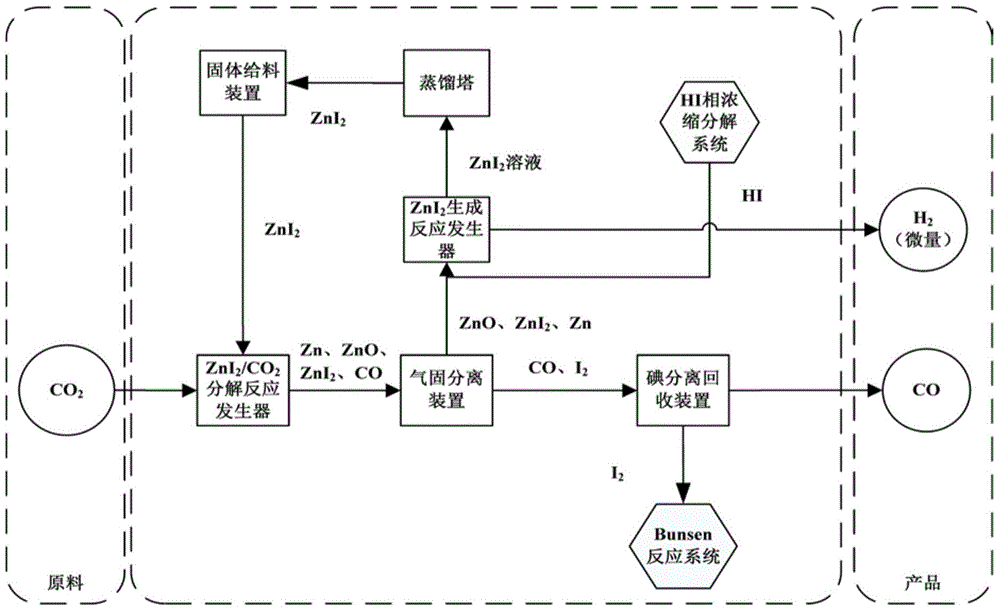

Method and device for simplifying thermo-chemical ZnSI cyclic decomposition of carbon dioxide and water

A technology of carbon dioxide and thermochemistry, applied in chemical instruments and methods, carbon monoxide, separation methods, etc., can solve the problems of high decomposition reaction temperature, complicated reaction steps, and difficult reverse reaction, etc., to reduce reaction steps, reduce the maximum heat source temperature, and operate Easy to run effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Set ZnI 2 with CO 2 The molar ratio is 1:1, the temperature of the reactor is raised to 1000°C at 1 atm and kept at a constant temperature, the temperature of the gas-solid separator is maintained at a constant temperature of 200°C, and the water cooling temperature of the iodine separation device is 30°C. According to the set ZnI 2 with CO 2 The molar ratio of the CO 2 , ZnI 2 Simultaneously into ZnI 2 / CO 2 Decompose the reaction generator to react (ZnI 2 →Zn+I 2 , CO 2 +Zn→ZnO+CO); Subsequently, the gas produced with solid products passes through the gas-solid separator, iodine separation device and gas collection device in turn to obtain solid products (ZnO, ZnI 2 mixture), solid I 2 and the final product CO. The resulting ZnO, ZnI 2 The mixture is fed into ZnI 2 Generate a reaction device that reacts with HI provided by the HI phase concentration and decomposition system in the presence of water at 1atm and 90°C (ZnO+HI→ZnI 2 +H 2 O) get ZnI 2 solut...

Embodiment 2

[0060] Set ZnI 2 with CO 2 The molar ratio is 1.5:1, the temperature of the reactor is raised to 800°C at 1 atm and kept at a constant temperature, the temperature of the gas-solid separator is maintained at a constant temperature of 200°C, and the water cooling temperature of the iodine separation device is 20°C. According to the set ZnI 2 with CO 2 The molar ratio of the CO 2 , ZnI 2 Simultaneously into ZnI 2 / CO 2 Decompose the reaction generator to react (ZnI 2 →Zn+I 2 , CO 2 +Zn→ZnO+CO); Subsequently, the gas produced with solid products passes through the gas-solid separator, iodine separation device and gas collection device in sequence to obtain solid products (Zn (trace), ZnO, ZnI 2 mixture), solid I 2 and the final product CO. The resulting Zn (trace), Zn and ZnI 2 The mixture is fed into ZnI 2 Generate a reaction device that reacts with HI provided by the HI phase concentration and decomposition system in the presence of water at 1atm and 50°C (ZnO+HI→Z...

Embodiment 3

[0062] Set ZnI 2 with CO 2 The molar ratio is 3.5:1, the temperature of the reactor is raised to 600°C at 1 atm and kept at a constant temperature, the temperature of the gas-solid separator is maintained at a constant temperature of 200°C, and the water cooling temperature of the iodine separation device is 0°C. According to the set ZnI 2 with CO 2 The molar ratio of the CO 2 , ZnI 2 Simultaneously into ZnI 2 / CO 2 Decompose the reaction generator to react (ZnI 2 →Zn+I 2 , CO 2 +Zn→ZnO+CO); Subsequently, the gas produced with solid products passes through the gas-solid separator, iodine separation device and gas collection device in sequence to obtain solid products (Zn (trace), ZnO, ZnI 2 mixture), solid I 2 and the final product CO. The resulting Zn (trace), Zn and ZnI 2 The mixture is fed into ZnI 2 Generate a reaction device that reacts with HI provided by the HI phase concentration and decomposition system in the presence of water at 1atm and 20°C (ZnO+HI→Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com