Pre-mixing device for sulfur-iodine cycle hydrogen production system and sulfur-iodine cycle hydrogen production system

A hydrogen production system and premixing technology, applied in the production of hydrogen and other directions, can solve the problems of uneven temperature, affecting the reaction conditions of Bunsen reaction, reducing the efficiency of hydrogen production in the sulfur-iodine cycle, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

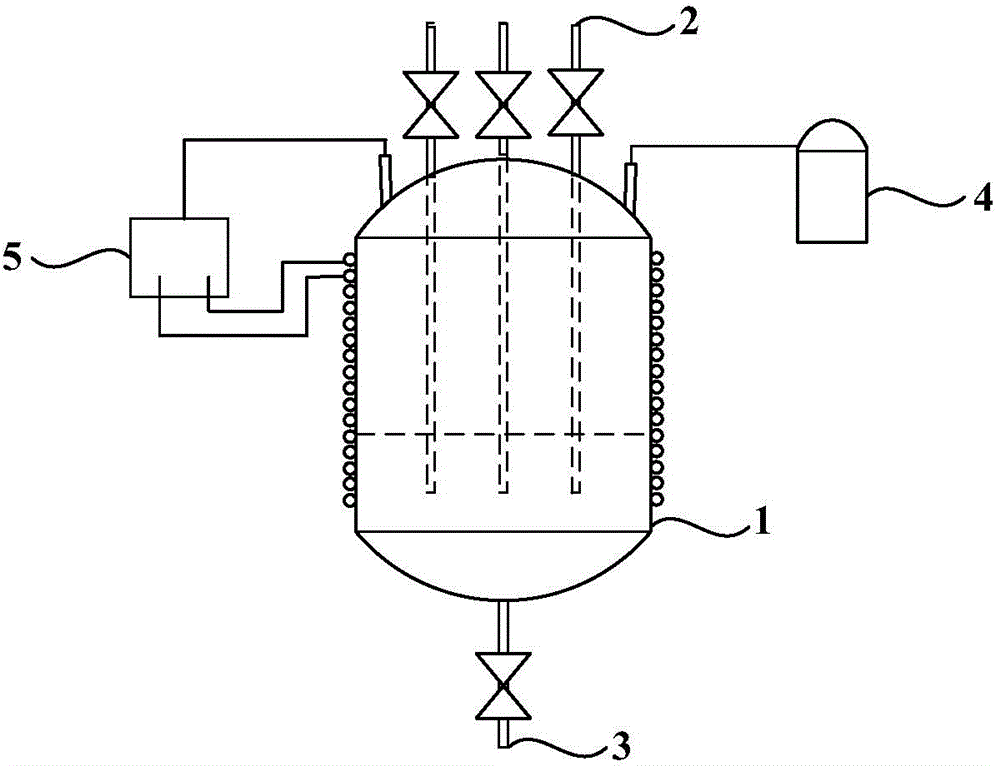

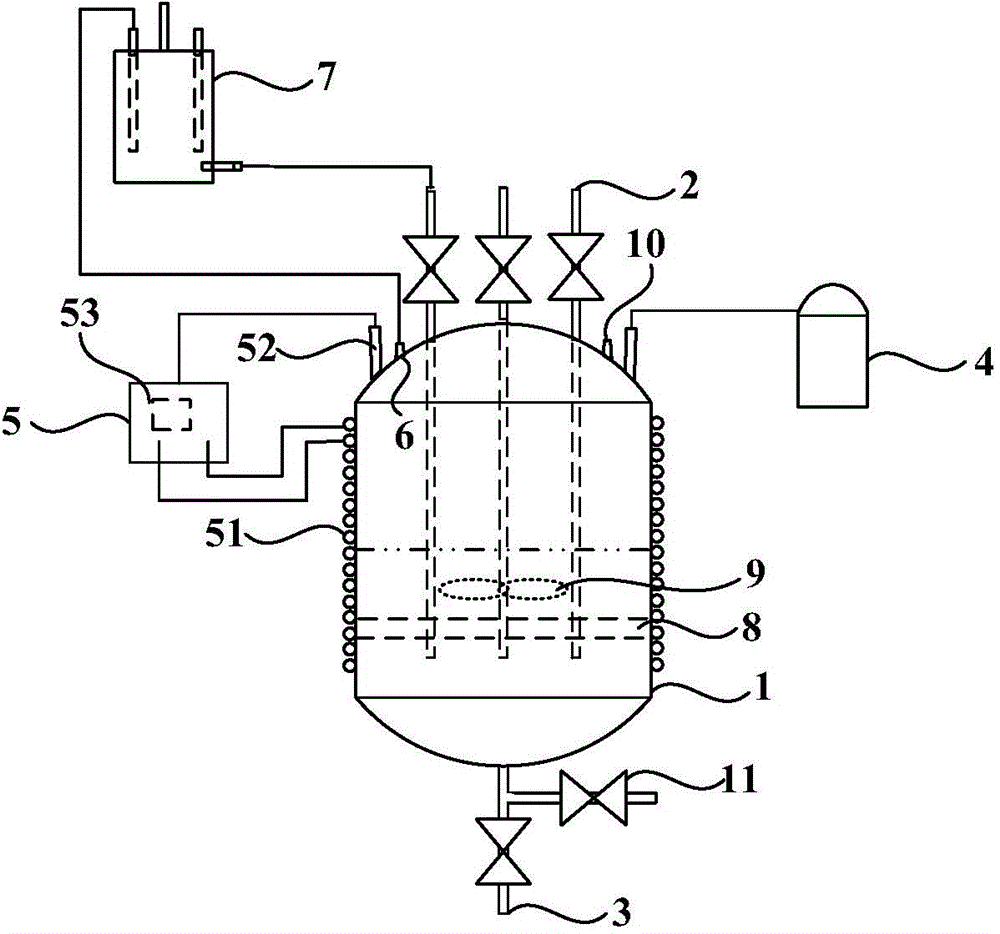

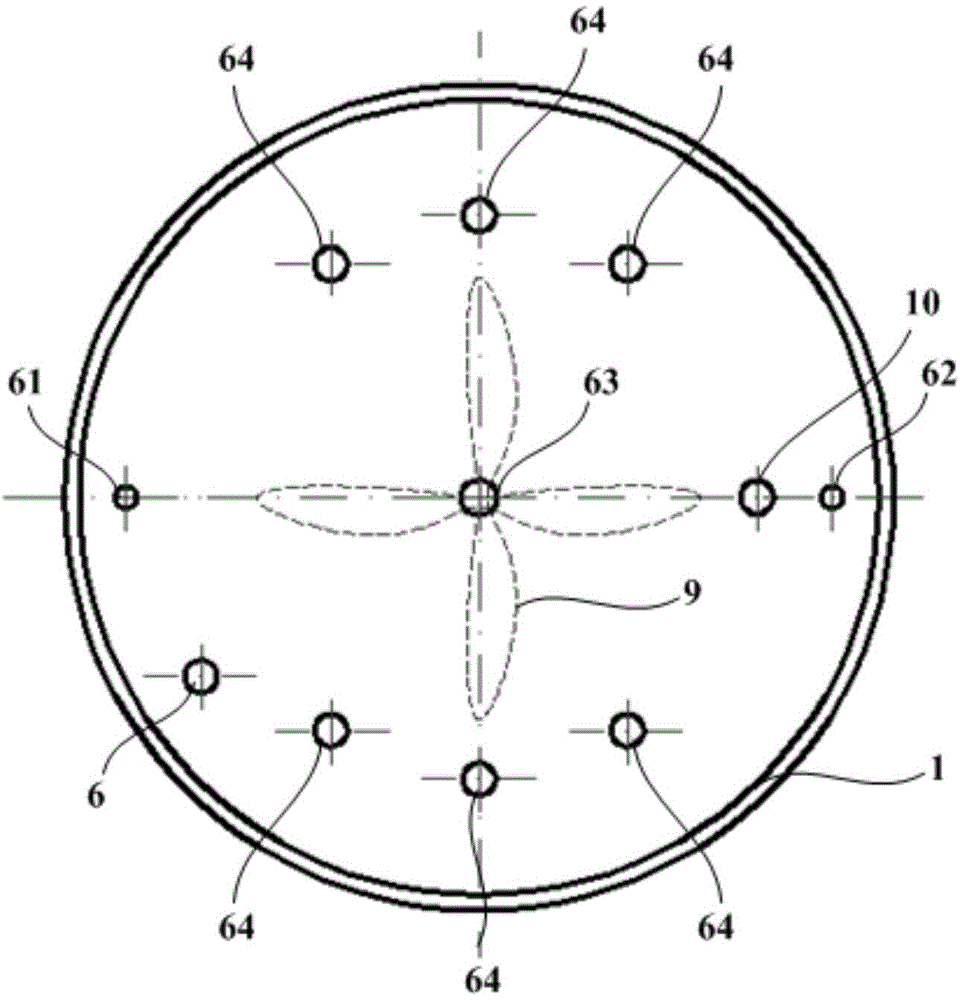

[0040] The invention provides a premixing device of a sulfur-iodine cycle hydrogen production system and a corresponding sulfur-iodine cycle hydrogen production system. In this technical scheme, a premixing device is added before the Bunsen reactor, which is used to mix the external feed for sulfur-iodine cycle hydrogen production, and absorb the internal return in the feed solution And it is well mixed with the feed, and achieves better Bunsen reaction conditions, so that after the material is discharged from the discharge pipe into the Bunsen reactor, the reaction can be effectively carried out, which greatly improves the efficiency of sulfur-iodine cycle hydrogen production. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

[0041] Embodiments of the present invention firstly provide a premixing device for a sulfur-iodine cycle hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com