Patents

Literature

43results about How to "Solving Wastewater Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

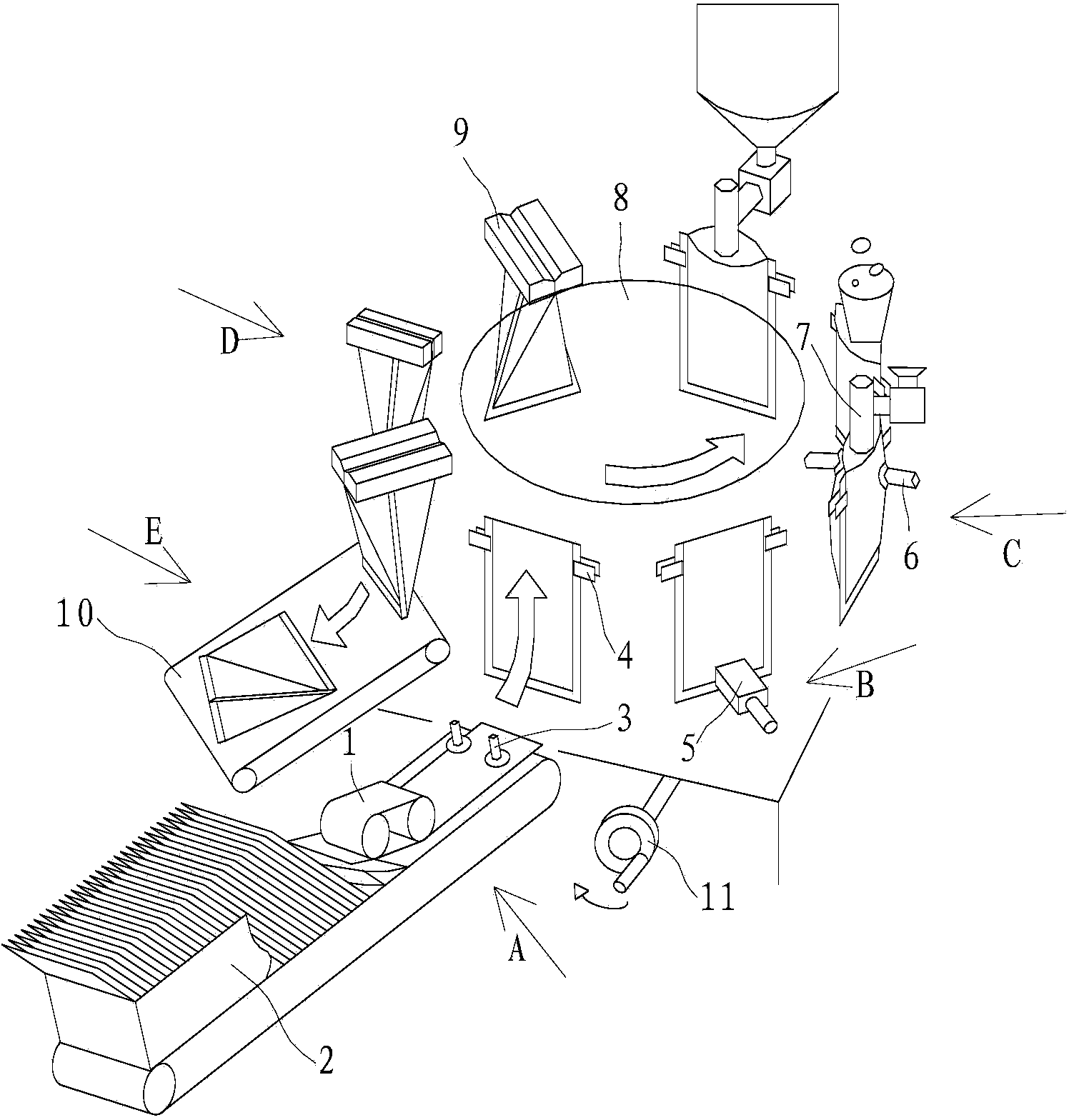

Automatic zongzi filling equipment and process

ActiveCN103964005AIncrease productivityReduce labor intensityWrapper twisting/gatheringLiquid materialRotary stageIntermittent motion

The invention discloses an automatic zongzi filling equipment and process. The equipment comprises a rotary table moving intermittently, a conveying mechanism, a feeding mechanism, a sealing mechanism and an output mechanism, wherein the conveying mechanism, the feeding mechanism, the sealing mechanism and the output mechanism are sequentially distributed in the circumferential direction of the rotary table; a plurality of clamping mechanisms are mounted on the rotary table in the circumferential direction; each clamping mechanism comprises a pair of supporting arms, the distance between each pair of supporting arms is adjustable, and each supporting arm is provided with a clamping jaw used for clamping a packaging bag; the conveying mechanism comprises a supply tank used for containing the packaging bags and a movable suction cup used for transferring the packaging bags in the supply tank to the clamping mechanism one by one; the feeding mechanism comprises a pair of bag opening suction cups matched with the obverse sides and the reverse sides of the packaging bags and a material conveying pipe feeding materials to the opened packaging bags; the sealing mechanism comprises two heat sealing films matched with each other; the output mechanism is used for carrying conveyor belts of products released by the clamping mechanisms. According to the equipment and process, zongzi can be automatically formed, production and manufacturing efficiency is improved, and cost and energy consumption are reduced.

Owner:ZHEJIANG WUFANGZHAI INDAL

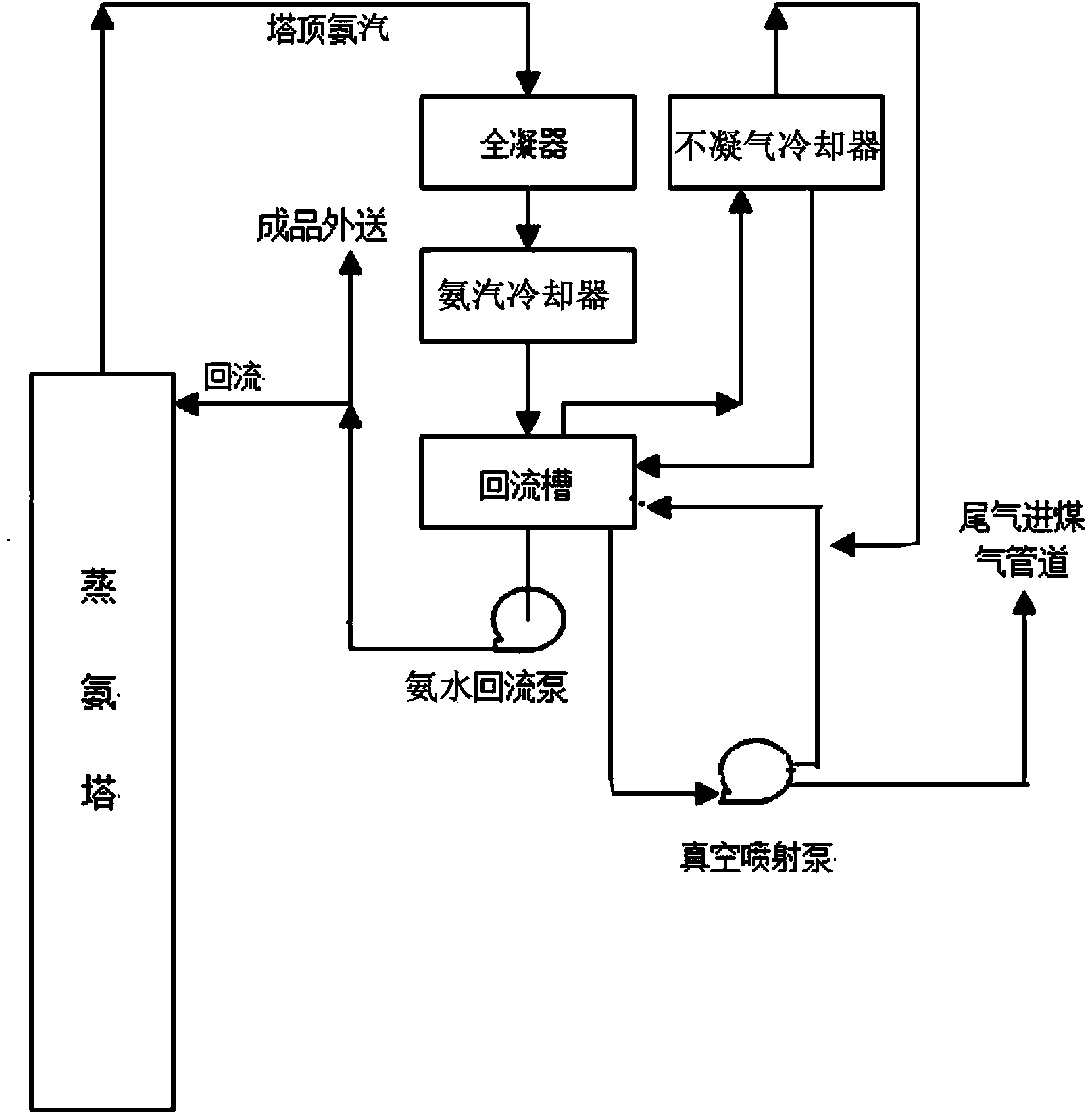

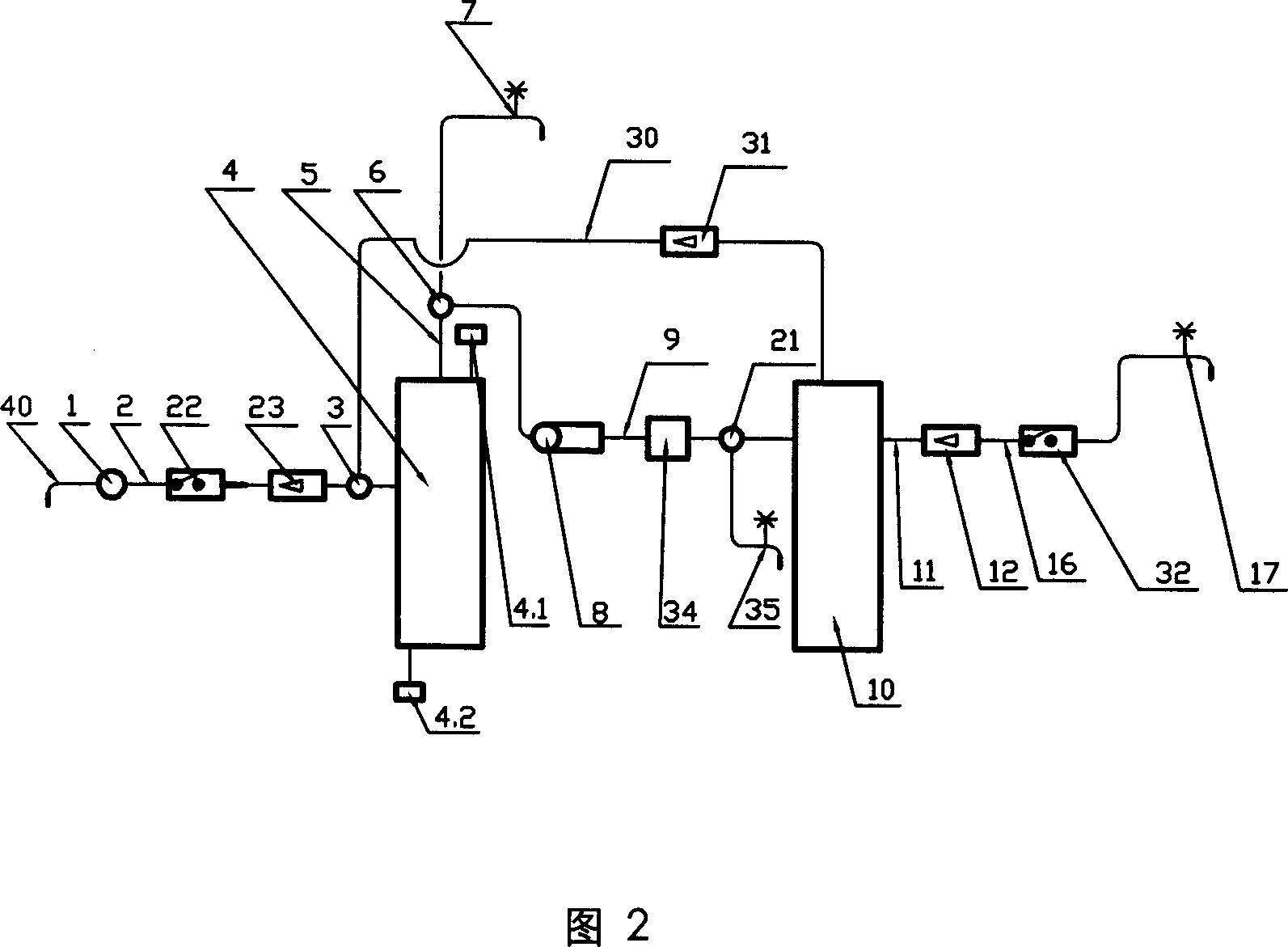

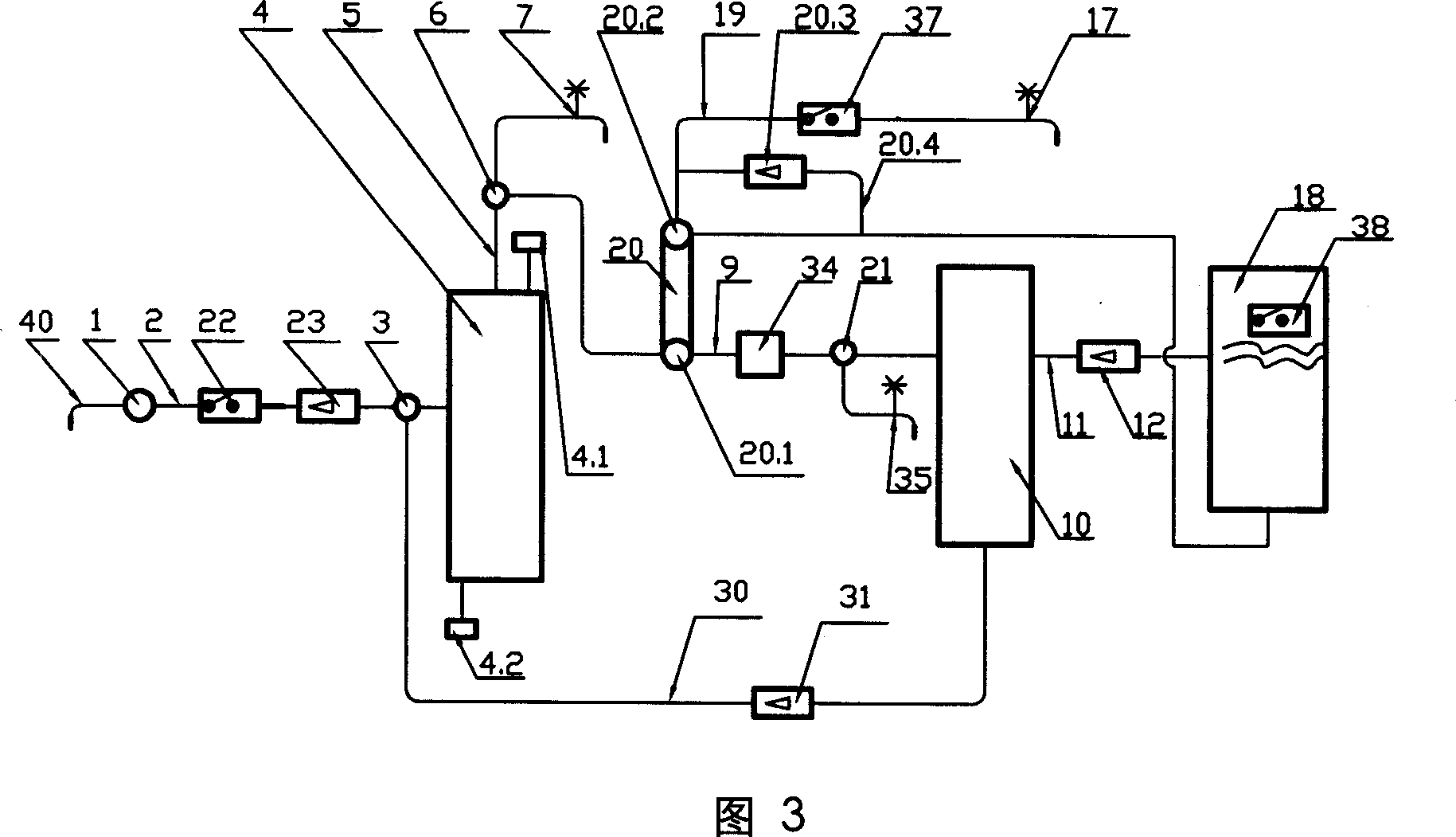

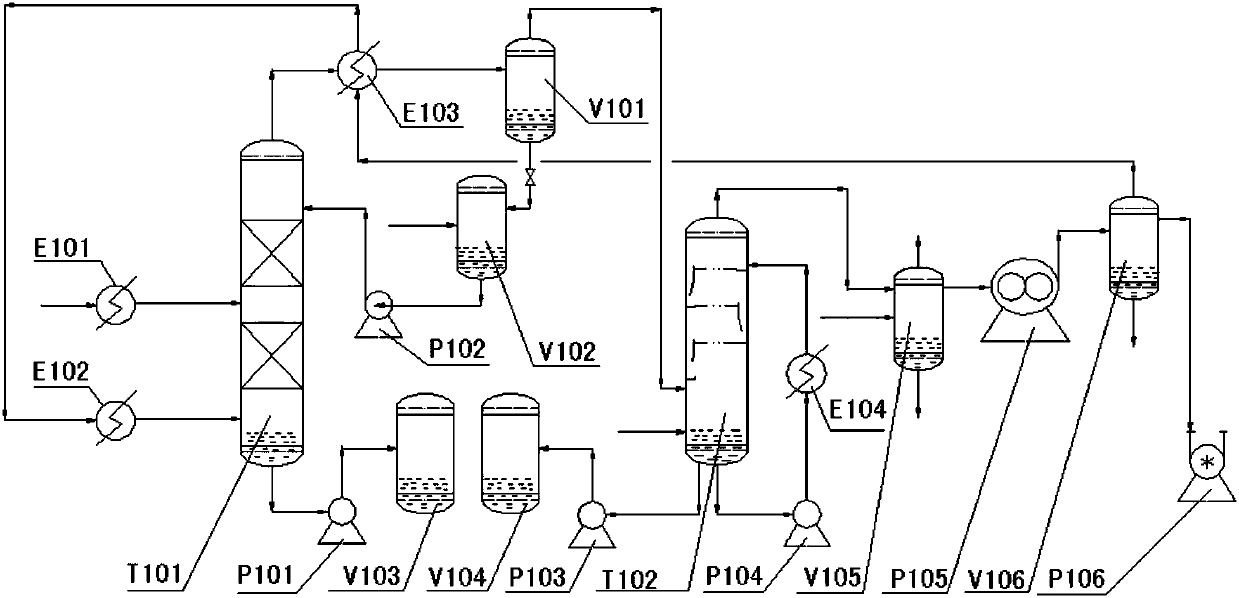

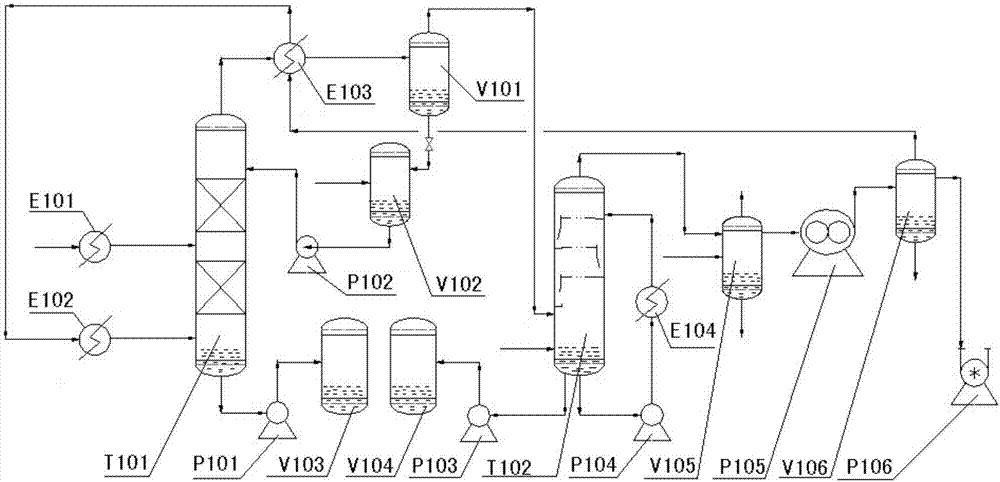

Device and process for stilling ammonia with negative pressure

InactiveCN103833049AReduce manufacturing costIncrease concentrationAmmonia preparation/separationRefluxGas cooler

The invention discloses a device and process for stilling ammonia with negative pressure, and belongs to the ammonia stilling technology. The device comprises an ammonia stilling tower, a total condenser, an ammonia cooler, a reflux tank, and an ammonia water reflux pump, which are connected in sequence; one path of the outlet end of the ammonia water reflux pump is connected with the ammonia stilling tower and while the other path of the outlet end of the ammonia water flux pump is used for transferring to the outside; the reflux tank, a non-condensable gas cooler and a vacuum injection pump form a circulation loop; and the vacuum injection pump is also connected with a gas pipeline. The process comprises the following steps of: performing ammonia stilling for vacuum circulating ammonia water; cooling the ammonia; transferring the obtained ammonia water into the reflux tank; cooling the non-condensable gas; transferring into the reflux tank to circulate under the effect of the vacuum injection pump; refluxing the first part the ammonia water produced in the reflux tank, transferring the second part of the ammonia water to the outside as a finished product, and circulating the third part of the ammonia water as circulating liquid; and then feeding the un-absorbed tail gas into the gas pipeline. With the adoption of the device and process for stilling ammonia with the negative pressure, the vacuum condition for negative-pressure ammonia stilling can be effectively realized, so that the negative-pressure operation can be carried out; in addition, the quality of ammonia is improved, the operation cost is low, the labor intensity is small, and other characteristics are also brought.

Owner:JIGANG GRP

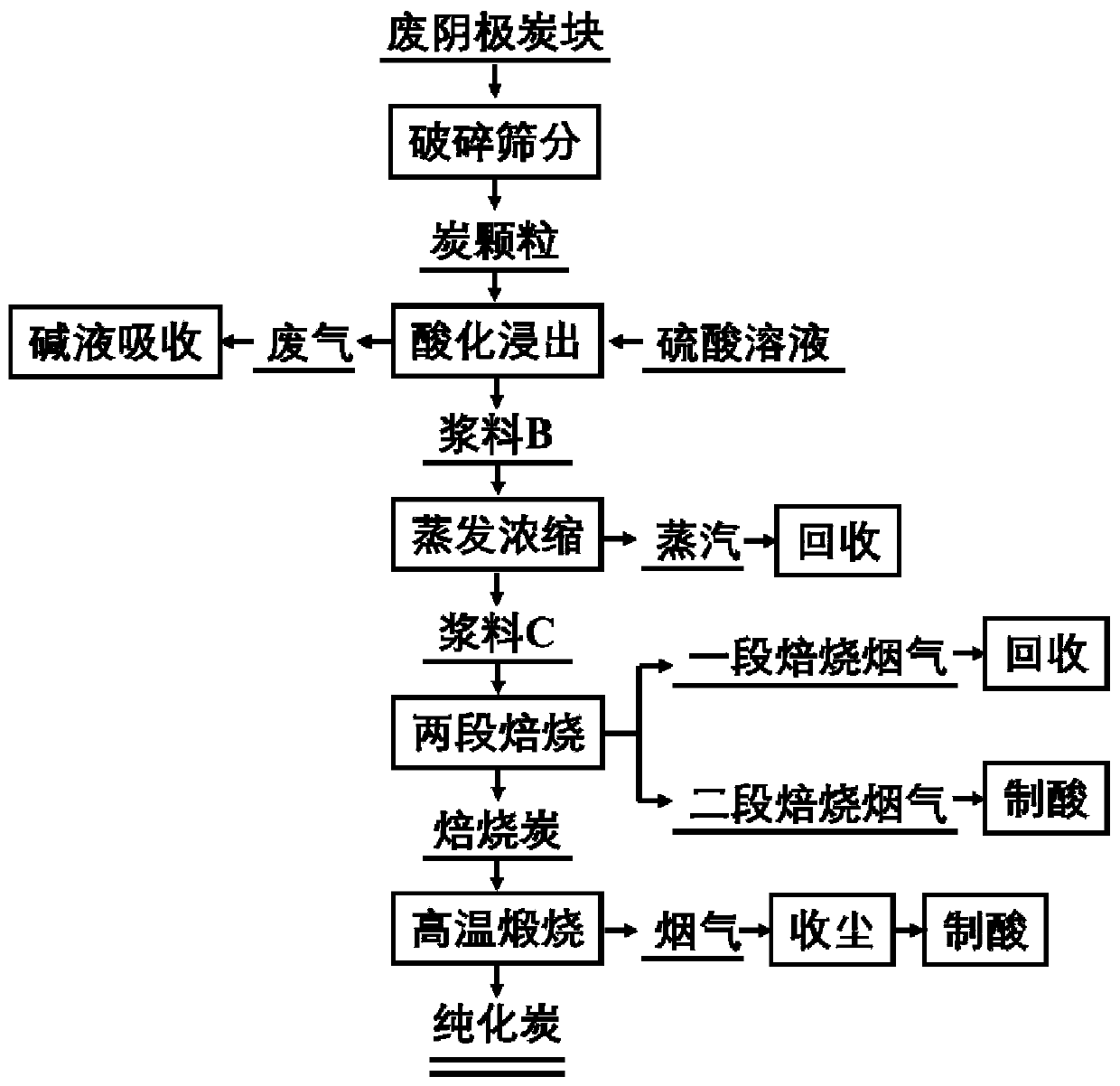

Method for recycling aluminum electrolysis waste cathode carbon blocks

ActiveCN111170299AAchieve recyclingAchieve cycleCarbon preparation/purificationAluminium fluoridesAluminium electrolysisFlue gas

The invention discloses a method for recovering aluminum electrolysis waste cathode carbon blocks, which comprises the following steps: (1) crushing and screening waste cathode carbon blocks to obtaincarbon particles; (2) mixing the carbon particles with a sulfuric acid solution to obtain slurry A, and then performing pressure leaching to obtain a slurry B; (3) evaporating and concentrating the slurry B until the mass percent of water is lower than 8% to obtain a slurry C; (4) adding concentrated sulfuric acid into the slurry C to obtain a slurry D, roasting at 150-300 DEG C for 0.5-10 hours,and roasting at 300-600 DEG C for 0.5-8 hours to obtain baked carbon; and (5) heating the baked carbon to 1200-3000 DEG C, and keeping the temperature for 0.5-20 hours to obtain the purified carbon.In the treatment process, high-temperature fluorine-containing flue gas and fluorine-containing wastewater are not generated, and fluorine, aluminum and carbon materials can be recycled, so that comprehensive recycling and cleaning treatment of the aluminum electrolysis waste cathode carbon blocks are realized.

Owner:CENT SOUTH UNIV

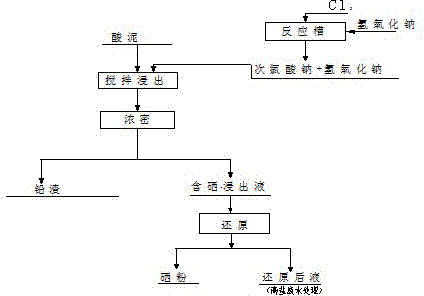

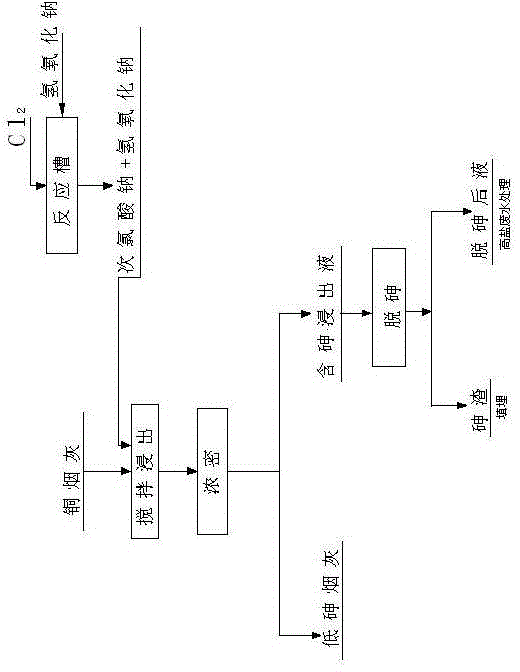

Method for recovering selenium from acid mud wastes of acid production with copper smelting smoke

InactiveCN103496676ASolving Recycling ProblemsHigh recovery rateElemental selenium/telluriumSlagSodium hydroxide

The invention discloses a method for recovering selenium from acid mud wastes of acid production with copper smelting smoke. The method comprises the steps of adding the acid mud into a solution containing sodium hypochlorite and sodium hydroxide, carrying out a selenium leaching reaction, filtering to obtain selenium removed slag and a sodium selenate containing solution, recovering lead, precious metals and valuable metals from the selenium removed slag, and carrying out acidification reduction on the sodium selenate solution to obtain rough selenium powder. Before recovering the selenium from the acid mud, arsenic and bismuth are separated from the selenium and lead in the acid firstly, the selenium removing rate is higher than 95%, the lead content in the slag is increased to 70-80%, the enrichment of the valuable metal lead in the slag is beneficial for a subsequent recovering process, the process is simple, the purpose of treatment of wastes with processes of wastes against one another is realized, the circular economy is realized, the production cost is low, and the metal recovering rate is high. In particular, residual chlorine in a production process is used for absorbing sodium hypochlorite in the waste solution, and then the selenium is directly removed from the acid mud wastes, so that the selenium recovering problem is solved, and meanwhile, the sodium hypochlorite wastewater problem is also solved.

Owner:JINCHUAN GROUP LIMITED

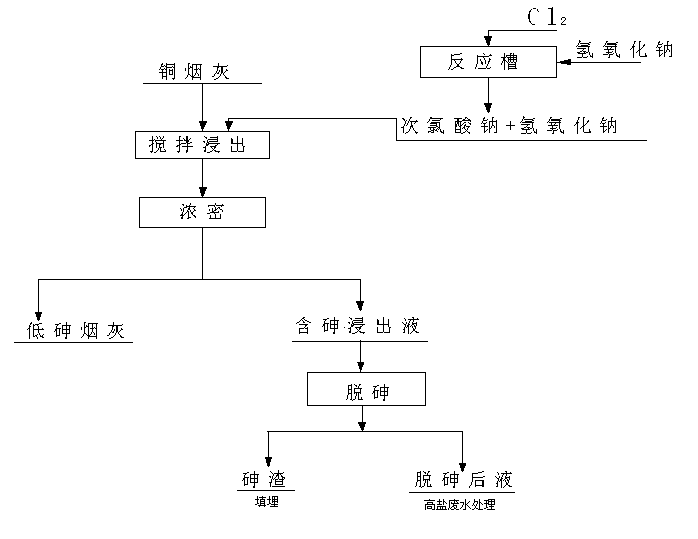

Wet-process open treatment method of arsenic in copper ashes

ActiveCN103233129AHigh recovery rateSolve the open circuit problemProcess efficiency improvementLiquid wasteImpurity

The invention discloses an open treatment method of arsenic in copper ashes and relates to a method for open pre-treatment of harmful arsenic impurities in intermediate material ashes in a copper smelting process. The wet-process open treatment method is characterized in that the treatment process comprises the following steps of: adding copper ashes to a solution containing sodium hypochlorite and sodium hydroxide; carrying out arsenic leaching reaction and filtering to obtain arsenic-removed slag and arsenic-removed solution; and recycling valuable metals including copper, lead, zinc and bismuth of the arsenic-removed slag. The wet-process open treatment method disclosed by the invention can be used for carrying out open treatment on the arsenic in the copper ashes before recycling the valuable metals, so that the subsequent recycling process of valuable metals is facilitated. Meanwhile, a utilization way for residual chlorine absorption liquid waste is found, so that the secondary pollution is avoided. Besides, the wet-process open treatment method for arsenic in the copper ashes is low in process cost and high in arsenic removal rate, and has great significance of improving environment protection, resource control and economical benefits.

Owner:JINCHUAN GROUP LIMITED

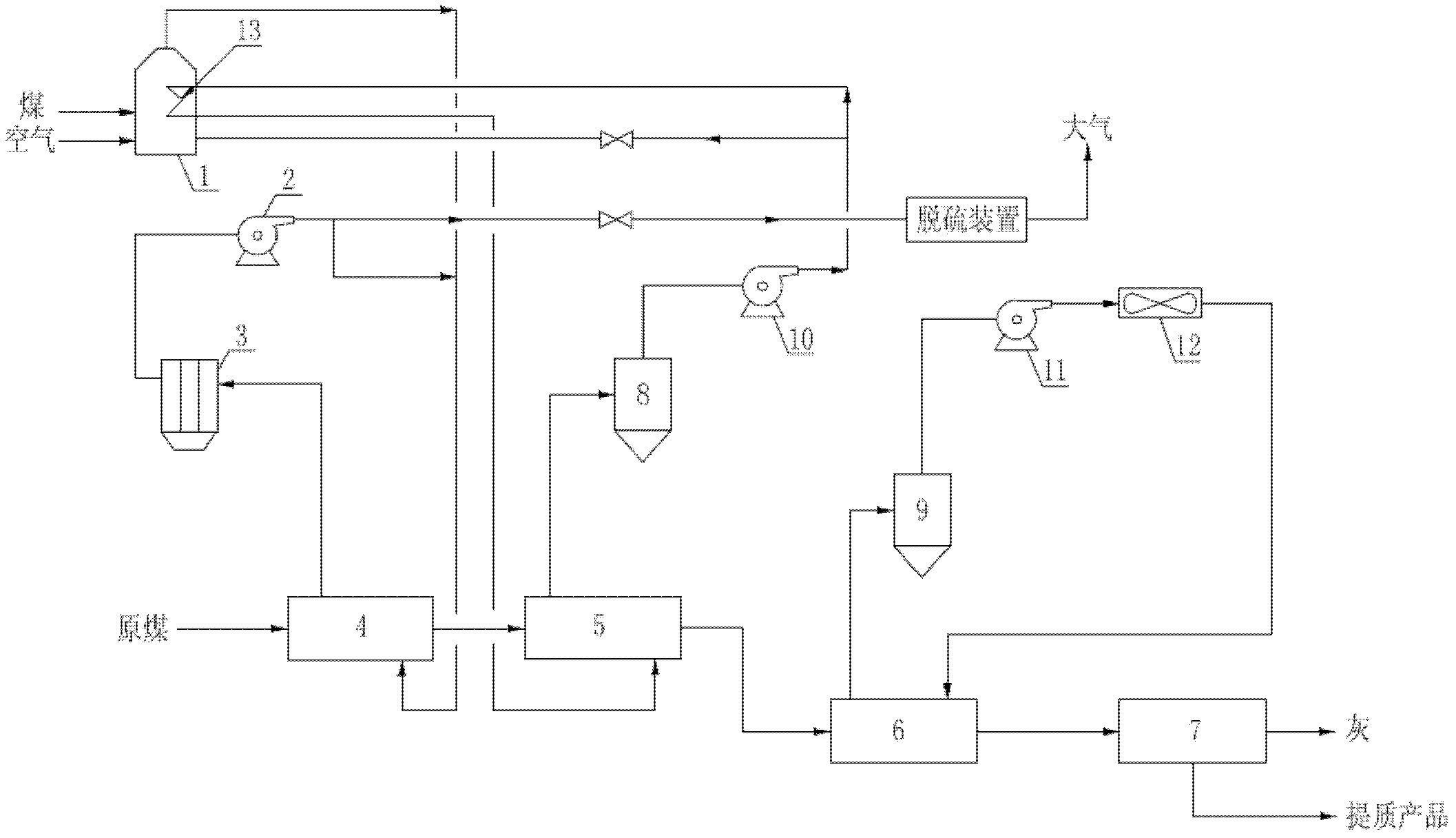

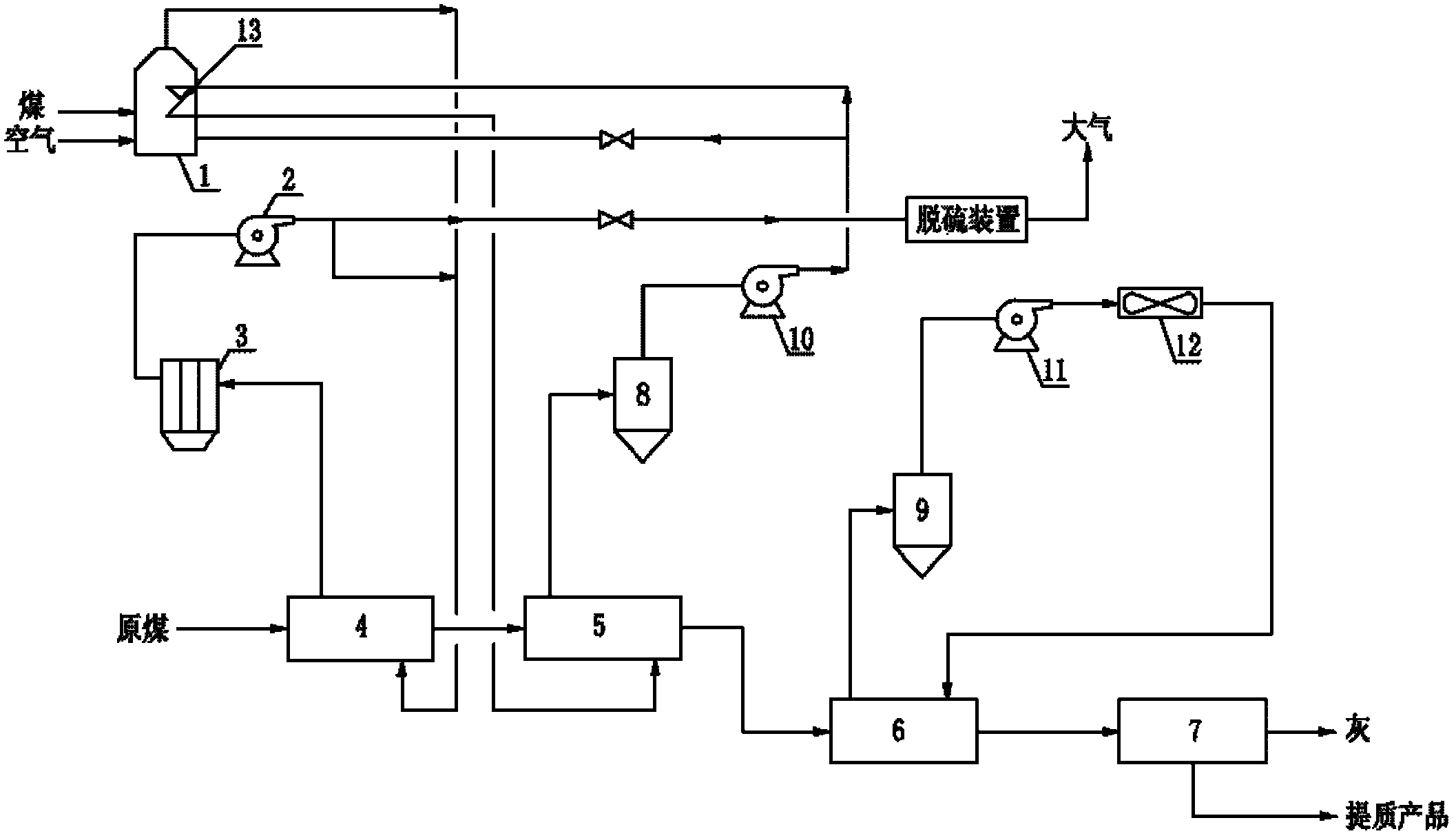

Quality-improving process and apparatus for high-ash low rank coal

InactiveCN102492518ASolving Wastewater ProblemsReduce manufacturing costDrying gas arrangementsSolid fuelsEnvironmental engineeringMoisture

The invention relates to a quality-improving process and apparatus for high-ash low rank coal and enables the problem that conventional quality-improving processes for low rank coal can only remove moisture but cannot remove ash to be overcome. The quality-improving process provided in the invention comprises the steps of primary drying for removal of external water in coal, secondary drying for removal of internal water in coal, dry cooling and removal of ash in cooled coal through winnowing so as to obtain high-quality coal. The apparatus provided in the invention comprises a drying system, a cooling system and a winnowing dedusting system. According to the invention, the advantages of a simple process, capacity of effectively removing water and ash, low production cost, low energy consumption and small investment for equipment are obtained.

Owner:WUHUAN ENG

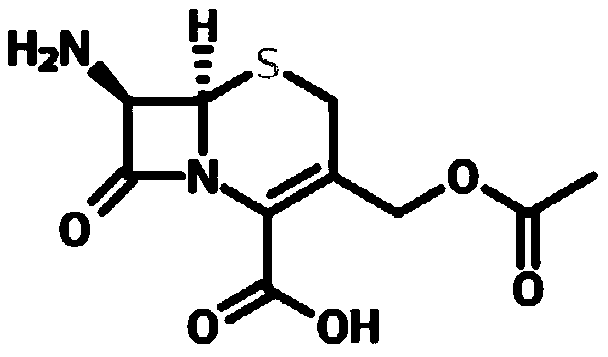

Preparation method of 7-aminocephalosporanic acid

ActiveCN110283869AImprove qualityLess impuritiesOrganic chemistryFermentationHigh concentrationDistillation

The invention relates to a preparation method of 7-aminocephalosporanic acid. The method comprises steps as follows: a cephalosporin C filtrate is separated from fermentation liquor in a membrane filtration manner; cephalosporin C is extracted from the filtrate by adopting an organic solvent which is immiscible with water, and cephalosporin C extract liquor is obtained; cephalosporin C in the extract liquor is subjected to reverse extraction into aqueous phase, the residual organic solvent is removed by reduced-pressure distillation, and an aqueous cephalosporin C sodium salt solution with high concentration is obtained; finally, after cephalosporin C is subjected to enzyme hydrolysis, crystallization, filtering, washing and drying, 7-aminocephalosporanic acid meeting the quality standard can be obtained. With the adoption of extraction and reverse extraction, impurities in the aqueous cephalosporin C sodium salt solution are reduced substantially, and the quality of the aqueous cephalosporin C sodium salt solution is improved, so that high-quality 7-aminocephalosporanic acid is obtained by enzyme hydrolysis.

Owner:SHANXI WEIQIDA PHARMA IND

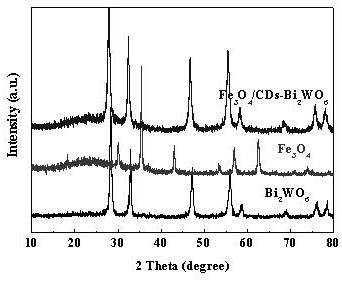

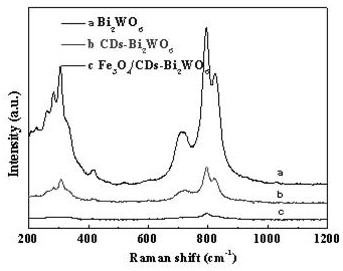

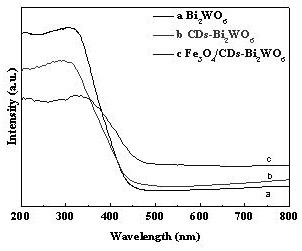

Preparation method and application of corncob biomass carbon dot composite Bi2WO6 photocatalyst based on magnetic Fe3O4 modification

PendingCN112108150AGood for recyclingAvoid wastingWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationPhoto catalysis

The invention belongs to the technical field of chemical preparation of environmental materials, and particularly relates to a preparation method and application of a corncob biomass carbon dot composite Bi2WO6 photocatalyst based on magnetic Fe3O4 modification. The method comprises the following steps: step 1, treating a corncob precursor; step 2, preparing biomass carbon dots (CDs); step 3, preparing Bi2WO6; step 4, preparing Fe3O4; step 5, preparing CDs / Bi2WO6; and step 6, adding the CDs / Bi2WO6 obtained in the step 5 into the Fe3O4 nanosphere precursor solution obtained in the step 4, conducting heating in a polytetrafluoroethylene reaction kettle, washing the obtained product with ethanol and deionized water, and conducting drying for later use. The magnetic Fe3O4 modified corncob biomass carbon dot composite Bi2WO6 photocatalyst prepared by the method is used for photocatalytic degradation of tetracycline. The corncobs are applied to preparation of biomass carbon dots, so that waste is turned into wealth; and Fe3O4 is used as a composite material to prepare the composite photocatalyst, so that the catalyst can be recycled and reused, and the waste of resources is avoided. Thephotocatalyst has excellent photocatalytic activity and stability.

Owner:TONGHUA NORMAL UNIV

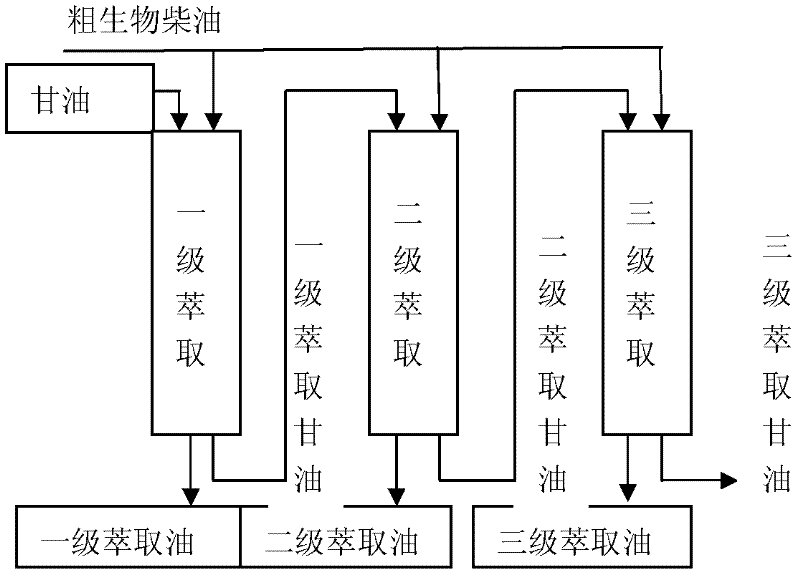

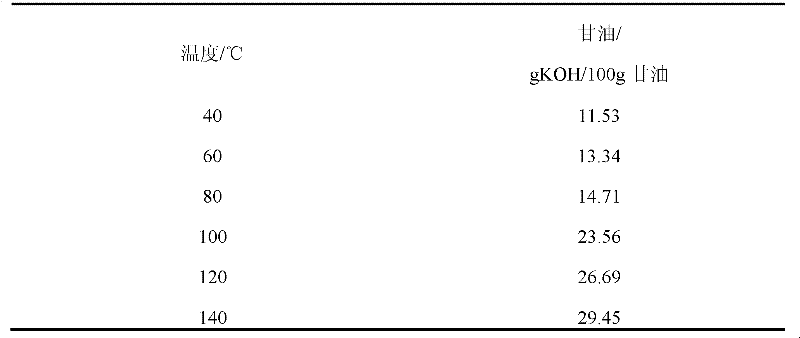

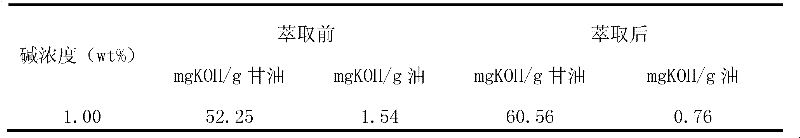

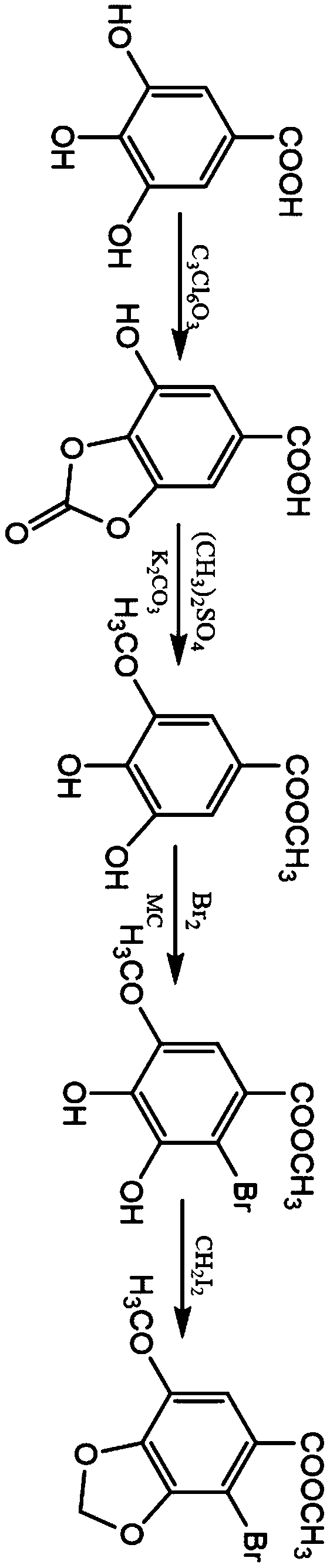

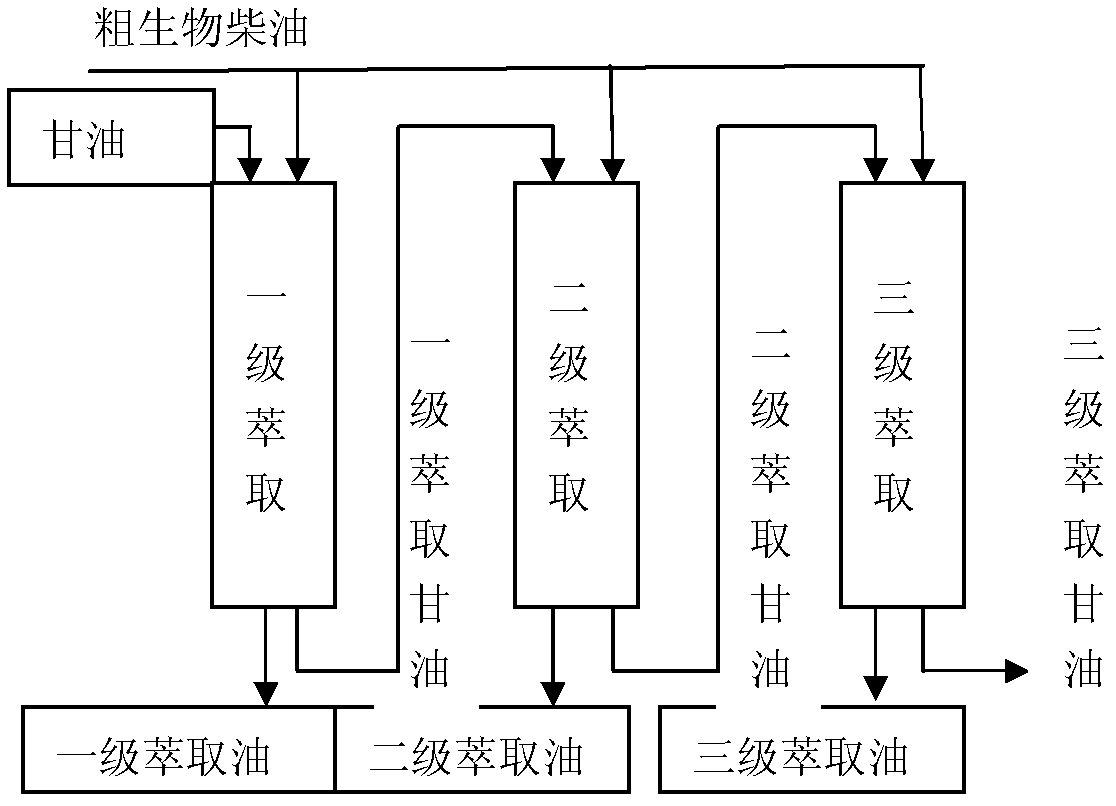

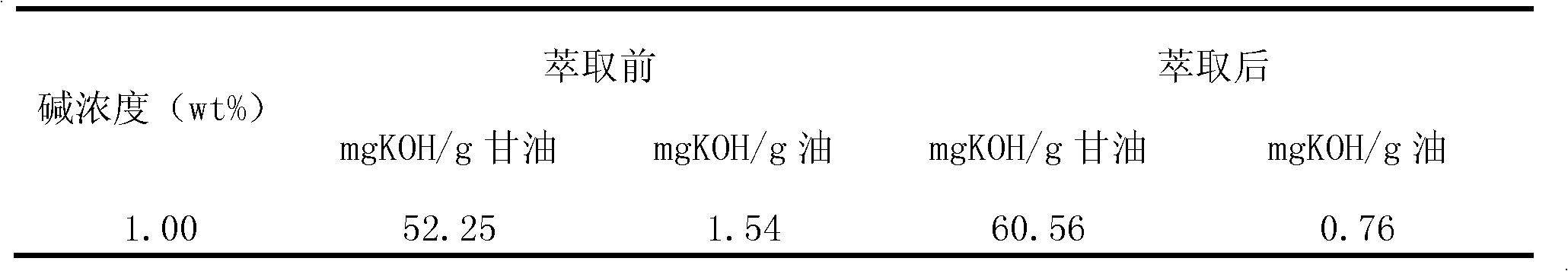

Method for removing base catalyst from crude biodiesel

ActiveCN102586012AAvoid alcoholysisImprove distillation yieldBiofuelsFatty-oils/fats refiningBiodieselGlycerol

The invention relates to a method for removing a base catalyst from crude biodiesel. The method comprises the following step of: removing the base catalyst from the crude biodiesel by taking glycerin as an extracting agent, wherein the extraction temperature is 60-150DEG C, the operating pressure is normal pressure, and a mass ratio of the crude biodiesel to the glycerin is 10-1. Compared with the prior art, the method has the advantages that: 1, the method for removing the base catalyst from the biodiesel by taking the biodiesel byproduct glycerin as the extracting agent avoids a problem of wastewater caused by a water washing process; 2, the base catalyst dissolved in the glycerin phase is separated in a cooling crystallization mode, the glycerin and the base catalyst can be cyclically applied to a production process mechanically, and production cost is reduced; and 3, the base catalyst is effectively removed, alcoholysis in the high temperature vacuum rectification process of the biodiesel is avoided, and the biodiesel rectification yield is improved.

Owner:ZHEJIANG UNIV OF TECH

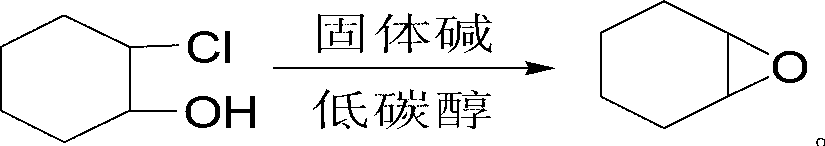

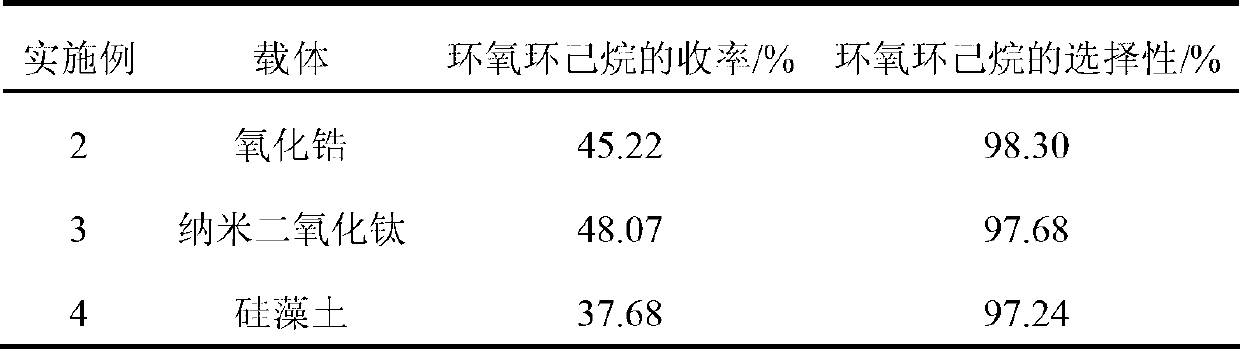

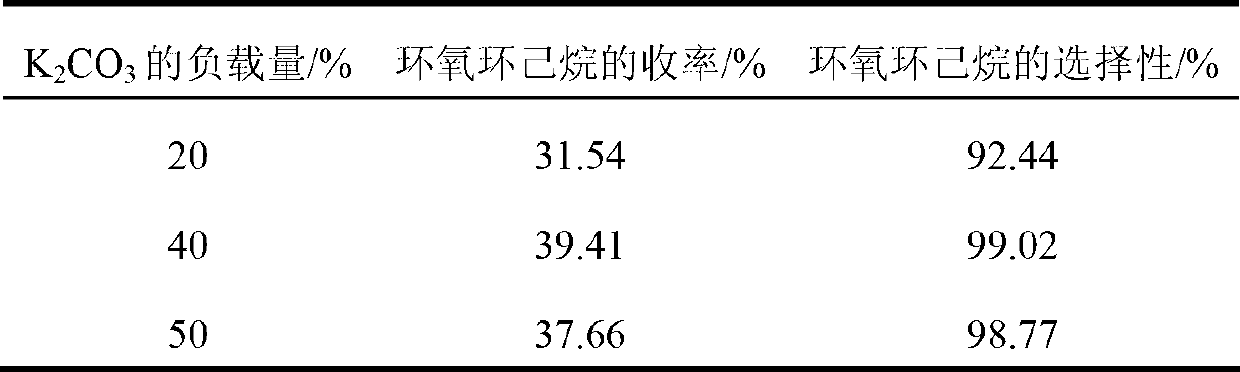

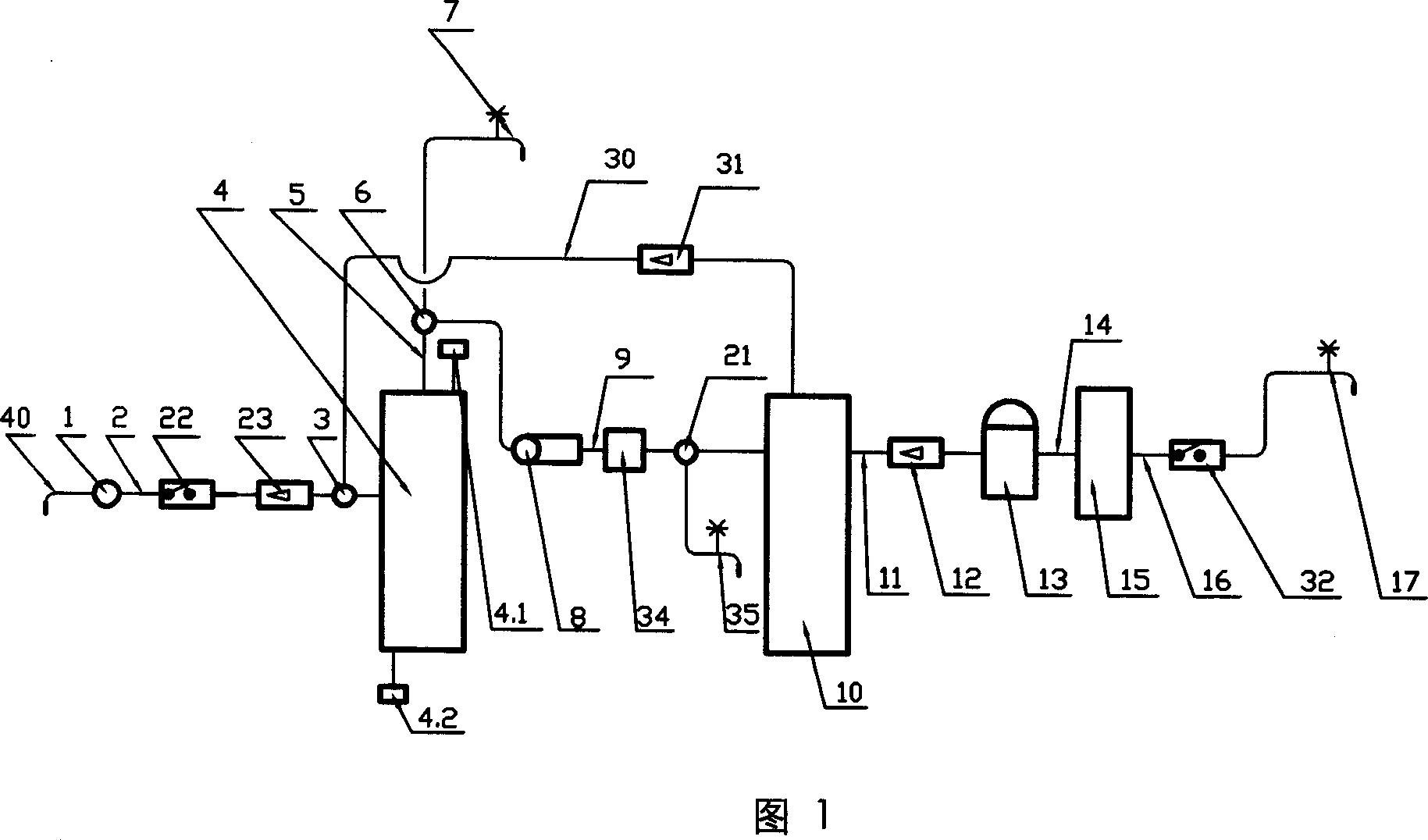

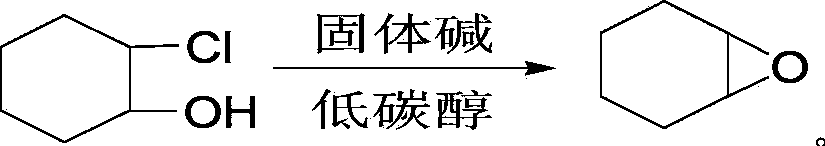

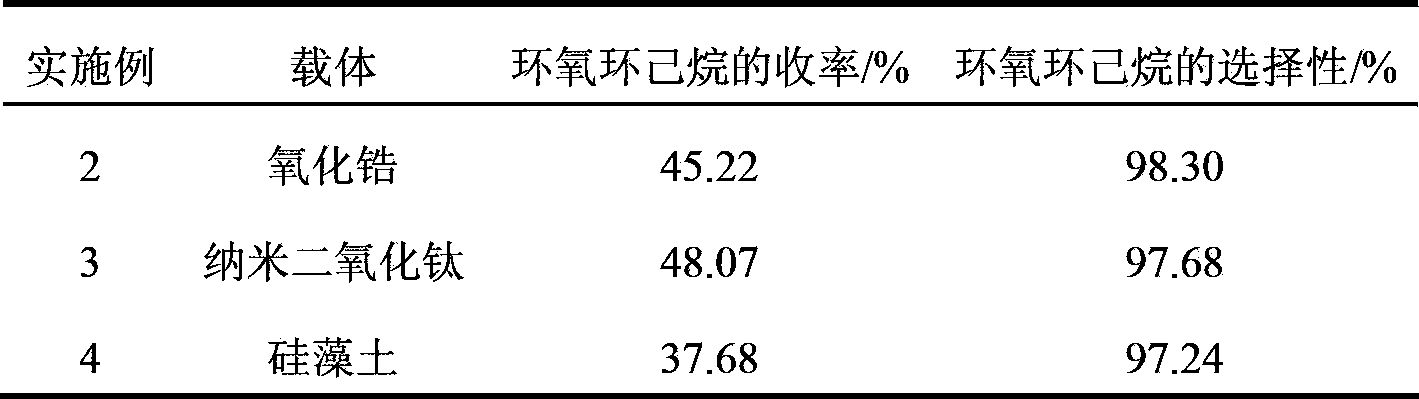

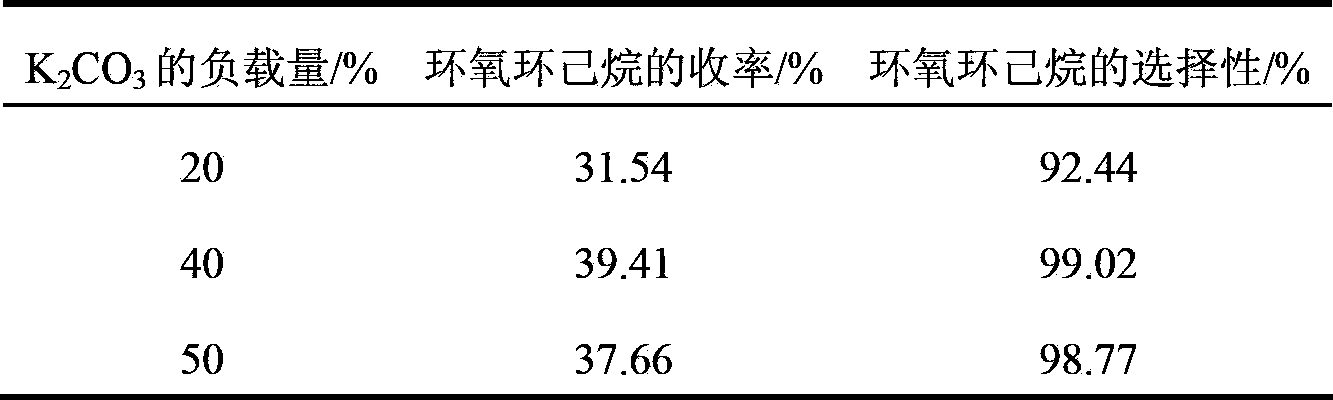

Method for utilizing o-chlorocyclohexanol to prepare cyclohexene oxide by cyclization

InactiveCN102993131ASolving Wastewater ProblemsReduce manufacturing costOrganic chemistryAlcoholWastewater

The invention relates to a method for utilizing o-chlorocyclohexanol to prepare cyclohexene oxide by cyclization. The method comprises the steps of weighing o-chlorocyclohexanol, solid alkali and a solvent, placing the o-chlorocyclohexanol, the solid alkali and the solvent into a reactor to undergo a reaction, performing a heating stirring reaction, obtaining a reaction mixture after the reaction is finished, and obtaining the product cyclohexene oxide by separation. The solid alkali is a load type metal salt, and the adopted solvent is lower alcohol. The method has the advantages that a large number of waste water caused by used sodium hydroxide serving as a catalyst is avoided, the production cost is reduced, the process is simple, the used solid alkali has no harm to the human body and can be separated from a product easily, the method is a green chemical process, the used solid alkali is high in selectivity for a principal product, and the method is favorable for the reaction.

Owner:NANJING UNIV OF TECH

Household water treating method and system with antioxidant reverse osmosis film

InactiveCN1974422AEasy to handleReduced risk of water leaksWater/sewage treatment bu osmosis/dialysisReverse osmosisReverse osmosisPore water pressure

The present invention is household water treating method and system with antioxidant reverse osmosis film. In the household water pipeline, are set successively a pressure limiting valve to limit the water pressure, a ultrafiltering water purifier to treat water initially to obtain sanitary water, and a antioxidant reverse osmosis unit with reverse osmosis film to treat partial water into pure water, with the concentrated water flowing out the reverse osmosis film being returned to the sanitary water treating unit. The present invention has simple water pre-treating process, low system operation pressure, less leakage possibility, low running cost and other advantages.

Owner:杨克庆

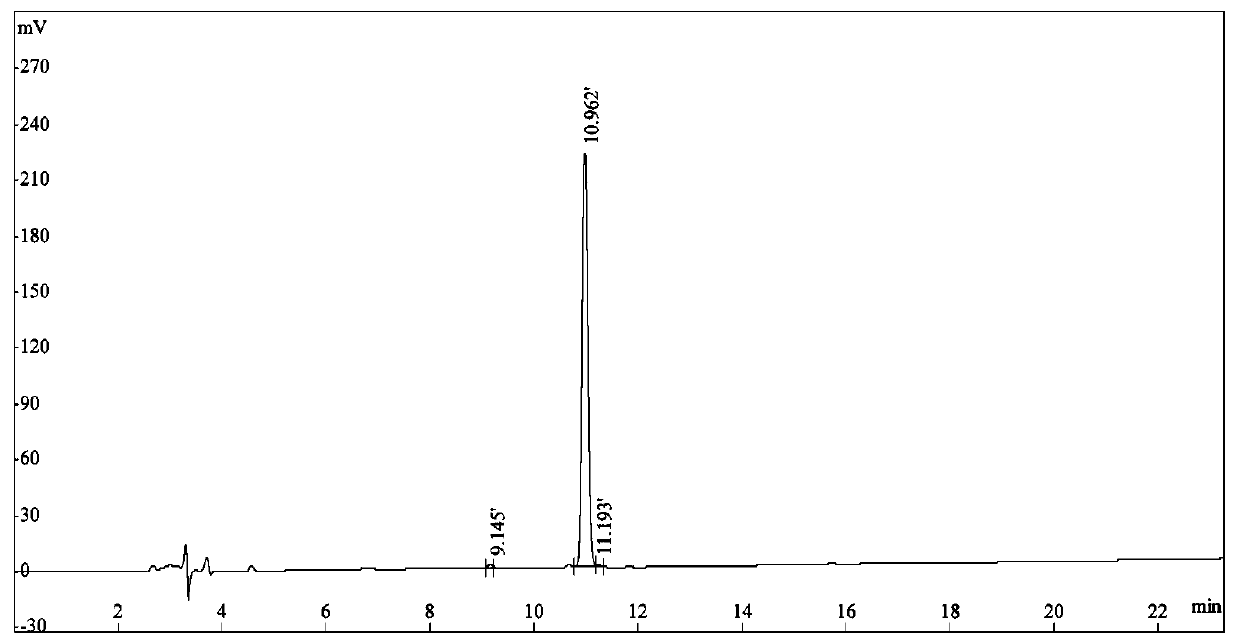

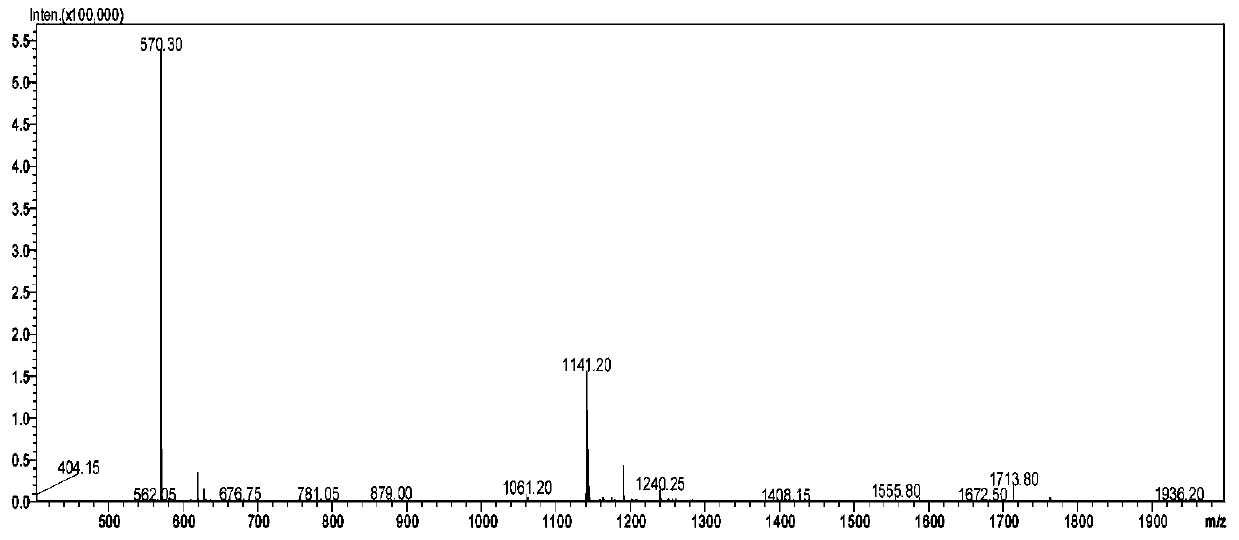

Sincalide solid-liquid-phase synthesis method

PendingCN110317257AInhibit side effectsHigh purityPeptide preparation methodsGastrins/cholecystokininsDipeptideAfter treatment

The invention relates to a sincalide solid-liquid-phase combined synthesis method. The technical problems are mainly solved that raw materials are high in price and after-treatment is complicated in the prior art. According to the technical scheme, the sincalide solid-liquid-phase synthesis method includes the following steps of firstly, synthesizing an Fmoc-Asp-Phe-CONH2 dipeptide segment througha liquid phase method; secondly, loading the dipeptide segment on 2-chlorotrityl chloride resin to obtain Fmoc-Asp(beta-2Cl-Trt Cl resin)-Phe-NH2; thirdly, sequentially connecting residual protectionamino acids through a solid-phase synthesis method to obtain a sincalide resin peptide (Asp-Tyr(SO3H)-Met-Gly-Trp-Met-Asp(beta-2Cl-Trt Cl resin)-Phe-CONH2); fourthly, conducting cutting to obtain a crude sincalide product (Asp-Tyr(SO3H)-Met-Gly-Trp-Met-Asp-Phe-CONH2), and conducting efficient liquid-phase spectrum separation and purification and freeze-drying and refining on the crude product toobtain sincalide.

Owner:GL BIOCHEM SHANGHAI

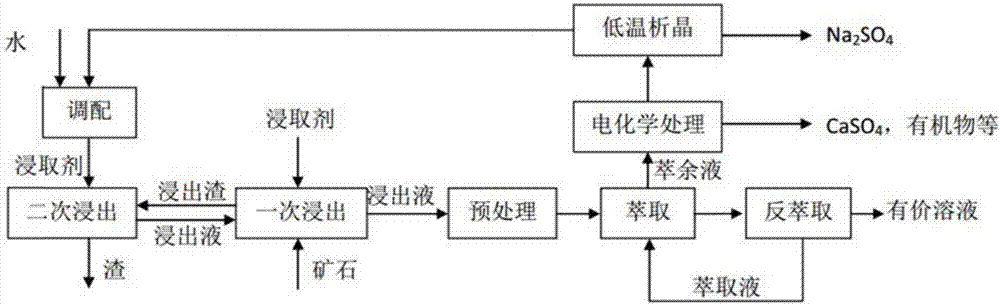

Comprehensive utilization method for waste water containing high-concentration sodium sulfate based on wet metallurgy process

InactiveCN107881341AAchieve recyclingSolving Wastewater ProblemsProcess efficiency improvementAlkali metal sulfites/sulfatesHigh concentrationSlag

The invention provides a comprehensive utilization method for waste water containing high-concentration sodium sulfate based on the wet metallurgy process. The comprehensive utilization method at least comprises the following steps that (1) an appropriate quantity of leaching agent is added into an ore raw material, wherein the leaching agent at least comprises sulfate ions and sulfite ions, thensolid-liquid separation is conducted, and leaching slag and leaching liquid are obtained correspondingly; (2) the leaching liquid is pre-treated, namely still standing for sediment is conducted, the leaching liquid is subjected to organic solvent extraction, and an extraction agent and extraction liquid are obtained; (3) the extraction agent is subjected to saponification to obtain a sediment, theextraction liquid is subjected to electrochemical treatment, after calcium ions and organic matter are removed, cooling for crystallization is conducted, and crystals and clear liquid are obtained; (4) at least part of the clear liquid is dosed to obtain a leaching agent, the leaching agent and the leaching slag in the step (1) are mixed and reacted again, and thus reaction slag and secondary leaching liquid are obtained; and (5) at least part of the secondary leaching liquid is utilized to return to the step (1) to be mixed and reacted with to-be-treated ore. The comprehensive utilization method is low in cost and high in efficiency.

Owner:SHANGHAI IND TECH INST

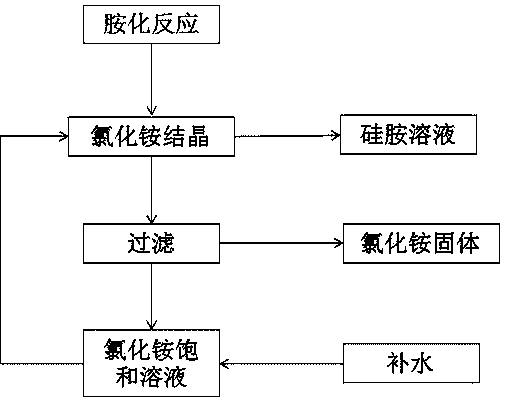

Method for recovering ammonium chloride in hexamethyldisilazane preparation process

ActiveCN104045662AReduce decompositionNo emissionsGroup 4/14 element organic compoundsAmmonium halidesChemical industryTrimethylsilyl chloride

The invention discloses a method for recovering ammonium chloride in a hexamethyldisilazane preparation process. The method comprises the following steps: 1, adding a saturated solution of ammonium chloride into a reaction solution obtained after a trimethylchlorosilane ammonification reaction, and stirring; 2, allowing the obtained solution to stand, and taking out the uppermost organic phase; 3, adding the saturated solution of ammonium chloride into a mixed solution residual in step 2, and stirring; 4, allowing the solution obtained in step 3 to stand, and taking out the uppermost layer organic phase toluene solution of hexamethyldisilazane; and 5, carrying out solid-liquid separation on a mixture residual in step 4 to obtain solid ammonium chloride and an ammonium chloride mother liquor. The method has the advantages of simple steps, operation of the whole process below 10DEG C, maximal reduction of the decomposition of hexamethyldisilazane, no wastewater emission, and fundamental solving of the ammonium chloride wastewater problem, and allows about 1t of wet ammonium chloride to be recovered in the preparation of 1t of hexamethyldisilazane; and recovered ammonium chloride can be used as a chemical industry raw material and a composite fertilizer raw material after being dried.

Owner:河北龙亿环境工程有限公司

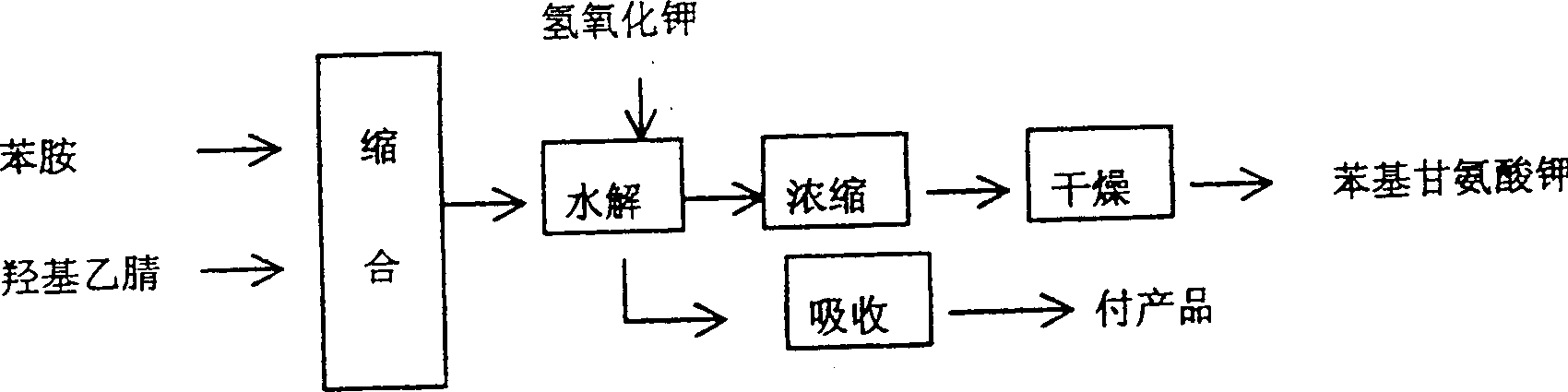

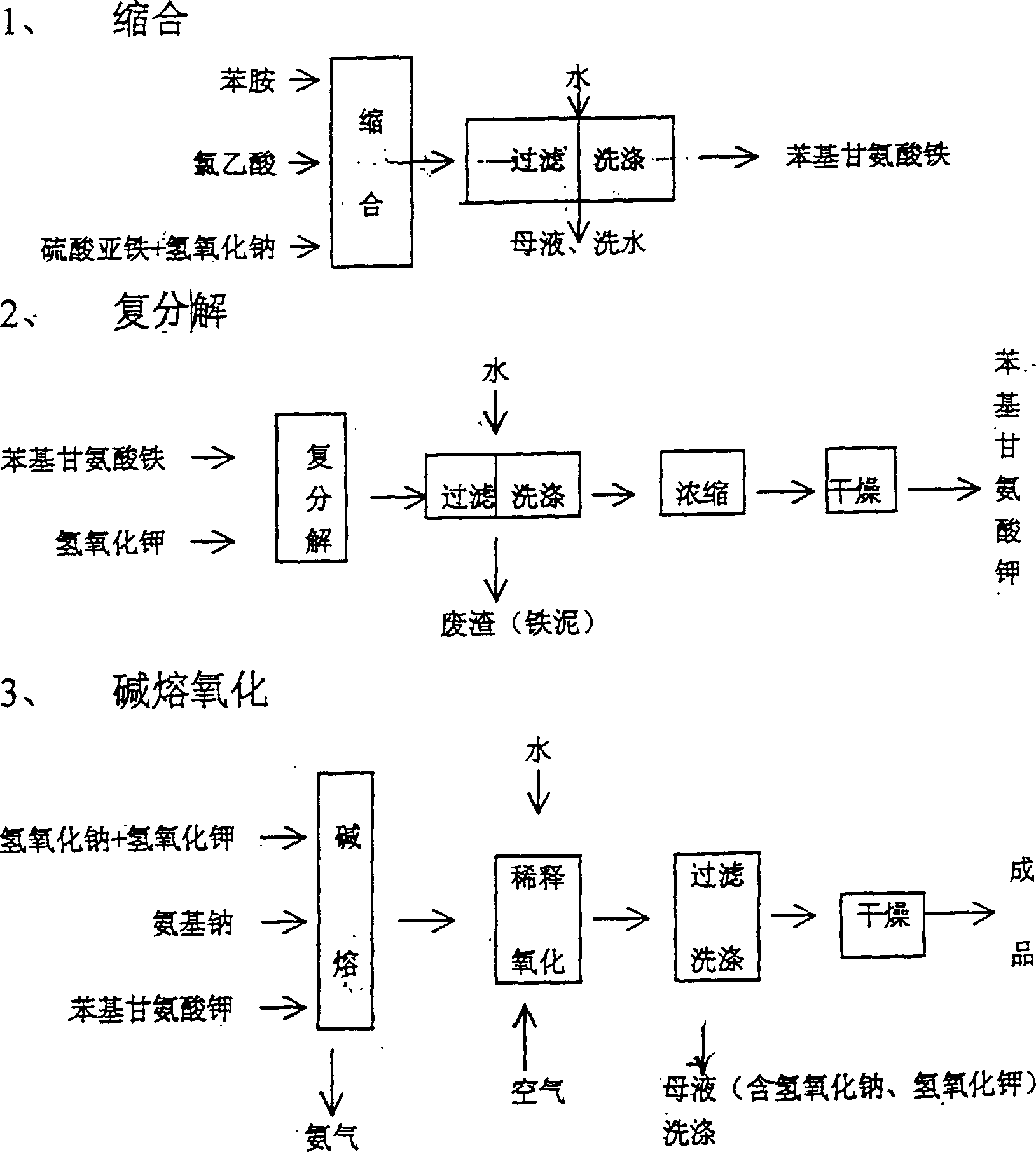

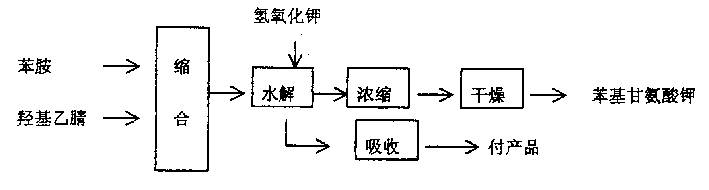

Method for producing indigo

InactiveCN1465624ASolving Wastewater ProblemsReduce energy consumptionIndigoid dyesPotassiumPotassium hydroxide

The production method of indigo includes the following steps: placing aniline and hydroxyacetonitrile into condensation reactor according to the mole ratio of 1:0.9-1:1.2, reacting for 2-8 hr. at 60-105 deg.C, then placing all the materials into hydrolysis reactor, adding potassium hydroxide into the hydrolysis reactor according to the mole ratio of aniline and potassium hydroxide of 1:0.9-1:1.2,boiling and refluxing to make hydrolysis reaction, adopting acid to absorb the ammonia gas discharged by reaction, concentrating reactant material, drying to obtain white and light-yellow powder or flake potassium phenylglycinate, then making the potassium phenylglycinate, sodium hydroxide, potassium hydroxide and amino sodium undergo the process of alkali fusion oxidation reaction so as to obtain the invented product indigo.

Owner:上海蓝建染化有限公司 +1

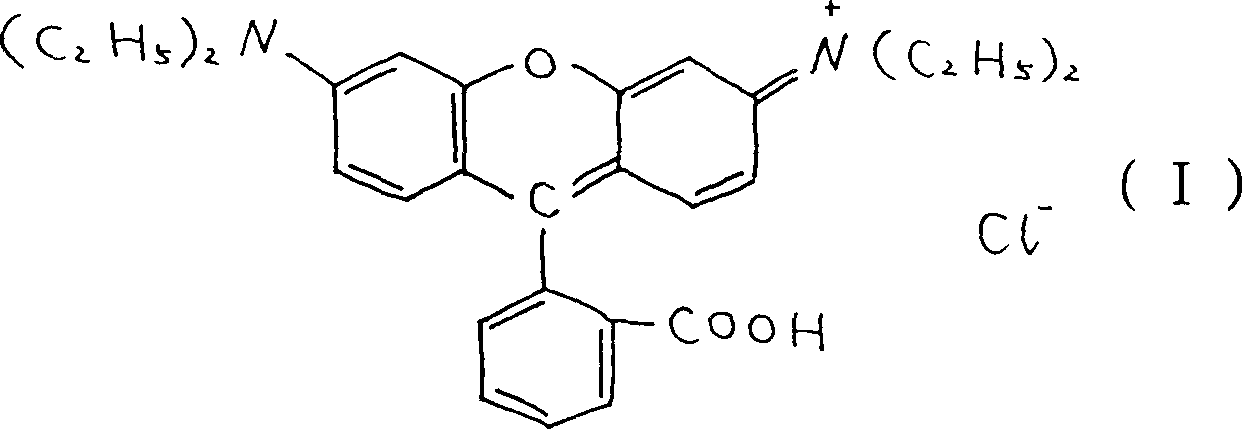

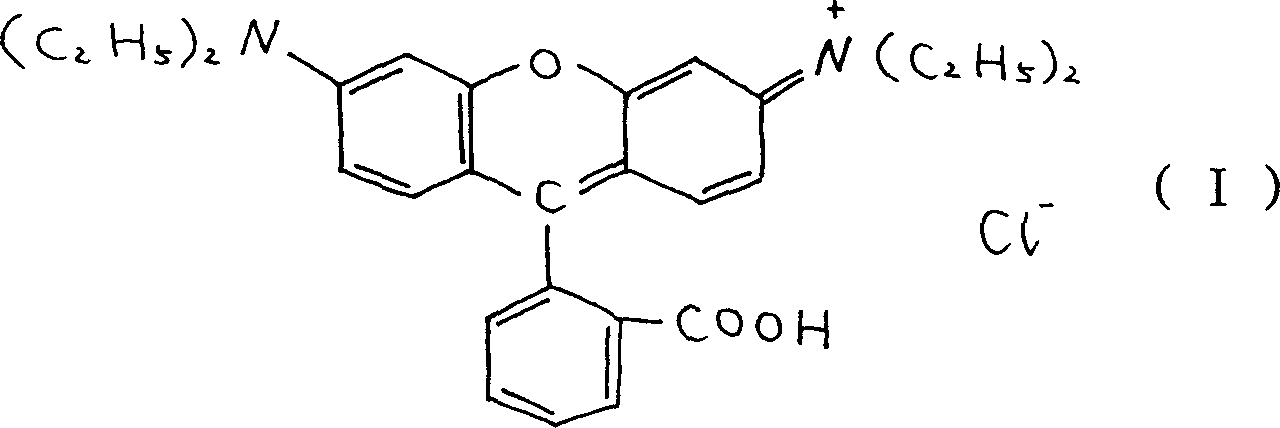

Prepn of rhodamin B

InactiveCN1810800ASave waterReduce manufacturing costOrganic chemistrySolventEnvironmental chemistry

The present invention discloses one process of preparing rhodamin B in low power consumption and environment friendly mode. Inside organic solvent of arene halide, m-hydroxy-N, N-diethyl aniline and phthalic anhydride produce condensation reaction to prepare rhodamin B. The process has the organic solvent recovered and reused, no waste water draining, low reaction temperature and short reaction period.

Owner:柳鸣

A kind of circulation gas stripping distillation method for extracting EPA&DHA from fish oil

ActiveCN106916062BIncreased EPA&DHA contentShort heating timeOrganic compound preparationSteam distillationFish oilVaporization

The invention relates to a circulation gas extractive rectification technology for extracting EPA and DHA from fish oil. The method is characterized in that the fish oil is pre-heat, is introduced into a rectifying tower and rectified under extractive rectification of inert gas circulation gas to obtain a mixture of EPA and DHA. The method employs light component of the inert gas circulation gas, and employs a backflow mode for high purity separating of the components, rectification and gas stripping are fusion during a whole process, the difference of the components volatility in the fish oil can be used, so that multitime partial vaporization and partial condensation can be carried out, the light component of the hot inert gas is used, partial pressure of the light component is reduced, the light component is developed to vaporization, and the light component content in a heavy phase is reduced. In the invention, high vacuum is not required, one time purification can be used for increasing the EPA and DHA content to more than 70%.

Owner:山东禹王制药有限公司 +1

Method for treating waste liquid from production of 2,6-di-t-butyl-p-cresol

ActiveCN106854026ASolve the real problemLow costWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesLiquid wasteThermal energy

The invention relates to a method for treating waste liquid from production of 2,6-di-t-butyl-p-cresol. The method comprises the following steps: (1) pretreatment of waste liquid; (2) concentration and neutralization of the waste liquid: preheating the waste liquid to 70 to 80 DEG C, then cooling and separating the waste liquid, delivering the separated waste liquid to a third-effect evaporation chamber and a third-effect heating chamber for heating, then introducing a heated mixture to a second-effect evaporation chamber and a second-effect heating chamber for heating, and then introducing a mixture to a first-effect evaporation chamber and a first-effect heater for heating; and (3) recovery of sodium p-toluenesulfonate: subjecting the mixture obtained in the previous step to filtering and separating, allowing a separated mixture to successively pass through an aggregate vortex chamber and a cyclone separator for separating and dedusting, and then carrying out discharging. According to the invention, heat produced in treatment of the waste liquid can be used as heat energy for production; condensed water can be repeatedly used; treatment cost for the waste liquid is effectively lowered; sodium p-toluenesulfonate can be recycled as a product for reuse; and conventional waste water problems are overcome, and green production is realized.

Owner:江苏迈达新材料股份有限公司

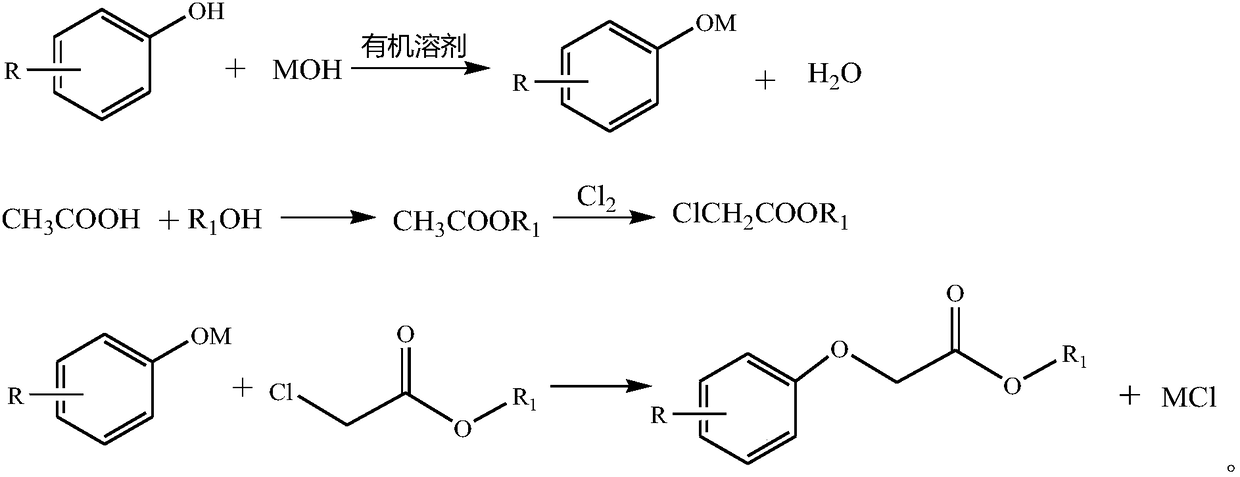

Preparation method of phenoxyacetic ester

InactiveCN108947835ARealize continuous productionImprove dehydration efficiencyOrganic compound preparationCarboxylic acid esters preparationIsobutanolChlorobenzene

The invention provides a preparation method of phenoxyacetic ester, wherein the preparation method includes the following steps: A) carrying out esterification reaction of acetic acid and alcohol to obtain acetic ester; B) introducing chlorine gas into acetic ester, and carrying out reaction to obtain chloroacetic ester; C) dehydrating a phenol compound and alkaline hydroxide into a salt in an organic solvent to obtain a salt of the phenol compound; D) after salt formation, mixing with chloracetic ester prepared in the step B), and carrying out condensation reaction to obtain phenoxyacetic ester, wherein the organic solvent is a mixture of any two kinds of toluene, xylene, chlorobenzene, phenol, butanol and isobutanol. The phenol is dehydrated into the salt in the mixed organic solvent, the system still maintains a uniform state in the dehydration process, continuous production is achieved, the dehydration efficiency is high and the efficiency of the whole production process is high. Moreover, the raw materials are easy to obtain, the production period is short, water is not needed in the reaction process, the energy consumption is low, the production cost is low, the yield of acetic acid is 99% or more, and the total yield of phenol can reach 99% or more.

Owner:SHANDONG RUNBO BIOTECH CO LTD

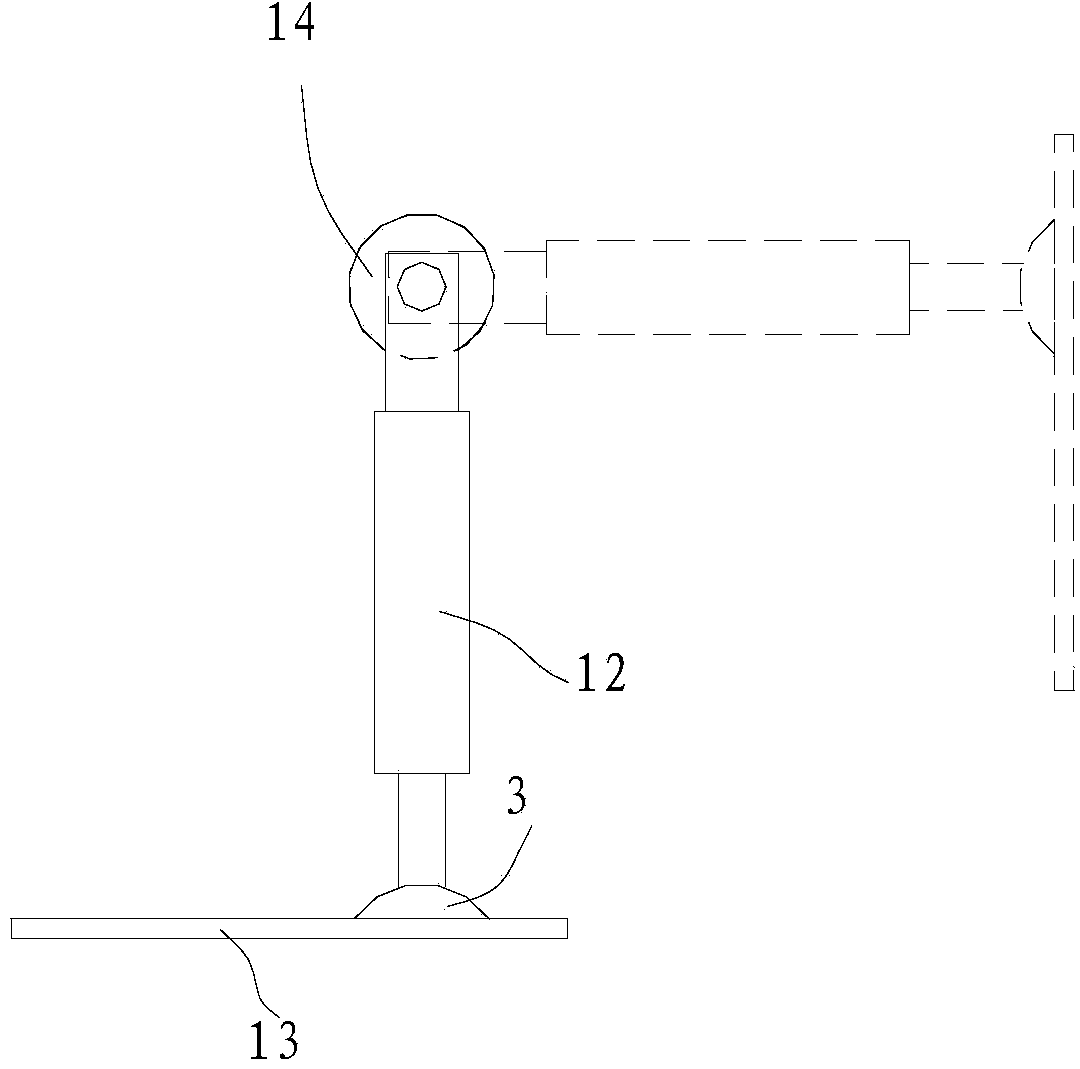

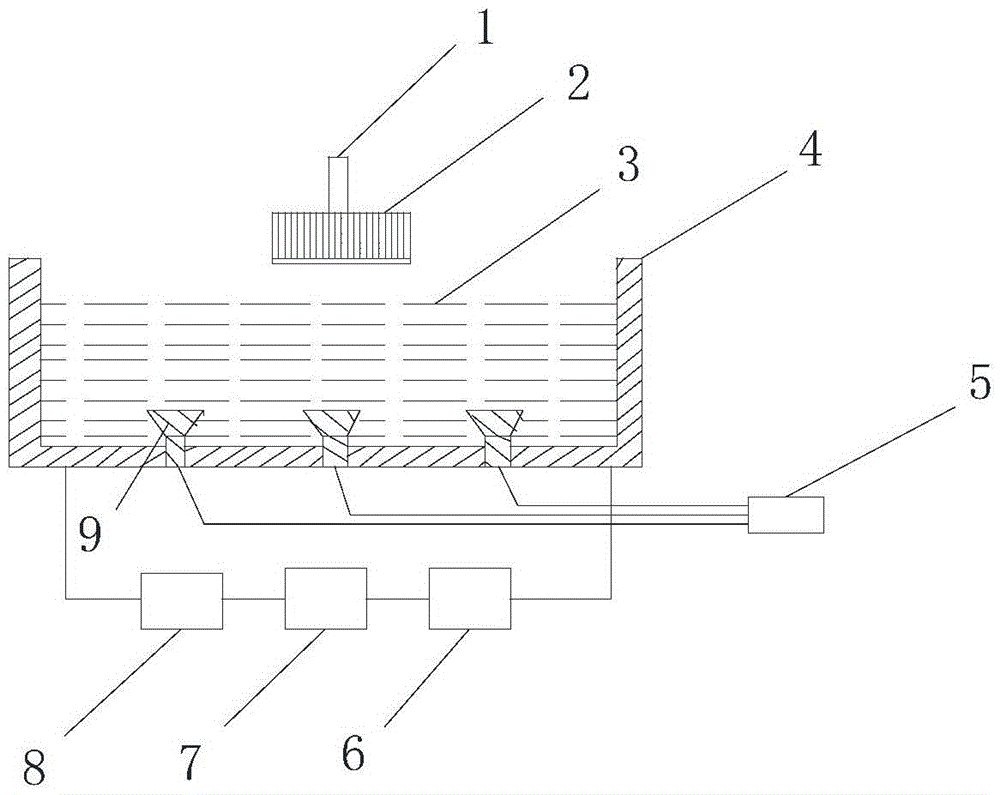

Extractor hood wind wheel cleaning device

InactiveCN105537183AGuaranteed performanceAvoid deformationCleaning using liquidsDynamic balanceTransducer

The invention discloses an extractor hood wind wheel cleaning device. The extractor hood wind wheel cleaning device is characterized by comprising a cleaning tank, an ultrasonic generator, a filter, a water pump, a heater and transducers; cleaning fluid is arranged in the cleaning tank; the filter, the water pump and the heater are connected together in series, and a circular structure is formed by the filter, the water pump, the heater and the cleaning tank; the circular flowing direction is from the cleaning tank, the filter, the water pump and the heater to the cleaning tank; the transducers are arranged at the bottom of the cleaning tank and connected with the ultrasonic generator. The problem that the cleaning effect is poor when extractor hood wind wheels are cleaned manually is solved, the phenomena of deformation and paint peeling off of the wind wheels caused by improper cleaning are also avoided, the dynamic balance of the cleaned wind wheels is effectively ensured, and the overall performance of an extractor hood is ensured. The ultrasonic cleaning technology is utilized, the wind wheels are soaked in the whole fluid, all surfaces, making contact with the fluid, of the wind wheels can be cleaned, and wind wheels which are in a complex shape, provided with many gaps and high in precision can be cleaned.

Owner:GUANGDONG MACRO GAS APPLIANCE

Method for coating substrates containing antimony compounds with tin and tin alloys

InactiveCN101027427AExcellent joinabilityIncreased durabilityLiquid/solution decomposition chemical coatingPrinted element electric connection formationAntimony compoundsAlloy

The present invention relates to a method for depositing tin or tin alloy layers on substrates containing antimony compounds as flameproofing agents or for improving the stampability, wherein the antimony compound is removed from the surface of the substrate material by an acid solution prior to metallization. Particularly preferred, pretreatment solutions containing hydrochloric acids are used for this purpose. The method is particularly suitable for producing joinable tin final layers on printed circuit boards containing antimony compounds, the tin final layers being applied onto copper portions of the conductor pattern which are not covered by the solder stop mask.

Owner:ATOTECH DEUT GMBH

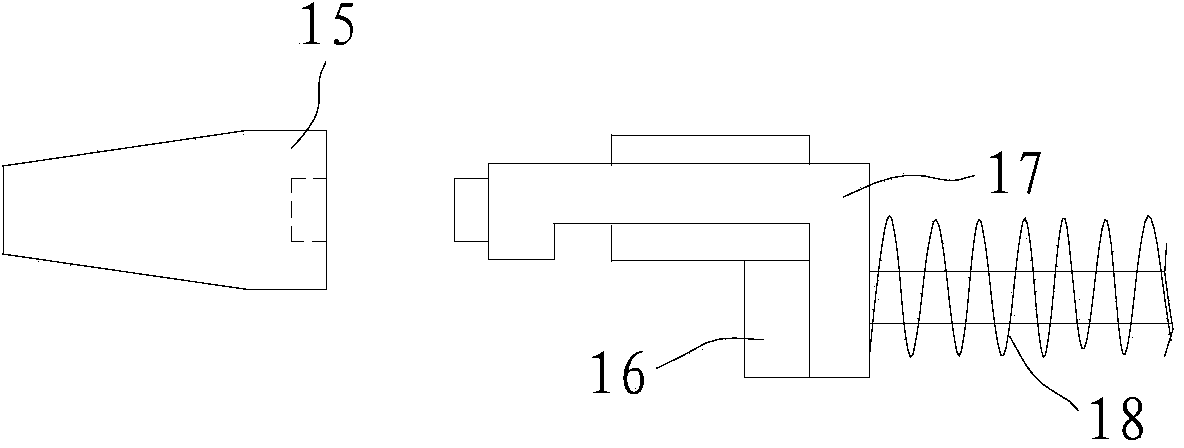

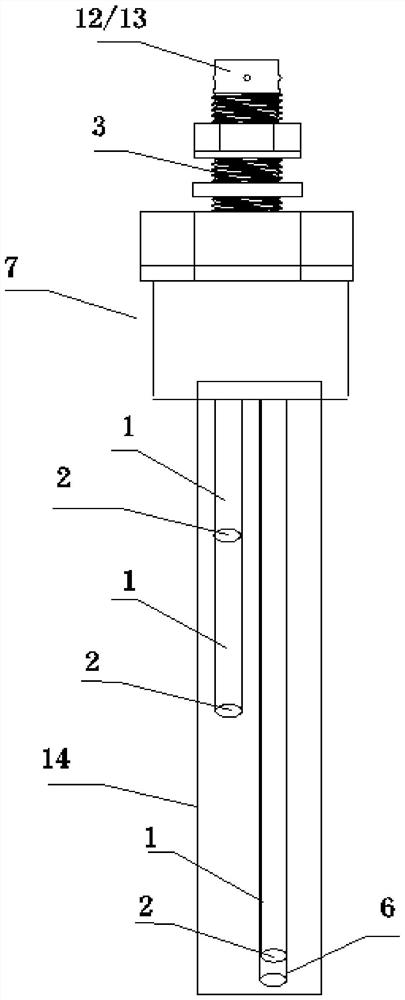

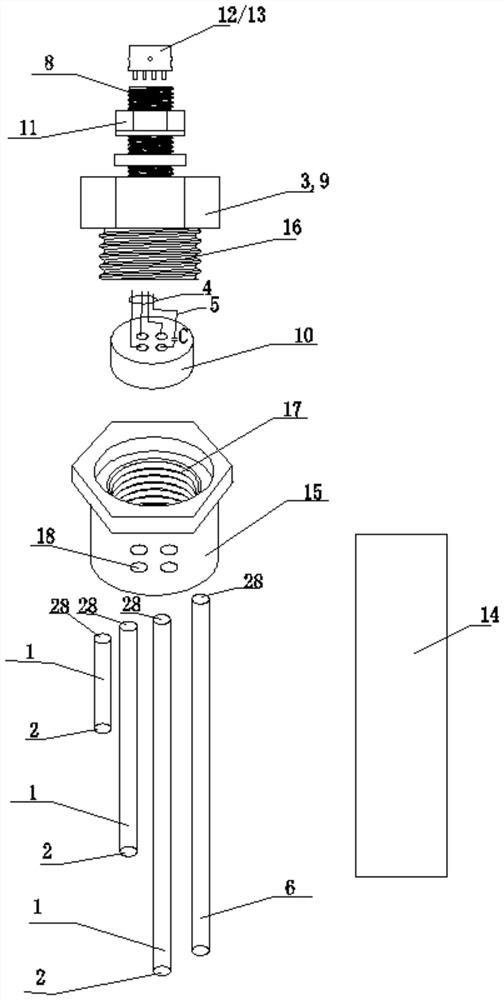

Water level sensor as well as water container and beverage dispenser comprising same

PendingCN111982236AAvoid defectsSolving Wastewater ProblemsBeverage vesselsLevel indicators by physical variable measurementCapacitanceHemt circuits

The invention discloses a water level sensor as well as a water container and a beverage dispenser comprising the same. The water level sensor comprises one or more metal electrodes, one end of each metal electrode is exposed as a detection end, and the other end of each metal electrode is fixed in an insulating fixing piece and is connected with a signal output circuit in the insulating fixing piece; the signal output circuit is connected with a signal output wiring harness or a radio frequency wireless monitoring circuit. The water level sensor is used for devices with liquid level measurement and control, such as a water container and a beverage dispenser, and is combined with a mapping capacitor and a set change excitation signal such as a square wave, a pulse or an alternating signaland the like generated by computer control; the defects of a magnetic levitation ball dry reed sensor can be overcome, the lowest water level can be detected, water can be completely pumped without remaining water, the problem of waste water of a water dispenser is solved, the problems of rusting and scaling of metal electrodes can be prevented or reduced, and the water dispenser has the advantages of being long in service life, simple in circuit and low in cost.

Owner:吴雪红

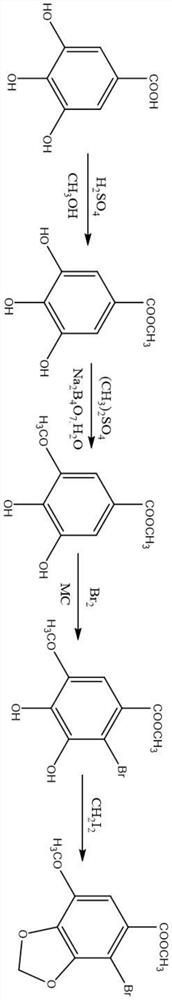

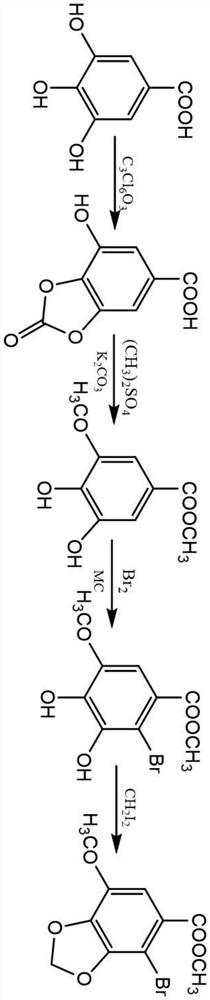

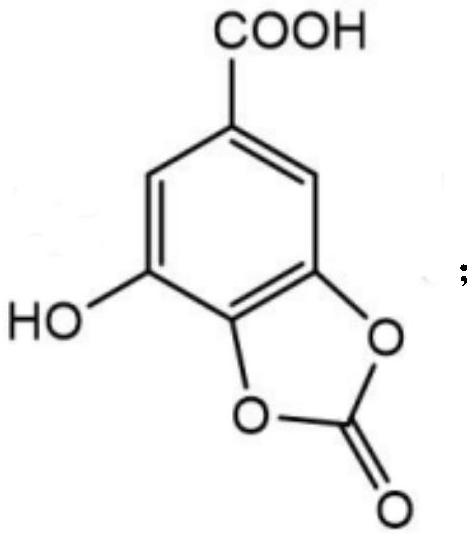

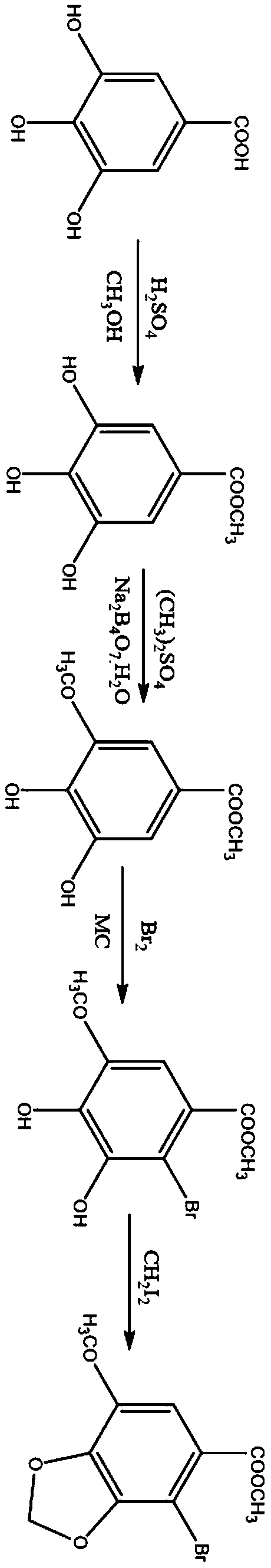

A kind of synthetic method of biphenyl diester intermediate

ActiveCN111004206BReduce processingMild reaction conditionsOrganic chemistryGallic acid esterIndustrial effluent

The invention belongs to the field of chemical pharmacy, and specifically discloses a method for synthesizing a biphenyl diester intermediate. Using gallic acid as a raw material, it undergoes an esterification reaction with solid phosgene to protect the o-diphenol hydroxyl group, followed by dimethylation and deprotection. Then, the biphenyl diester intermediate is obtained through bromination and methylation. The synthesis method of the bifendate intermediate of the present invention adopts phosgene to protect the ortho-diphenol hydroxyl group, the protection is complete, the reaction condition is mild, the process is simple, and the operation is convenient. Through the exploration and optimization of conditions, the product yield and purity are high, and the waste water problem in the borax protection method is solved, without damaging the environment, and it reduces the treatment of industrial waste water in the later stage, and reduces the production cost of the overall process to the greatest extent. high application.

Owner:苏州诚和医药化学有限公司

Synthetic method of bifendate intermediate

ActiveCN111004206AReduce processingMild reaction conditionsOrganic chemistryGallic acid esterIndustrial effluent

The invention belongs to the field of chemical pharmacy, and particularly discloses a synthesis method of a bifendate intermediate, and the method comprises the following steps: by using gallic acid as a raw material, carrying out esterification reaction with solid phosgene to protect o-diphenolic hydroxyl, carrying out dimethylation and deprotection, and carrying out bromination and methylenationto obtain the bifendate intermediate. According to the synthetic method of the bifendate intermediate, the phosgene is adopted to protect the o-diphenolic hydroxyl, protection is complete, reaction conditions are mild, the process is simple, and operation is convenient. By exploring and optimizing conditions, the product yield and purity are high, the wastewater problem in a borax protection method is solved, the environment is not damaged, the later industrial wastewater treatment is reduced, the production cost of the whole process is reduced to the maximum extent, and the method has extremely high application value.

Owner:苏州诚和医药化学有限公司

Method for removing base catalyst from crude biodiesel

ActiveCN102586012BAvoid alcoholysisImprove distillation yieldBiofuelsFatty-oils/fats refiningBiodieselWastewater

The invention relates to a method for removing a base catalyst from crude biodiesel. The method comprises the following step of: removing the base catalyst from the crude biodiesel by taking glycerin as an extracting agent, wherein the extraction temperature is 60-150DEG C, the operating pressure is normal pressure, and a mass ratio of the crude biodiesel to the glycerin is 10-1. Compared with the prior art, the method has the advantages that: 1, the method for removing the base catalyst from the biodiesel by taking the biodiesel byproduct glycerin as the extracting agent avoids a problem of wastewater caused by a water washing process; 2, the base catalyst dissolved in the glycerin phase is separated in a cooling crystallization mode, the glycerin and the base catalyst can be cyclically applied to a production process mechanically, and production cost is reduced; and 3, the base catalyst is effectively removed, alcoholysis in the high temperature vacuum rectification process of the biodiesel is avoided, and the biodiesel rectification yield is improved.

Owner:ZHEJIANG UNIV OF TECH

Wet-process open treatment method of arsenic in copper ashes

ActiveCN103233129BHigh recovery rateSolve the open circuit problemProcess efficiency improvementLiquid wastePollution

The invention discloses an open treatment method of arsenic in copper ashes and relates to a method for open pre-treatment of harmful arsenic impurities in intermediate material ashes in a copper smelting process. The wet-process open treatment method is characterized in that the treatment process comprises the following steps of: adding copper ashes to a solution containing sodium hypochlorite and sodium hydroxide; carrying out arsenic leaching reaction and filtering to obtain arsenic-removed slag and arsenic-removed solution; and recycling valuable metals including copper, lead, zinc and bismuth of the arsenic-removed slag. The wet-process open treatment method disclosed by the invention can be used for carrying out open treatment on the arsenic in the copper ashes before recycling the valuable metals, so that the subsequent recycling process of valuable metals is facilitated. Meanwhile, a utilization way for residual chlorine absorption liquid waste is found, so that the secondary pollution is avoided. Besides, the wet-process open treatment method for arsenic in the copper ashes is low in process cost and high in arsenic removal rate, and has great significance of improving environment protection, resource control and economical benefits.

Owner:JINCHUAN GROUP LIMITED

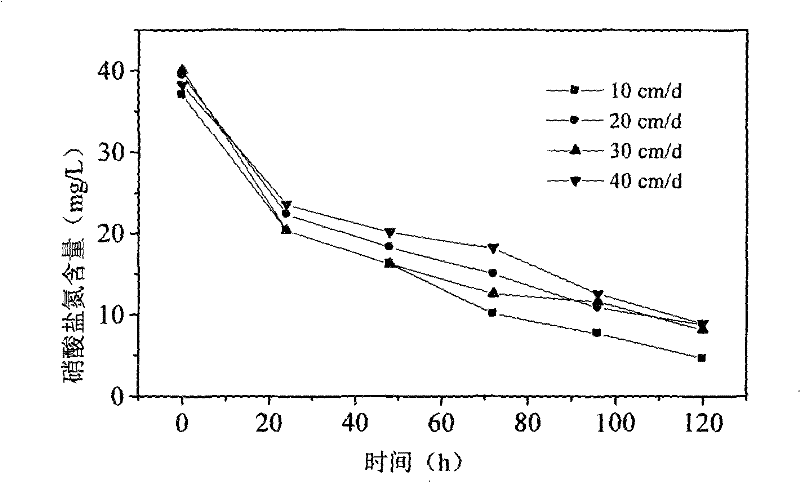

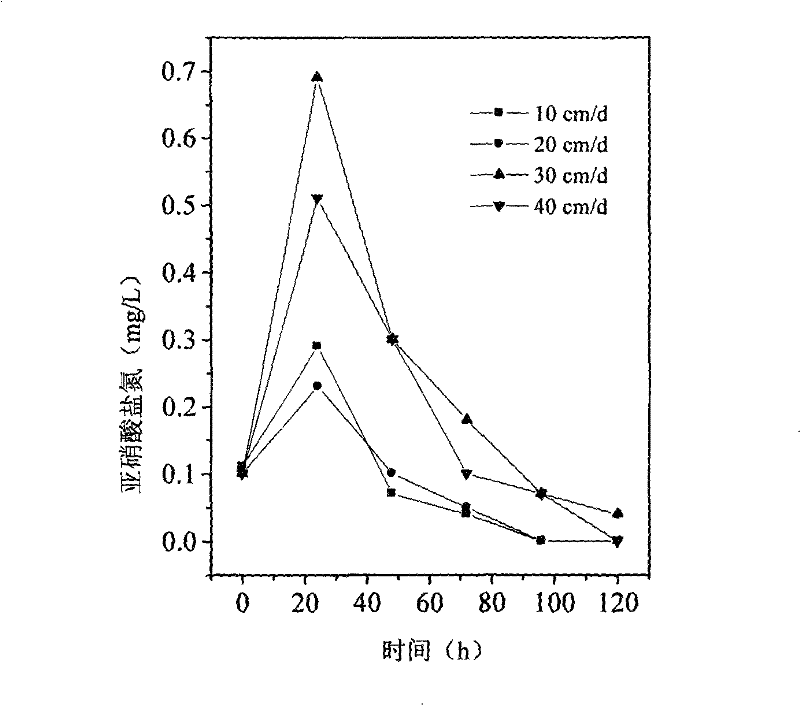

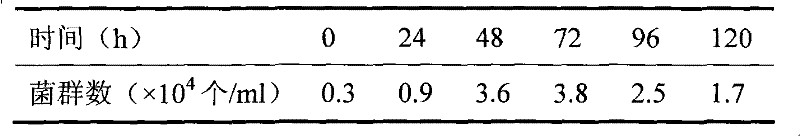

Method for in situ restoring groundwater azotate pollution with corn stalk

InactiveCN101492206BSolve pollutionSolve the use problemTreatment with anaerobic digestion processesGroundwater nitrateHydrolysate

The invention relates to a method for remedying the nitrate pollution of underground water in situ with maize straws, which is characterized in that maize straws or a maize straw hydrolysate serving as a denitrification carbon source and flora-enriched liquid rich in denitrifying bacteria florae are added in nitrate polluted underground water to remove nitrate nitrogen from underground water through bio-denitrification. The method realizes the harmless use of biomass maize straws and remedies the nitrate pollution of underground water effectively.

Owner:HEFEI UNIV OF TECH

Method for utilizing o-chlorocyclohexanol to prepare cyclohexene oxide by cyclization

InactiveCN102993131BSolving Wastewater ProblemsReduce manufacturing costOrganic chemistryAlcoholWastewater

The invention relates to a method for utilizing o-chlorocyclohexanol to prepare cyclohexene oxide by cyclization. The method comprises the steps of weighing o-chlorocyclohexanol, solid alkali and a solvent, placing the o-chlorocyclohexanol, the solid alkali and the solvent into a reactor to undergo a reaction, performing a heating stirring reaction, obtaining a reaction mixture after the reaction is finished, and obtaining the product cyclohexene oxide by separation. The solid alkali is a load type metal salt, and the adopted solvent is lower alcohol. The method has the advantages that a large number of waste water caused by used sodium hydroxide serving as a catalyst is avoided, the production cost is reduced, the process is simple, the used solid alkali has no harm to the human body and can be separated from a product easily, the method is a green chemical process, the used solid alkali is high in selectivity for a principal product, and the method is favorable for the reaction.

Owner:NANJING TECH UNIV

A circulating gas stripping distillation system for extracting EPA&DHA from fish oil

ActiveCN106673998BIncreased EPA&DHA contentShort heating timeOrganic compound preparationSteam distillationGas compressorBuffer tank

The invention relates to a circulating gas stripping rectification system for extracting EPA and DHA from fish oil. The system comprises a gas stripping rectification tower, wherein the top of the gas stripping rectification tower is connected with the top of a heat exchange tower; the bottom of the gas stripping rectification tower is connected with a gas stripping tower kettle storage tank through a gas stripping tower kettle extraction pump; the gas stripping rectification tower is also connected with a raw material preheater and a nitrogen heater; the top of the gas stripping rectification tower is also connected with a washing tower; the top of the washing tower is connected with a fan buffer tank; the fan buffer tank is connected with a vacuum buffer tank through a gas compressor; the vacuum buffer tank is also connected with a vacuum pump and the heat exchange tower separately; the heat exchange tower is also connected with the nitrogen heater; the bottom of the washing tower is connected with a washing tower kettle storage tank through a washing tower kettle extraction pump; the bottom of the washing tower is also connected with a circulating cooler through a washing tower circulating pump, and the circulating cooler is connected with the upper part of the washing tower. The circulating gas stripping rectification system of the invention does not need high vacuum, and the content of the EPA and the DHA can be improved to above 70% by one-time purification.

Owner:山东禹王制药有限公司 +1

A green preparation process of phenolic resin without waste water discharge

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com