CO2 zero-emission coal-to-methanol system and method for chemical hydrogen production and application

A coal-to-methanol, zero-emission technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems that the total amount of hydrogen cannot meet the hydrogen demand and the limited installed capacity, so as to improve energy utilization efficiency and reduce Energy consumption and the effect of reducing system investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

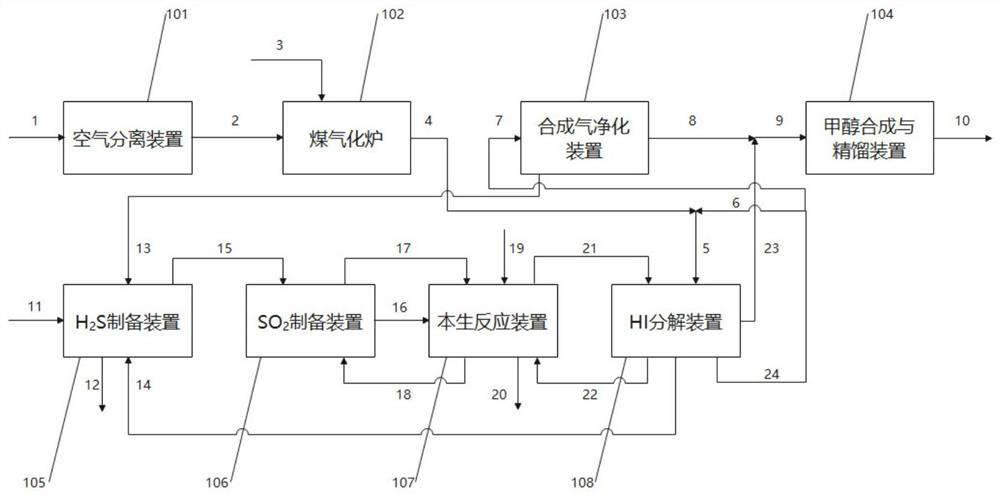

Method used

Image

Examples

Embodiment 1

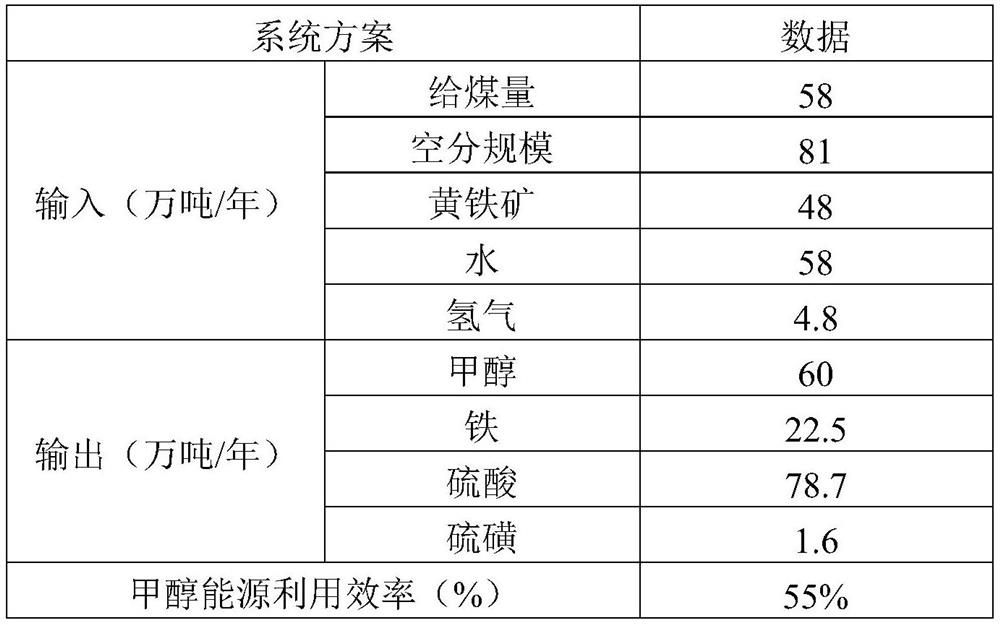

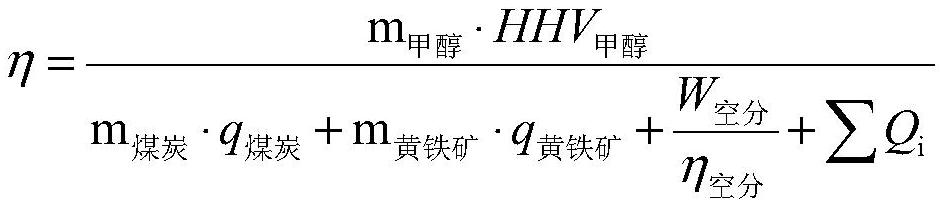

[0060] Based on the production of 600,000 tons / year of methanol, the above-mentioned method and system were used to calculate the overall performance of the system at base load in Example 1. The composition parameters of raw coal are shown in Table 1. Generally, the comprehensive energy utilization efficiency of coal-to-methanol is about 37% to 44%, and the CO 2 The emission is 1.12 million tons / year, and the coal consumption is 1.11 million tons / year. The results are shown in Table 2. The hydrogen production energy utilization efficiency of the system in Example 1 is about 55%, and the CO in the production process 2 The emission is 0, and the coal consumption is reduced by 530,000 tons / year.

[0061] Table 1 Composition parameters of raw coal

[0062] Moisture, mass% Ash content, mass% Volatile matter, mass% Fixed carbon, mass% Calorific value, MJ / kg 8 27.6 9.14 55.26 22.36

[0063] Table 2 embodiment 1 overall performance data

[0064]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com