Comprehensive utilization method for waste water containing high-concentration sodium sulfate based on wet metallurgy process

A hydrometallurgical, high-concentration technology, applied in the improvement of process efficiency, alkali metal sulfite/sulfite, alkali metal compounds, etc., can solve the problem of high cost of hydrometallurgy process, and solve the problem of excessive energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

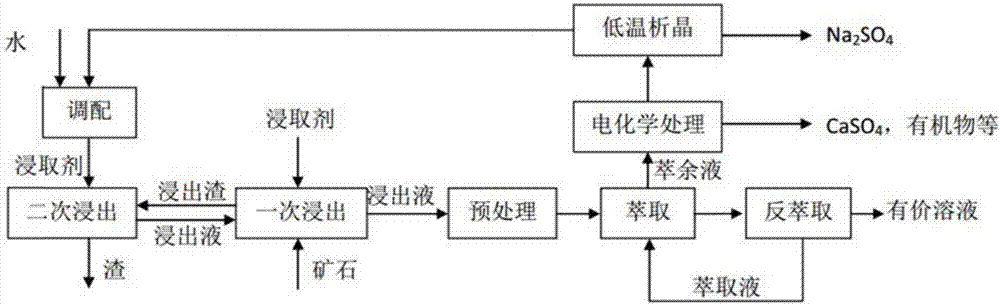

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Carry out hydrometallurgy for a certain nickel-containing ore (main components include Ni, Fe, Ca, etc.), determine the hydrogen ion concentration consumed according to the content of nickel and other metals in the ore, and carry out the leaching solution ratio on this basis deployment.

[0041] 1) Use a ball mill to crush the ore raw material, and keep more than 80% of the outlet particle size at 10mm.

[0042] 2) Transfer the crushed ore to the leaching equipment for leaching, the leaching temperature is 50°C, the total concentration of sulfate and sulfite in the leaching solution (containing sulfuric acid and sulfurous acid) is 3.4mol / L, and the concentration of hydrogen ions 1mol / L, solid-liquid separation is carried out after the leaching agent is completely consumed (leaching time is 12h), the leaching solution enters the next process, and the leaching residue continues to leaching;

[0043] 3) The leaching solution in step 2 is sent to the pretreat...

Embodiment 2

[0048] Embodiment 2: Carry out hydrometallurgy for a certain nickel-containing ore (main components include Ni, Fe, Ca, etc.), determine the hydrogen ion concentration consumed according to the content of nickel and other metals in the ore, and carry out the leaching solution ratio on this basis deployment.

[0049] 1) Use a ball mill to crush the ore raw material, and keep more than 80% of the outlet particle size at 5 mm.

[0050] 2) Transfer the crushed ore to the leaching equipment for leaching. The leaching temperature is 50°C. The total concentration of sulfate and sulfite in the leaching solution is 3mol / L, and the concentration of hydrogen ions is 1mol / L. After the agent is completely consumed, solid-liquid separation is carried out (leaching time is 6h), the leachate enters the next process, and the leaching residue continues to be leached;

[0051] 3) The leaching solution in step 2 is sent to the pretreatment tank for precipitation and iron removal, and then extrac...

Embodiment 3

[0056] Embodiment 3: Carry out hydrometallurgy for a certain nickel-containing ore (the main components include Ni, Fe, Ca, etc.), determine the hydrogen ion concentration consumed according to the content of nickel and other metals in the ore, and then carry out the leaching solution ratio on this basis deployment.

[0057] 1) Use a ball mill to crush the ore raw material, and keep more than 80% of the outlet particle size at 5 mm.

[0058] 2) Transfer the crushed ore to the leaching equipment for leaching. The leaching temperature is 40°C. The total concentration of sulfate and sulfite in the leaching solution is 2.8mol / L, and the concentration of hydrogen ions is 1mol / L. After the extraction agent is completely consumed, solid-liquid separation is carried out (leaching time is 24 hours), the leachate enters the next process, and the leaching residue continues to be leached;

[0059] 3) The leaching solution in step 2 is sent to the pretreatment tank for precipitation and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com