Druss, preparation method and preparation equipment thereof

A carbon black and acetylene technology, applied in fibrous fillers and other directions, can solve problems such as high pollution and high emissions, and achieve the effects of reducing production costs, reducing energy consumption, and reducing particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing carbon black. The method comprises: (A) contacting a carbonaceous material with a high-temperature plasma at 1400-1800° C. for a cracking reaction to obtain a cracked product rich in acetylene; (B) combining the steps (A) The cleavage product obtained is subjected to acetylene decomposition reaction to obtain carbon black.

[0031] Wherein, the working gas of the high-temperature plasma can be a mixed gas of hydrogen and argon, and the power of the high-temperature plasma is 10kW-200kW for a carbonaceous material of 1 kg / min.

[0032] The invention utilizes high-temperature plasma to crack carbonaceous materials. Using a mixture of hydrogen and argon as the working gas can better crack the carbonaceous material. Preferably, the volume ratio of hydrogen and argon in the working gas is (1-4):1; The flow rate is 50-100L / min.

[0033] In the present invention, the working gas is delivered to the plasma generator to obtain high...

Embodiment 1

[0080] This example is used to illustrate the preparation method of the carbon black provided by the present invention.

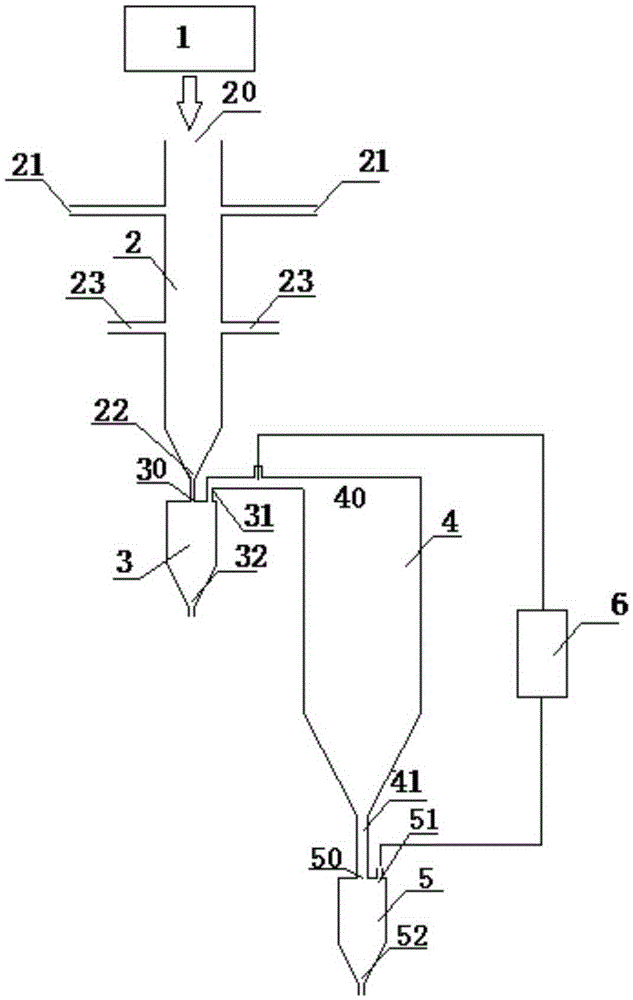

[0081] according to figure 1 The device implementation shown,

[0082] (A) Cracking to produce acetylene: the working gas of hydrogen and argon with a volume ratio of 1:1 is delivered to the plasma generator 1, and the flow rate of the working gas is 15L / min; the working current of the plasma generator 1 is set to 60A, working voltage is 100V (the power of high temperature plasma is 6000W), obtain high temperature plasma and send in the cracking reaction section 2 by plasma inlet 20; Nitrogen is transported from the raw material inlet 21 to the cracking reaction section 2, the feed rate of coal tar is 30ml / min, and the flow rate of nitrogen is 2L / min.

[0083] The cracking reaction of coal tar occurs at 1800°C, argon gas is fed into the cracking reaction section 2 from the quenching agent inlet 23, and the temperature of the cracking product is controlled...

Embodiment 2

[0088] This example is used to illustrate the preparation method of the carbon black provided by the present invention.

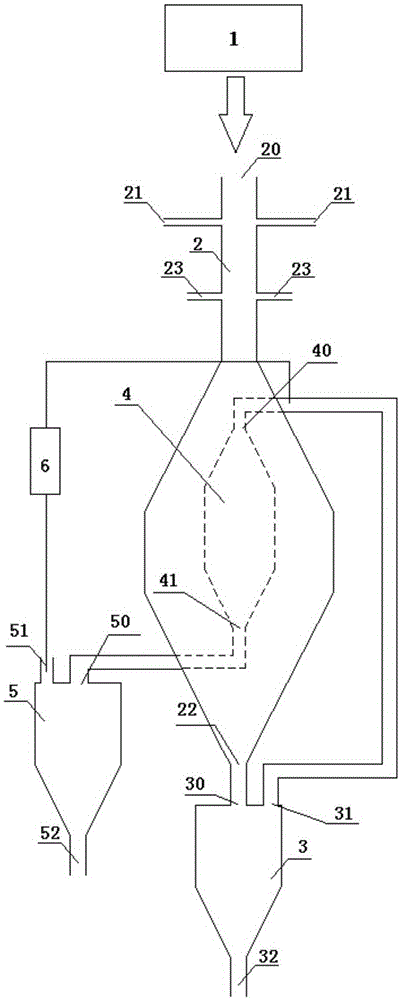

[0089] according to figure 2 The device implementation shown,

[0090] (A) Cracking to produce acetylene: the working gas of hydrogen and argon with a volume ratio of 4:1 is delivered to the plasma generator 1, and the flow rate of the working gas is 20L / min; the working current of the plasma generator 1 is set to 80A, the working voltage is 125V (the power of the high temperature plasma is 10000W), and the high temperature plasma is obtained and sent into the cracking reaction section 2 through the plasma inlet 20; at the same time, the coal powder (with a particle size of 40 μm or less) is removed from the raw material with nitrogen gas The inlet 21 is delivered to the cracking reaction section 2, the feed rate of pulverized coal is 50ml / min, and the flow rate of nitrogen is 2L / min.

[0091] At 1400°C, the cracking reaction of pulverized coal occurs, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com