System and method for preparing ammonia gas by utilizing sulfur-containing flue gas of boiler

A boiler flue and flue gas technology, applied in chemical instruments and methods, ammonia compounds, sulfur compounds, etc., can solve the problems of difficult to meet the high temperature of sulfuric acid, poor economy and high price of hydrogen production by pyrolysis of sulfuric acid, and achieve the cost of hydrogen production less, beneficial to environmental protection, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Example data

[0060] Flue gas from a 1000MW boiler mainly includes 73.28% nitrogen, 12.67% carbon dioxide, 8.37% water vapor, 5.4% oxygen, and 0.1% sulfur dioxide by volume.

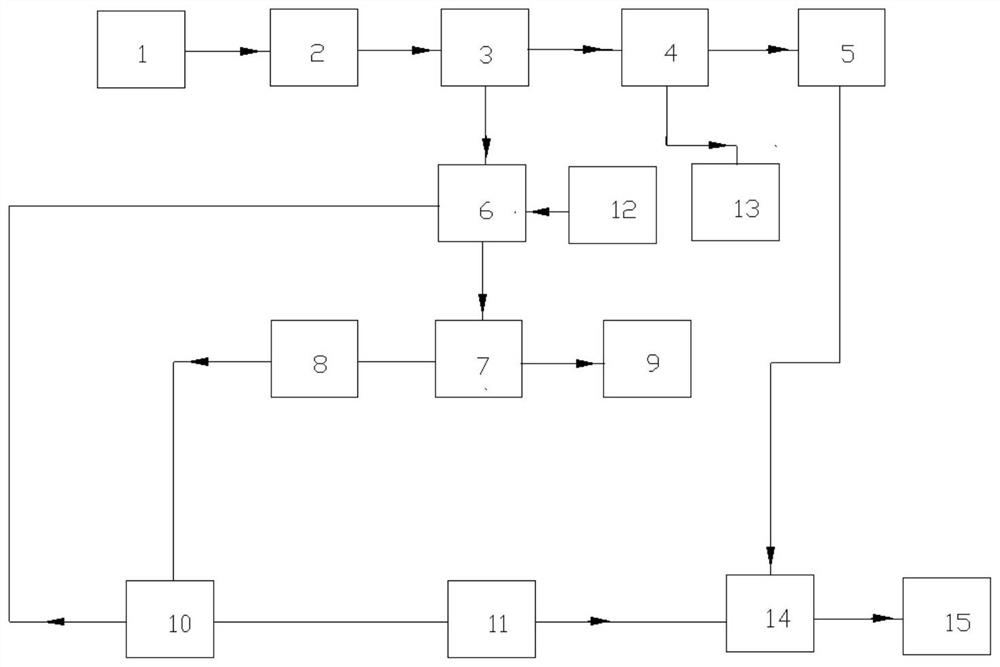

[0061] The flue gas coming out of the spray cooling device 2 is cooled to below -95°C in the first-stage low-temperature scrubber 3. Since the melting point of sulfur dioxide is -72.4°C, the sulfur dioxide in the flue gas is solidified at this time. 3 separated into the Bunsen reactor 6; the sulfur dioxide produced is about 9500kg / h, and theoretically 77000m2 of hydrogen can be produced 3 / d, worth about 770,000 yuan; can produce 340t / d of high-purity sulfuric acid, worth about 170,000 yuan.

[0062] The sulfur dioxide-removed flue gas cooled by the primary low-temperature scrubber 3 to below -95°C continues to cool down to below -120°C in the secondary low-temperature scrubber 4. Since the melting point of carbon dioxide is -78.5°C, the flue gas in the flue gas The carbon dioxide solidifies in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com