Water-permeable brick for pavement

A technology of permeable bricks and bricks, applied in the field of road surface purification, can solve the problems of loss of permeable function, shortened service life, cracking of brick surface, etc., and achieve the effect of improving water quality, reducing pollution and preventing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]In the present invention, the preparation method of the microbial agent can be well known to those skilled in the art, for example, it can include: inoculating Bacillus subtilis, Rhodopseudomonas palustris, Bacillus licheniformis and Lactobacillus plantarum into the culture medium respectively to cultivate. Wherein, Bacillus subtilis, Rhodopseudomonas paluscans, Bacillus licheniformis and Lactobacillus plantarum can be respectively cultivated in independent culture systems.

[0036] Specifically, the cultivation method of Bacillus subtilis (Bacillus subtilis) according to the present invention is not particularly limited, and is known to those skilled in the art. For example, Bacillus subtilis can be cultivated in seed culture medium (LB medium) until bacterial Density OD 600 Value is 0.6-0.8, obtains bacterium liquid, then in the production culture medium (glucose 5g of soybean meal 30g, peptone 2g, distilled water 1000ml, pH7.0-7.2) inoculate the Bacillus subtilis of ...

Embodiment 1

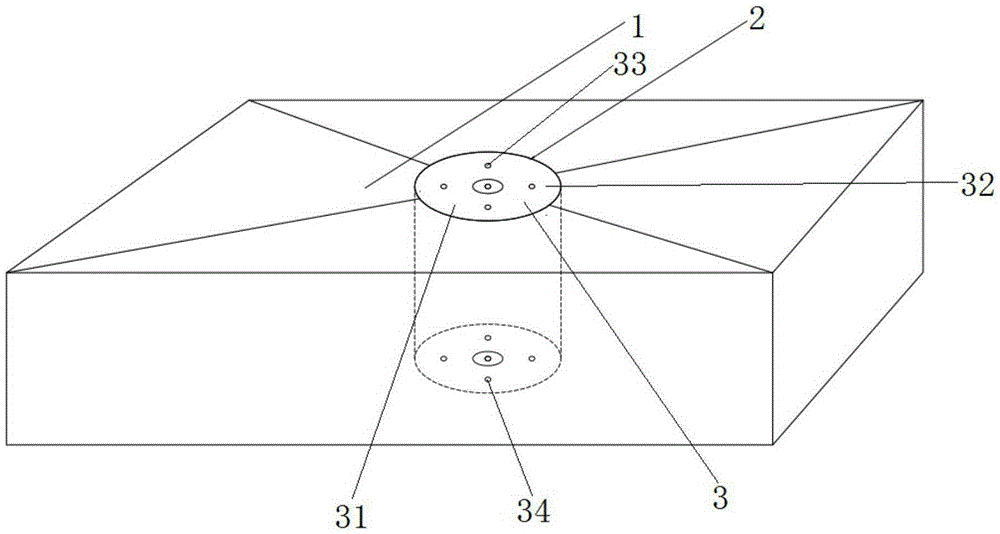

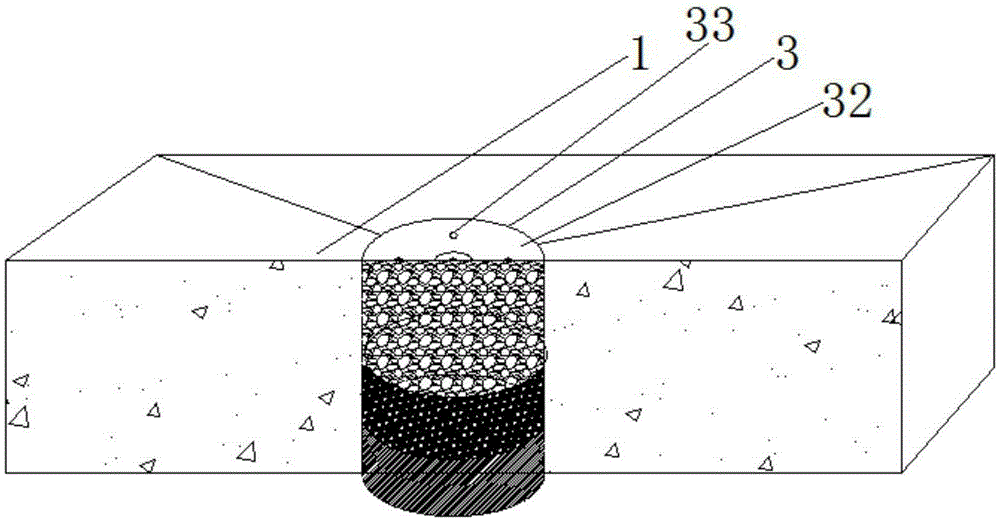

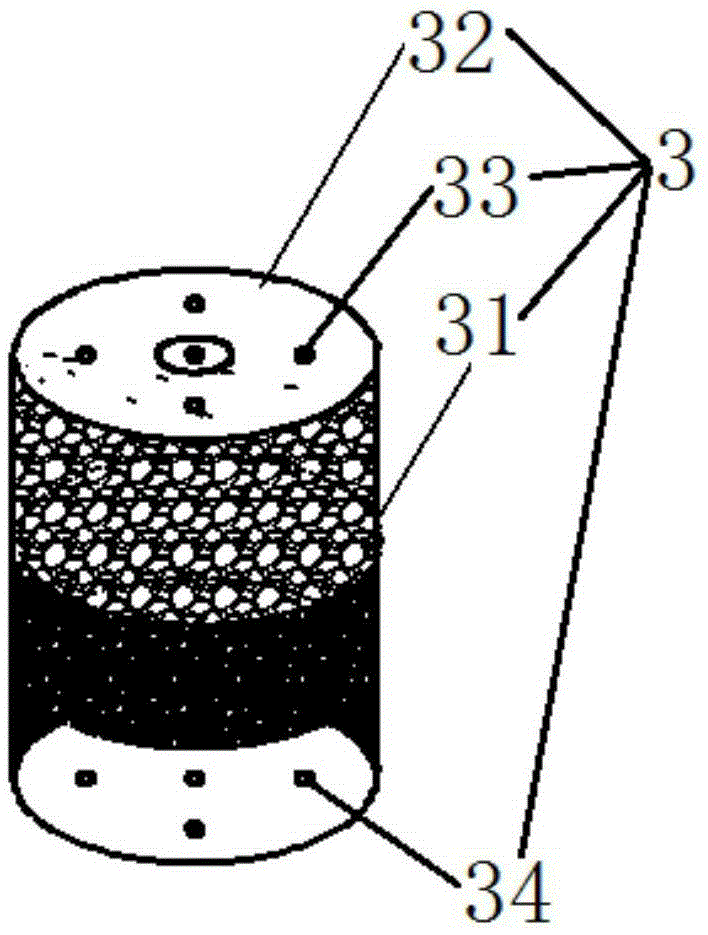

[0054] This embodiment is used to illustrate the microbial bacterial agent of the present invention and the filter device 3 of the permeable brick for pavement using the microbial agent.

[0055](1) Inoculate 5 parts by weight of Bacillus subtilis bacterium liquid (purchased from China Agricultural Microorganism Culture Collection Center) in 100 parts by weight of medium (glucose 5g, soybean meal 30g, peptone 2g, distilled water 1000ml, pH7.0-7.2). And the product number is CFCC10442, cultivated in the same LB medium as above to the bacterial density OD 600 value of 0.6-0.8, to obtain the bacteria liquid), 37 ° C culture, sampling during the culture process and observed by microscope direct counting method, until the number of live bacteria of Bacillus subtilis is 10 8 cfu / gram.

[0056] (2) Inoculate 5 parts by weight of Bacillus licheniformis bacterium liquid (purchased From the China Agricultural Microorganism Culture Collection Center and the product number is ACCC01870,...

Embodiment 2

[0062] This embodiment is used to illustrate the microbial bacterial agent of the present invention and the filter device 3 of the permeable brick for pavement using the microbial agent.

[0063] According to the method of Example 1, the Bacillus subtilis obtained respectively in steps (1) to (4) is mixed with Rhodopseudomonas palustris, Bacillus licheniformis and Lactobacillus plantarum according to the ratio, the difference is that the mixing ratio In the obtained microbial agent, the cfu ratio of Bacillus subtilis to Rhodopseudomonas palustris, Bacillus licheniformis and Lactobacillus plantarum is 1:0.8:0.1:0.3. The obtained mixed bacterial solution is vacuum-dried, pulverized, and passed through a 40-mesh sieve to make a solid bacterial agent, which is placed in the filter barrel 31 of the permeable brick together with the quartz sand with a particle size of 0.8-1.8 mm and the top plate 32 is covered. , the height of the quartz sand filler layer is 118mm, and the addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com