System and method for comprehensive utilization of boiler sulfur-containing flue gas and fly ash

A boiler and fly ash technology, applied in chemical instruments and methods, aluminum-sulfur compounds, aluminum sulfate, etc., can solve the problems of high price, difficult to meet the high temperature of sulfuric acid, and poor economical production of hydrogen by pyrolysis of sulfuric acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

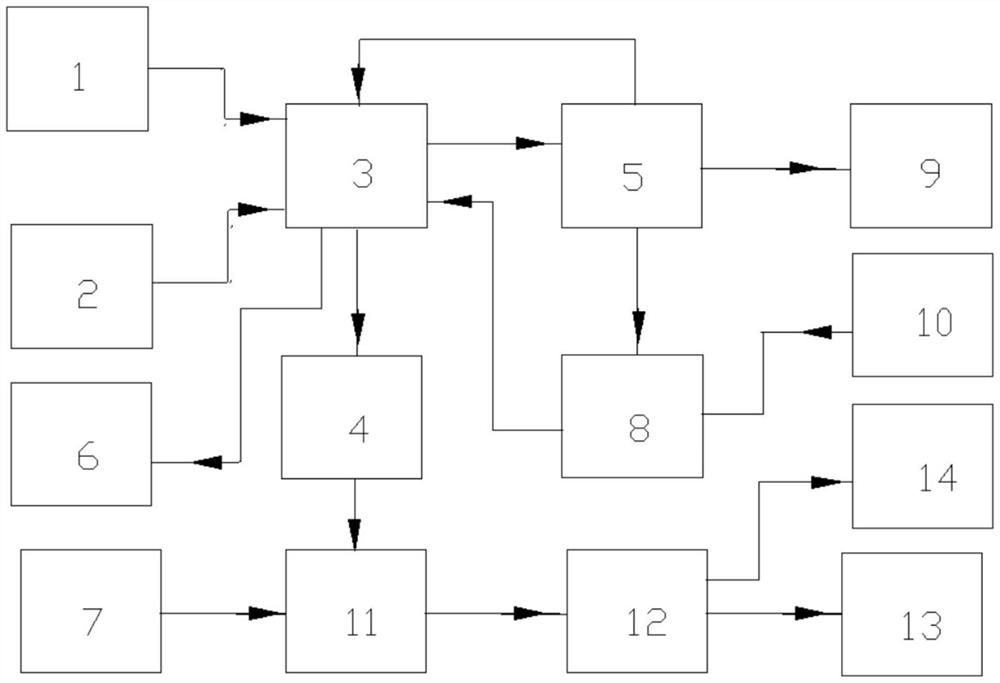

Image

Examples

Embodiment

[0058] The main proportion of the flue gas volume of a 600MW boiler is: nitrogen 80.4%, carbon dioxide 13.1%, oxygen 6.3%, sulfur dioxide 0.16%. Boiler fly ash contains 51% of silicon dioxide and 26% of aluminum oxide.

[0059] Using sulfur dioxide in boiler flue gas to produce hydrogen can produce 120,000 cubic meters of hydrogen, worth about 1.2 million yuan; 600 tons of aluminum sulfate, worth about 600,000 yuan; more than 800 tons of silicon dioxide, worth about 4 million yuan . The economic value is considerable. At the same time, it can reduce 120,000 cubic meters of carbon dioxide emissions produced by the desulfurization system due to the consumption of limestone, and the social benefits are considerable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com