Automatic zongzi filling equipment and process

A technology for filling equipment and zongzi, which is applied in the field of automatic filling equipment for zongzi, which can solve the problems of increased pollution treatment, low heat energy utilization rate, and mildew on the surface of zongzi leaves, so as to omit secondary high-temperature sterilization, solve oil pollution and Effects of waste water and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

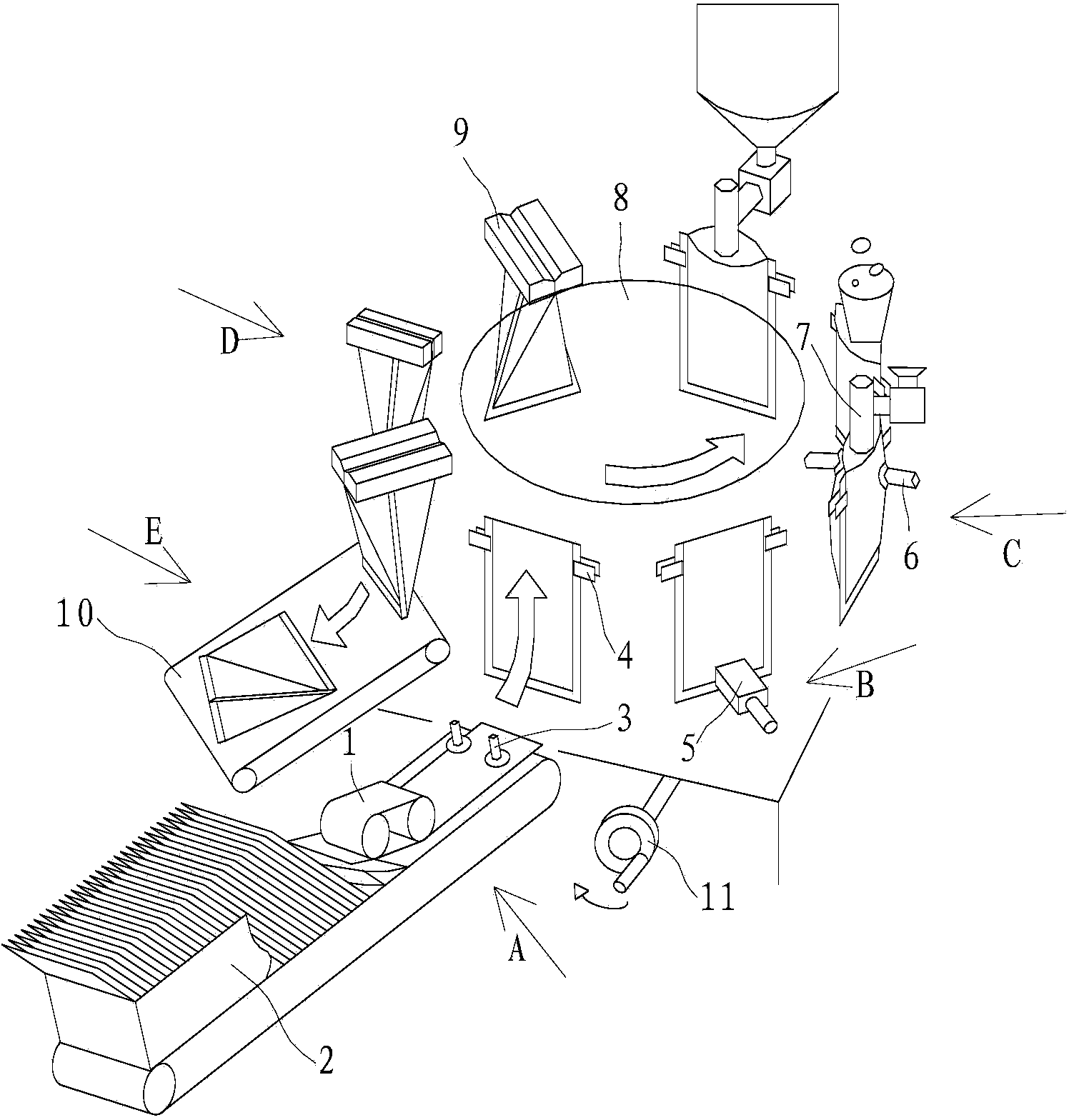

[0051] Below in conjunction with accompanying drawing, the Zongzi automatic filling equipment of the present invention is described in detail.

[0052] Such as figure 1 As shown, an automatic filling equipment for zongzi, including an intermittently moving rotary table, and a conveying mechanism (as indicated by arrow A in the figure) and a printing mechanism (as indicated by arrow B in the figure) distributed sequentially around the circumference of the rotary table , Feeding mechanism (pointed by arrow C in the figure), sealing mechanism (pointed by arrow D in the figure) and output mechanism (pointed by arrow E in the figure).

[0053] The rotary table can adopt existing technology to drive its intermittent rotation by a motor.

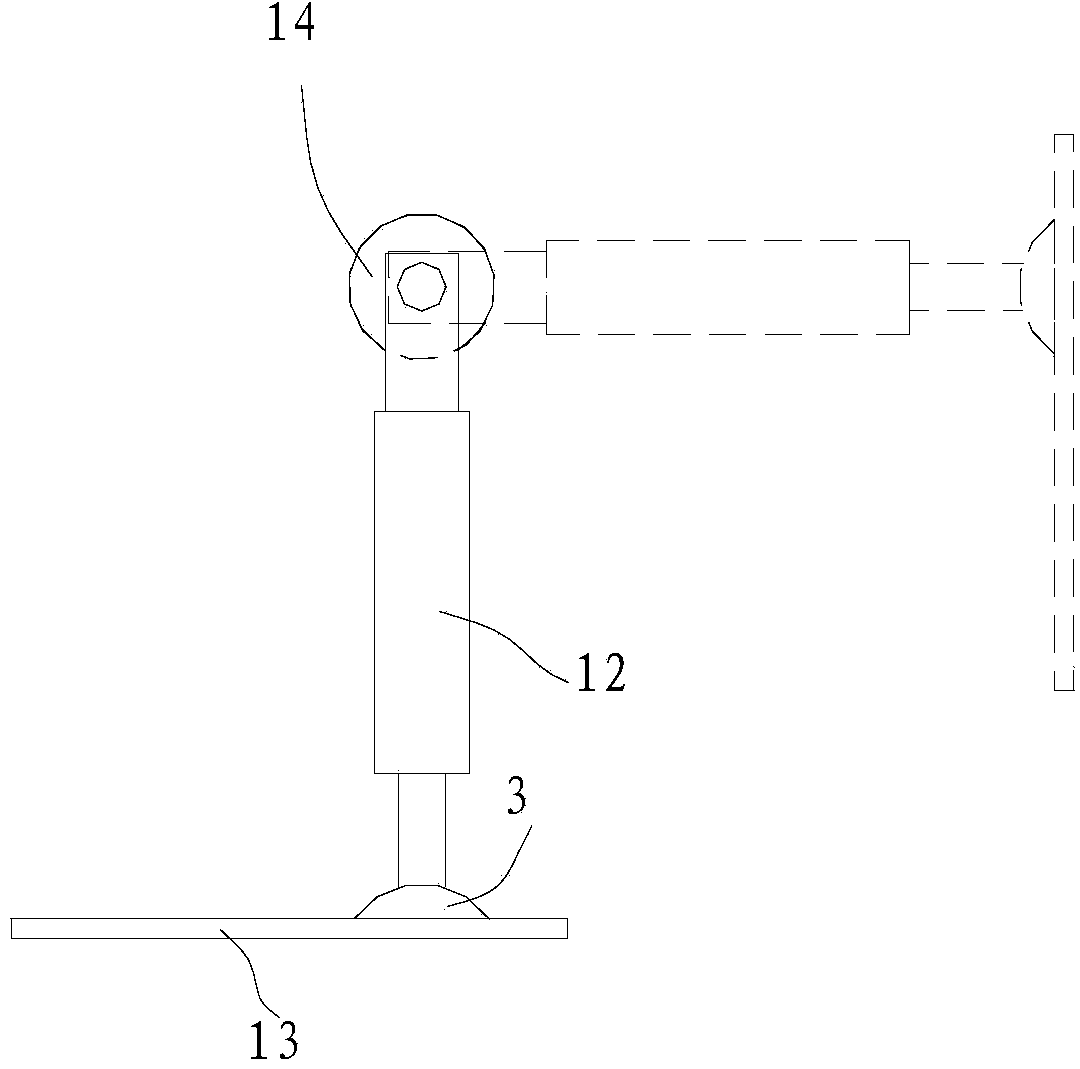

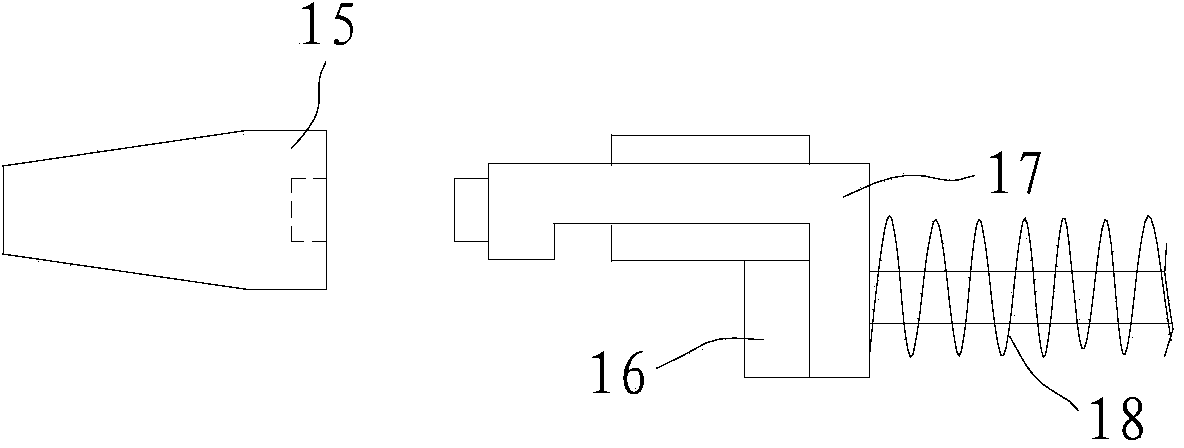

[0054] The conveying mechanism includes a supply tank 2 for containing packaging bags, and a movable suction cup 3 for transferring the packaging bags in the supply tank 2 to the clamping mechanism 4 one by one; figure 1 , figure 2 As shown, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com