Iodine-sulfur cyclic hydrogen production method and system based on efficient light energy utilization

A hydrogen production system and light energy technology, applied in chemical instruments and methods, hydrogen, hydrogen production and other directions, can solve the problem of no iodine-sulfur coupling, and achieve the effect of reducing equipment requirements, simple purification process, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

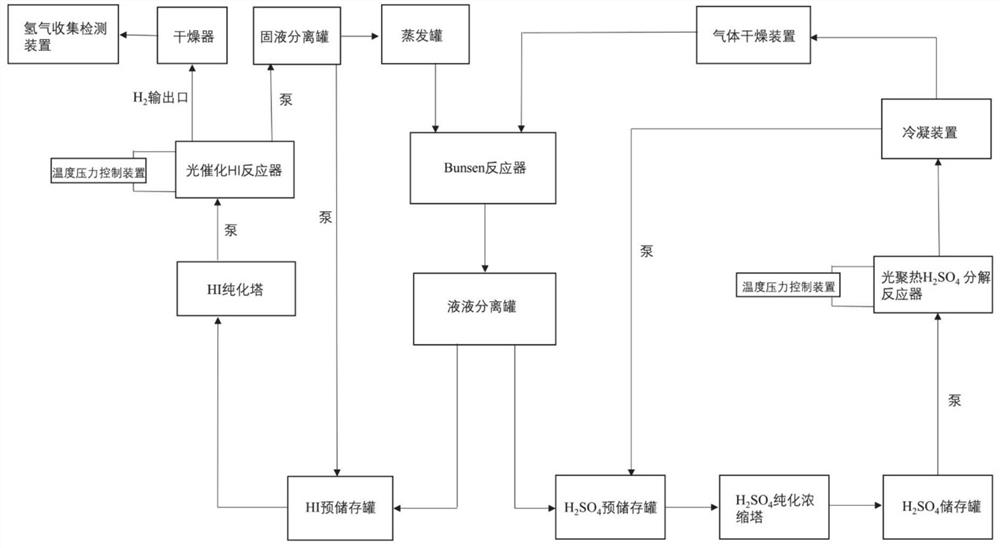

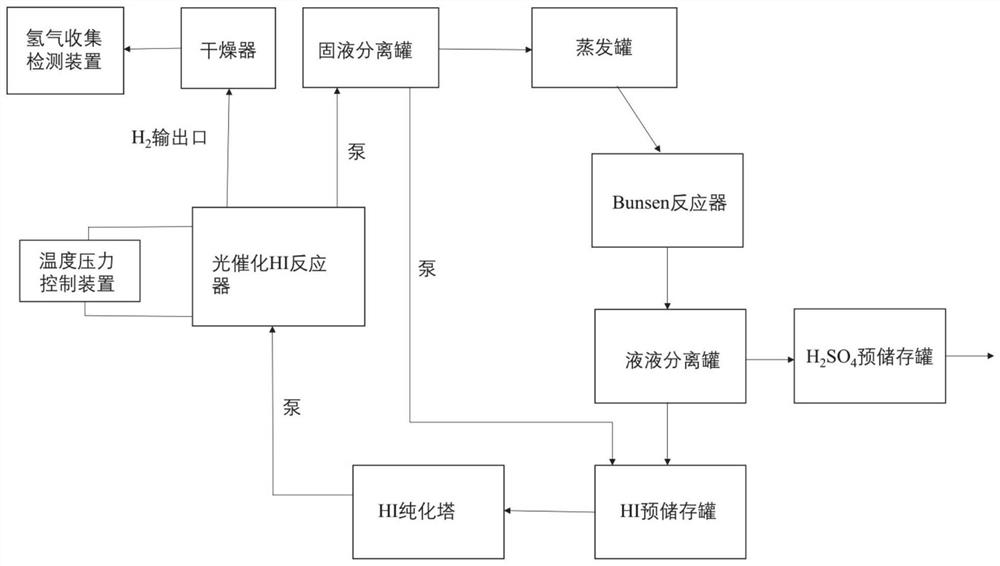

[0059] An iodine-sulfur cycle hydrogen production system based on high-efficiency light energy utilization, photocatalytic HI decomposition unit, Bunsen reaction unit, photopolymerization thermal decomposition H 2 SO 4 device unit.

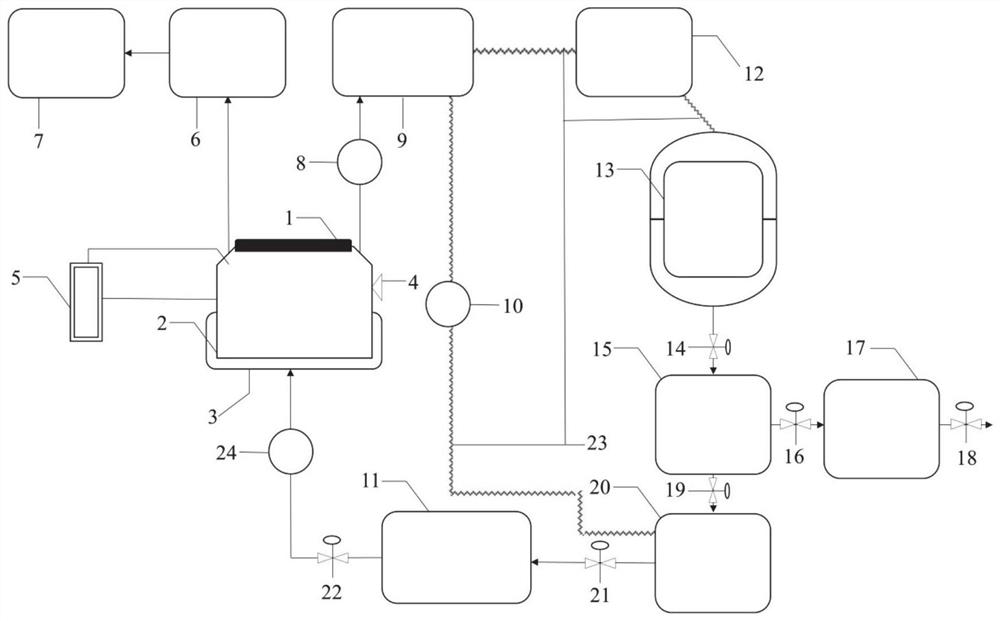

[0060] Photocatalytic HI decomposition unit, such as Figure 1~3 Shown, comprise photocatalytic decomposition HI reactor 2, solid-liquid separation tank 9, I 2 Evaporation tank 12, drier 6, hydrogen collection and detection device 7, HI purification tower 11.

[0061] The material outlet of the photocatalytic decomposition HI reactor 2 is connected to the inlet of the solid-liquid separation tank 9, and the solid-phase outlet of the solid-liquid separation tank 9 is connected to I 2 The entrance of the evaporation tank 12; the photocatalytic decomposition HI reactor 2 includes a kettle body and a kettle cover 1 that cooperate with each other, the kettle cover 1 is located on the upper part of the kettle body, the kettle body is made of glass, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com