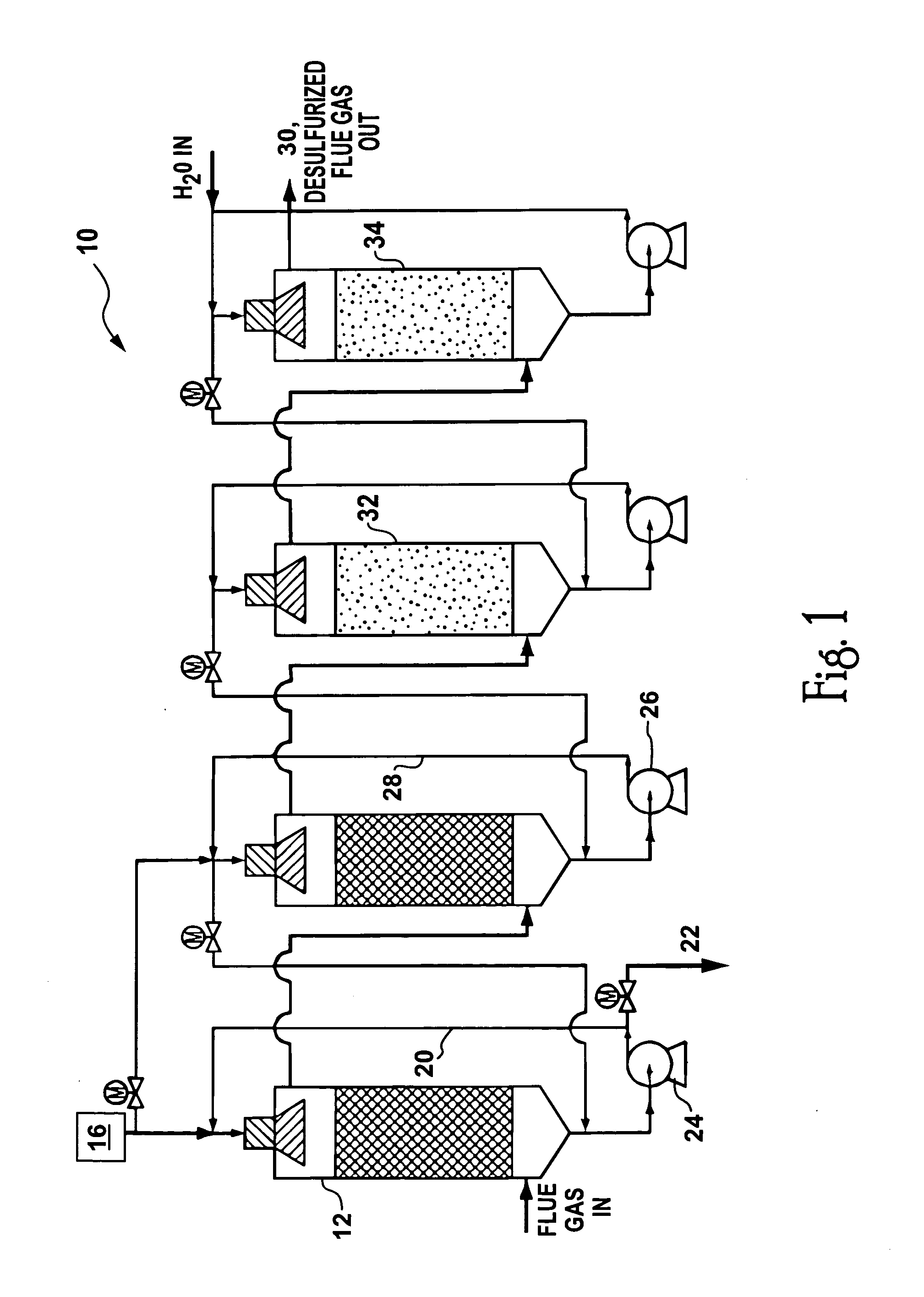

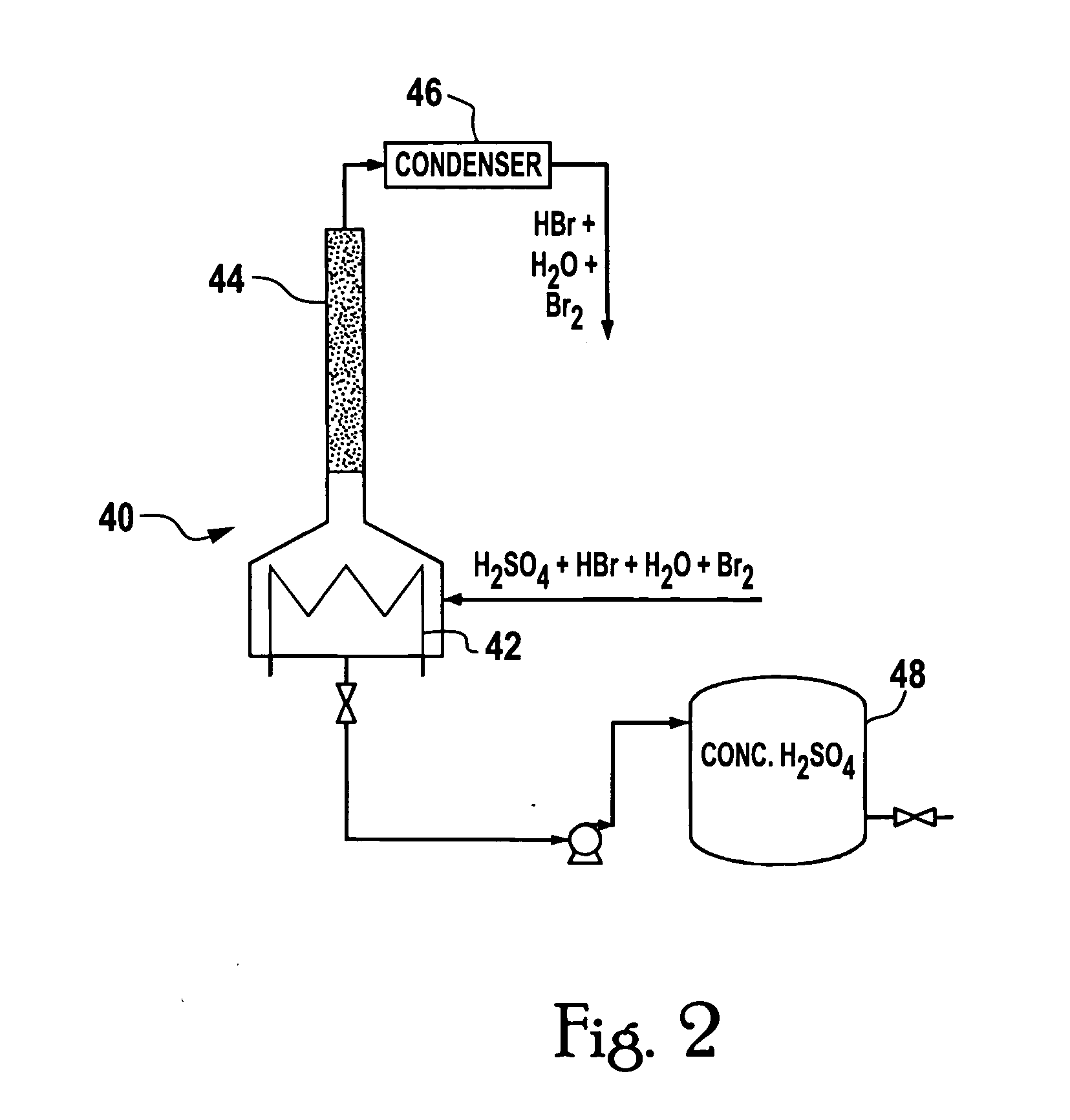

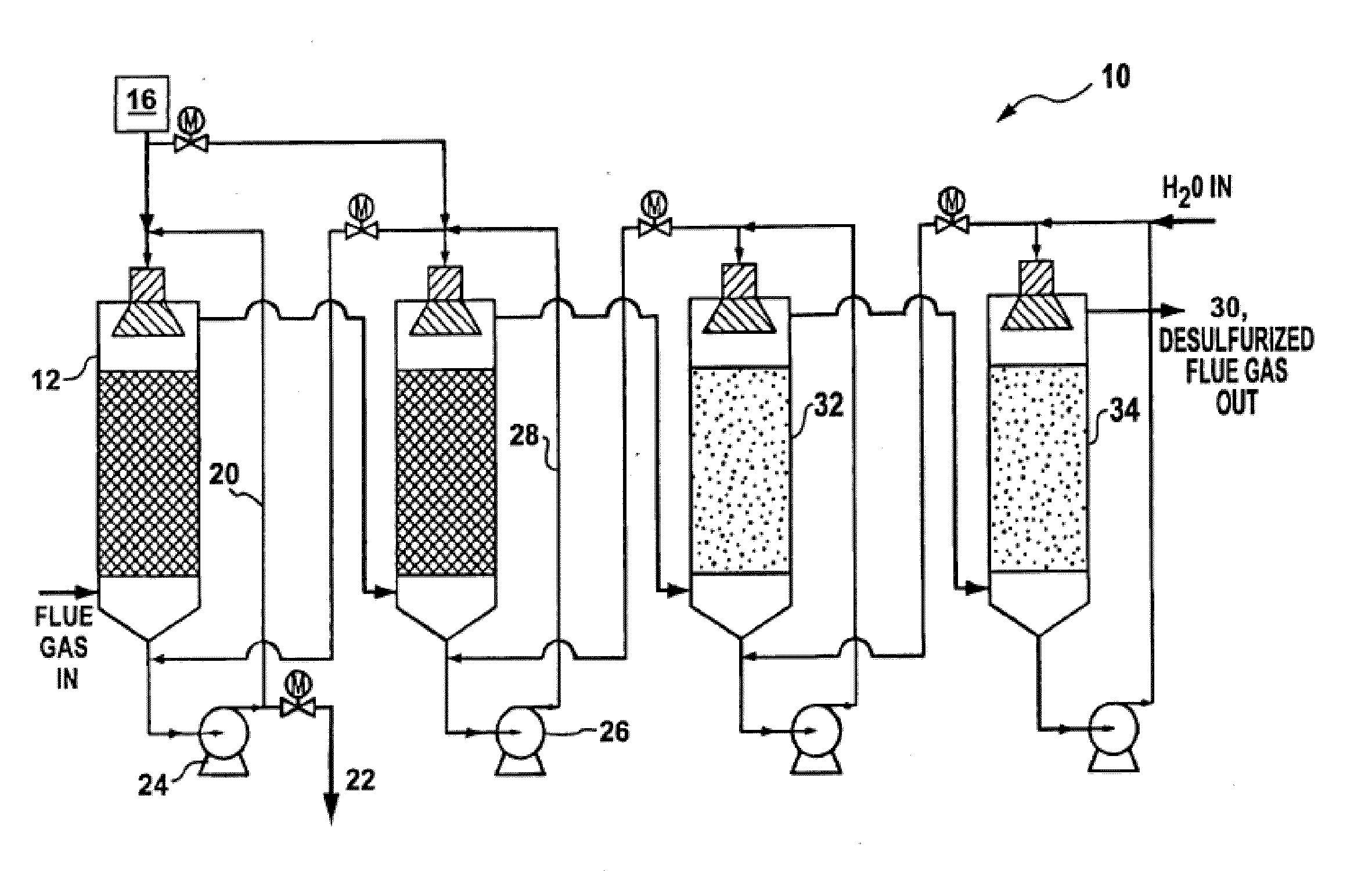

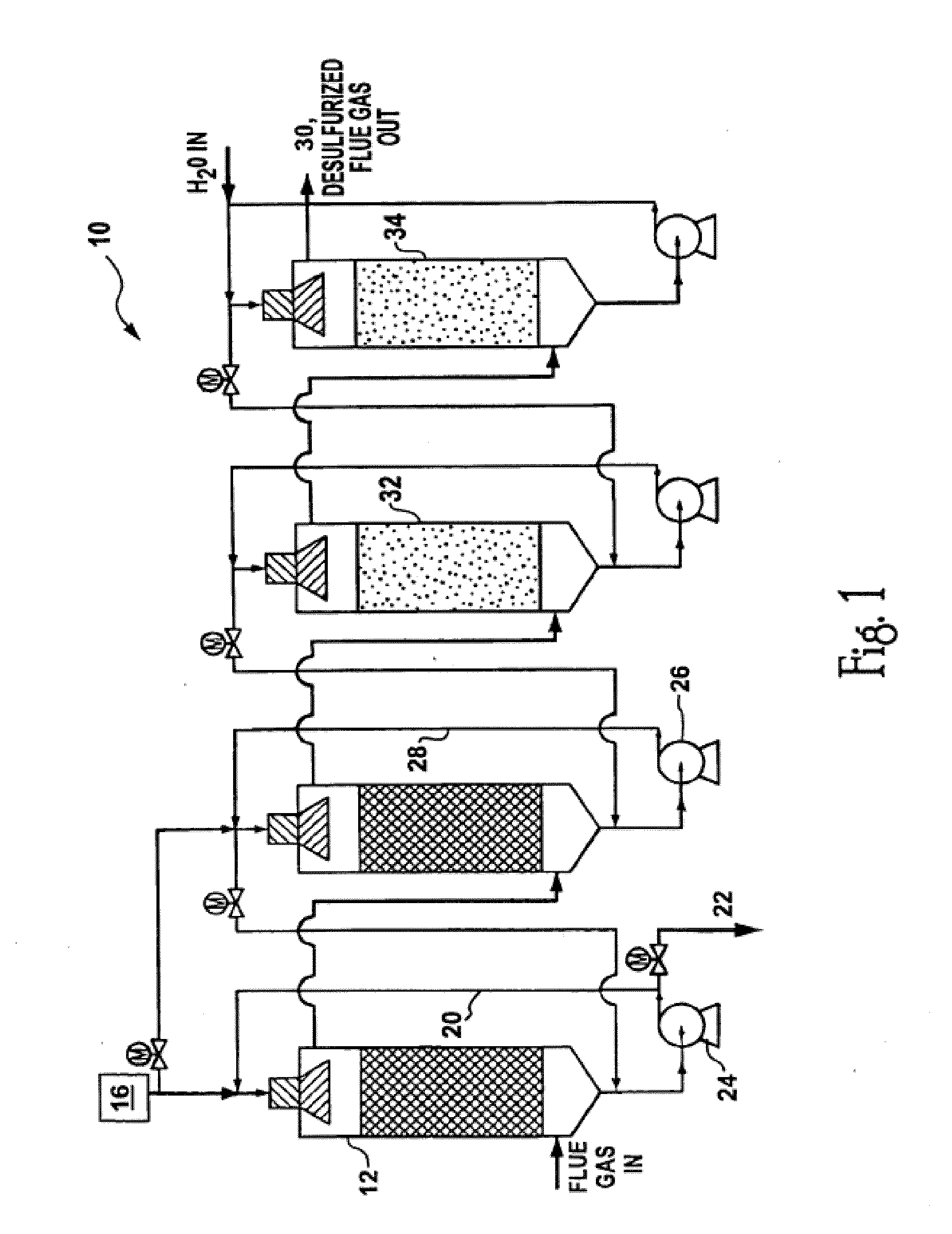

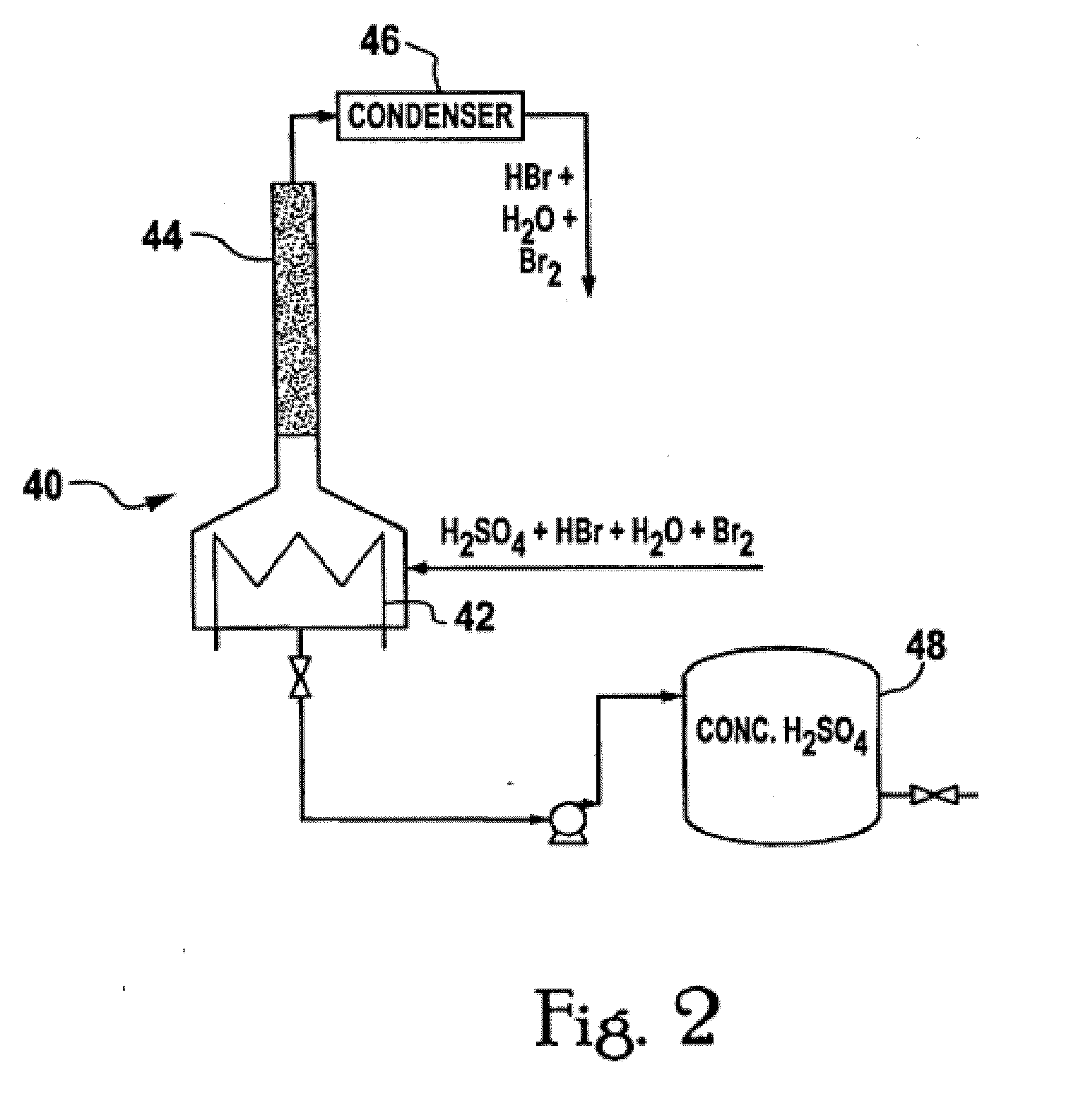

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:SOLAR REACTOR TECH

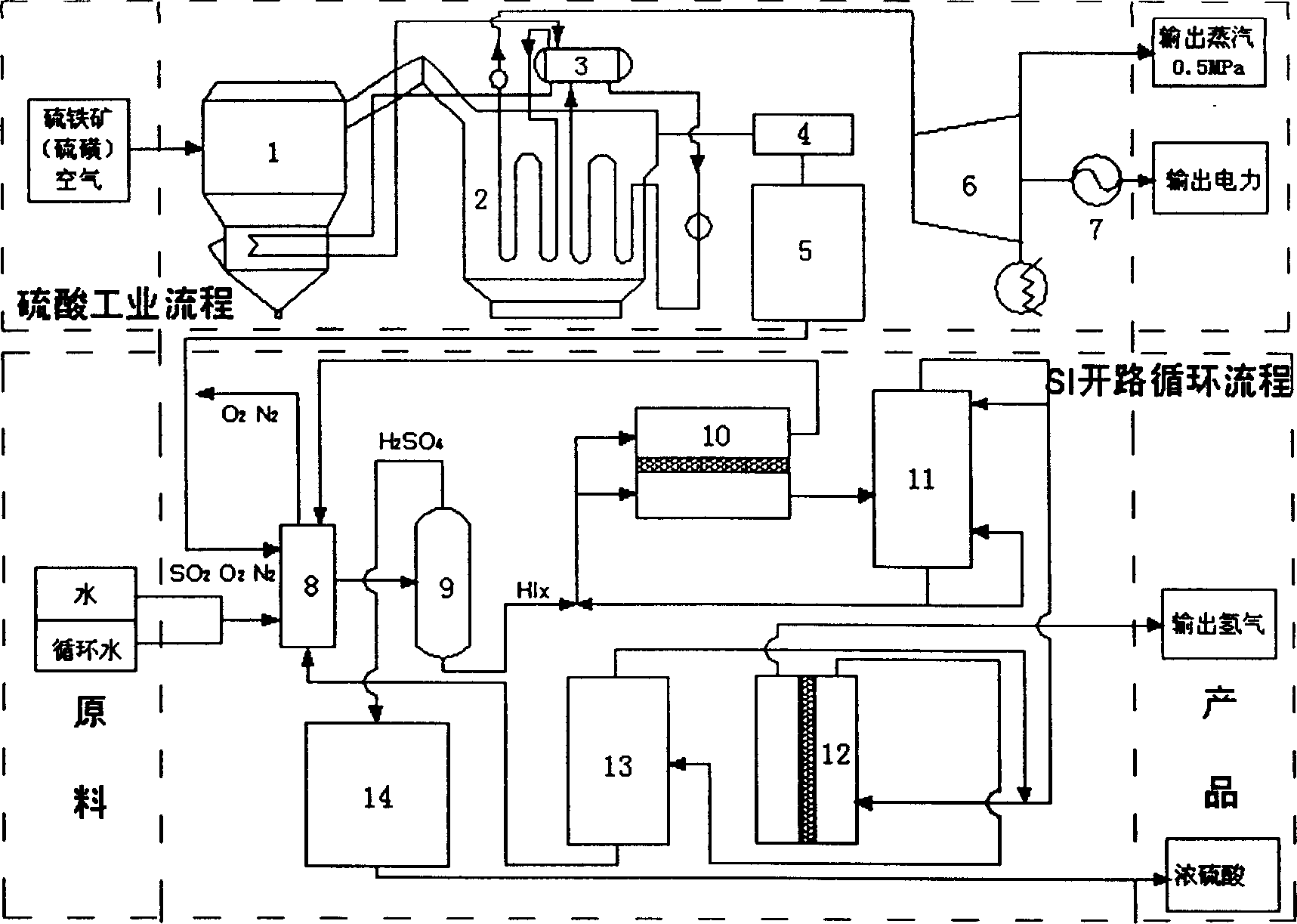

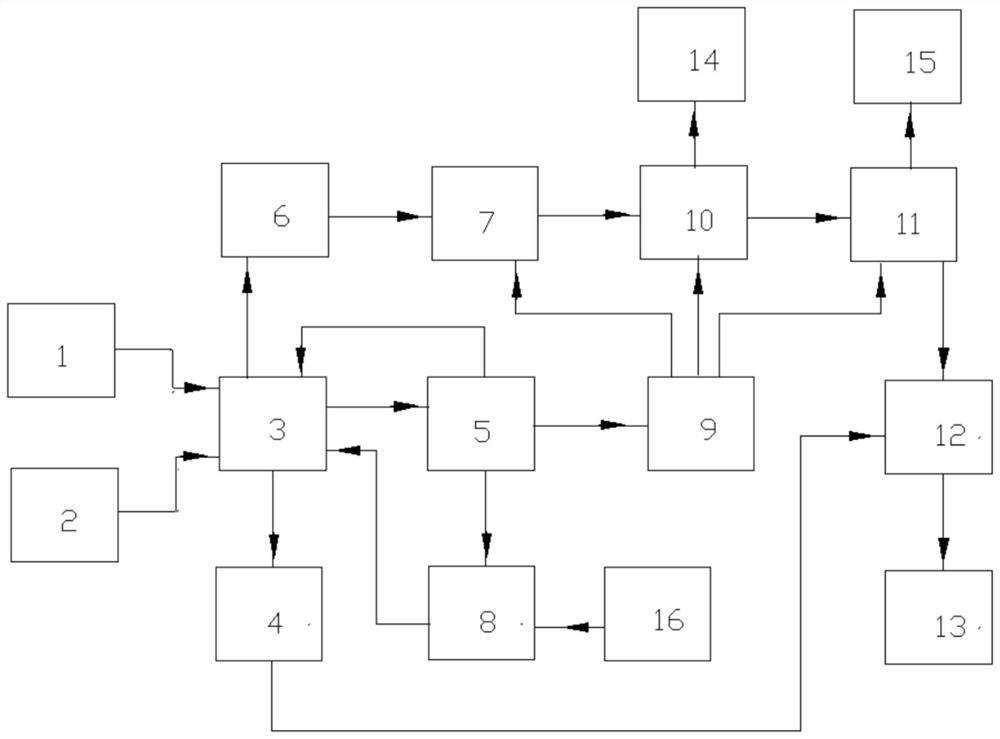

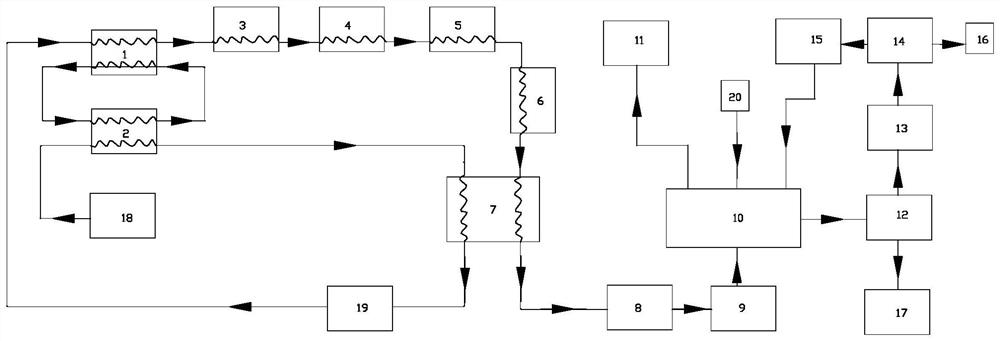

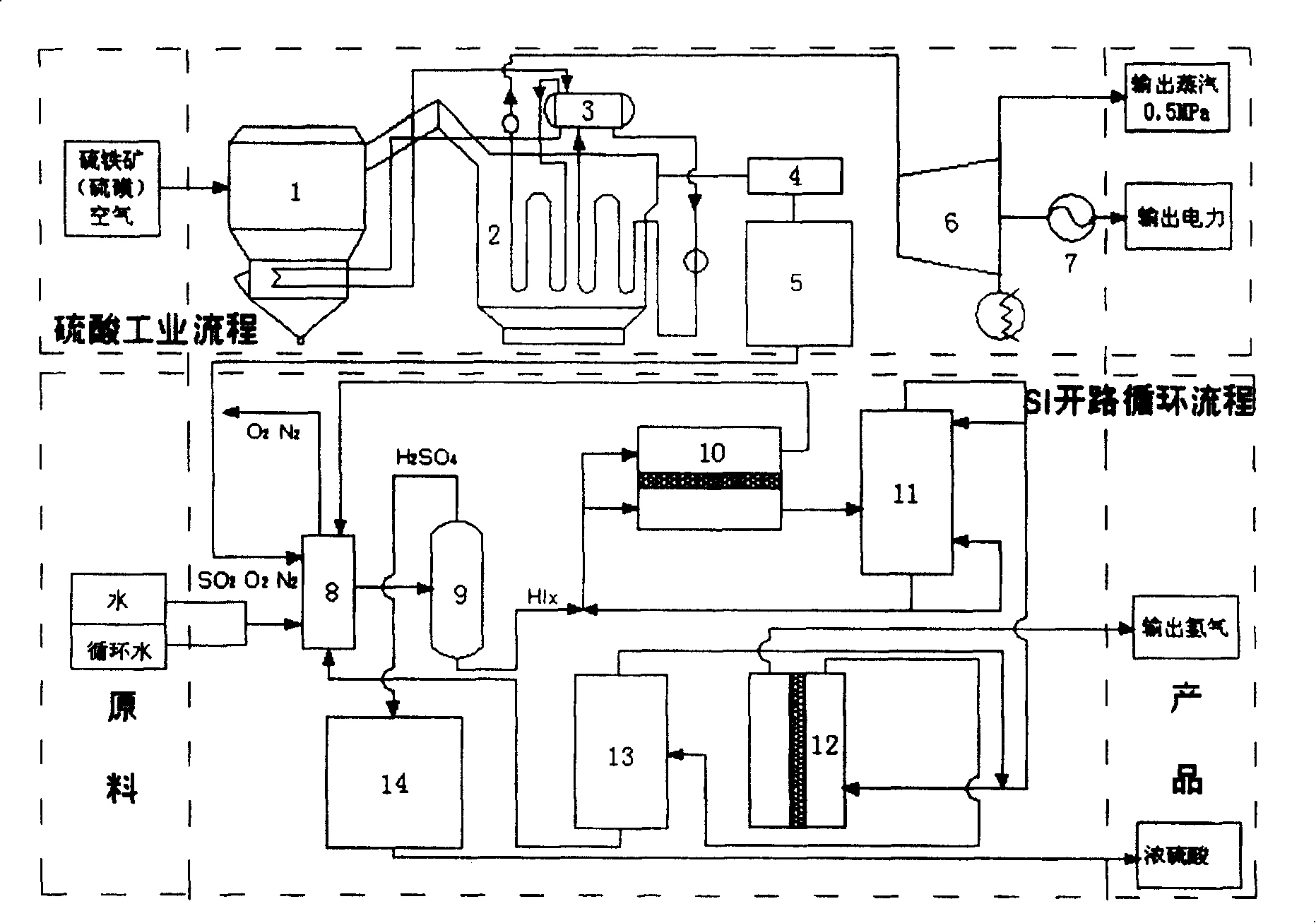

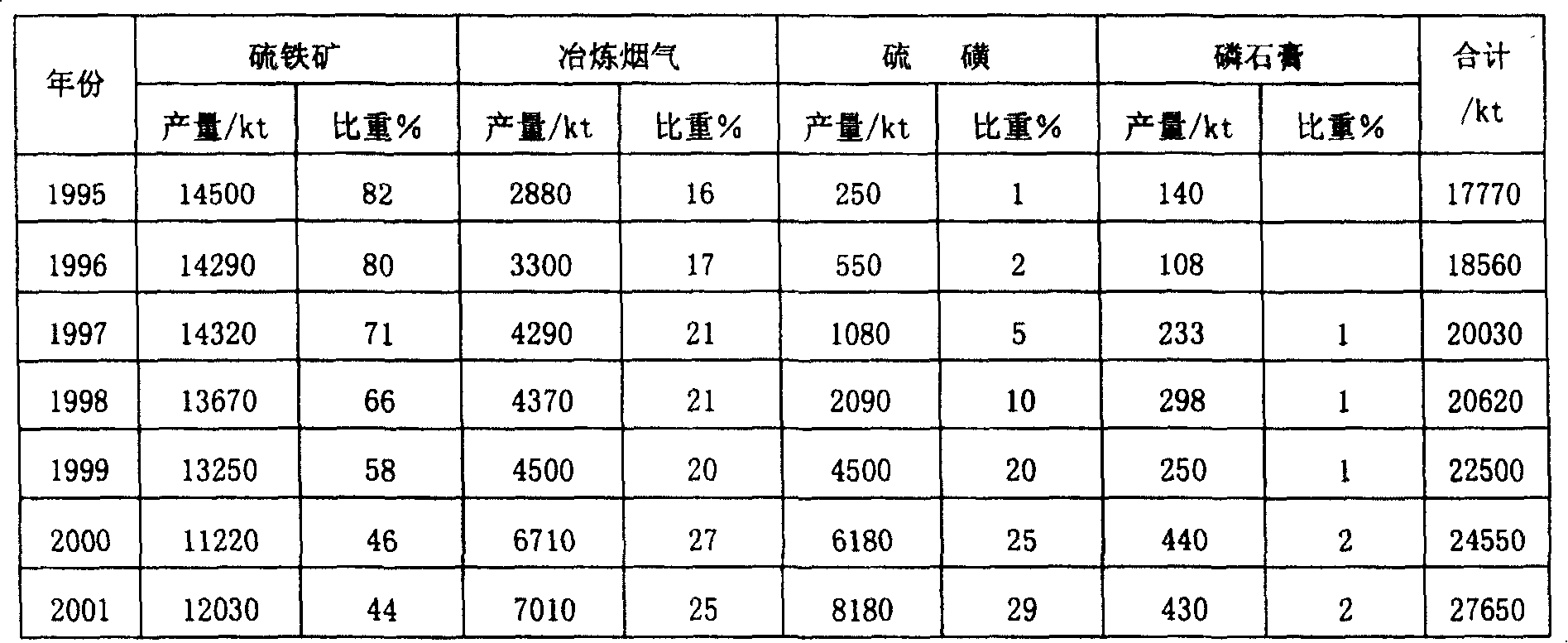

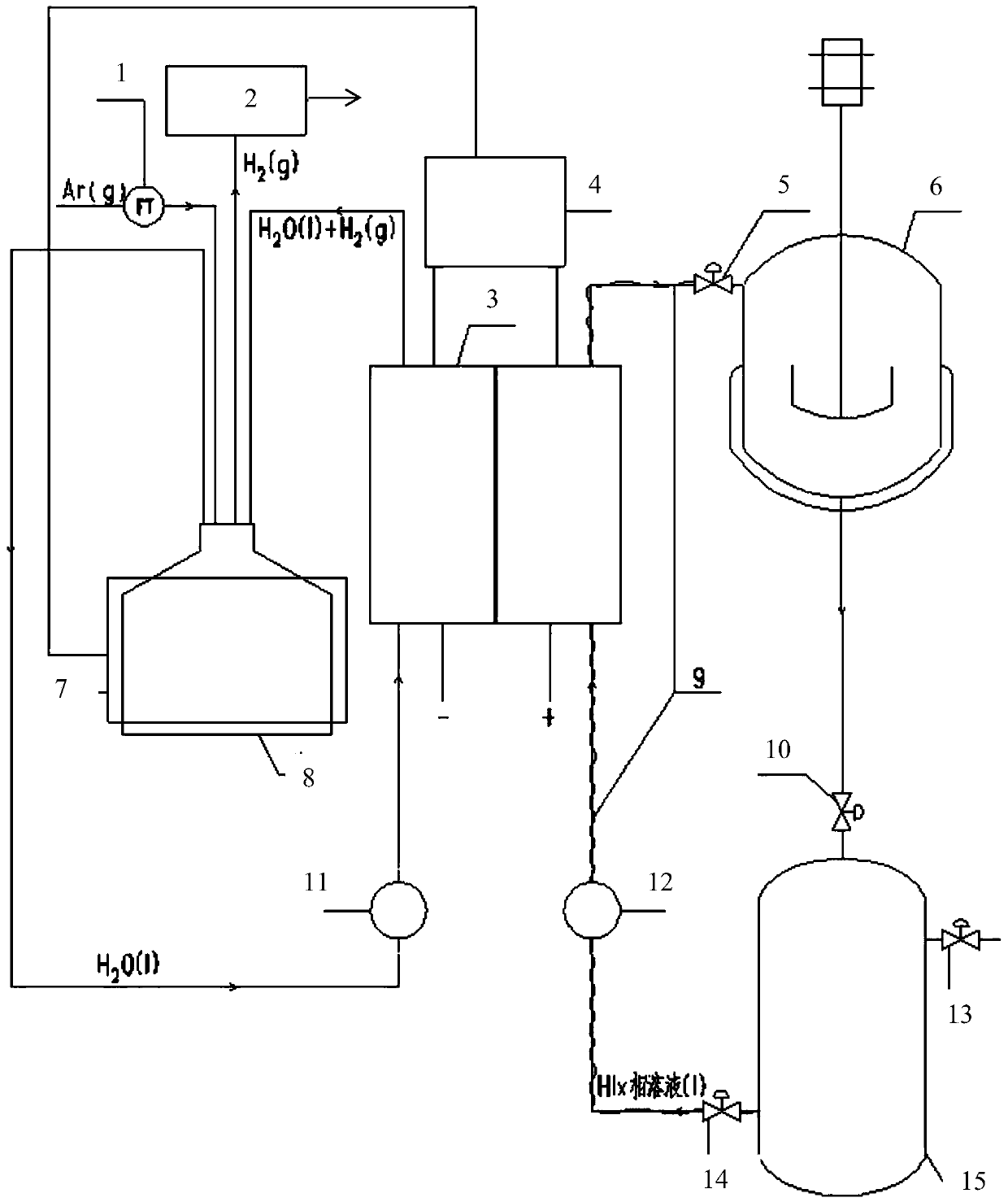

Technical method of sulfur iodine open circuit circulation hydrogen manufacture and its equipment

ActiveCN1785796AReduce the temperatureReduce energy consumptionIodine/hydrogen-iodideSulfur-trioxide/sulfuric-acidIt equipmentHydrogen

The present invention relates to a process for preparing hydrogen gas, and is aimed at providing a technological process capable of combining sulfur-iodine open-circuit circulation and sulfuric aid industry to simultaneously produce hydrogen gas and sulfuric acid and provide electric power and its equipment. Said method includes the following steps: roasting sulfur-bearing mineral, Bunsen reaction, separating HIx phase and H2SO4 phase solution, using electroosmose process to concentrate and purify HIx phase and utilizing HI membrane catalytic decomposition reactor to make decomposition to obtain I2 and find product H2.

Owner:ZHEJIANG UNIV

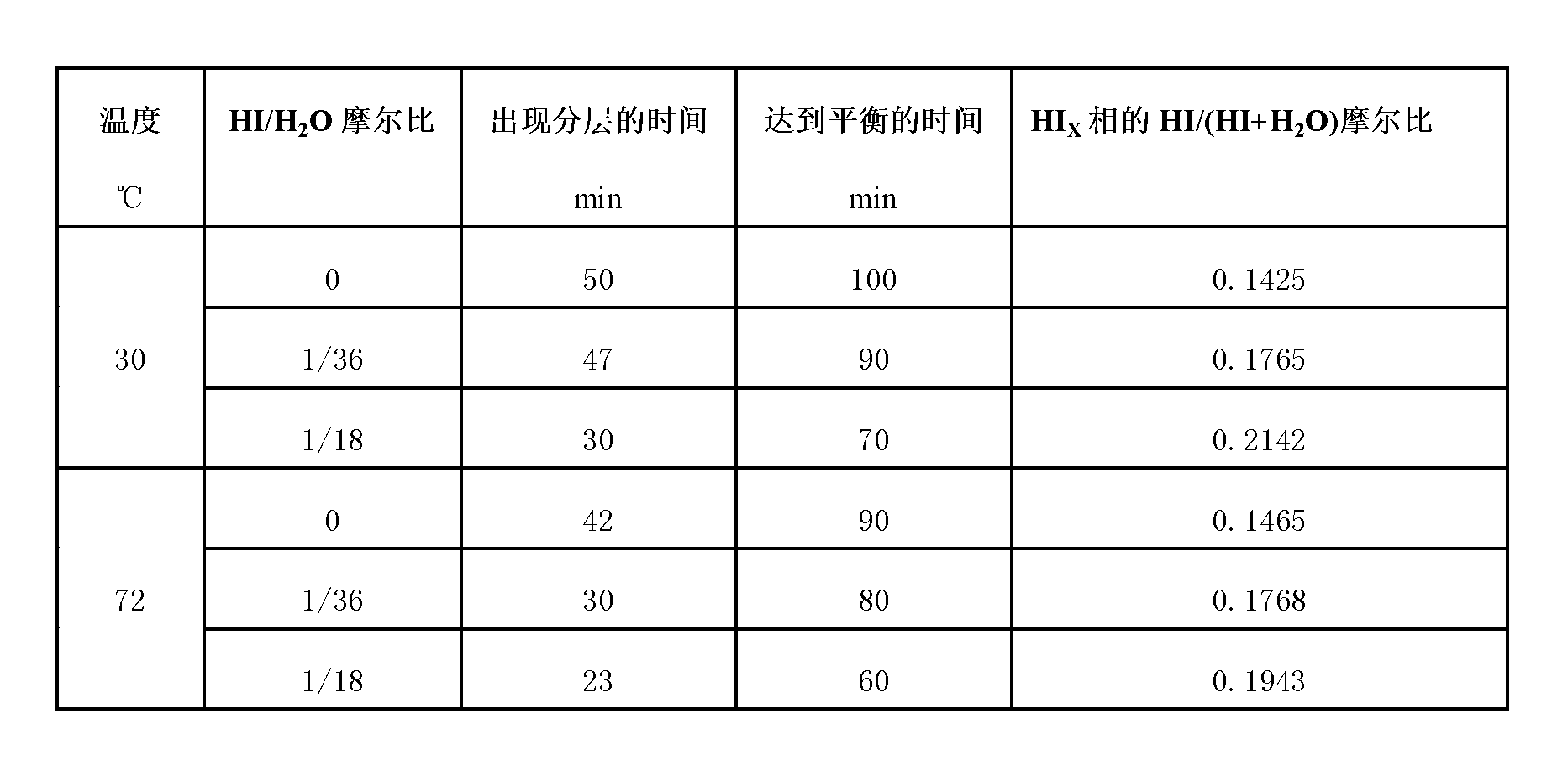

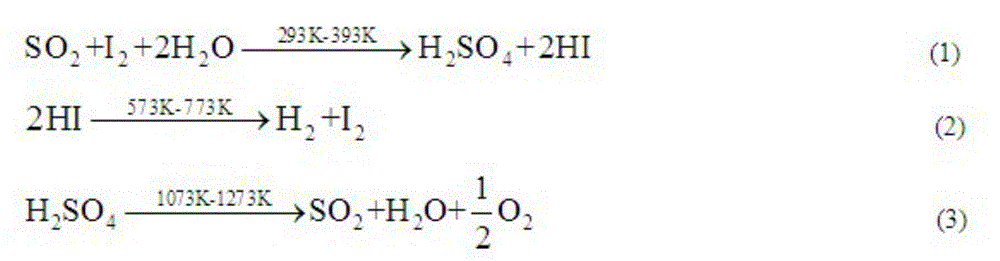

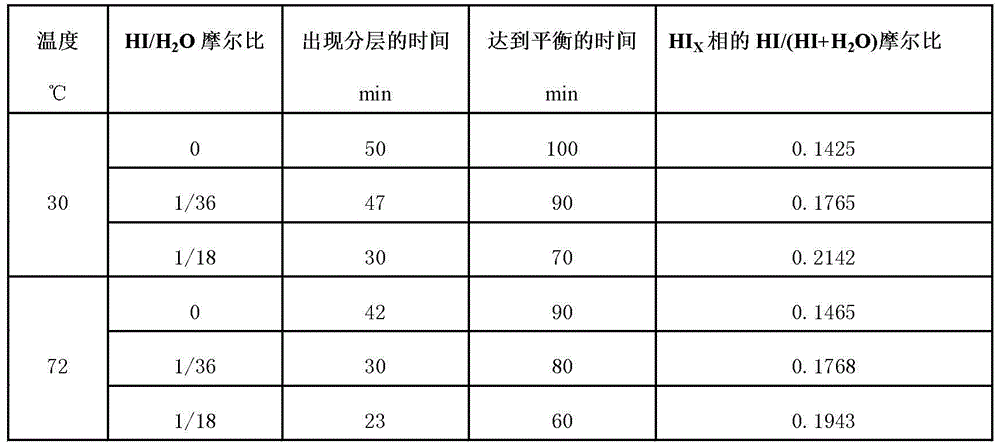

Method for promoting Bunsen reaction in thermochemical iodine-sulfur cycle for hydrogen manufacturing

ActiveCN103213945AOmit the concentration stepIncreased reaction kinetic rateHydrogen productionMass ratioDistillation

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

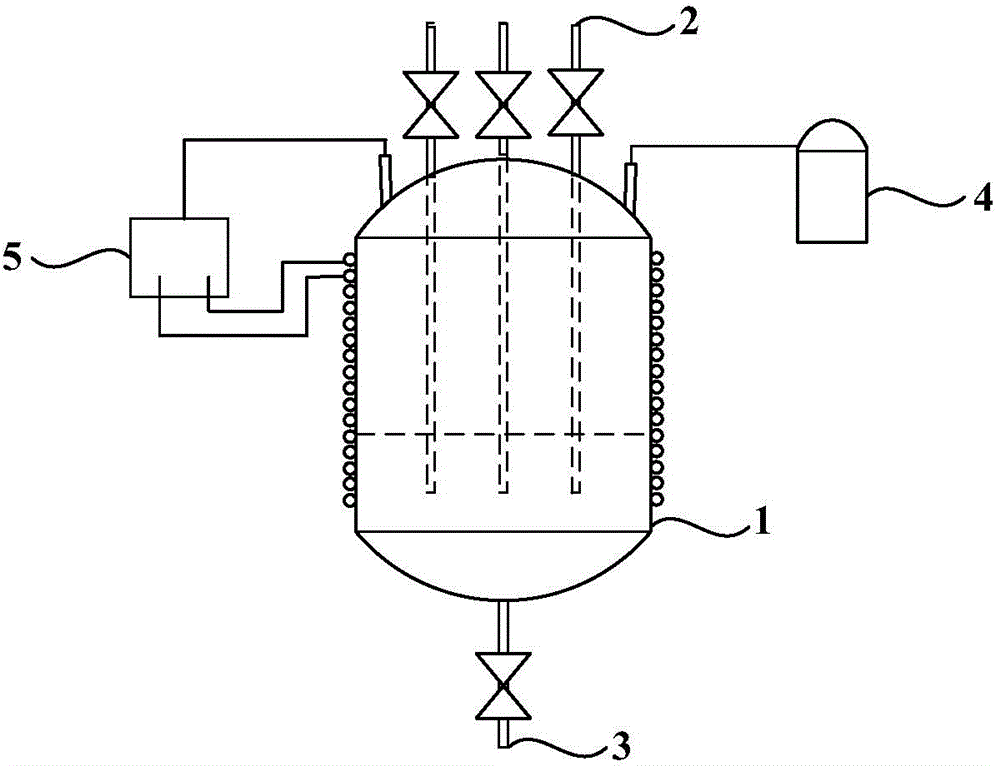

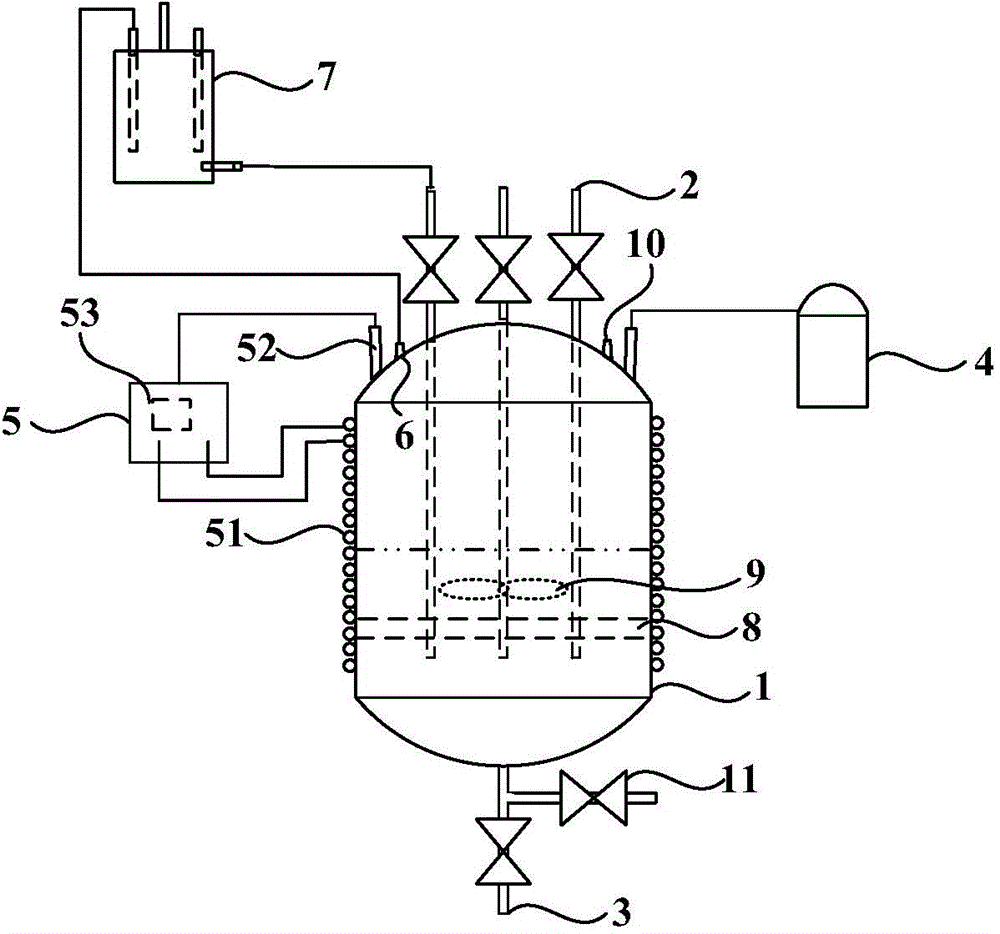

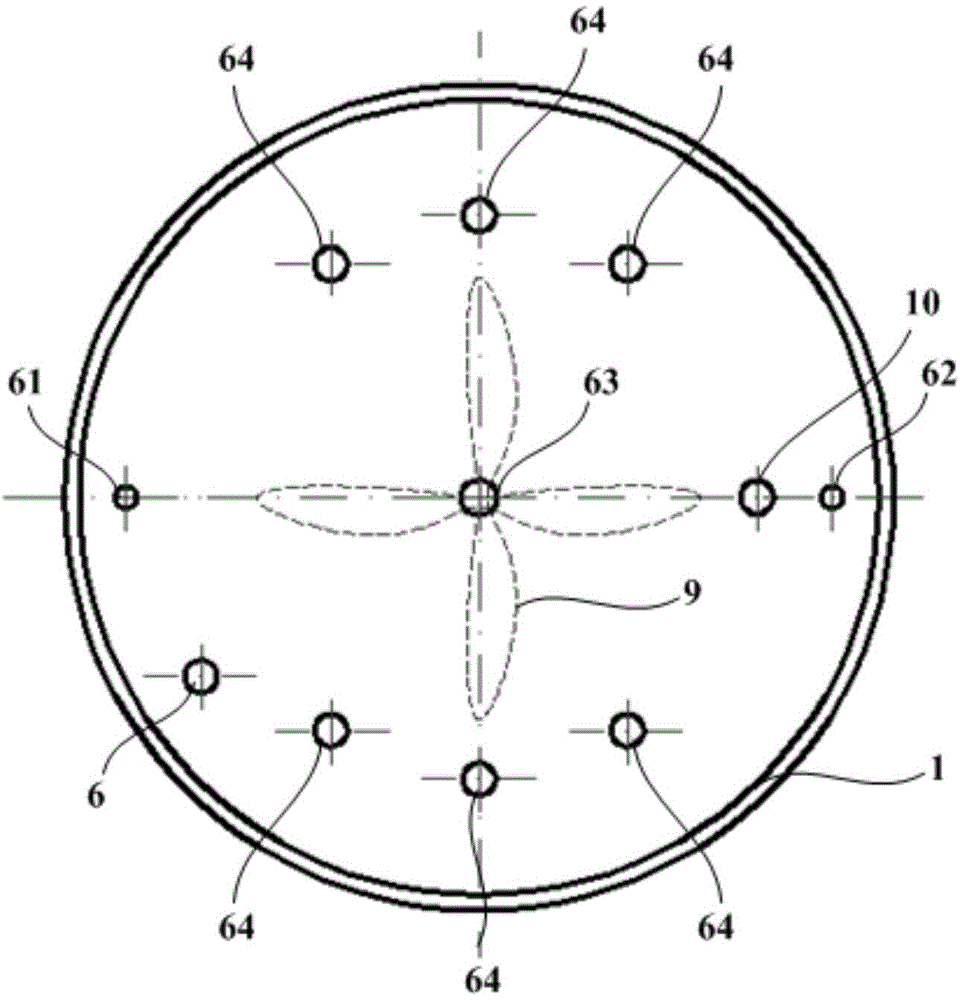

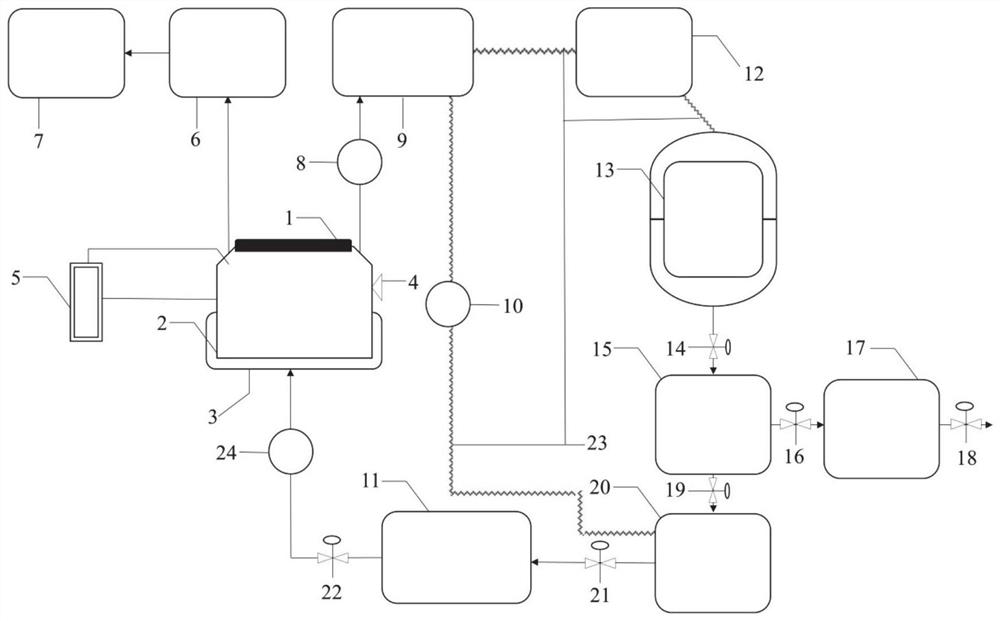

Pre-mixing device for sulfur-iodine cycle hydrogen production system and sulfur-iodine cycle hydrogen production system

InactiveCN104817057AImproving the efficiency of cyclic hydrogen productionJia Bunsen Reaction ConditionsHydrogen productionTemperature controlSulphur iodide

Relating to the technical field of sulfur-iodine cycle hydrogen production, the invention discloses a pre-mixing device for a sulfur-iodine cycle hydrogen production system and the corresponding sulfur-iodine cycle hydrogen production system. The pre-mixing device consists of: a reaction kettle, which is internally provided with a feeding solution prepared in advance; at least one feed pipe, with one end of each feed pipe being located outside the reaction kettle, and the other end being located below the liquid level of the feeding solution, and with the return material of the hydrogen production system entering the reaction kettle through the at least one feed pipe; a discharge pipe that is located at the bottom of the reaction kettle and has a discharge valve, and is connected to a Bunsen reactor of the hydrogen production system; a pressure control apparatus for controlling the pressure in the reaction kettle; and a temperature control apparatus for controlling the temperature in the reaction kettle. With the pre-mixing device provided by the invention, the feeding solution and the return material can be fully mixed to reach a good Bunsen reaction condition, and the efficiency of sulfur-iodine cycle hydrogen production is greatly improved.

Owner:ANKE SMART CITY TECH PRC

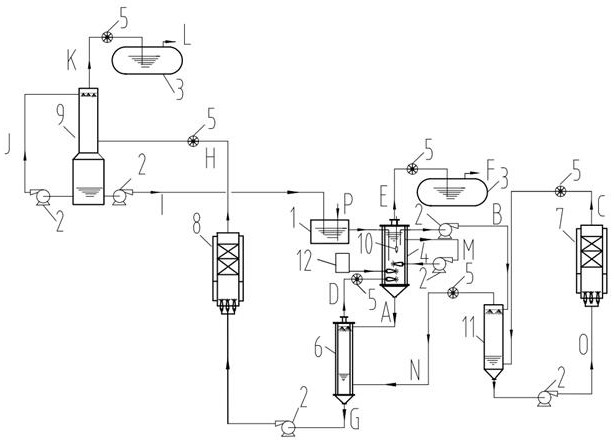

Thermal chemical sulfur-iodine circulating hydrogen production full-process method and device

ActiveCN114195094AWell mixedPrevent precipitationHydrogen productionReactive separationPhysical chemistry

The invention discloses a thermochemical sulfur-iodine circulating hydrogen production whole-process method and device. According to the invention, a Bunsen reaction section is coupled with an HIx and H2SO4 two-phase separation section, and an HIx purification section is coupled with a concentration section. High-temperature mixed gas of the H2SO4 decomposition tower is directly introduced into the H2SO4 concentration tower, and a large amount of water in the H2SO4 solution is quickly vaporized under the condition of no external heat source, so that the purpose of concentrating the H2SO4 solution is achieved; the high-temperature mixed gas continues to enter a downstream HIx purification and concentration tower, a large amount of water in an HIx system is vaporized and taken away, and the purpose of concentrating the HI solution is achieved. H2SO4 mingled in an HIx system is converted into SO2 in an oxygen-enriched environment and is taken away, so that the purpose of purifying the HI solution is achieved. After hydrogen in the condensing tower is separated, the residual iodine-containing liquid is recycled and returns to the Bunsen reaction separation tower, and the investment and the energy consumption can be reduced by more than 40% compared with the traditional sulfur-iodine hydrogen preparation method.

Owner:浙江百能科技有限公司

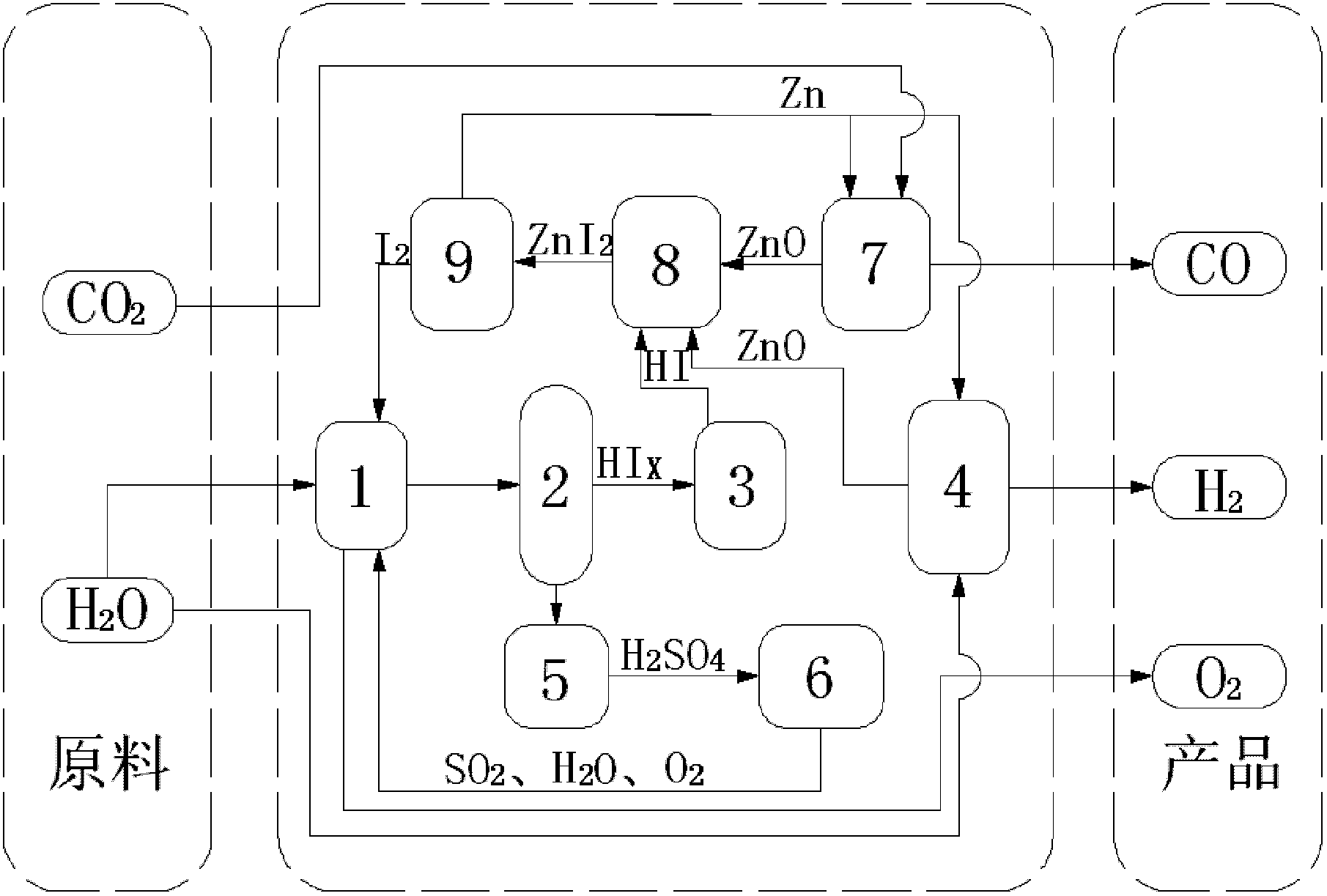

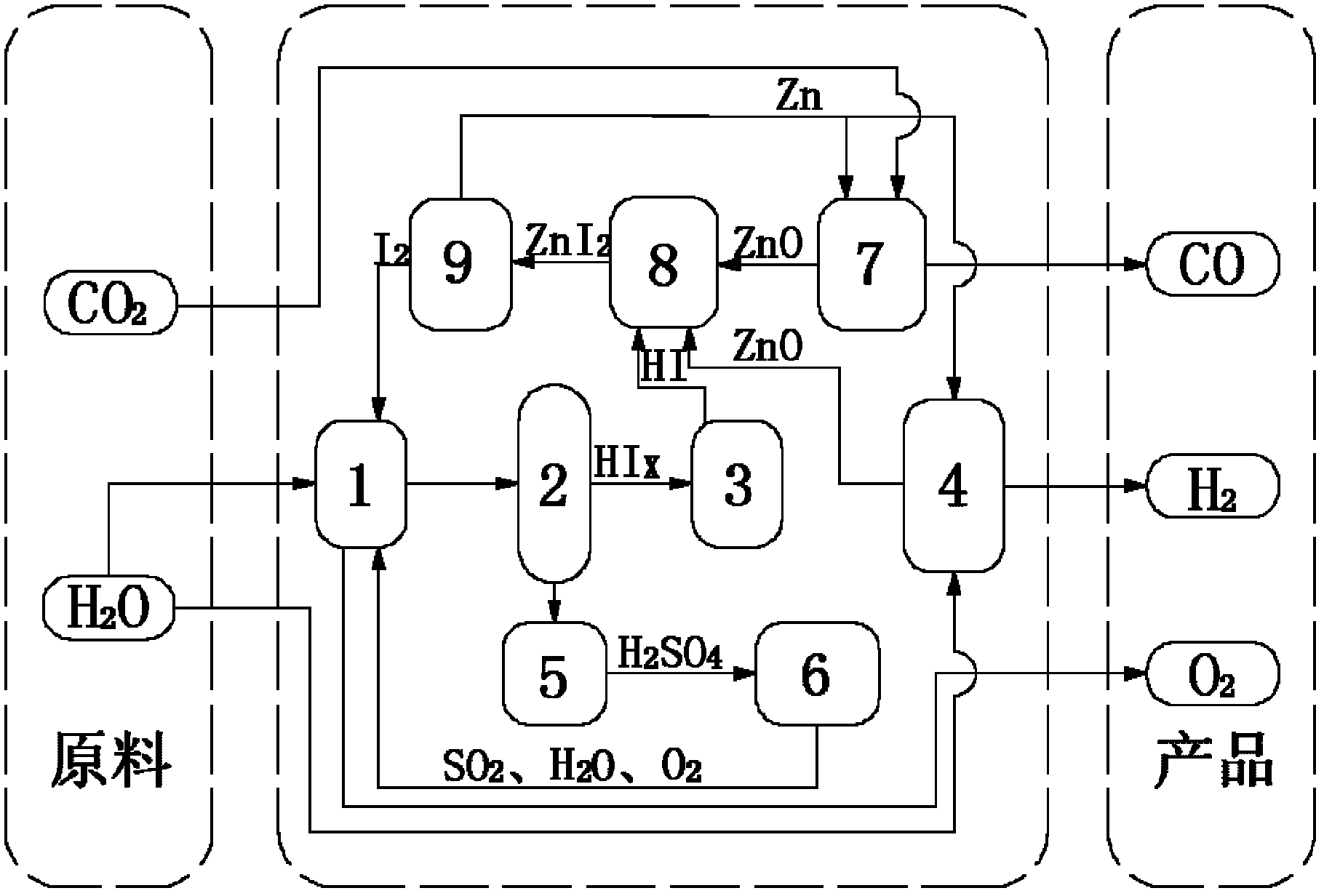

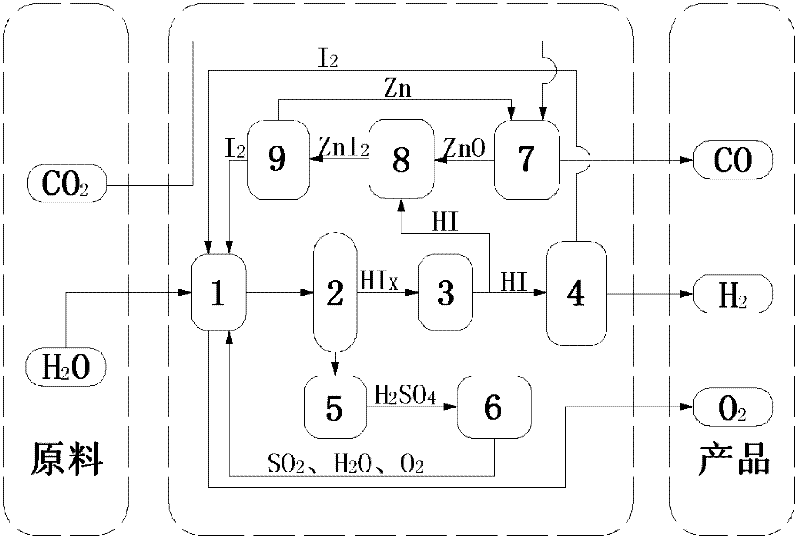

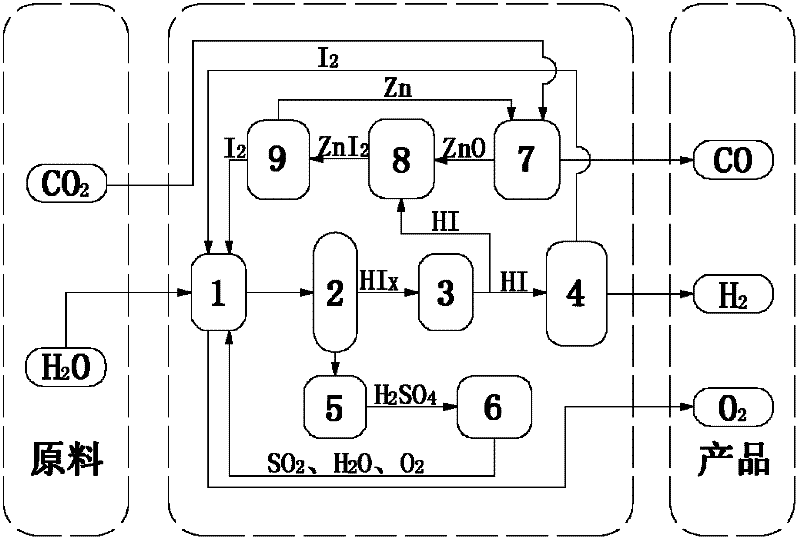

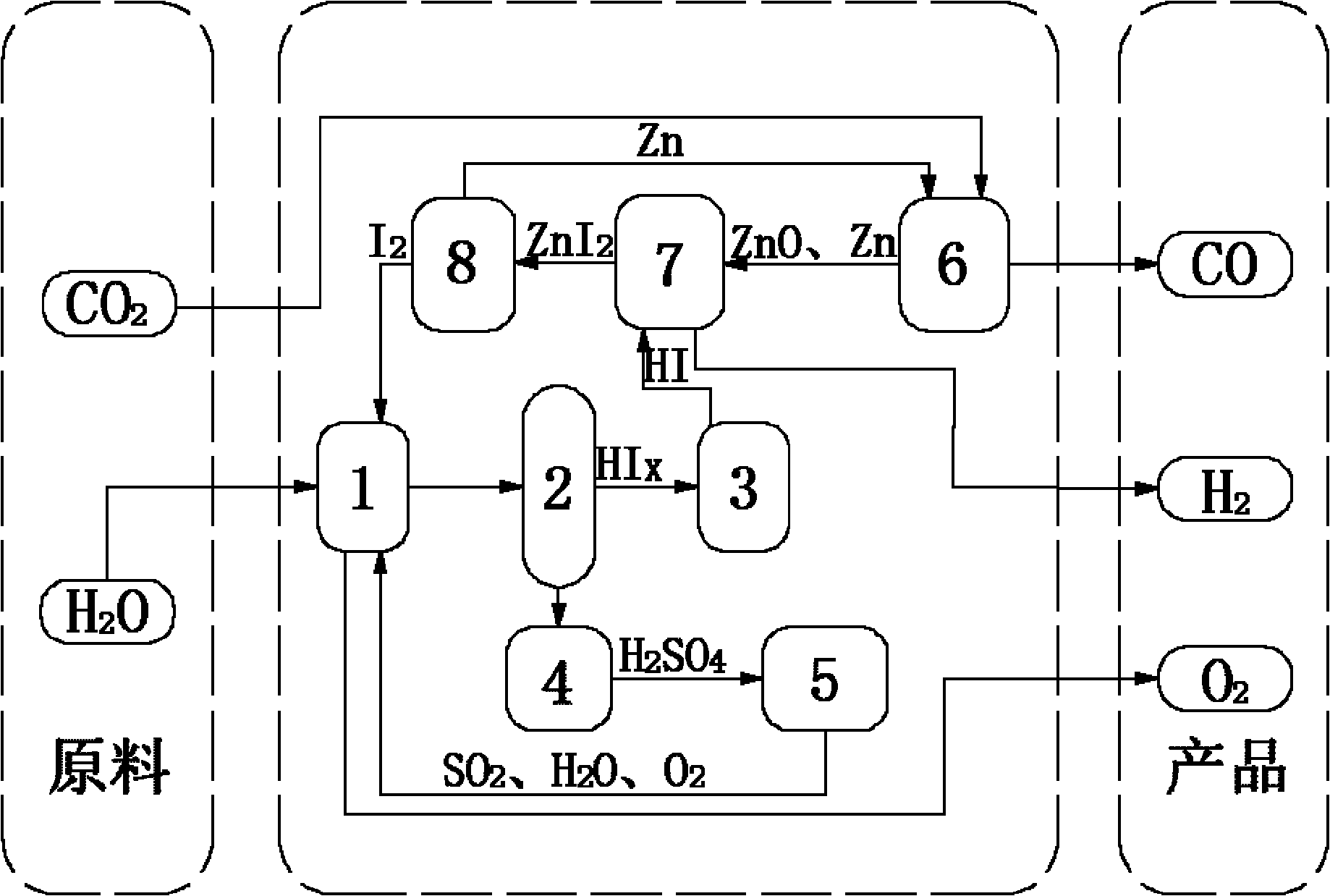

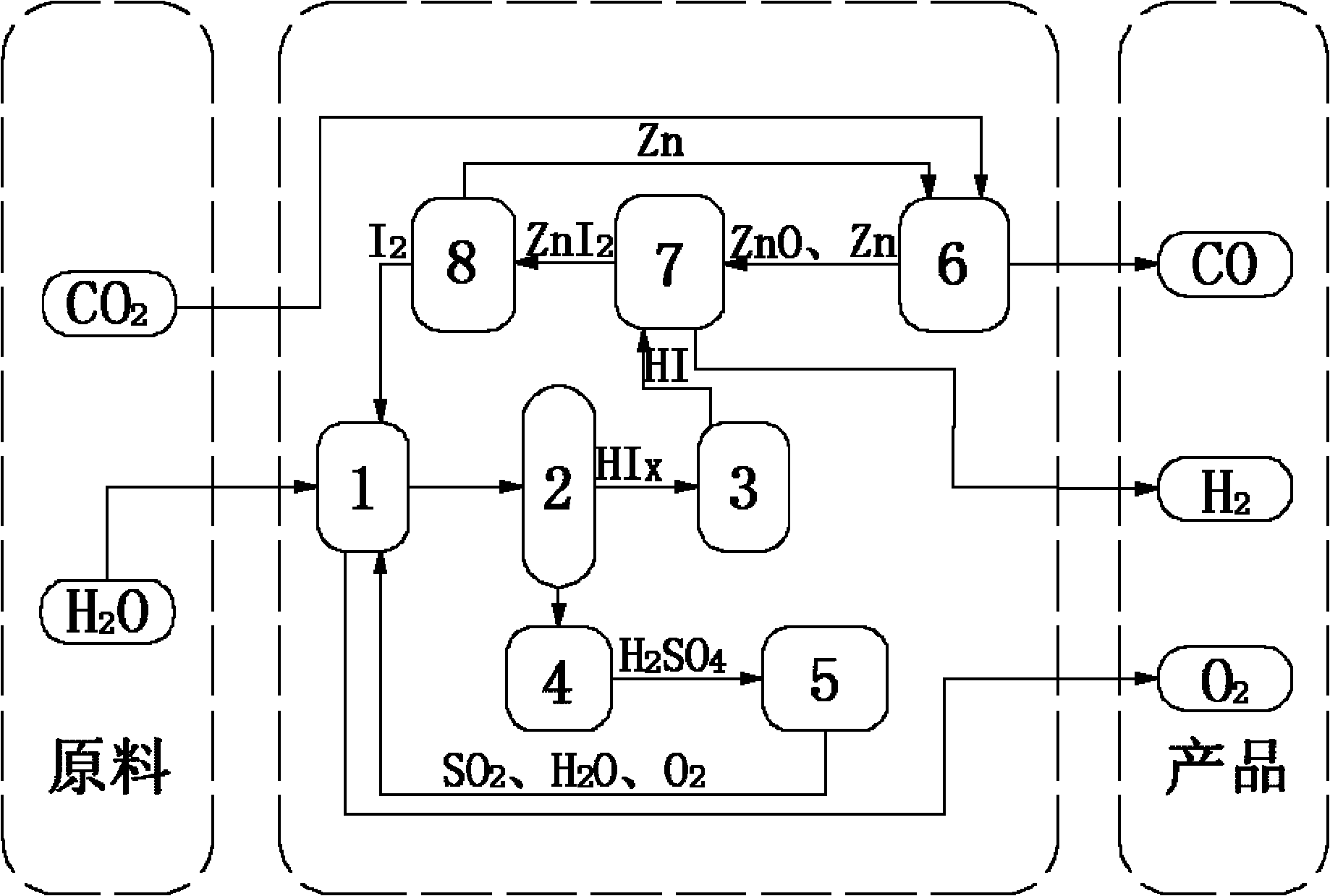

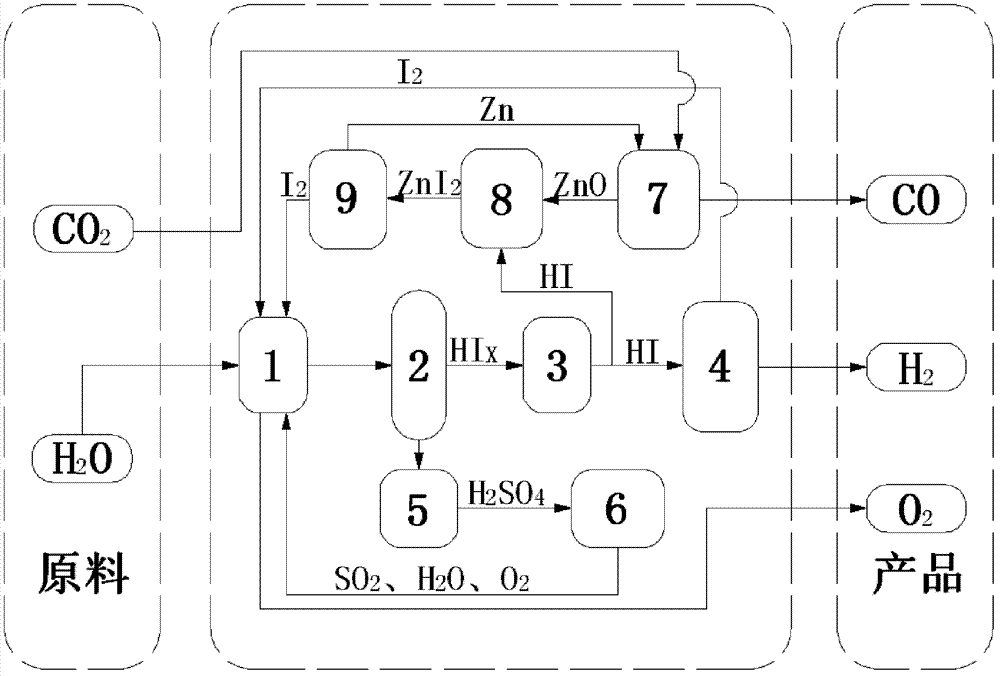

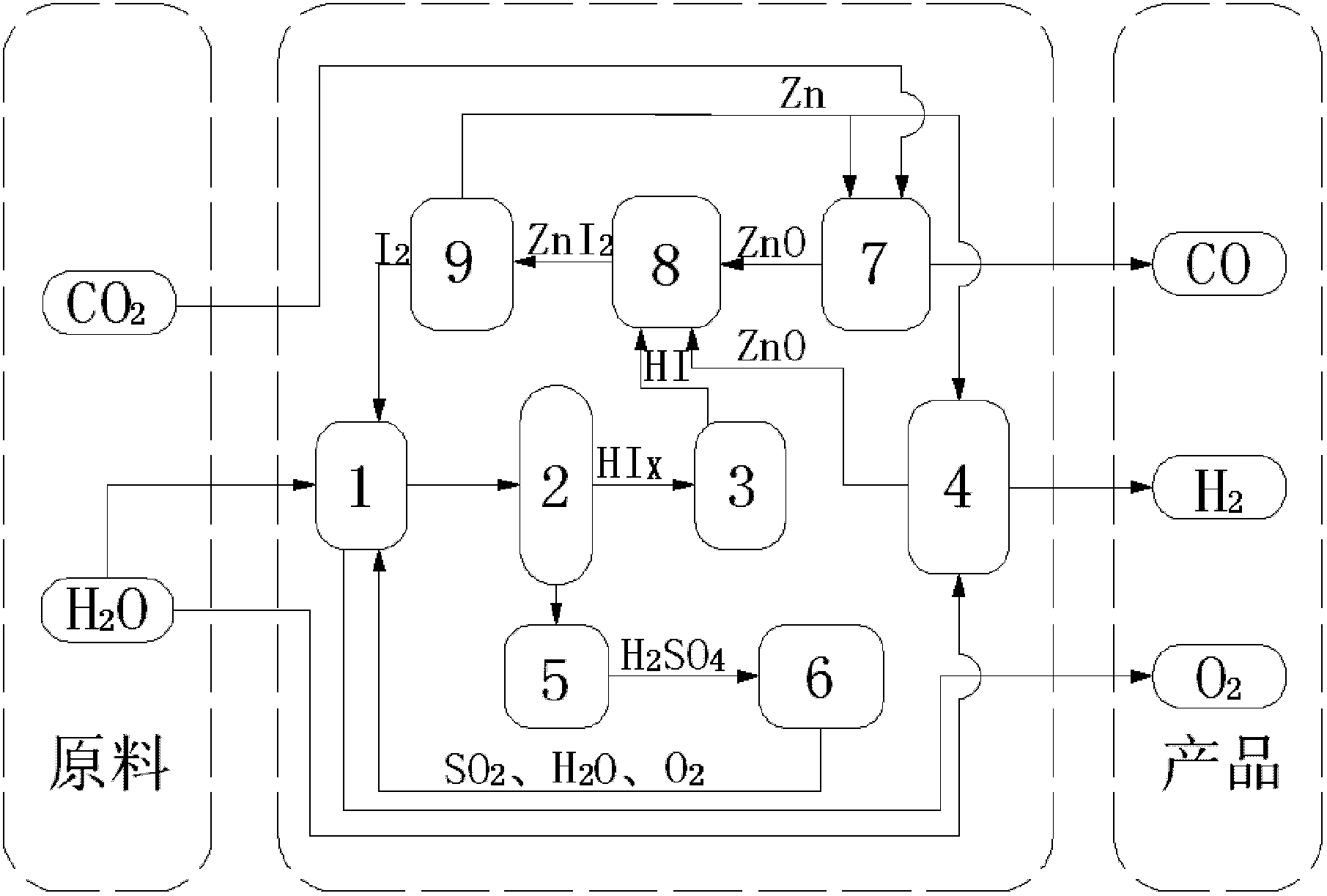

Method and device for decomposing CO2 and H2O through thermo-chemistry circulation reaction system

ActiveCN102553407AReduce the temperatureAppropriate reaction temperatureDispersed particle separationAir quality improvementMultiple formsFixed bed

The invention relates to the technology of CO2 emission reduction and aims at providing a method and a device for decomposing CO2 and H2O through a thermo-chemistry circulation reaction system. The method includes: leading H2O, I2 and SO2 to a Bunsen reaction device for a spontaneous heat producing reaction, and leading CO2 to a fixed bed or a fluid bed reactor to produce a heat producing reaction with metal Zn or Ni. Products of all the reactions are recycled and used through the reaction devices and the final products are H2, CO and O2. The maximum heat source temperature is relatively low (lower than 900 DEG C), and other type of heat sources including solar energy, nuclear energy and the like can be used. Negative influence caused by incomplete reactions of Zn and CO2 is reduced, reaction temperature is proper, and scale industry application can be achieved easily.

Owner:浙江百能科技有限公司

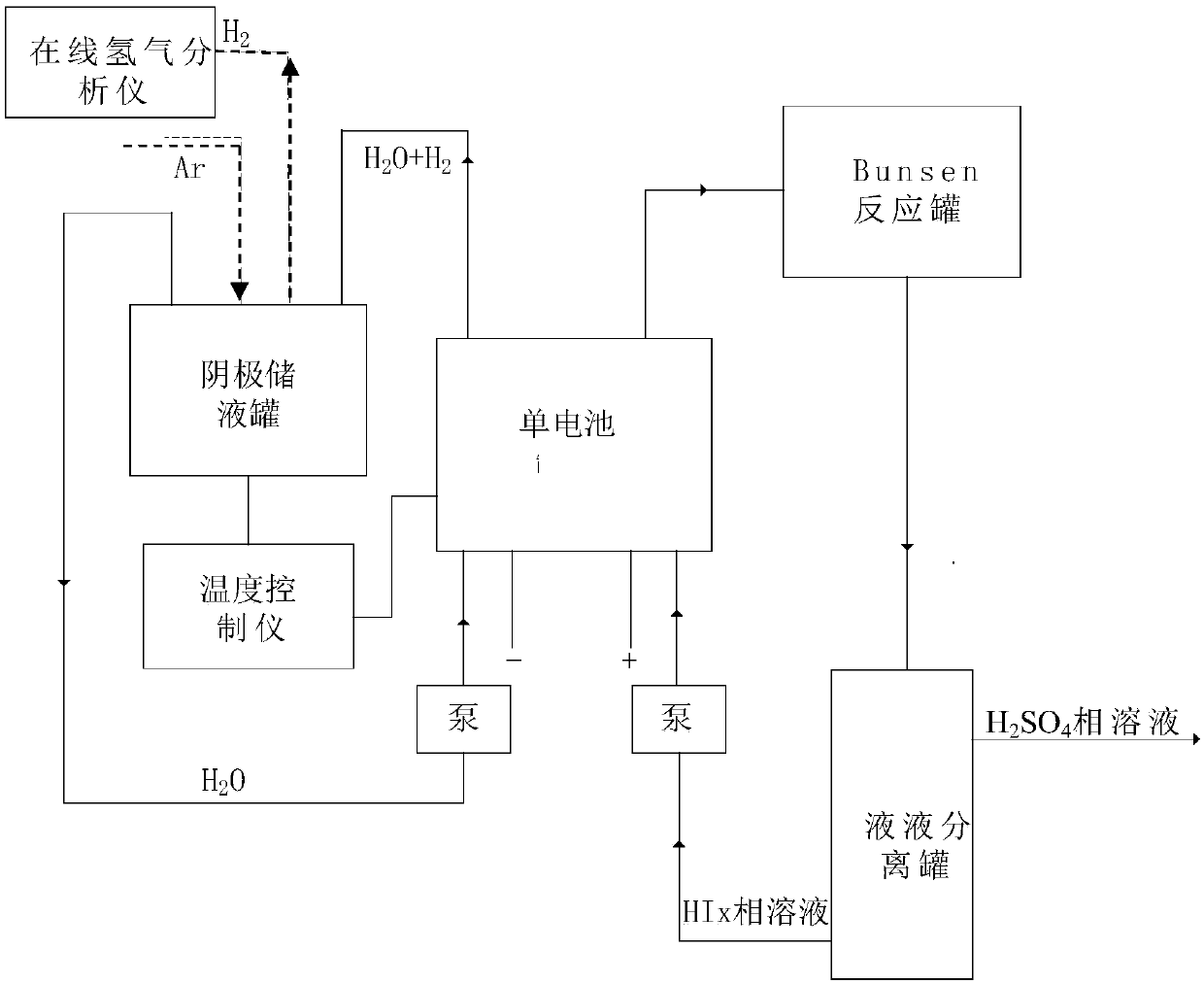

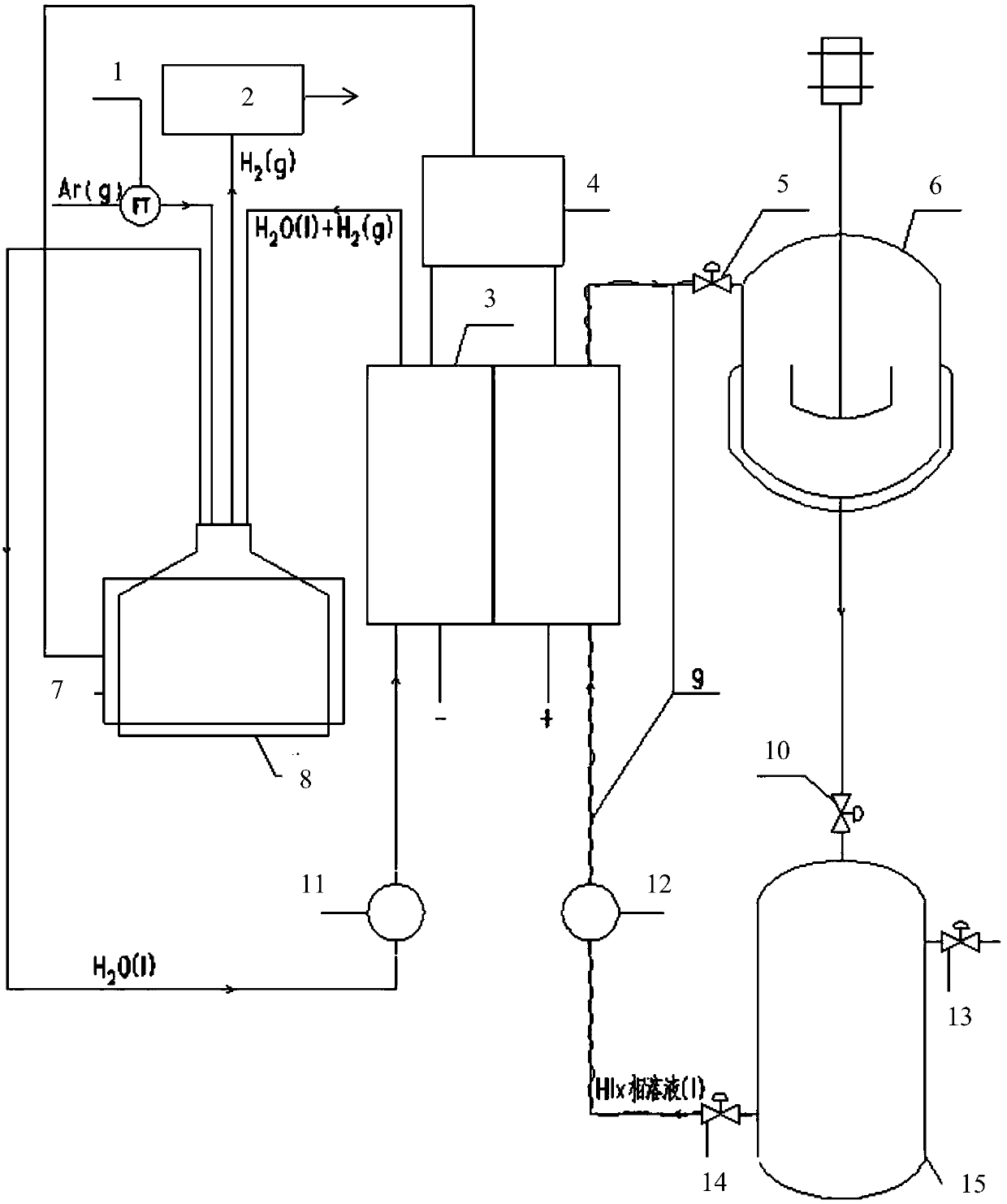

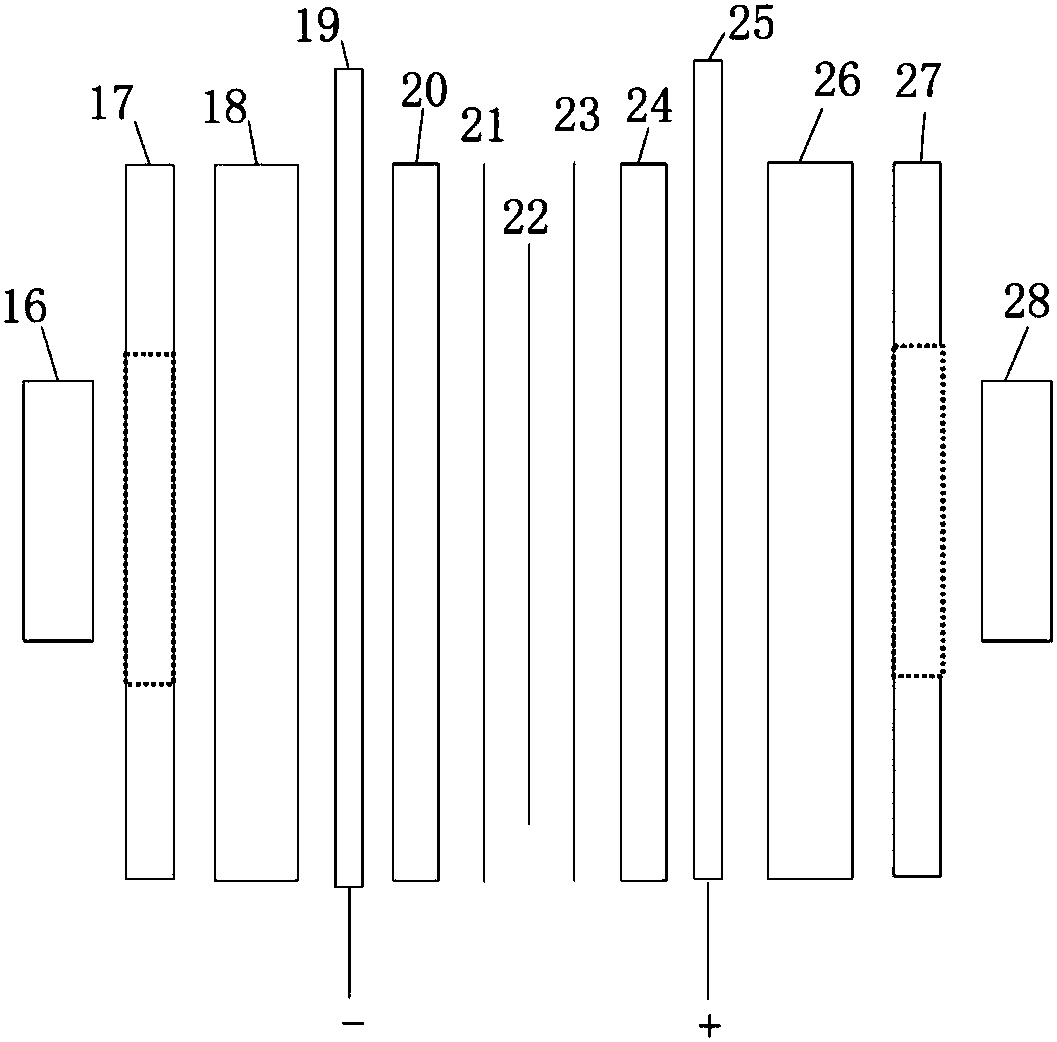

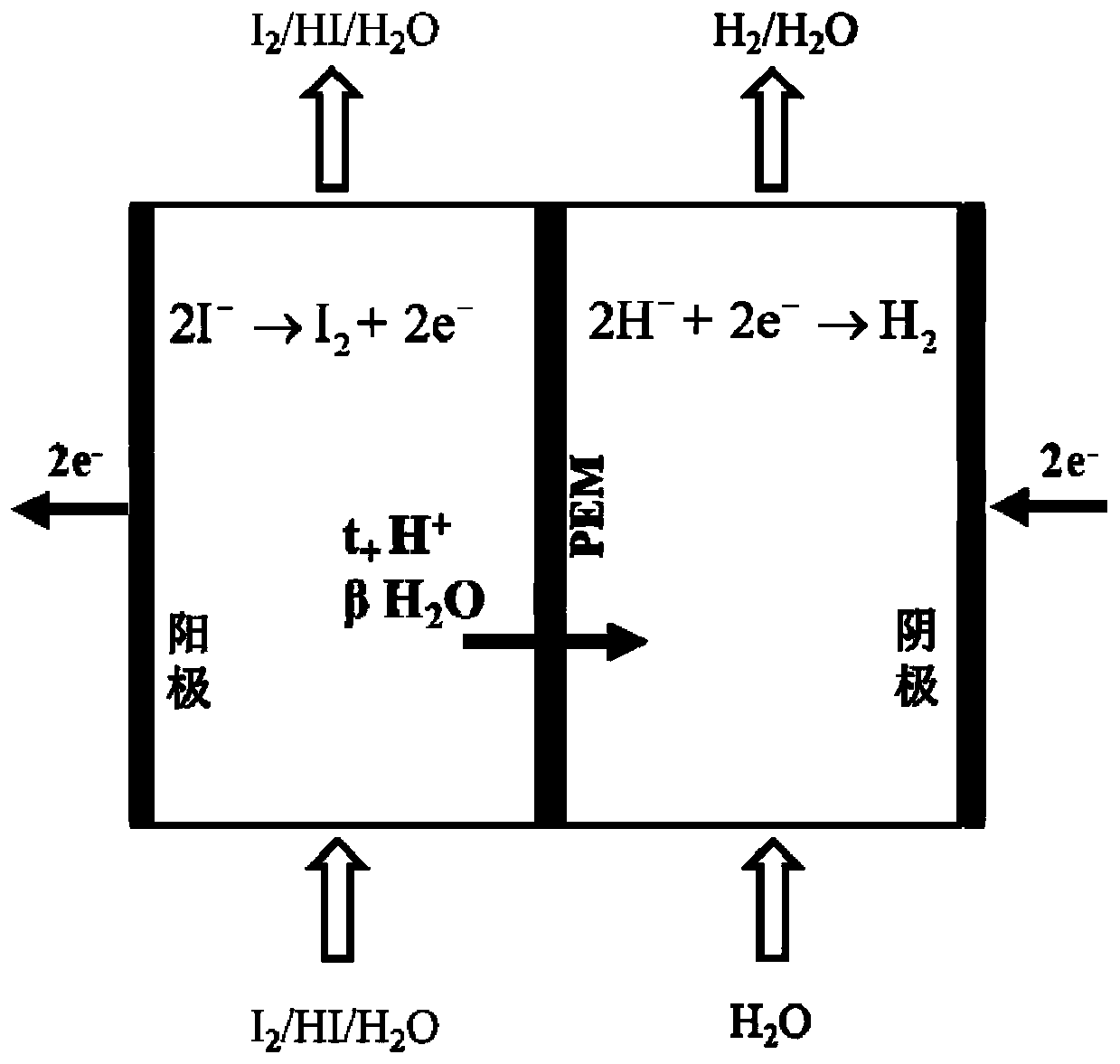

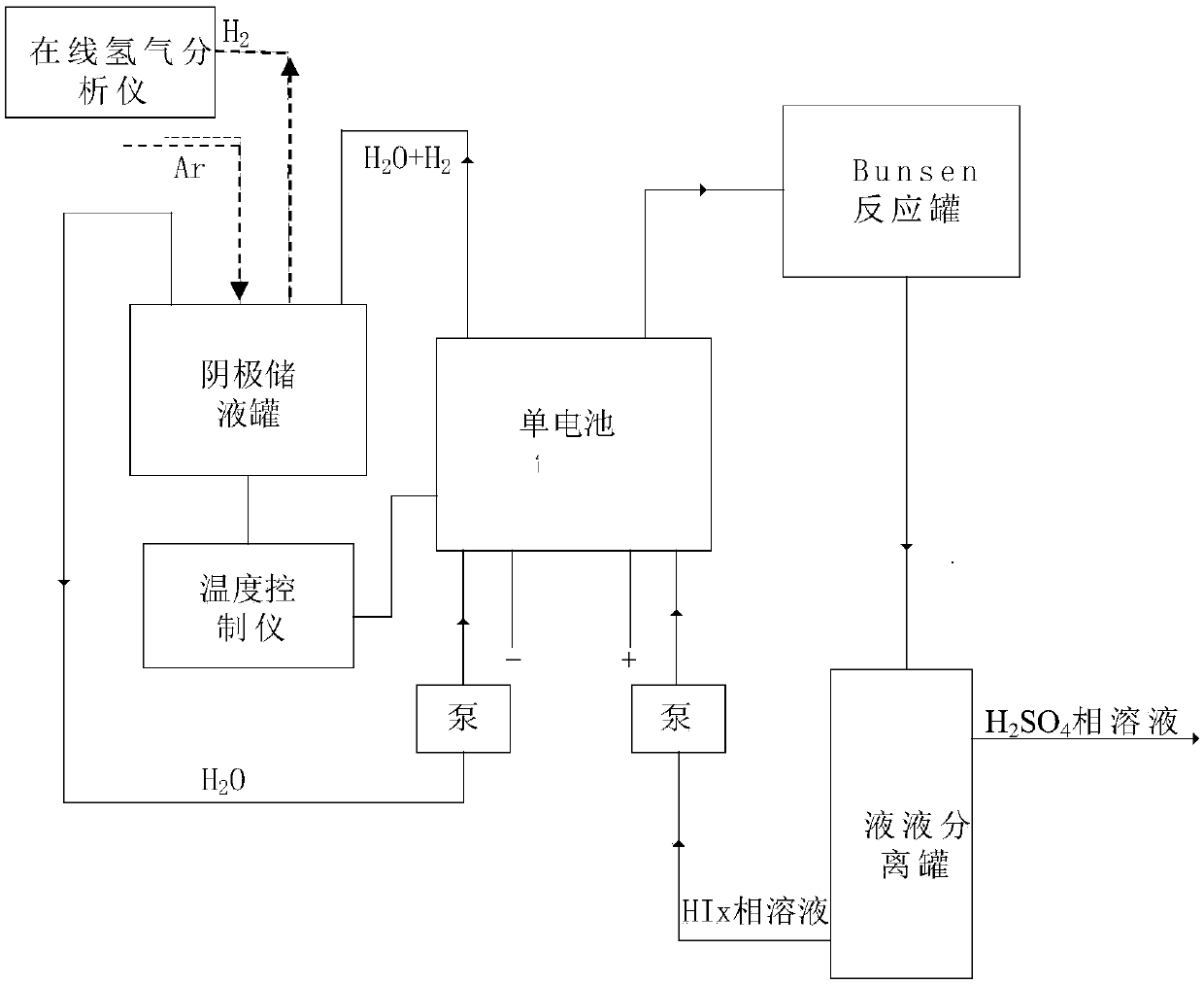

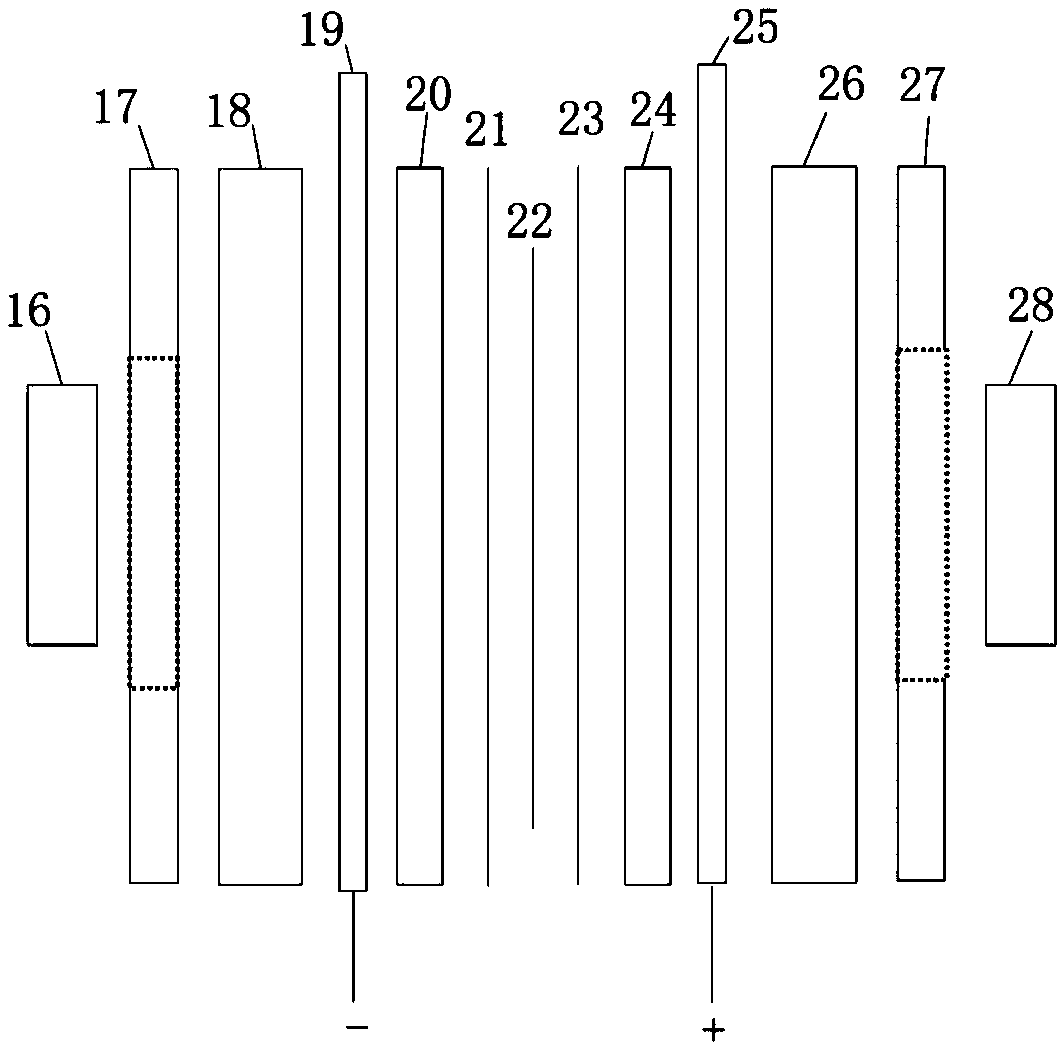

Hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and device

ActiveCN107904617AOmit enrichmentEliminate the distillation processCellsDiaphragmsElectrolysisDistillation

The invention relates to the technology of sulphur and iodine circulation hydrogen production, and particularly provides a hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and a device. The method includes the steps that a monocell is used as a reactor, the monocell has anode graphite electrode and cathode graphite electrode, and a proton exchange membrane is used as a diaphragm; HIx homogeneous solution in the sulphur and iodine circulation hydrogen production system is injected into the anode side, and deionized water is injected into the cathode side; power supply is turned on to carry out decomposition reaction, I- of the anode side HIx homogeneous solution is oxidized to I2, and generated H+ passes through proton exchange membrane to reach the cathode side and is reduced to hydrogen; HIx homogeneous solution of the anode side enters a Bunsen reactor to be Bunsen reaction raw material in a circulating modeafter electrolytic reaction, and hydrogen generated from cathode side is sent out. According to the hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production, an HIx solution is directly decomposed adopting electrochemistry method, the original process of concentration and distillation is omitted, and the process and the device are greatly simplified. Hydrogen is generated from cathode, and the separation problem with HI gas does not need to be considered.

Owner:ZHEJIANG UNIV

Method and device for preparing CO and H2 by thermochemical cycle decomposition of CO2 and H2O

ActiveCN102583239AReduce the temperatureAppropriate reaction temperatureEnergy inputHydrogen productionFluidized bedDecomposition

The invention relates to a CO2 emission reduction technology and aims at providing a method and device for preparing CO and H2 by thermochemical cycle decomposition of CO2 and H2O. According to the method, H2O, I2 and SO2 are fed into a Bunsen reaction device to perform a spontaneous exothermic reaction; CO2 gas is introduced to a fixed bed or a fluidized bed reactor and performs an exothermic reaction with metal Zn or Ni; and products in various reaction process are recycled by various reaction devices and final products are H2, CO and O2. The highest heat source temperature of the device is lower (less than 900DEG C) and other various forms of heat sources such as solar energy and nuclear energy can be used; the negative influence caused by incomplete reaction of Zn and CO2 is reduced to a certain degree; and the reaction temperature is proper and the scale industrial application is easily realized.

Owner:浙江百能科技有限公司

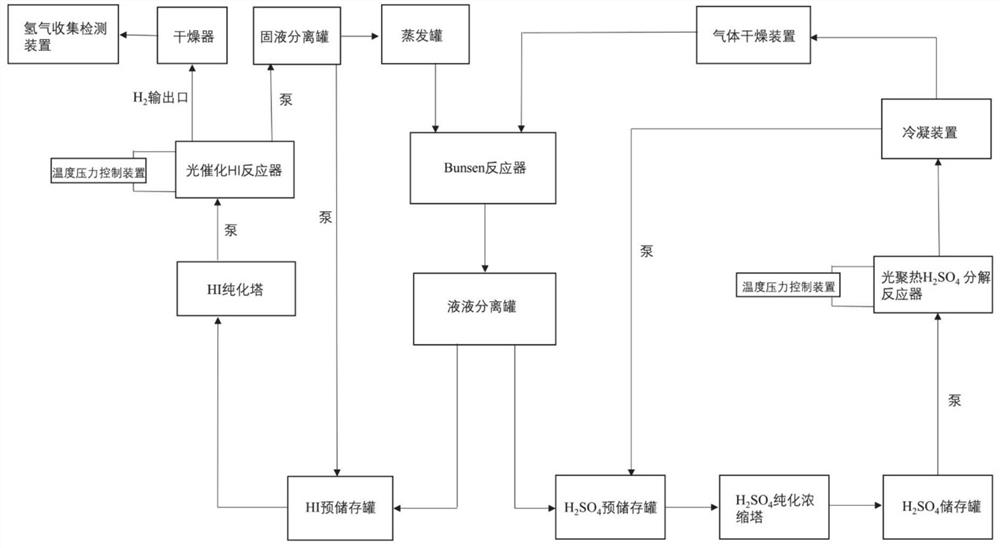

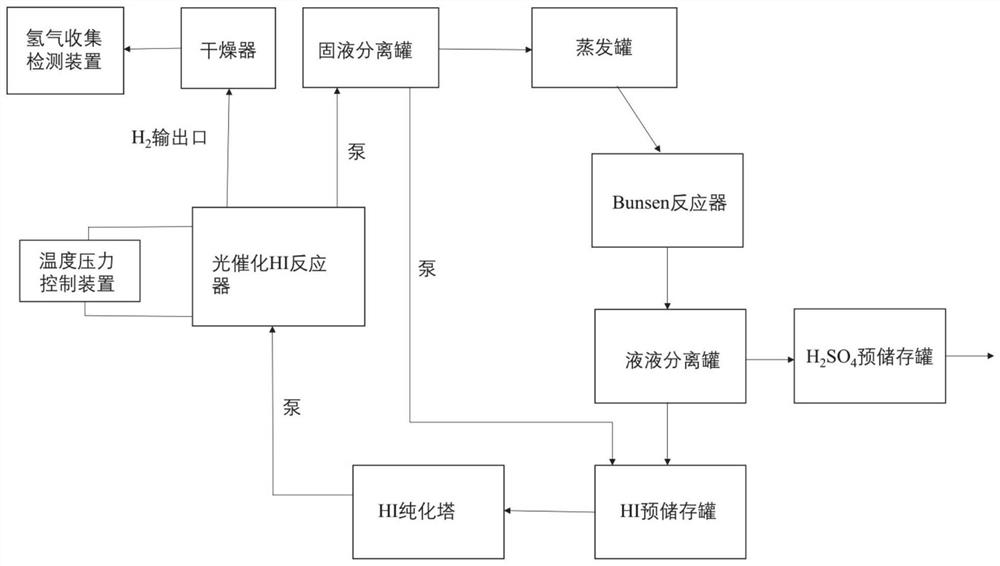

Iodine-sulfur cyclic hydrogen production method and system based on efficient light energy utilization

PendingCN112142001ARealize the combination of cycle hydrogen productionAchieve decompositionEnergy inputHydrogen productionPtru catalystLight energy

The invention discloses an iodine-sulfur cycle hydrogen production method and system based on high-efficiency light energy utilization. The method comprises the steps: carrying out photocatalytic decomposition on an HI solution through solar illumination to obtain hydrogen, carrying out solid-liquid separation on the remaining material after photocatalytic decomposition to obtain elemental iodine,and carrying out a Bunsen reaction on the elemental iodine, sulfur dioxide and water to obtain HI and H2SO4, wherein HI prepared from Bunsen is used as a raw material for photocatalytic decomposition, H2SO4 generated by the Bunsen reaction is decomposed to generate SO2 under the condition of sunlight light heat gathering and heating, SO2 generated by decomposition of H2SO4 is used as a raw material for the Bunsen reaction, and the catalyst for photocatalytic decomposition is a catalyst based on methyl amino lead iodide. According to the method, solar energy can be used for replacing heat energy consumed in the circulation process, so that the reaction cost can be reduced to a great extent, and the method has a certain industrial application prospect.

Owner:SHANDONG UNIV

Iodine-sulfur cycle for nuclear hydrogen production with improved thermo-chemical efficiency

InactiveUS20130195749A1Reduce corrosionImprove thermo-chemical efficiencyChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxideThermal energyCyclic process

Disclosed herein is an iodine-sulfur cycle for nuclear hydrogen production, which can improve thermochemical efficiency. The iodine-sulfur cycle is advantageous in that the amount of excess water and iodine supplied to a Bunsen reaction process is minimized, thus minimizing the amount of thermal energy consumed in the recovery and recirculation process thereof, in that sulfuric acid having stronger hydrophilicity than hydrogen iodide absorbs excess water in large quantities in a spontaneous liquid-liquid phase separation process, so that, after the spontaneous liquid-liquid phase separation process, the concentration of hydrogen iodide in a hydrogen iodide solution exceeds a concentration at an azeotropic point without conducting an additional concentration process, with the result that highly-concentrated hydrogen iodide gas can be obtained only through a flashing process, thereby decreasing energy consumption and simplifying the process and thus improving economical efficiency, and in that process temperature and pressure can be decreased, thus greatly deceasing the corrosivity in an operational environment. Therefore, the iodine-sulfur cycle according to the present invention can be usefully used for high-efficient and environmentally-friendly nuclear hydrogen production.

Owner:KOREA ADVANCED INST OF SCI & TECH

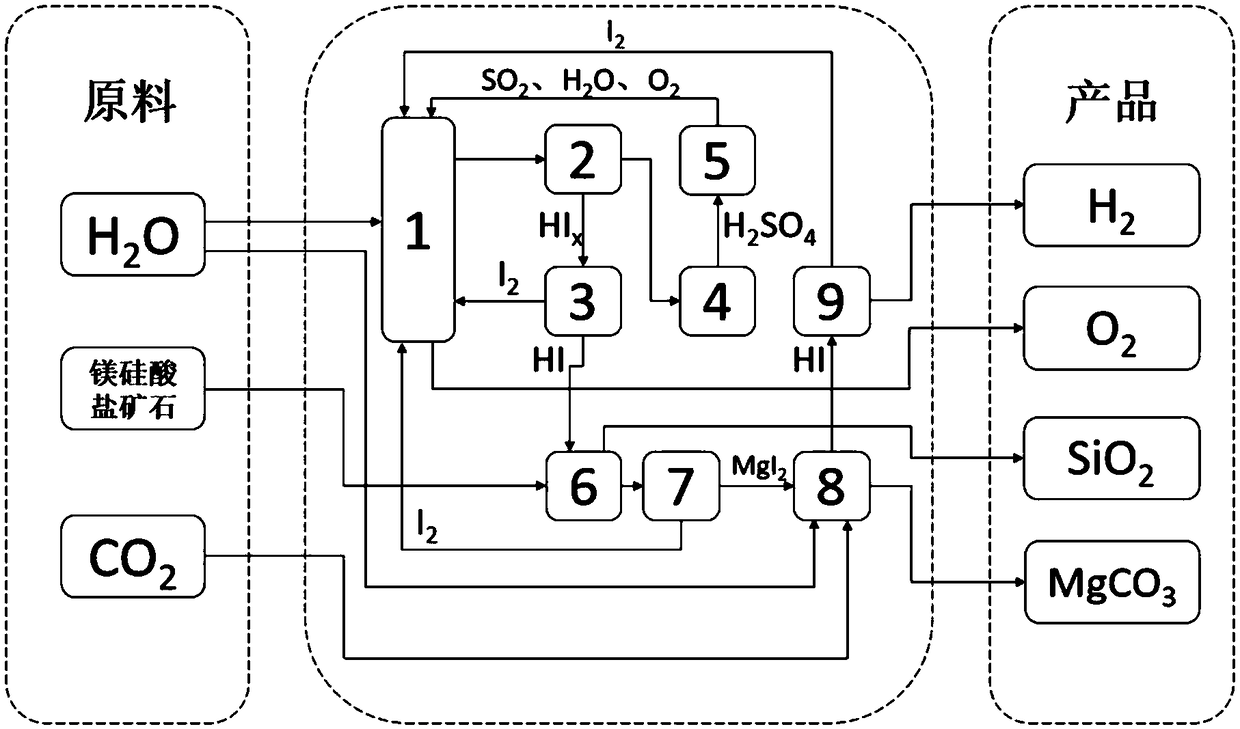

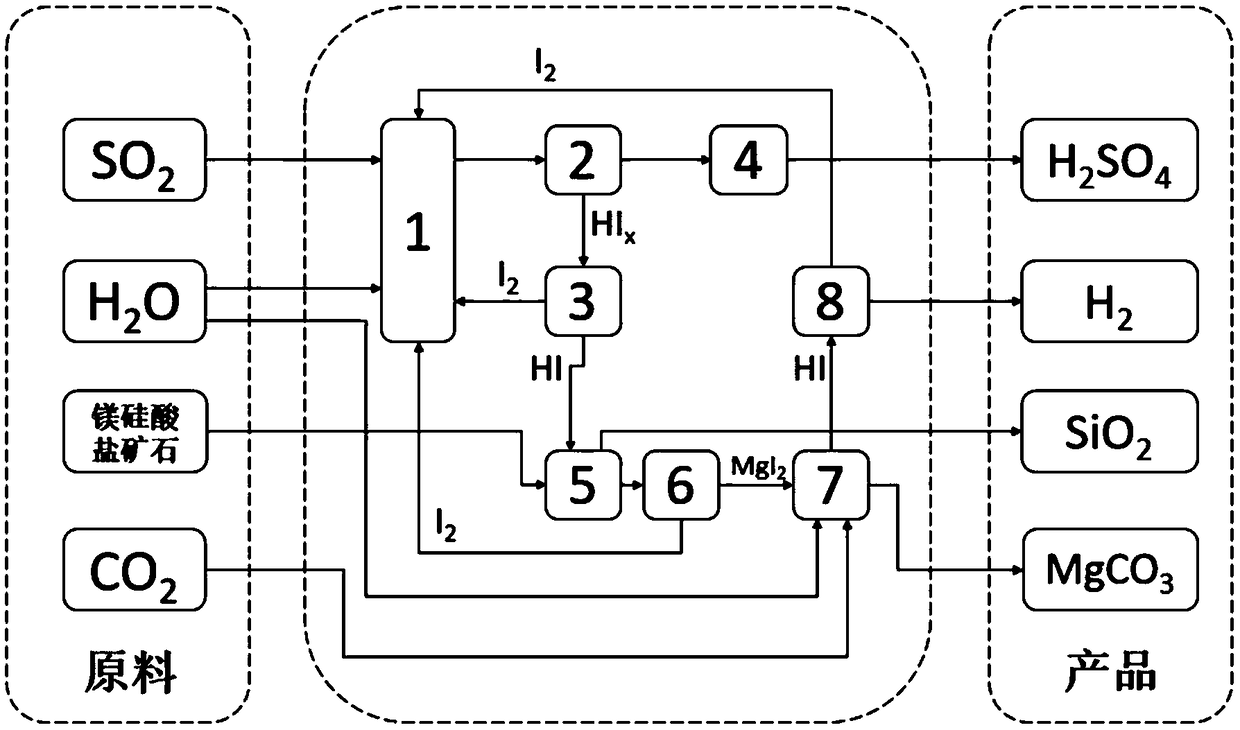

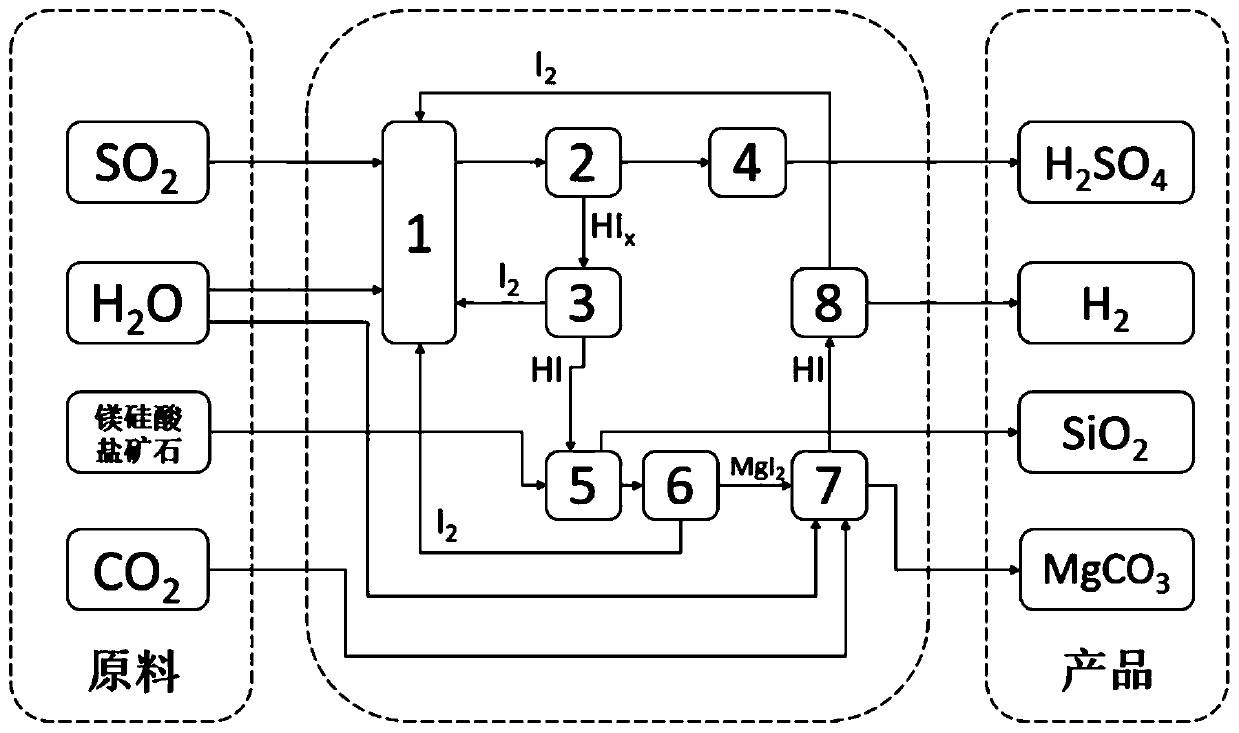

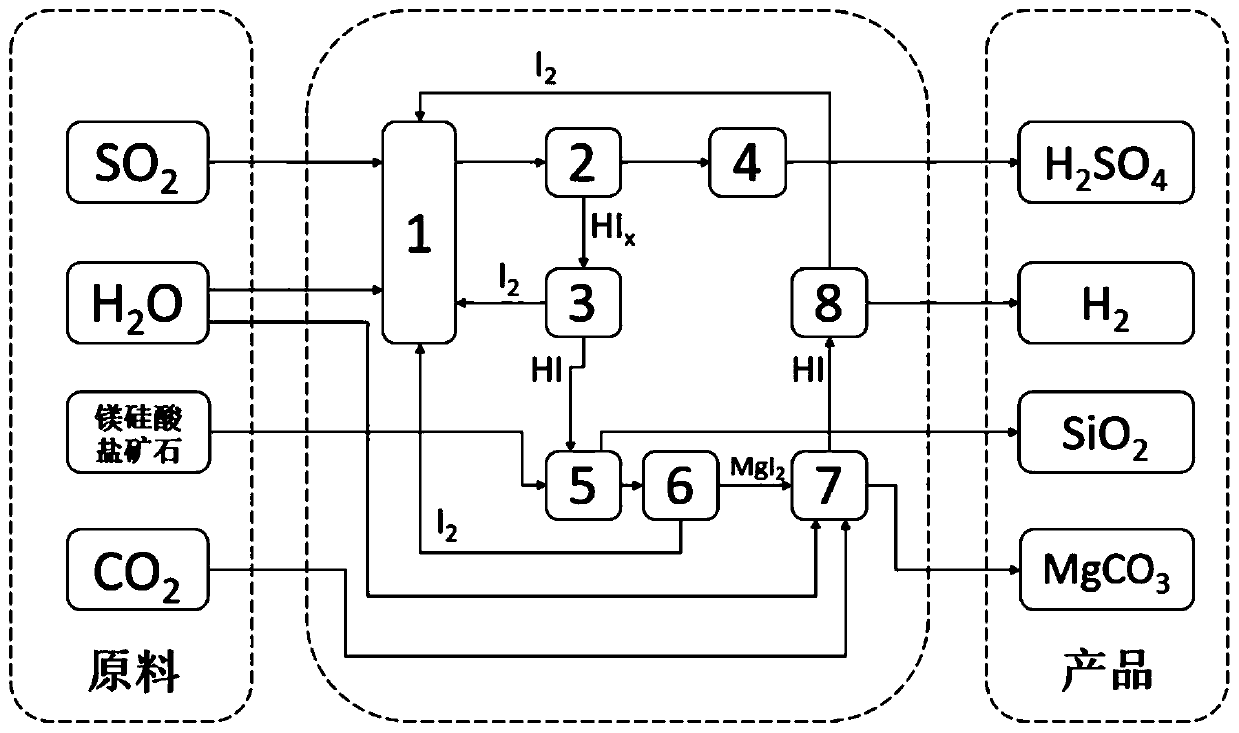

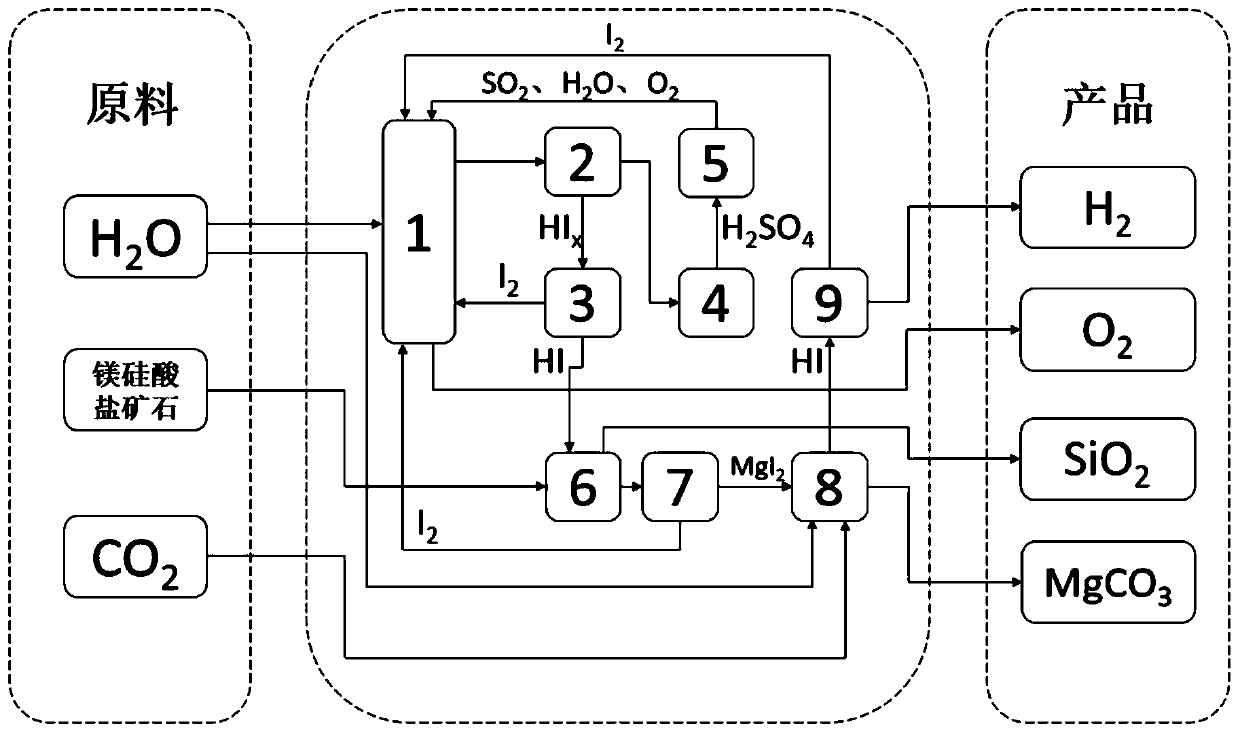

Method and device for preparing H2 by simultaneous thermochemical cycle mineralization of CO2 and decomposition of H2O

ActiveCN108821315AIncrease added valueAvoid distillation separation processMagnesium carbonatesHydrogen productionDistillationCatalytic decomposition

Owner:ZHEJIANG UNIV

Method and device for preparing H2 and coproducing H2SO4 through thermochemical cycle mineralization of CO2 during decomposition of H2O

ActiveCN108715438AIncrease added valueAvoid distillation separation processSilicaMagnesium carbonatesDistillationReaction temperature

The invention relates to the field of CO2 emission reduction and thermochemical hydrogen production and aims to provide a method and a device for preparing H2 and coproducing H2SO4 through thermochemical cycle mineralization of CO2 during decomposition of H2O. A Bunsen reaction device is connected with a liquid phase separation device which is connected with a HIx concentration device and a H2SO4concentration device, the HIx concentration device is connected with the Bunsen reaction device and a Mg12 generation reactor which is connected with a Mg12 distillation device, the Mg12 distillationdevice is connected with the Bunsen reaction device and a Mg12 hydrolysis carbonation reactor which is connected with a HI catalytic decomposition reactor, and the HI catalytic decomposition reactor is connected with the Bunsen reaction device. CO2 mineralization technology and hydrogen production through thermochemical sulfur-iodine open cycle decomposition of water are organically combined creatively, and CO2 is mineralized and fixed in mild reaction conditions while H2 and H2SO4 with high added value are coproduced; hydrogen production cycle and mineralization technology are organically combined, so that higher theoretical heat efficiency is realized; the method is proper in reaction temperature and easy for large-scale industrial application.

Owner:ZHEJIANG UNIV

Method and device for thermo chemolysis of CO2 and H2O based on reaction substance circulation

ActiveCN102553408AReduce the temperatureReduce negative impactDispersed particle separationAir quality improvementReaction temperatureBunsen reaction

The invention relates to a CO2 emission reduction technology and aims at providing a method and a device for thermo chemolysis of CO2 and H2O based on reaction substance circulation. The method comprises the steps of feeding the H2O, I2 and SO2 into a Bunsen reaction device for automatic heat release reaction; communicating CO2 gas to a static bed or a fluid bed reactor for heat release reaction with metal Zn or Ni; circulating the products in each reaction process through each reaction device, wherein the final products are H2, CO and O2. The device provided by the invention has a lower maximum heat resource temperature (less than 900 DEG C); heat resources, such as solar energy, nuclear energy and other types can be used; negative influence caused by incomplete reaction of Zn and CO2 is reduced to a certain extent; the device is appropriate in reaction temperature and easy to realize industrial application in scale.

Owner:浙江百能科技有限公司

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:HEATON HARLEY L +4

Method and device for preparing CO and H2 by thermochemical cycle decomposition of CO2 and H2O

ActiveCN102583239BReduce the temperatureAppropriate reaction temperatureEnergy inputHydrogen productionDecompositionFluidized bed

The invention relates to a CO2 emission reduction technology and aims at providing a method and device for preparing CO and H2 by thermochemical cycle decomposition of CO2 and H2O. According to the method, H2O, I2 and SO2 are fed into a Bunsen reaction device to perform a spontaneous exothermic reaction; CO2 gas is introduced to a fixed bed or a fluidized bed reactor and performs an exothermic reaction with metal Zn or Ni; and products in various reaction process are recycled by various reaction devices and final products are H2, CO and O2. The highest heat source temperature of the device is lower (less than 900DEG C) and other various forms of heat sources such as solar energy and nuclear energy can be used; the negative influence caused by incomplete reaction of Zn and CO2 is reduced to a certain degree; and the reaction temperature is proper and the scale industrial application is easily realized.

Owner:浙江百能科技有限公司

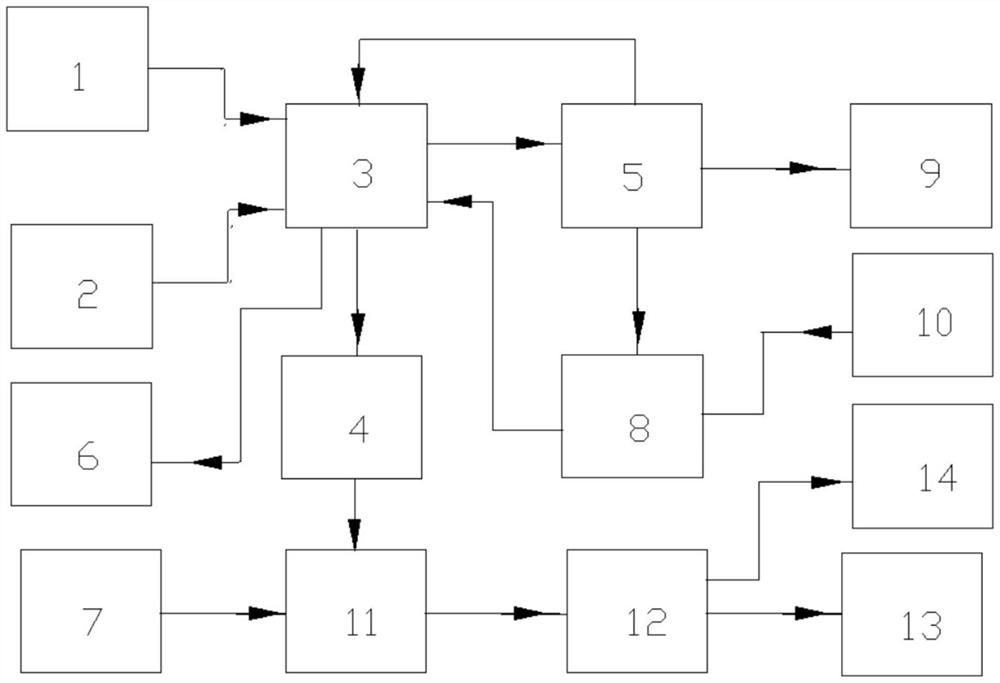

System and method for comprehensive utilization of boiler sulfur-containing flue gas and fly ash

PendingCN112811454ASolve the difficulties of high temperature pyrolysis hydrogen productionReduce energy consumptionSilicaHydrogen productionSilicon dioxideSulfur containing

A system and method for comprehensive utilization of boiler sulfur-containing flue gas and fly ash are characterized in that a boiler flue outlet is connected to a Benzoic reaction device, the Benzoic reaction device is connected with a water supply device, a reactor exhaust device, an inlet of a sulfuric acid collection device and a hydrogen iodide decomposition device, the hydrogen iodide decomposition device is connected with an iodine recovery device, a hydrogen collection device, and a fourth inlet of the Benzoic reaction device, the iodine recovery device is connected with the iodine supply device, and an outlet of the iodine recovery device is connected with the Benzoic reaction device; the sulfuric acid collection device is connected with the aluminum sulfate preparation device, the aluminum sulfate preparation device is connected with an outlet of the boiler fly ash system and an inlet of the aluminum sulfate treatment device, and an outlet of the aluminum sulfate treatment device is connected with inlets of the aluminum sulfate storage device and the silicon dioxide treatment and storage device; and based on the system, sulfuric acid generated in the hydrogen production process is used for absorbing disulfur trioxide in the fly ash, meanwhile, silicon dioxide with high purity can be generated, aluminum sulfate and silicon dioxide with high additional value are formed, and waste substances are recycled.

Owner:XIAN THERMAL POWER RES INST CO LTD

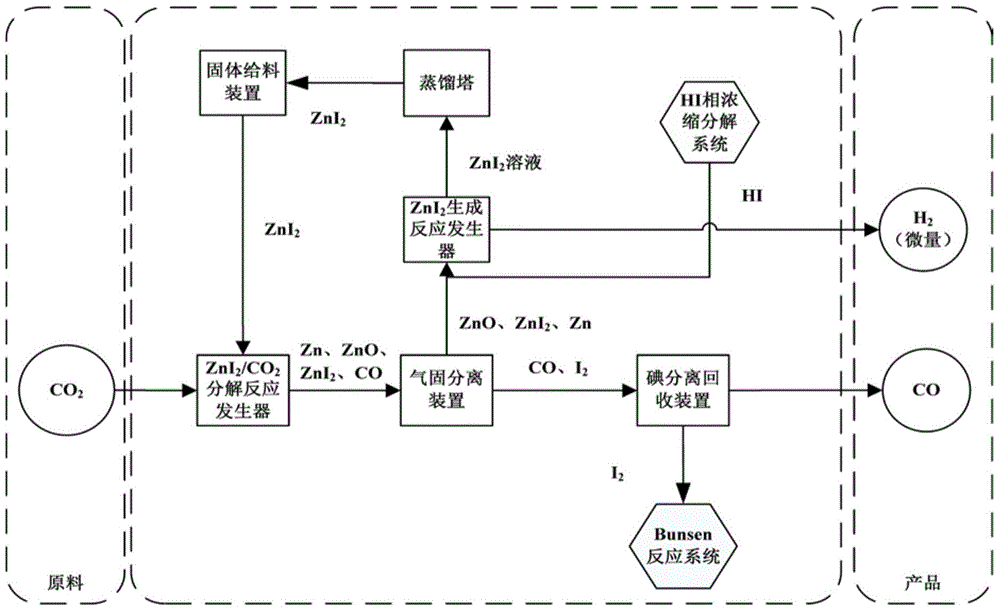

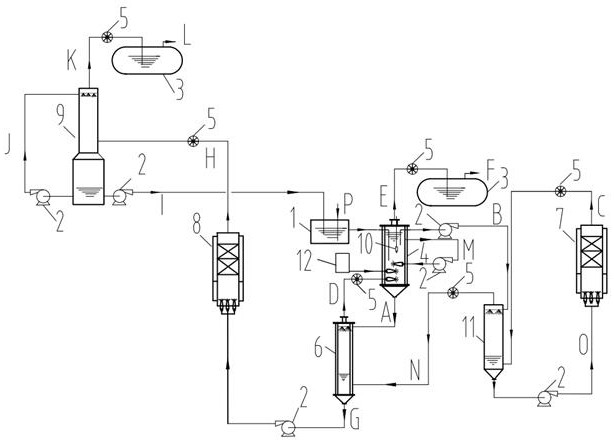

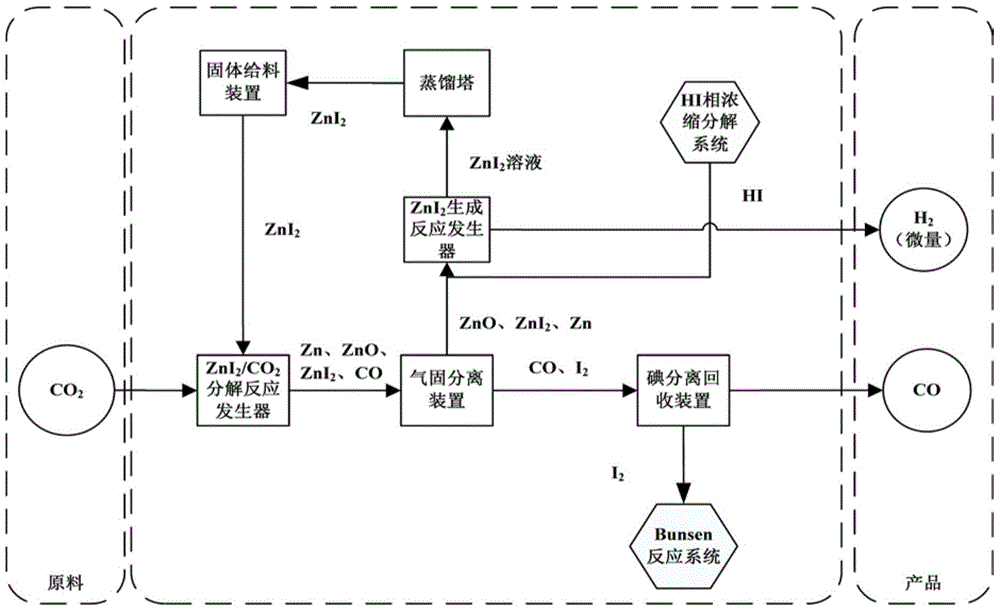

Method and device for simplifying thermo-chemical ZnSI cyclic decomposition of carbon dioxide and water

ActiveCN104477911AThe reaction device is simpleFew reaction stepsProductsReagentsGas solidDecomposition

The invention relates to the field of thermo-chemical cycle systems, and aims to provide a method and a device for simplifying thermo-chemical ZnSI cyclic decomposition of carbon dioxide and water. The method mainly comprises the following steps: performing isothermal reaction on ZnI2 and CO2 to obtain Zn, ZnO, ZnI2, I2 and CO, then performing gas-solid separation, separating CO out from the gas product, reacting the solid product, water and HI to generate ZnI2 and H2O, and preparing ZnI2 solid. The device comprises a distillation tower, a solid feeding device, a ZnI2 / CO2 decomposition reaction generator, a gas-solid separation device, an iodine separation and recovery device, a ZnI2 generator, an HI phase concentrate decomposition system and a Bunsen reaction system. By adopting the method and the device, a thermo-chemical ZnSI cycle system is simplified from a six-step mode to a five-step mode, so that the reaction steps are reduced, the reaction device is simplified, the operation is convenient, no additional matters are introduced and the initial input cost is reduced.

Owner:ZHEJIANG UNIV

A whole-process method and device for thermochemical sulfur-iodine cycle hydrogen production

ActiveCN114195094BWell mixedPrevent precipitationHydrogen productionReactive separationPhysical chemistry

The invention discloses a method and a device for the whole process of thermochemical sulfur-iodine cycle hydrogen production. The present invention combines the Bunsen reaction section with HIx and H 2 SO 4 The two-phase separation section is coupled together, coupling the HIx purification section and the concentration section. h 2 SO 4 The high-temperature mixed gas of the decomposition tower is directly passed into the H 2 SO 4 In the concentration tower, under the condition of no external heat source, H 2 SO 4 A large amount of water in the solution vaporizes rapidly to achieve concentrated H 2 SO 4 The purpose of the solution: the high-temperature mixed gas continues to enter the downstream HIx purification and concentration tower, and a large amount of water in the HIx system is vaporized and taken away to achieve the purpose of concentrating the HI solution. H inclusion in HIx system 2 SO 4 Converted to SO in an oxygen-enriched environment 2 It is taken away to achieve the purpose of purifying the HI solution. After the hydrogen is separated in the condensation tower, the remaining iodine-containing liquid is reused and returned to the Bunsen reaction separation tower, which can reduce the investment and energy consumption of hydrogen production by more than 40% compared with the traditional sulfur-iodine preparation.

Owner:浙江百能科技有限公司

Method for promoting bunsen reaction in thermochemical sulfur-iodide cycle hydrogen production

ActiveCN103213945BOmit the concentration stepIncreased reaction kinetic rateHydrogen productionDistillationKinetic rate

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

System and method for preparing ammonium sulfate by utilizing sulfur-containing flue gas of boiler

PendingCN112811440ASolve the difficulties of high temperature pyrolysis hydrogen productionReduce energy consumptionIodineHydrogen productionSulfur containingAmmonium sulfate

Owner:XIAN THERMAL POWER RES INST CO LTD

Hydrogen-electricity co-production system and method for coal-fired boiler

ActiveCN114655923ANo emissionsLow running costHydrogen iodideEmission preventionEngineeringHydrogen storage system

According to the hydrogen-electricity co-production system and method for the coal-fired boiler, the coal-fired boiler, sulfur-iodine circulating hydrogen production and supercritical carbon dioxide power generation are coupled, and hydrogen-electricity co-production is carried out; comprising a coal-fired carbon dioxide boiler, a carbon dioxide power generation system, a high-temperature heat exchanger, a medium-temperature heat exchanger, a denitration module, a low-temperature heat exchanger, an air pre-heater, a dust remover, an induced draft fan, a biochemical reactor, a flue gas emission system, a separation system, a hydrogen iodide solution concentration and rectification system, a hydrogen iodide decomposition system, an iodine recovery system, a hydrogen storage system and a sulfuric acid storage system. An air supply system, an air powder system and a water supply system. According to the method, the iodine solution is used for absorbing sulfur dioxide in the boiler flue gas, no extra carbon dioxide emission is generated, iodine can be recycled, and the operation cost is low; the polluting gas sulfur dioxide generated by the boiler is used for producing hydrogen, so that the pollution is reduced, and the energy is increased; the supercritical carbon dioxide power generation work is in the highest efficiency temperature section, and the power generation efficiency is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Technical method of sulfur iodine open circuit circulation hydrogen manufacture and its equipment

ActiveCN100400412CReduce the temperatureReduce energy consumptionIodine/hydrogen-iodideHydrogen productionIt equipmentHydrogen

The present invention relates to a process for preparing hydrogen gas, and is aimed at providing a technological process capable of combining sulfur-iodine open-circuit circulation and sulfuric aid industry to simultaneously produce hydrogen gas and sulfuric acid and provide electric power and its equipment. Said method includes the following steps: roasting sulfur-bearing mineral, Bunsen reaction, separating HIx phase and H2SO4 phase solution, using electroosmose process to concentrate and purify HIx phase and utilizing HI membrane catalytic decomposition reactor to make decomposition to obtain I2 and find product H2.

Owner:ZHEJIANG UNIV

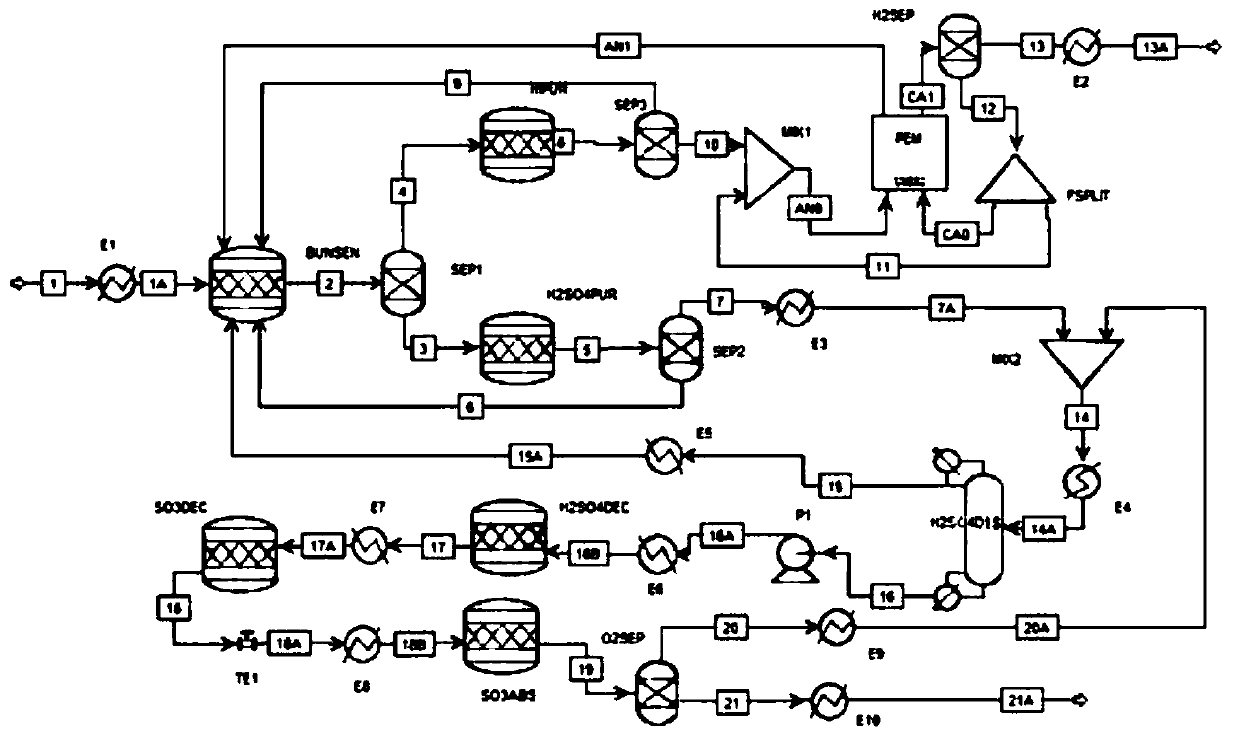

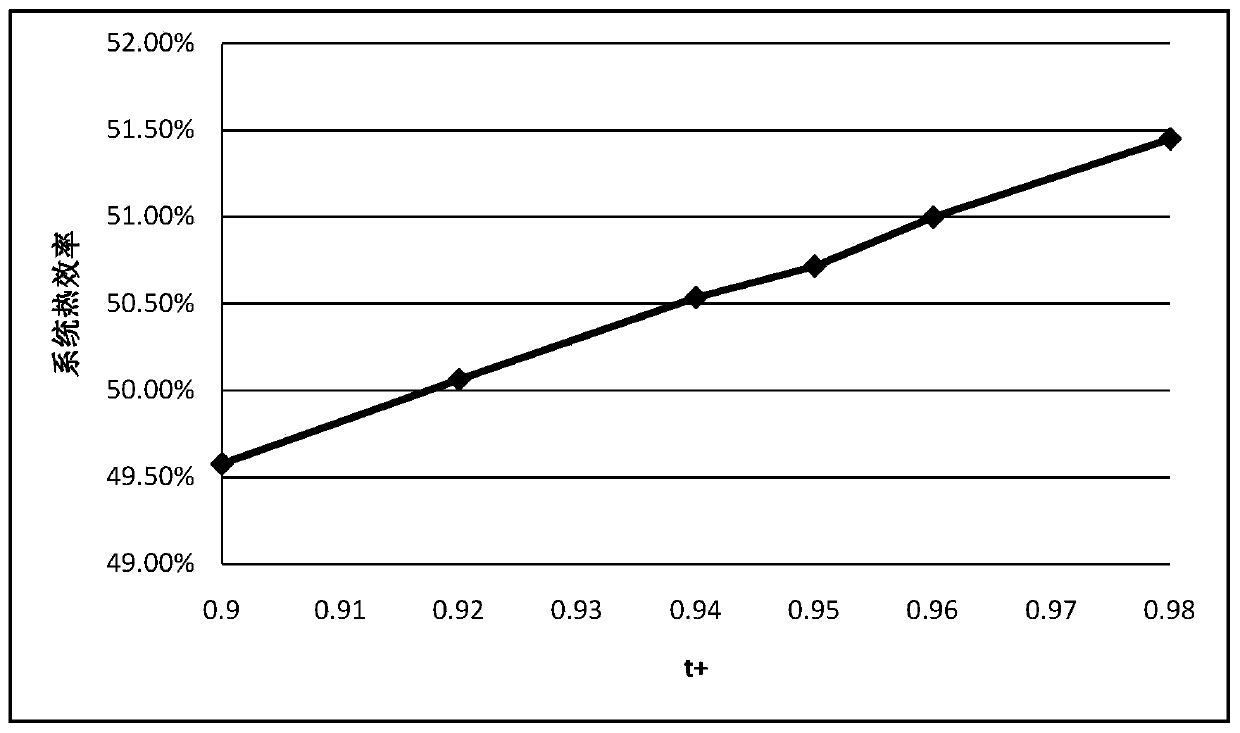

Hydroiodic acid electrolysis modeling and process simulation method for sulfur-iodine cycle hydrogen production

ActiveCN110348144ARealize data interactionHigh thermal efficiencyChemical processes analysis/designDesign optimisation/simulationEnergy balancingElectrolysis

The invention provides a hydroiodic acid electrolysis modeling and process simulation method for sulfur-iodine cycle hydrogen production, and solves the problems of complex sulfur-iodine cycle hydrogen production process and high energy consumption. The method comprises the following steps: establishing a hydroiodic acid electrolysis mathematical model according to a Faraday second law and a massconservation relationship; inputting the model into an EXCEL file to achieve EXCEL modeling; building a hydroiodic acid electrolysis USER2 custom module by means of simulation software Aspen Plus, andassociating the hydroiodic acid electrolysis USER2 custom module with an EXCEL file to realize data interaction; setting relevant parametersreasonably according to an experiment result, and completing debugging through simulation operation of the custom module. Further, the USER2 custom module is connected with a Bunsen reaction unit, a sulfuric acid decomposition unit and other modules; the sulfur-iodine cycle hydrogen production whole process is designed, related material and energy balance calculation and thermal efficiency analysis are carried out according to design requirements, and a guidance scheme is provided for designing and simplifying the whole sulfur-iodine cycle hydrogen production system and improving the thermal efficiency of the system.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method and device for hydrogen production by electrochemical decomposition of hi in sulfur-iodine cycle hydrogen production

The invention relates to the technology of sulphur and iodine circulation hydrogen production, and particularly provides a hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and a device. The method includes the steps that a monocell is used as a reactor, the monocell has anode graphite electrode and cathode graphite electrode, and a proton exchange membrane is used as a diaphragm; HIx homogeneous solution in the sulphur and iodine circulation hydrogen production system is injected into the anode side, and deionized water is injected into the cathode side; power supply is turned on to carry out decomposition reaction, I- of the anode side HIx homogeneous solution is oxidized to I2, and generated H+ passes through proton exchange membrane to reach the cathode side and is reduced to hydrogen; HIx homogeneous solution of the anode side enters a Bunsen reactor to be Bunsen reaction raw material in a circulating modeafter electrolytic reaction, and hydrogen generated from cathode side is sent out. According to the hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production, an HIx solution is directly decomposed adopting electrochemistry method, the original process of concentration and distillation is omitted, and the process and the device are greatly simplified. Hydrogen is generated from cathode, and the separation problem with HI gas does not need to be considered.

Owner:ZHEJIANG UNIV

Method and device for thermochemical cycle mineralization of CO2 and simultaneous decomposition of H2O to produce H2 and co-production of H2SO4

ActiveCN108715438BIncrease added valueAvoid distillation separation processSilicaMagnesium carbonatesDistillationCatalytic decomposition

The invention relates to the field of CO2 emission reduction and thermochemical hydrogen production and aims to provide a method and a device for preparing H2 and coproducing H2SO4 through thermochemical cycle mineralization of CO2 during decomposition of H2O. A Bunsen reaction device is connected with a liquid phase separation device which is connected with a HIx concentration device and a H2SO4concentration device, the HIx concentration device is connected with the Bunsen reaction device and a Mg12 generation reactor which is connected with a Mg12 distillation device, the Mg12 distillationdevice is connected with the Bunsen reaction device and a Mg12 hydrolysis carbonation reactor which is connected with a HI catalytic decomposition reactor, and the HI catalytic decomposition reactor is connected with the Bunsen reaction device. CO2 mineralization technology and hydrogen production through thermochemical sulfur-iodine open cycle decomposition of water are organically combined creatively, and CO2 is mineralized and fixed in mild reaction conditions while H2 and H2SO4 with high added value are coproduced; hydrogen production cycle and mineralization technology are organically combined, so that higher theoretical heat efficiency is realized; the method is proper in reaction temperature and easy for large-scale industrial application.

Owner:ZHEJIANG UNIV

thermochemical cycle mineralization co 2 Simultaneously decompose h 2 o make h 2 method and device

ActiveCN108821315BIncrease added valueAvoid distillation separation processMagnesium carbonatesHydrogen productionFluid phaseDistillation

The invention relates to the field of CO2 discharging reduction and thermochemical hydrogen production, and aims to provide a method and device for preparing H2 by simultaneous thermochemical cycle mineralization of CO2 and decomposition of H2O. A Bunsen reaction device is connected with a liquid phase separation device; the liquid phase separation device is connected with a HIx concentration device and a H2SO4 concentration device respectively; the H2SO4 concentration device, a concentrated H2SO4 catalytic decomposition device and the Bunsen reaction device are connected in sequence; the HIxconcentration device is connected with the Bunsen reaction device and a MgI2 generation reactor; the MgI2 generation reactor is connected with a MgI2 distillation device; the MgI2 distillation deviceis connected with the Bunsen reaction device and a MgI2 hydrolytic carbonation reactor; the MgI2 hydrolysis carbonation reactor is connected with an HI catalytic decomposition reactor; and the HI catalytic decomposition reactor is then connected with the Bunsen reaction device. According to the device, a CO2 mineralization technology and thermochemical sulfur-iodine open-cycle water decompositionfor hydrogen production are organically combined creatively; CO2 is mineralized and fixed under a relatively mild reaction condition, and H2 with a high additional value is co-produced; and an HI-I2 rectification process in a traditional hydrogen production cycle is avoided, and higher heat efficiency is achieved.

Owner:ZHEJIANG UNIV

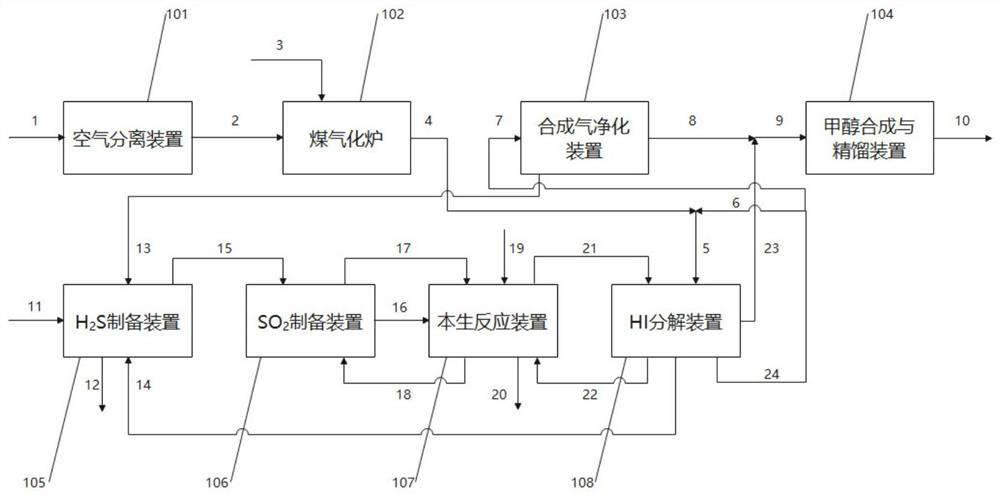

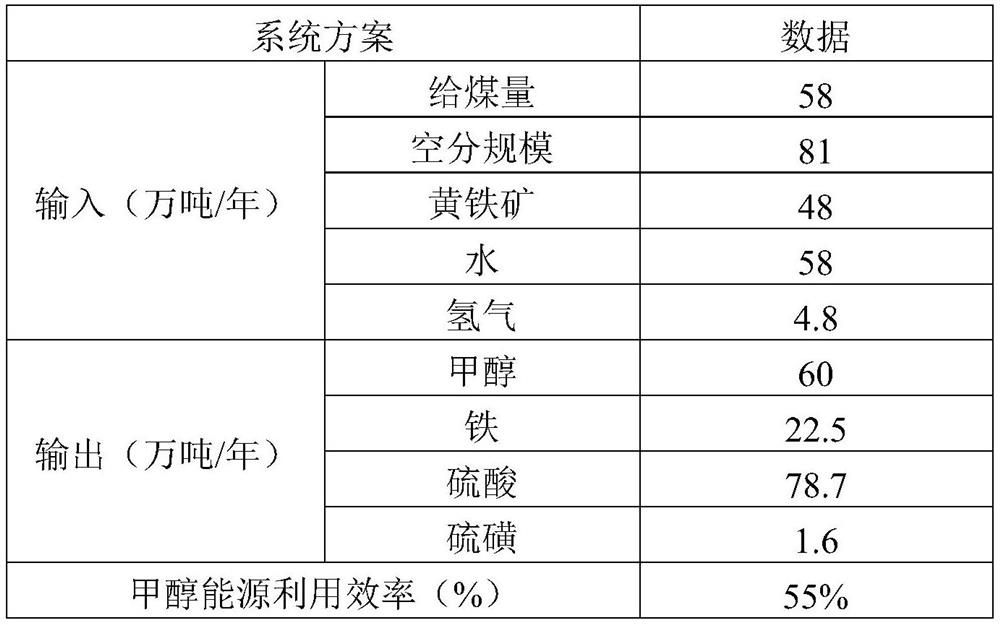

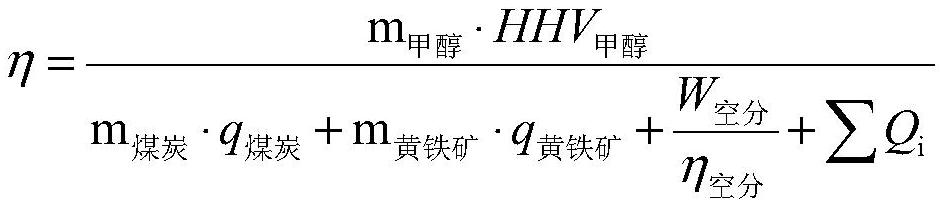

CO2 zero-emission coal-to-methanol system and method for chemical hydrogen production and application

ActiveCN113402362ASmall scaleImprove utilization efficiencyOrganic compound preparationChemical industryChemical productsHydrogen production

The invention relates to a CO2 zero-emission coal-to-methanol system and method for chemical hydrogen production, and application of the CO2 zero-emission coal-to-methanol system and method. The system comprises an air separation device, a coal gasifier device, a synthesis gas purification device, a methanol synthesis and rectification device, an H2S preparation device, an SO2 preparation device, a Bunsen reaction device and an HI decomposition device. According to the CO2 zero-emission coal-to-methanol system for chemical hydrogen production, the water-gas conversion link in the traditional coal chemical process is omitted, and the technological process is simplified; meanwhile, CO2 is not generated in the whole production process, so that the coal consumption and the energy consumption of the system are greatly reduced under the condition of generating the same quantity of chemical products, the scales of the coal gasifier and the synthesis gas purification device are also greatly reduced, the system investment is reduced, the energy utilization efficiency of the system is greatly improved, and the economic benefit of the system is also improved; and zero emission of CO2 in the coal chemical process is achieved, and efficient and clean utilization of coal with low energy consumption and low emission is achieved.

Owner:国能经济技术研究院有限责任公司

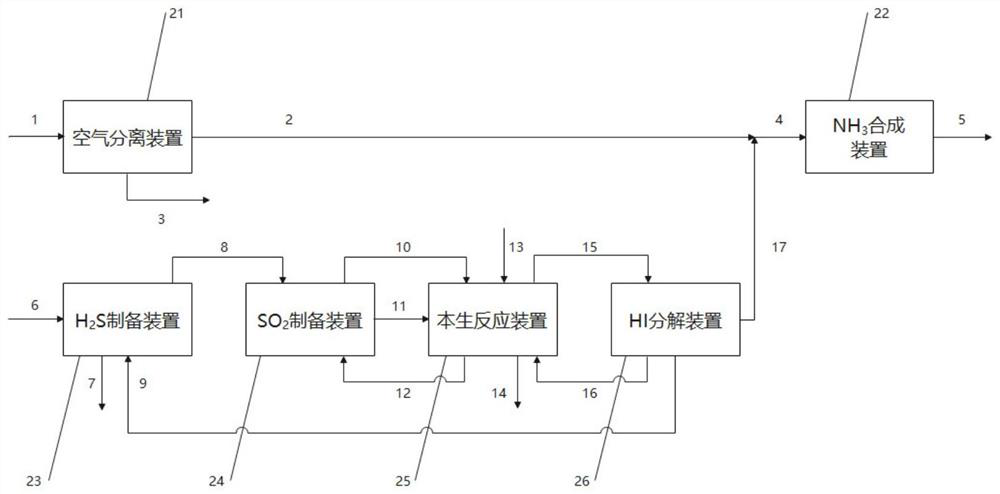

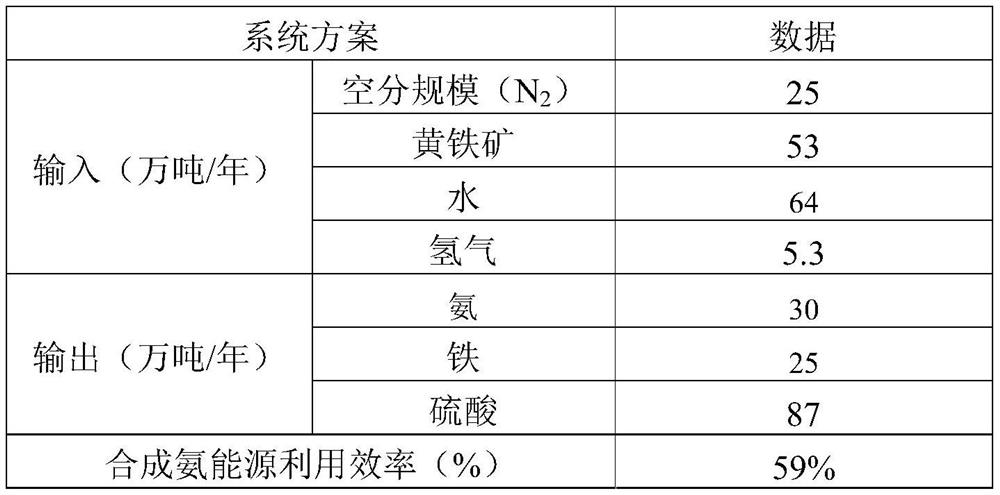

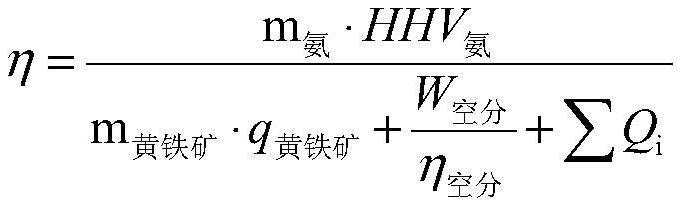

CO2 zero-emission ammonia synthesis system and method based on iodine-sulfur semi-open circulating hydrogen production and application of CO2 zero-emission ammonia synthesis system and method

ActiveCN113401920ASimple processLess investmentNitrogen purification/separationSulfur compoundsPhysical chemistryAir separation

Owner:国能经济技术研究院有限责任公司

Method and device for simplifying thermochemical znsi cycle decomposition of carbon dioxide and water

ActiveCN104477911BThe reaction device is simpleFew reaction stepsProductsReagentsDecompositionDistillation

The invention relates to the field of thermo-chemical cycle systems, and aims to provide a method and a device for simplifying thermo-chemical ZnSI cyclic decomposition of carbon dioxide and water. The method mainly comprises the following steps: performing isothermal reaction on ZnI2 and CO2 to obtain Zn, ZnO, ZnI2, I2 and CO, then performing gas-solid separation, separating CO out from the gas product, reacting the solid product, water and HI to generate ZnI2 and H2O, and preparing ZnI2 solid. The device comprises a distillation tower, a solid feeding device, a ZnI2 / CO2 decomposition reaction generator, a gas-solid separation device, an iodine separation and recovery device, a ZnI2 generator, an HI phase concentrate decomposition system and a Bunsen reaction system. By adopting the method and the device, a thermo-chemical ZnSI cycle system is simplified from a six-step mode to a five-step mode, so that the reaction steps are reduced, the reaction device is simplified, the operation is convenient, no additional matters are introduced and the initial input cost is reduced.

Owner:ZHEJIANG UNIV

Method and device for decomposing CO2 and H2O through thermo-chemistry circulation reaction system

ActiveCN102553407BReduce the temperatureAppropriate reaction temperatureDispersed particle separationAir quality improvementFluidized bedFixed bed

The invention relates to the technology of CO2 emission reduction and aims at providing a method and a device for decomposing CO2 and H2O through a thermo-chemistry circulation reaction system. The method includes: leading H2O, I2 and SO2 to a Bunsen reaction device for a spontaneous heat producing reaction, and leading CO2 to a fixed bed or a fluid bed reactor to produce a heat producing reaction with metal Zn or Ni. Products of all the reactions are recycled and used through the reaction devices and the final products are H2, CO and O2. The maximum heat source temperature is relatively low (lower than 900 DEG C), and other type of heat sources including solar energy, nuclear energy and the like can be used. Negative influence caused by incomplete reactions of Zn and CO2 is reduced, reaction temperature is proper, and scale industry application can be achieved easily.

Owner:浙江百能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com