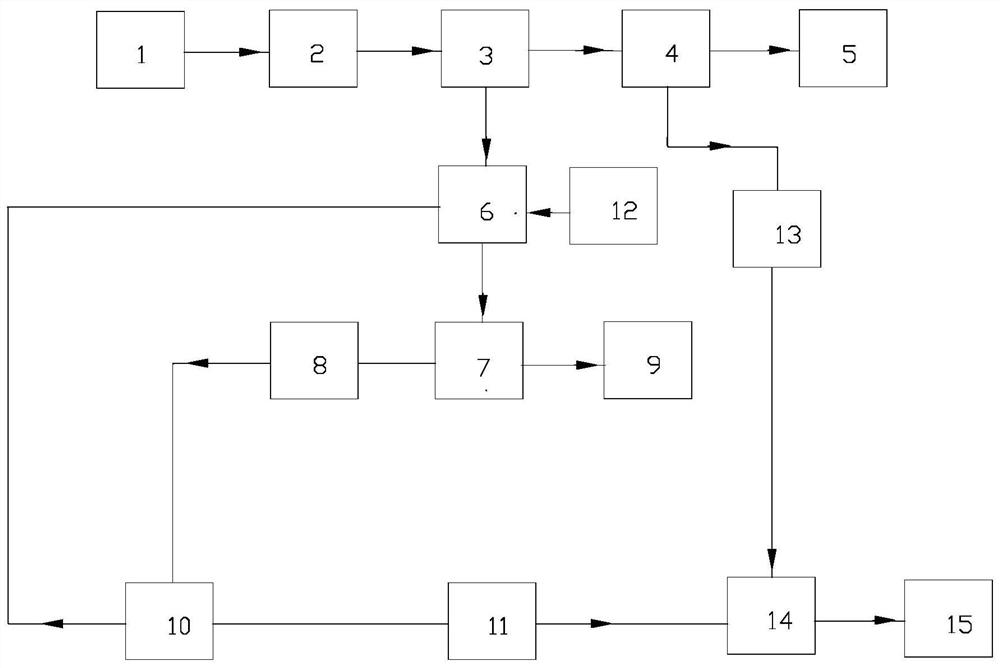

System and method for preparing methane by utilizing sulfur-containing flue gas of boiler

A technology for methane production and boiler flue, which is applied in the production of hydrogen, hydrocarbon production from carbon oxides, organic chemistry, etc., to achieve the effects of environmental protection, low cost of hydrogen production, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The volume ratio of a 1000MW boiler flue gas is: nitrogen 73.28%, carbon dioxide 12.67%, water vapor 8.37%, oxygen 5.4%, sulfur dioxide 0.1%. Utilizing the technology proposed in the present invention, the unit can extract more than 220 tons of sulfur dioxide, 19,000 tons of carbon dioxide and 70,000 m3 of hydrogen every day from the flue gas under full load conditions. 3 , to prepare 340 tons of sulfuric acid. 27 tons of methanol can be synthesized by using the produced hydrogen and extracted carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com