Hydroiodic acid electrolysis modeling and process simulation method for sulfur-iodine cycle hydrogen production

A modeling method, the technology of hydroiodic acid, applied in the direction of electrical digital data processing, special data processing applications, chemical process analysis/design, etc., can solve problems such as complex processes, and achieve the effect of improving the thermal efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

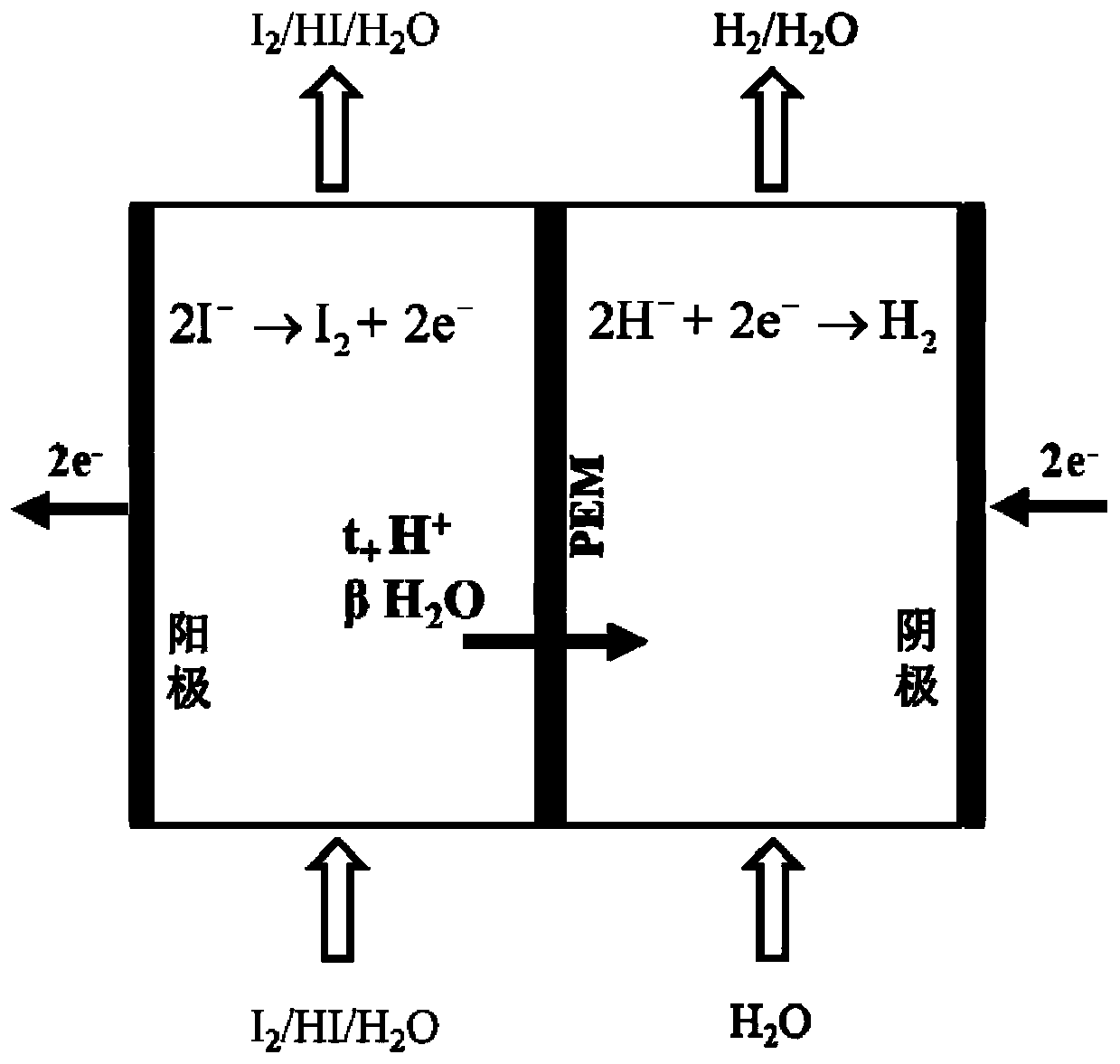

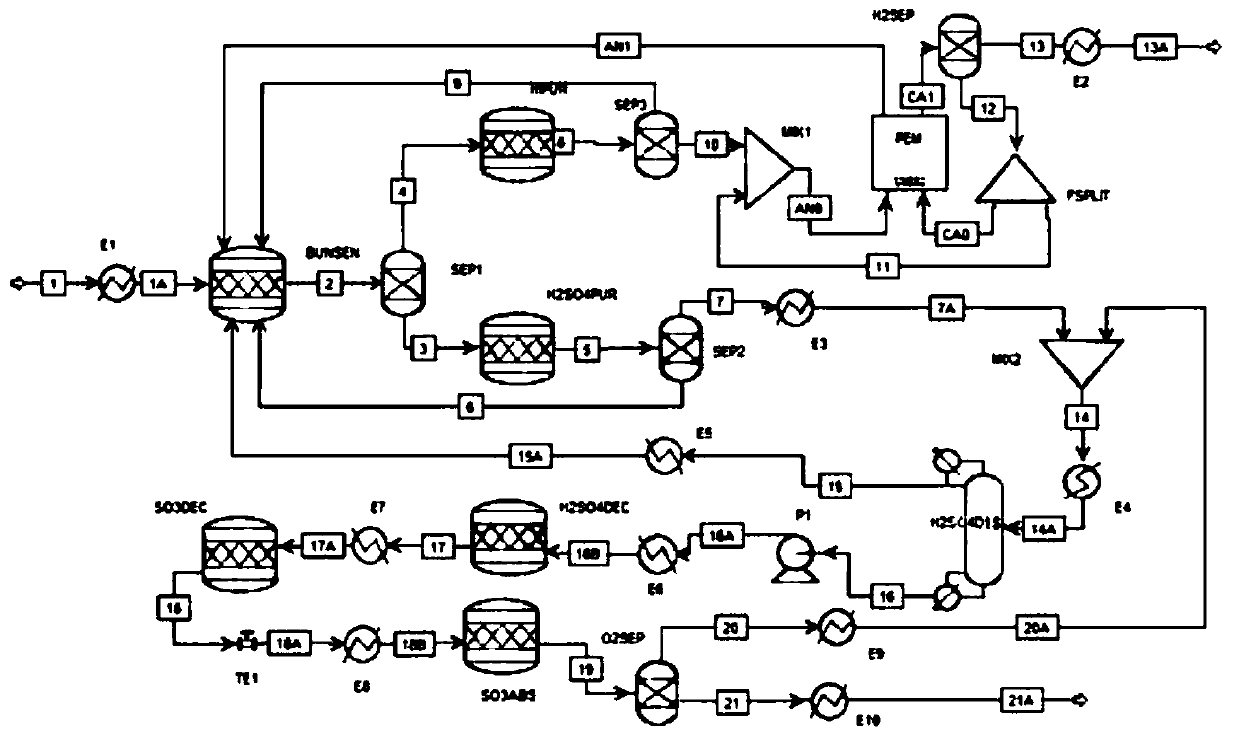

[0067] Set the hydroiodic acid electrolysis parameter t + is 0.95, β is 3, and the effective area of the membrane is 0.0025m 2 , the current density is 1.01A / cm 2 . Design and introduce the sulfur-iodide cycle hydrogen production process after the introduction of hydroiodic acid electrolysis, as shown in the attached figure 2 Shown, including the Bunsen reaction unit, sulfuric acid decomposition unit and hydroiodic acid electrolysis unit. The feed to the Bunsen reaction consists of H 2 O, HI, SO 2 , I 2 , and its corresponding feed ratio is n(H 2 O):n(HI):n(SO 2 ):n(I 2 )=58.96:4.16:32.67:4.21. With the goal of hydrogen production of 10L / h, the ELECNTRL method is used globally. The calculated material balance results of the above three units are shown in Table 6-8.

[0068] Table 6 Information of each material flow in the Bunsen reaction unit

[0069]

[0070]

[0071] Information of each material flow in the sulfuric acid decomposition unit in table 7

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com