Hydrogen-electricity co-production system and method for coal-fired boiler

A technology for coal-fired boilers and power generation systems, applied in combustion methods, chemical instruments and methods, separation methods, etc., can solve problems such as difficulty, and achieve the effects of reducing pollution, improving power generation efficiency, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

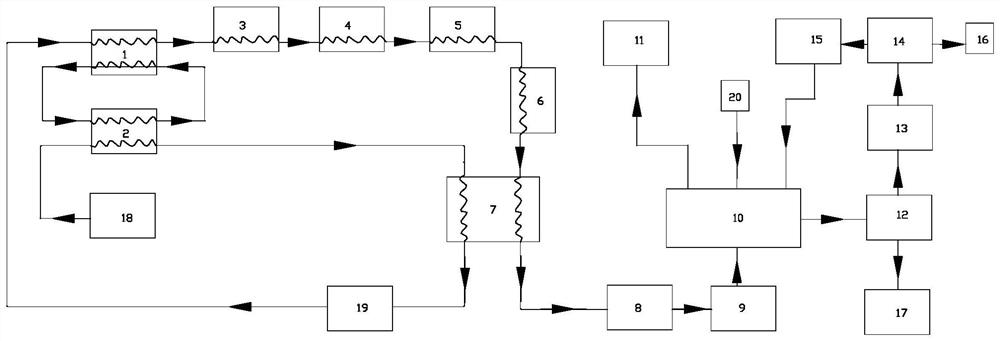

Image

Examples

Embodiment

[0057] The invention is used to build a carbon dioxide coal-fired boiler generator set that can generate 750MW of heat, and the boiler burns coal with a sulfur content of 0.8%. The unit does not need circulating water system, condensate water system, water supply system, deaerator system, high and low pressure heater system, main steam system, demineralized water system, the system is greatly simplified, and the investment cost can be greatly reduced.

[0058] The temperature of carbon dioxide can reach 620℃, the pressure can reach 28MPa, and the carbon dioxide turbine can be turned to generate 350MW of electricity;

[0059] The air required for boiler combustion is used to cool the carbon dioxide after the carbon dioxide turbine does work, and the carbon dioxide temperature can be cooled to a temperature close to the critical temperature. The carbon dioxide power generation system does not require additional cooling sources, which improves the heat utilization efficiency;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com