New process for preparing tribenuron-methyl by using one-pot method

A technology for trisulfuron-methyl and a new process is applied to the field of a new process for preparing trisulfuron-methyl by a one-pot method, which can solve the problems of increasing triphosgene leakage, high consumption, difficult quantitative reaction, etc. Danger, reduce energy waste, simplify the effect of the reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

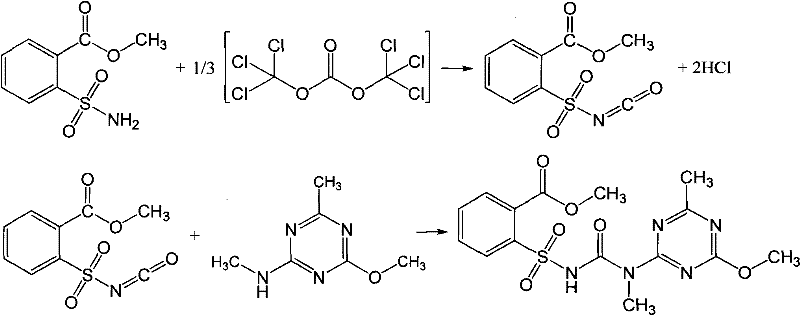

[0006] Embodiment 1: a new preparation process of tribenuron-methyl, the process is first reacted with methyl o-formate benzenesulfonamide and solid phosgene, and the reaction product continues to react with methyl triazine to prepare tribenuron-methyl, the reaction formula is as follows:

[0007]

[0008] In a 500 ml four-neck flask equipped with a thermometer, a stirrer and a condenser tube, add 0.1 mol of methyl o-formate benzenesulfonamide, add 0.04 mol of solid phosgene, 0.06 mol of n-butyl isocyanate, and xylene 250 milliliters, heat up to reflux after stirring evenly, and after stirring for 3 hours under reflux, steam the catalyst and solvent under reduced pressure (for the next previous step reaction to apply directly), add 250 milliliters of fresh xylene solvent, add 0.1mol methyltriazine, the temperature of the reaction mixture solution was raised to 70° C., and the stirring was continued for 2 hours. After the reaction was finished, the solvent was precipitated u...

Embodiment 2

[0009] Embodiment two: in the 500 milliliter four-neck flasks that thermometer, stirrer and condensing pipe are equipped with, add the methyl o-formate benzene sulfonamide of 0.1mol, add the solid phosgene of 0.04mol, and the catalyst of reclaiming and 250 milliliters of solvents After stirring evenly, it was heated to reflux, and after stirring for 3 hours under reflux, the catalyst and solvent were evaporated under reduced pressure (continuing to apply mechanically next time), and 250 milliliters of xylene solvent was added, and 0.1mol of methyl triazine was added. , the temperature of the reaction mixed solution was raised to 70° C., and the stirring was continued for 2 hours. After the reaction, desolvation under reduced pressure (the solvent will be used next time), and post-treatment, drying to obtain 31.7 grams of product, the yield is 80.2% based on methyl o-formate benzenesulfonamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com