Patents

Literature

87results about How to "Solve excessive energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

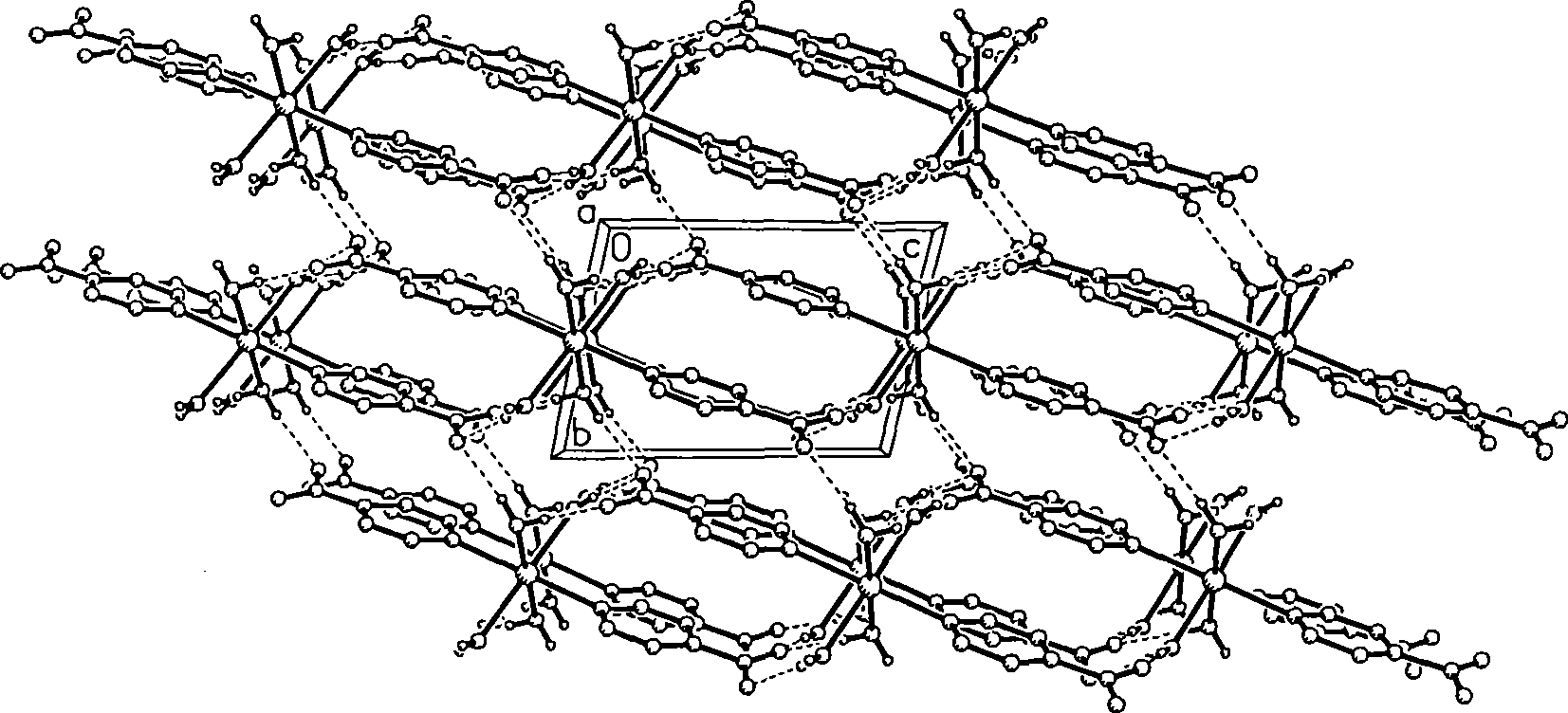

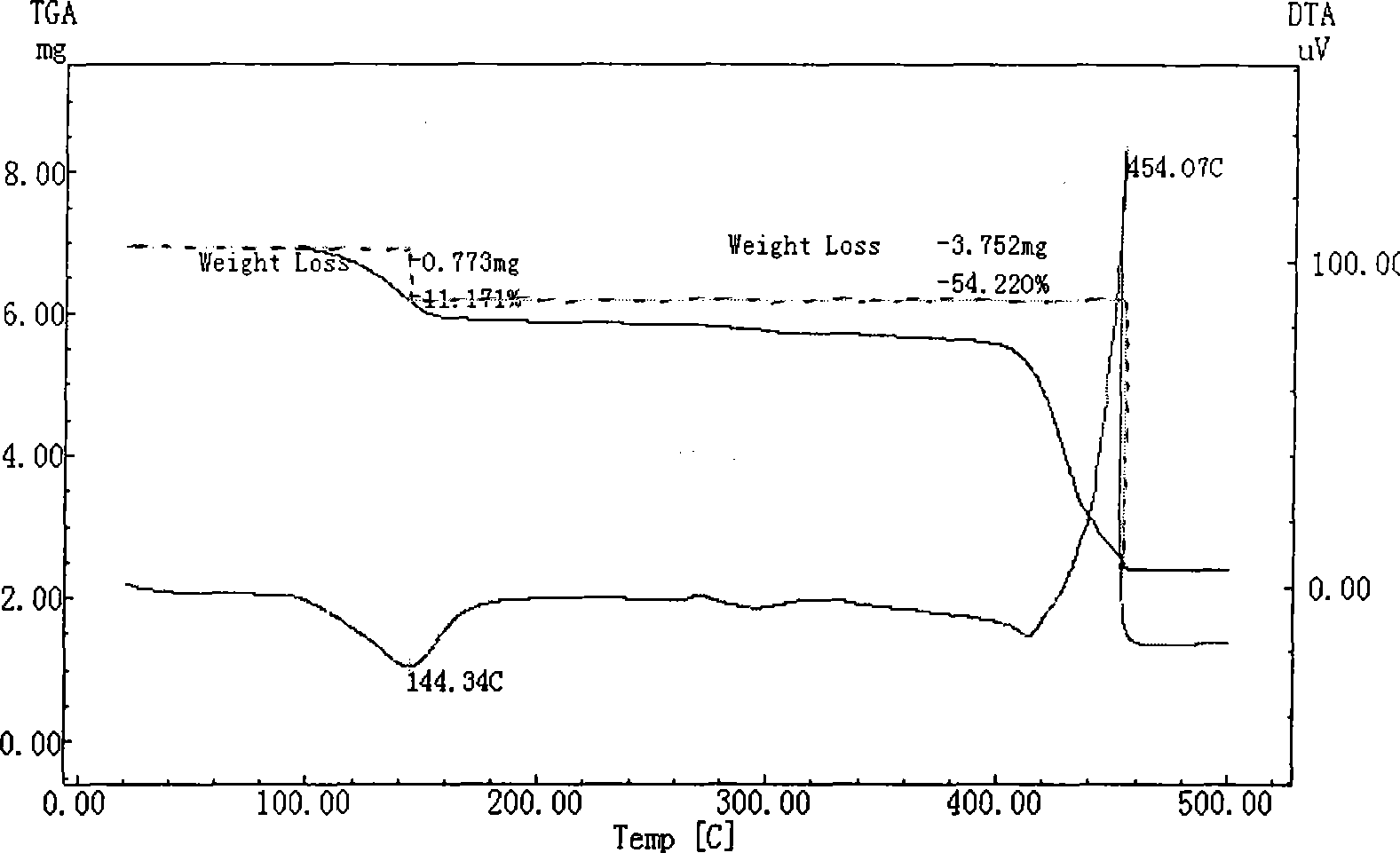

Method for low-temperature atmosphere-pressure hydrothermal synthesis of stephanoporate metal-organic framework

InactiveCN101429209AFully contactedQuality improvementCadmium organic compoundsZinc organic compoundsMetal-organic frameworkChemistry

The invention discloses a method for hydrothermally synthesizing a porous metal-organic framework under low temperature and normal pressure, which comprises the following steps: 1) bivalent transition metal salt is put into proper amount of distilled water to be dissolved; 2) a multidentate organic ligand is put into proper amount of distilled water, and ammonia (30 percent, W / W) is added into the solution until the organic ligand is dissolved; 3) solutions obtained in step 1) and step 2) are mixed, and diluted by the distilled water; 4) the solution obtained in step 3) reacts for 4 to 24h at a temperature of between 80 and 100 DEG C, and is naturally cooled to room temperature at an environmental temperature to obtain an MOF crystal product; and 5) the MOF crystal product obtained in step 4) is filtered, MOF crystals are colleted and washed by the distilled water and absolute ethyl alcohol respectively, and the product is obtained after the natural drying. By performing a hydrothermal reaction in an ammonia solution, the method has mild conditions needed by the synthesis, less energy consumption and time consumption, and does not need a voltage resistant reactor. Therefore, the method is simpler and has lower cost; and a porous crystal material obtained by the synthesis has potential application value in the fields of gas separation, gas storage and heterogeneous catalysis.

Owner:CHONGQING UNIV

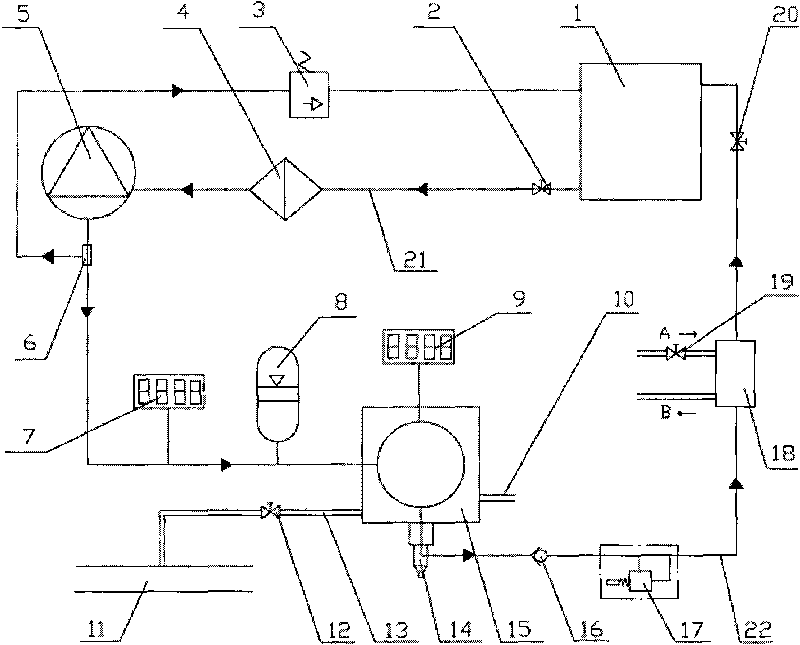

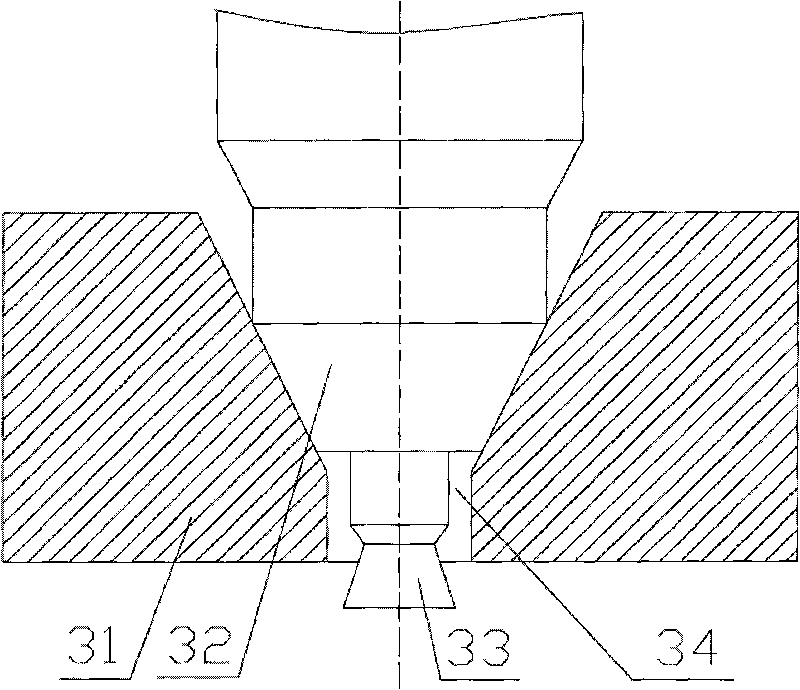

SCP urea injection system for post treatment of diesel engine emissions

ActiveCN101737127AImprove metering accuracyImprove stabilityInternal combustion piston enginesExhaust apparatusTemperature controlExhaust fumes

The invention discloses an SCP urea injection system for the post treatment of diesel engine emissions, which belongs to internal combustion engine waste gas purification systems, comprises a urea solution box, a conveying pump, a filter, a urea nozzle, a pressure sensor and a temperature sensor, and is characterized in that the urea injection system comprises an energy accumulator, a large-capacity injection accommodating cavity and a device for heating urea solution by diesel exhaust, wherein the energy accumulator is connected with a main pipeline of the system in parallel and is used for stabilizing the pressure of the main pipeline; the large-capacity injection accommodating cavity is directly connected with the urea nozzle; and the device for heating the urea solution by the diesel exhaust comprises a waste gas inlet pipe, a temperature control valve, a waste gas outlet pipe and the like, wherein the urea nozzle adopts a pintle type nozzle which can prevent the urea from being crystallized at a low temperature to block an injection orifice. The system can realize precise and reliable injection metering of the urea solution.

Owner:CHINA FIRST AUTOMOBILE

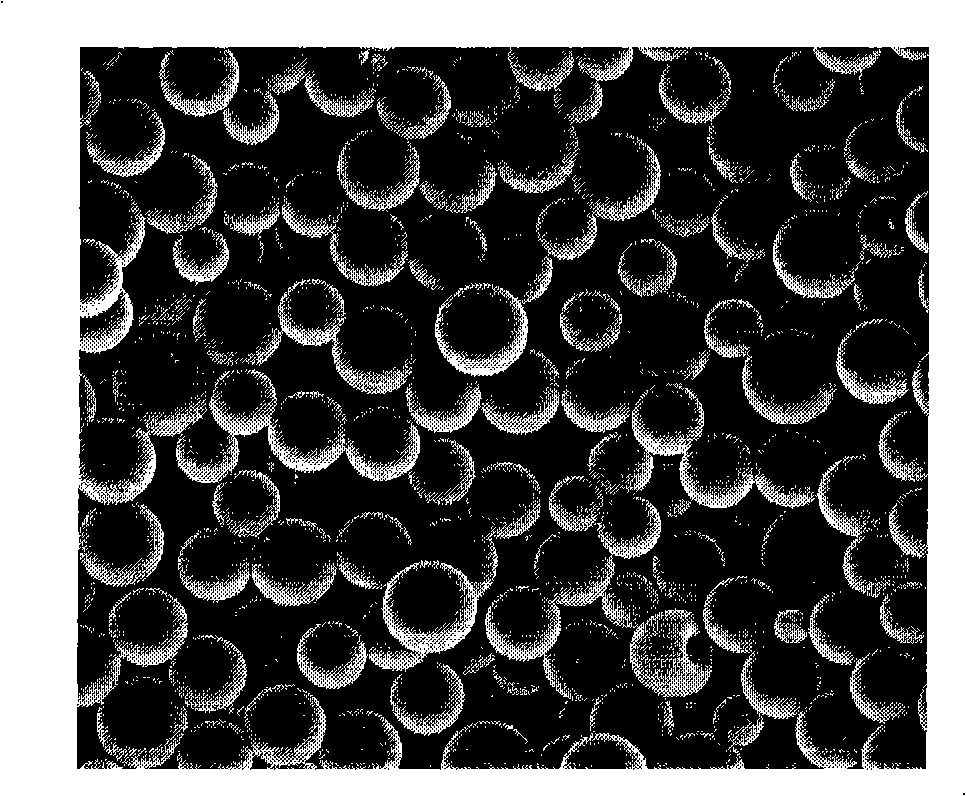

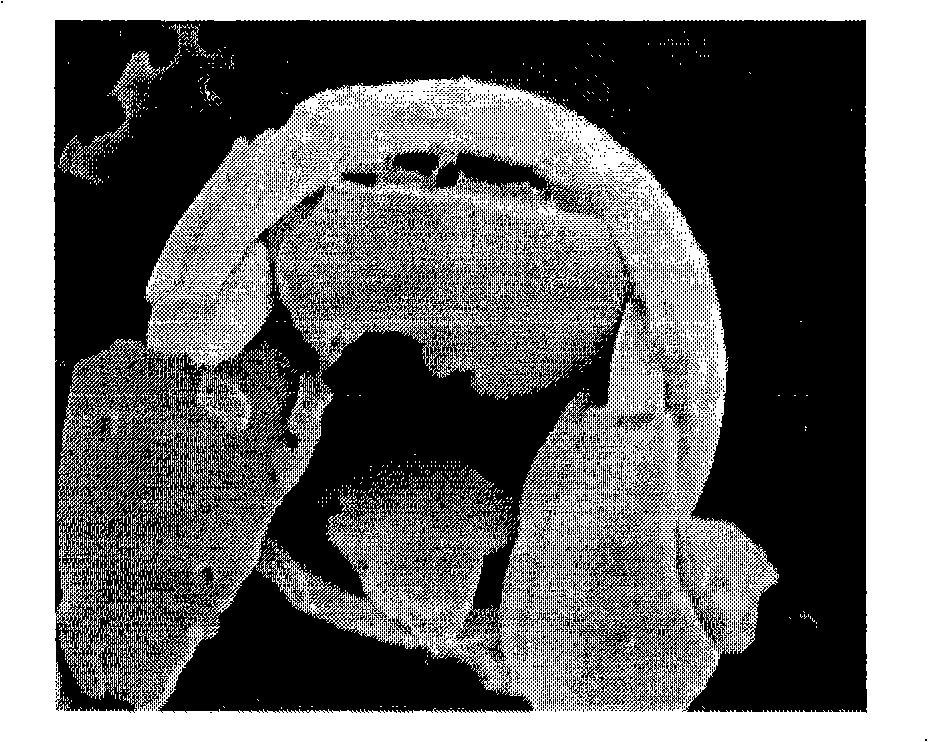

Epoxy resin micro-capsule and its preparation method

InactiveCN101319055AImprove sealingGood mechanical propertiesMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention discloses an epoxy resin microcapsule and a preparation method thereof. The epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein, the capsule core is an epoxy resin, and the capsule wall is a composition of an aepoxy acrylate resin, a polymerizable emulsifying agent, a crosslinking agent and an optical initiator; and the polymerization method of the capsule wall is ultraviolet irradiation and film forming through curing. The preparation method for the microcapsule comprises the following steps that: core materials, wall materials and an ultraviolet initiator are added into a water solution which is dissolved with a surfactant in turn under the condition of high-speed stirring; after an oil-in-water emulsion system is prepared by emulsification, ultraviolet light is immediately used for irradiating the emulsion, and the surface compositions of oil-in-water liquid droplets undergo in-situ polymerization and film forming through curing; a great dealof water is added for repeated sedimentation and water scrubbing; and microcapsule products are prepared through vacuum freeze drying of microcapsule deposits. The method has a simple technique, low energy consumption, quick speed and friendly environment. The capsule prepared takes the shape of a regular sphere, has good leak tightness and heat resistance, and can be widely applied to self-repairing of self-setting thread fasteners and thermosetting resin substrate composite materials.

Owner:SUN YAT SEN UNIV

Preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for pet

ActiveCN102630827AImprove freshnessReduce fishy smellAnimal feeding stuffWorking-up animal fodderRaw meatBiting

The invention relates to the field of pet food, and in particular relates to a preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for a pet. According to the preparation method disclosed by the invention, poultry, livestock meat or bright flesh of fish or fresh skin of animals such as pig, calf and fish is taken as raw material, the raw material is minced and chopped, moulded and frozen and then split, or the raw material is directly split and then frozen, or the raw material is split into the required shape and then frozen, subsequently microwave vacuum dryingis carried out, and sterilizing and packaging are carried out, and thus the edible jerky or calfskin, pigskin and fish skin biting chew for the pet is obtained. The edible jerky or calfskin, pigskin and fish skin biting chew finished product can show primary colour of raw meat, has a strong meat flavour and maintains nutrition of a meat product while a food calling function is realized. The edible jerky or calfskin, pigskin and fish skin biting chew can be taken as a meat snack for the pet and also can be taken as a nutritional supplement for an old-aged dog or little dog after being rewatered and torn up.

Owner:JIANGSU YIHE PET PROD CO LTD

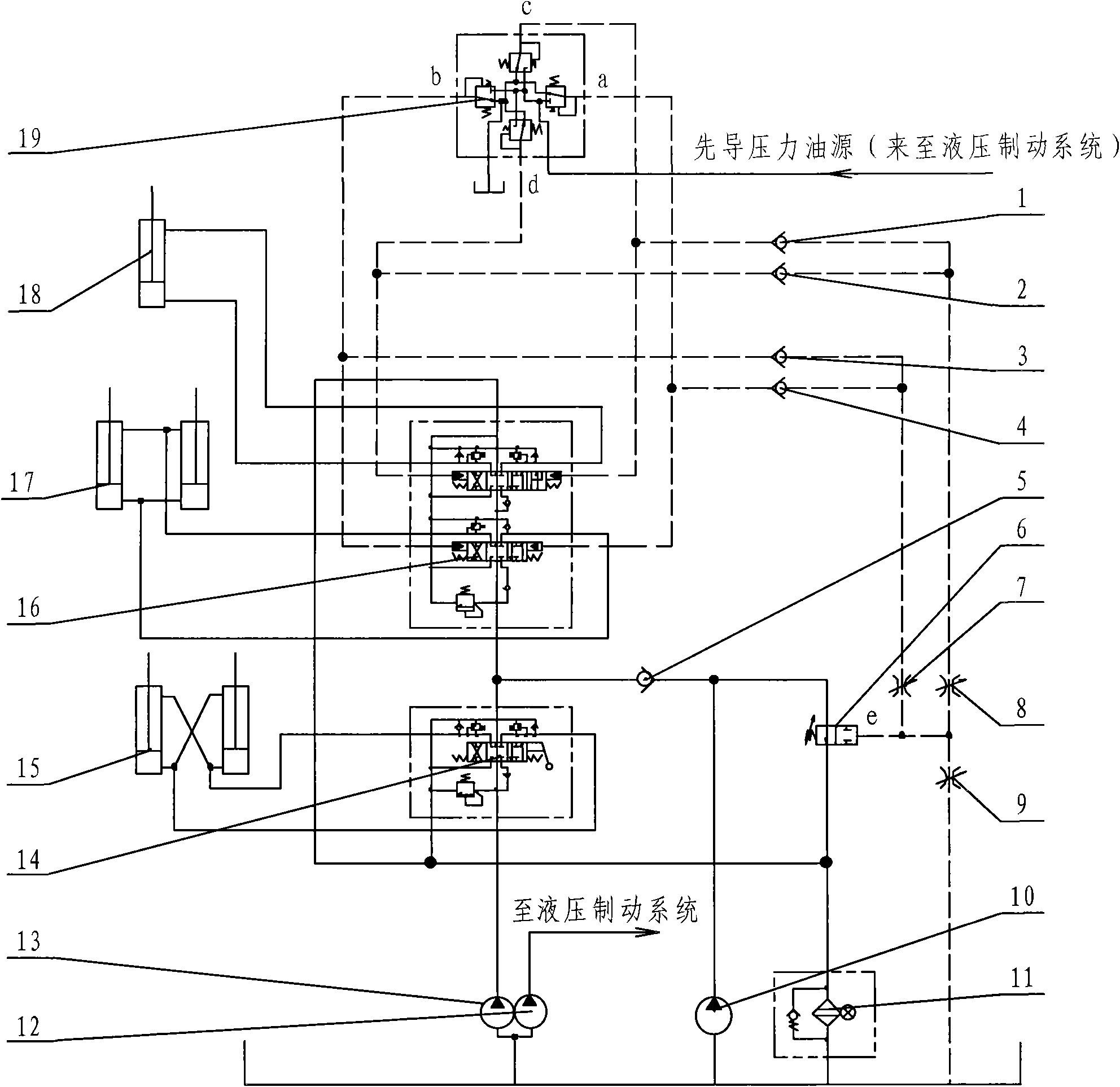

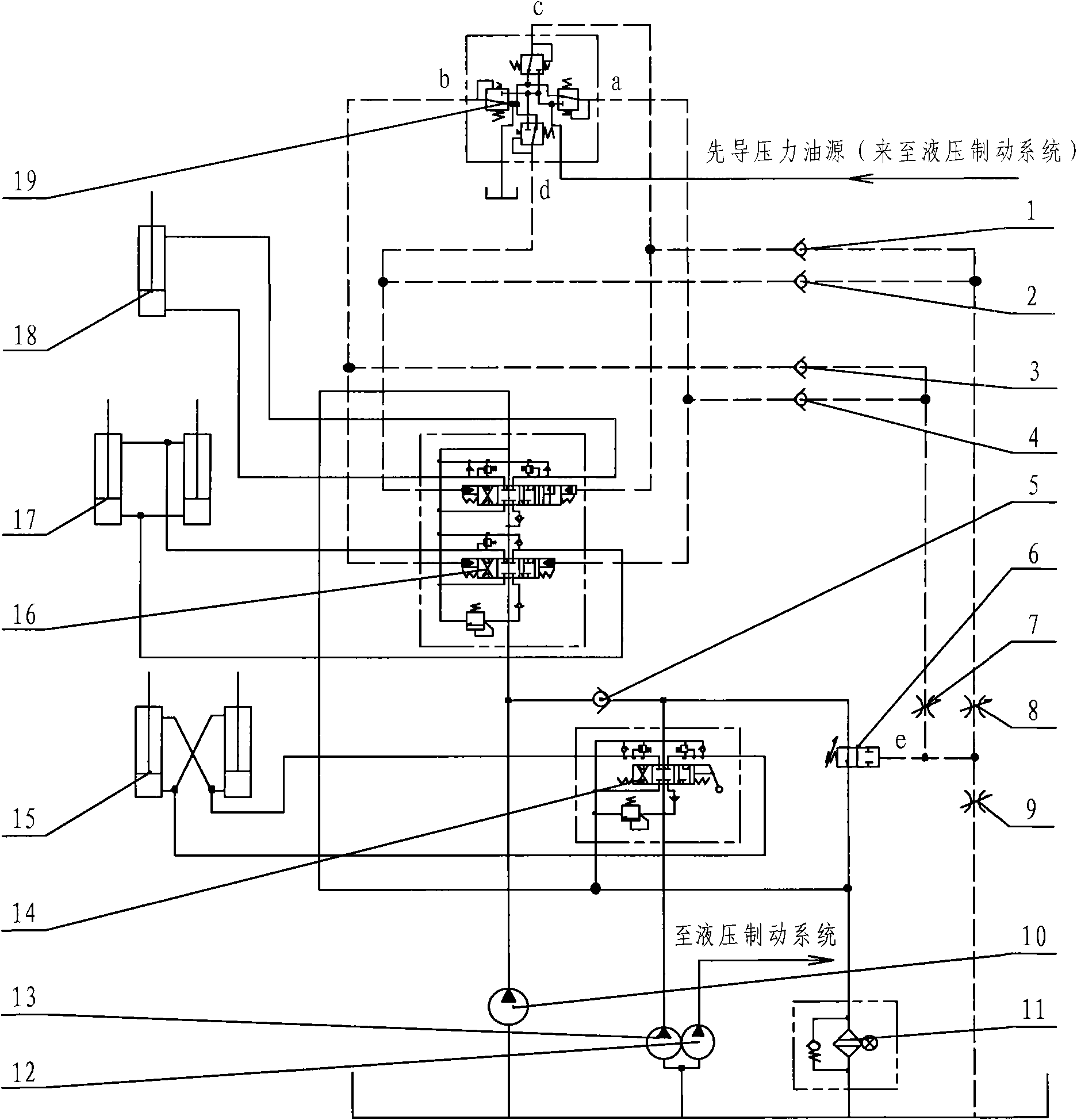

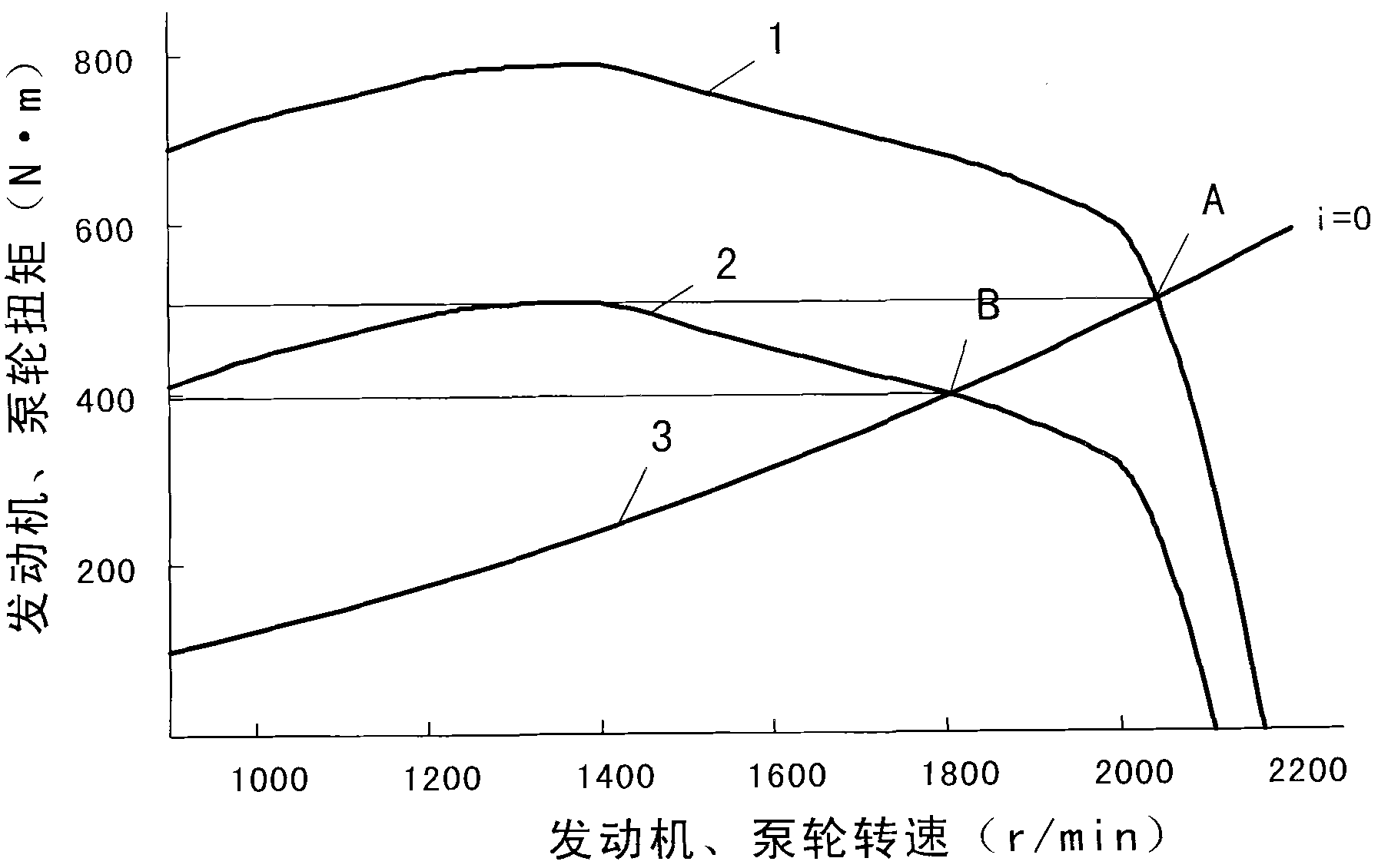

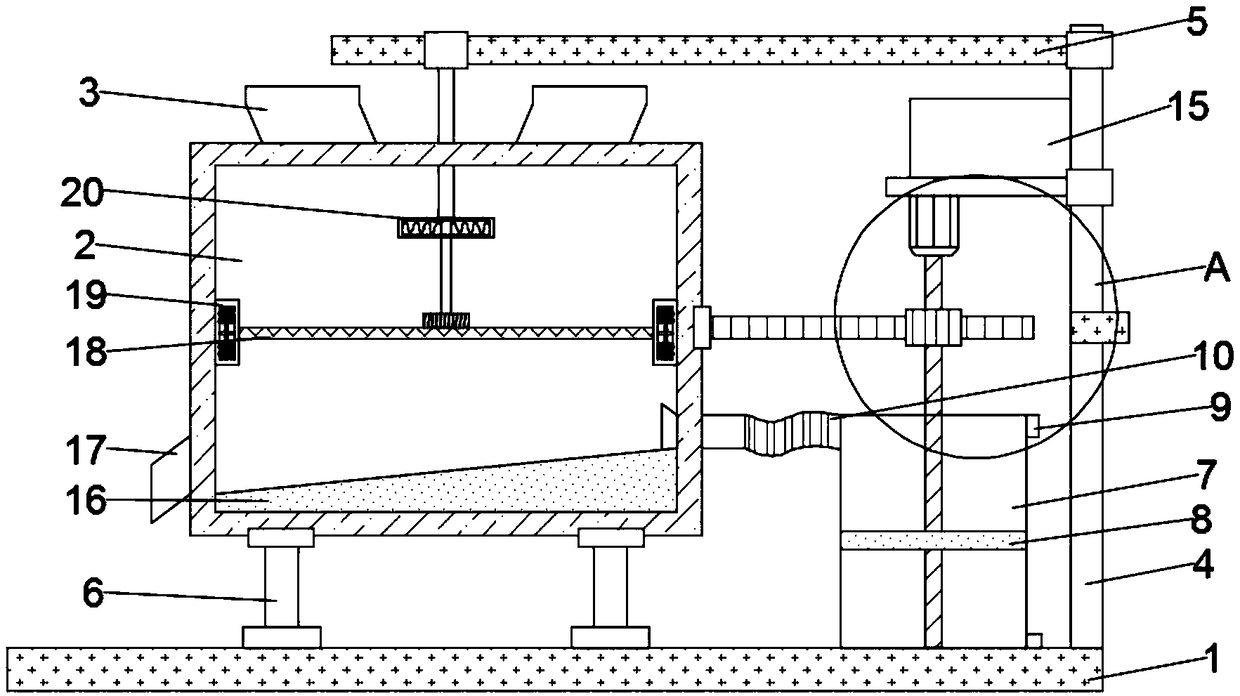

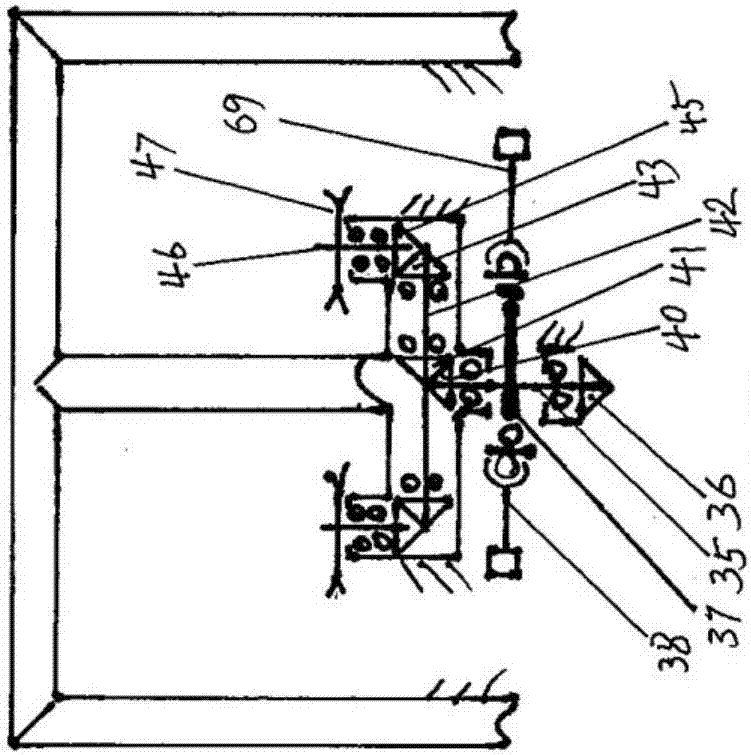

Quantitative pump hydraulic control system of work mechanism of underground carrying scraper

InactiveCN101858091AImprove energy utilizationSolve excessive energy consumptionServomotor componentsMechanical machines/dredgersOil supplyPilot valve

The invention discloses a quantitative pump hydraulic control system of a work mechanism of an underground carrying scraper, comprising a steering oil pump, a steering multi-path valve, a work oil pump, a work multi-path valve and a pilot valve, wherein a plurality of control oil paths are arranged between the pilot valve and the work multi-path valve; an outlet oil path of the steering oil pump is connected with an inlet oil path of the steering multi-path valve; an outlet oil path in the middle path of the steering multi-path valve and an outlet oil path of the work oil pump are combined into an oil path which is connected with an inlet oil path of the work multi-path valve; and a pressure-relief bypass is arranged on the outlet oil path in the middle path of the steering multi-path valve or the outlet oil path of the work oil pump and is provided with a hydraulic control two-position and two-way valve, so that the work mechanism of the underground carrying scraper can automatically select a single-pump oil supply state or a dual-pump oil supply state according to the operation requirement. In addition, the energy utilization rate of the quantitative pump hydraulic control system of the underground carrying scraper can be improved and the equipment availability of the underground carrying scraper can be improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

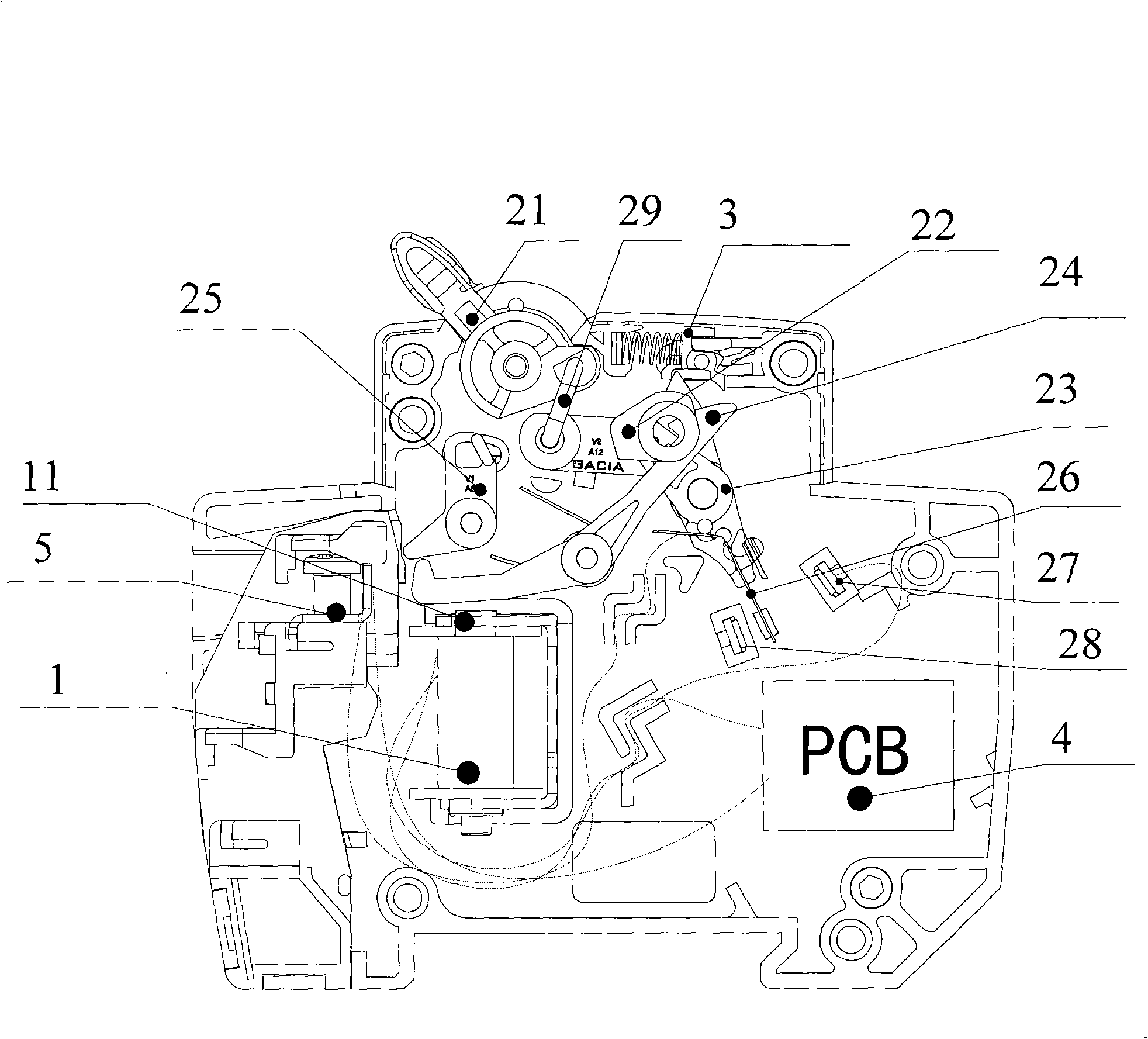

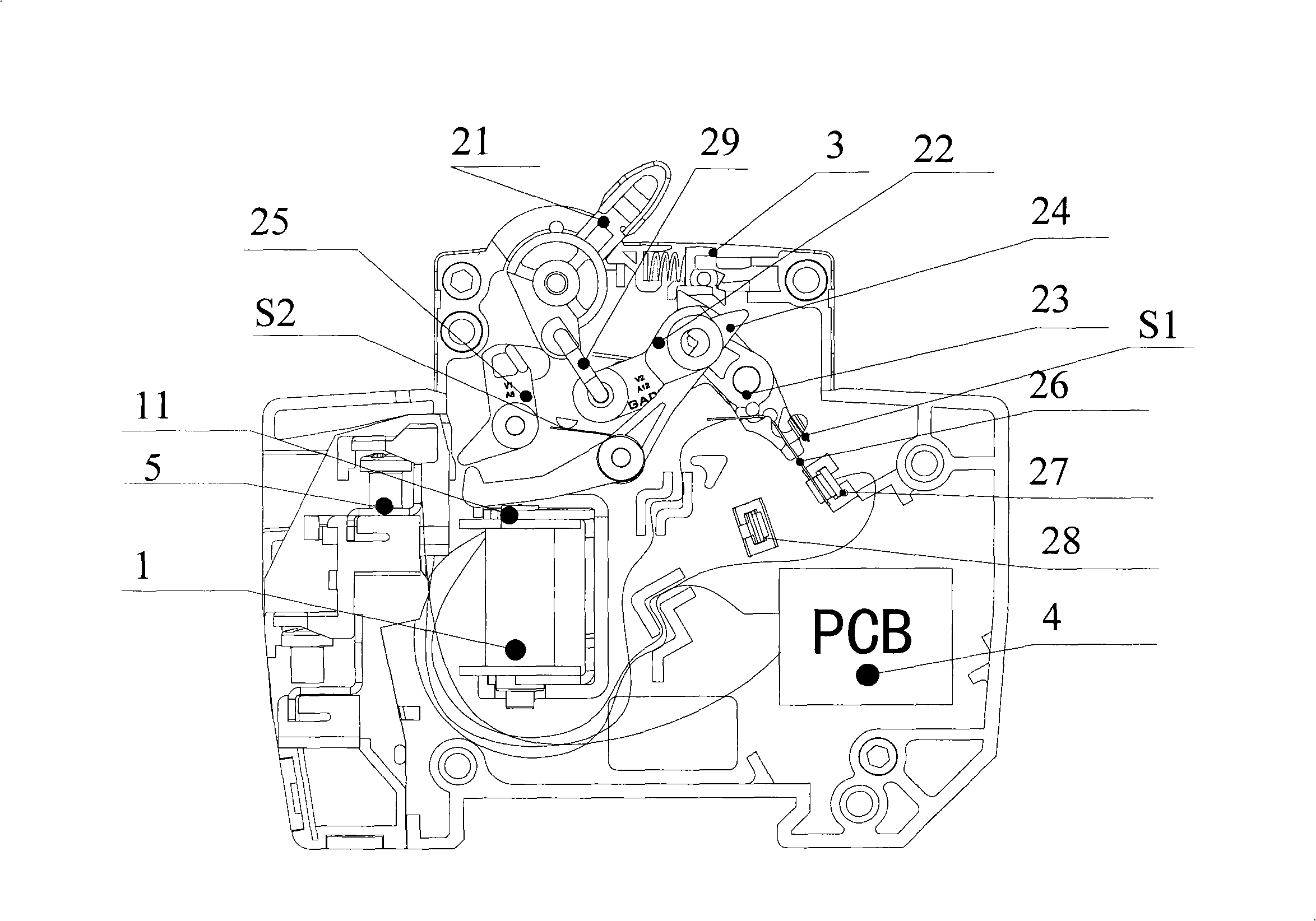

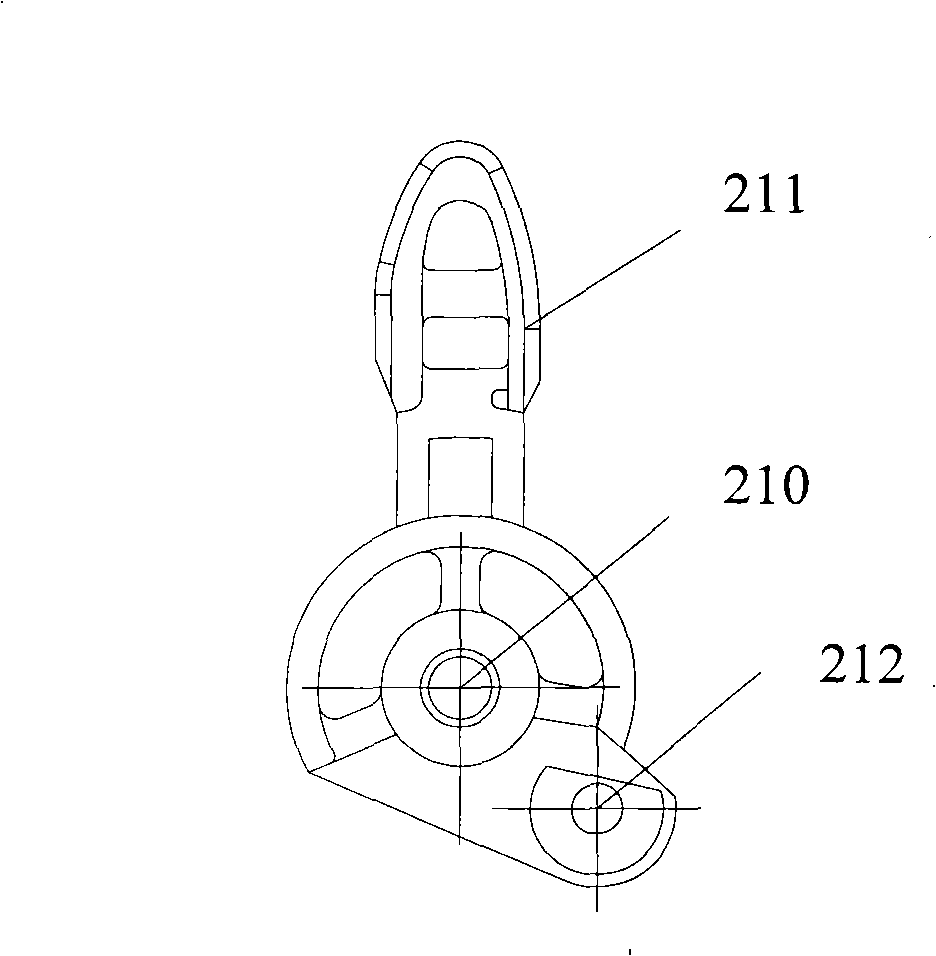

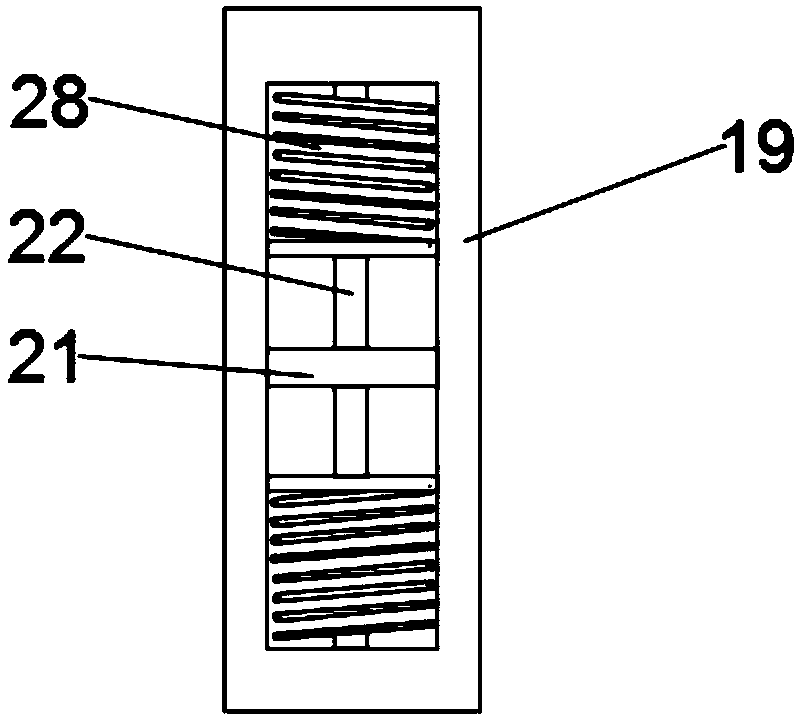

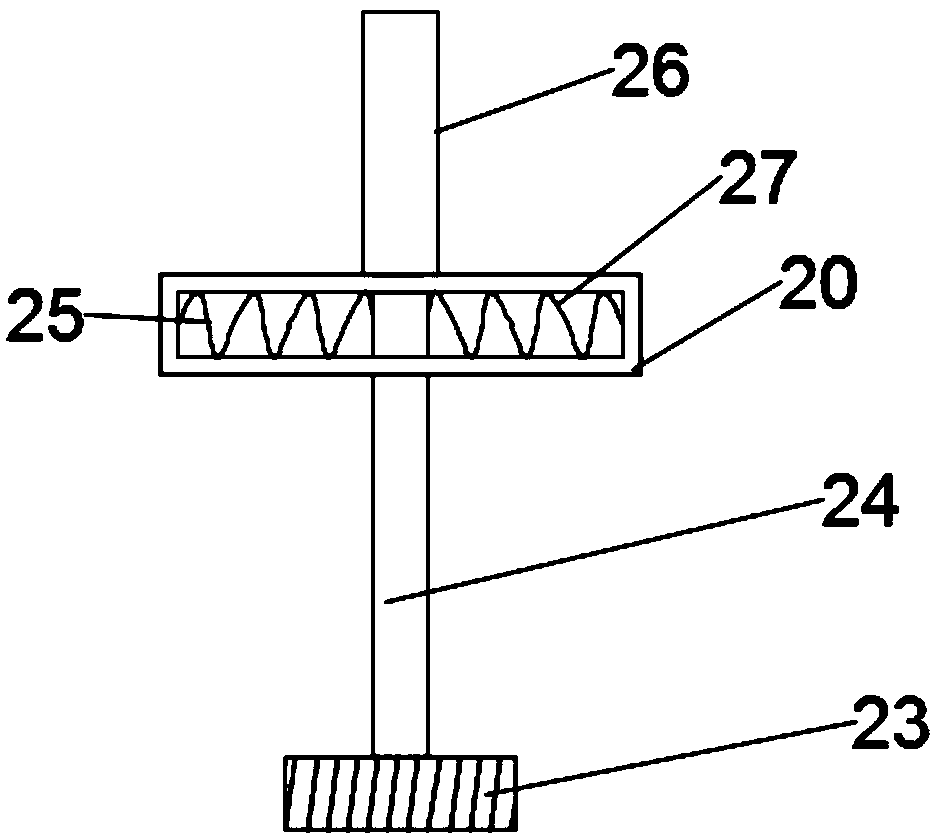

Tripping device

InactiveCN101540244ASolve excessive energy consumptionSimple designSwitch operated by falling voltageProtective switch operating/release mechanismsWeak currentEffective energy

The invention relates to a tripping device used for receiving a shunt trip signal and cutting off a power supply of an external small breaker. The tripping device comprises a shell, and a tripper (1) and a transmission mechanism which are arranged inside the shell, wherein the tripper (1) comprises a coil, an iron core and a biasing spring; and the transmission mechanism comprises a handle (21), a lever (22), a push rod (23), a lock catch (24) and a tripping lever (25). The transmission mechanism of the tripping device is designed more concisely and reasonably and can achieve the perfect transmission effect; furthermore, the tripping device controls two circuit states through the tripper, well utilizes the weak current of an electronic circuit to control undervoltage and a voltage loss circuit and achieves the effective energy-saving effect.

Owner:GACIA ELECTRICAL APPLIANCE

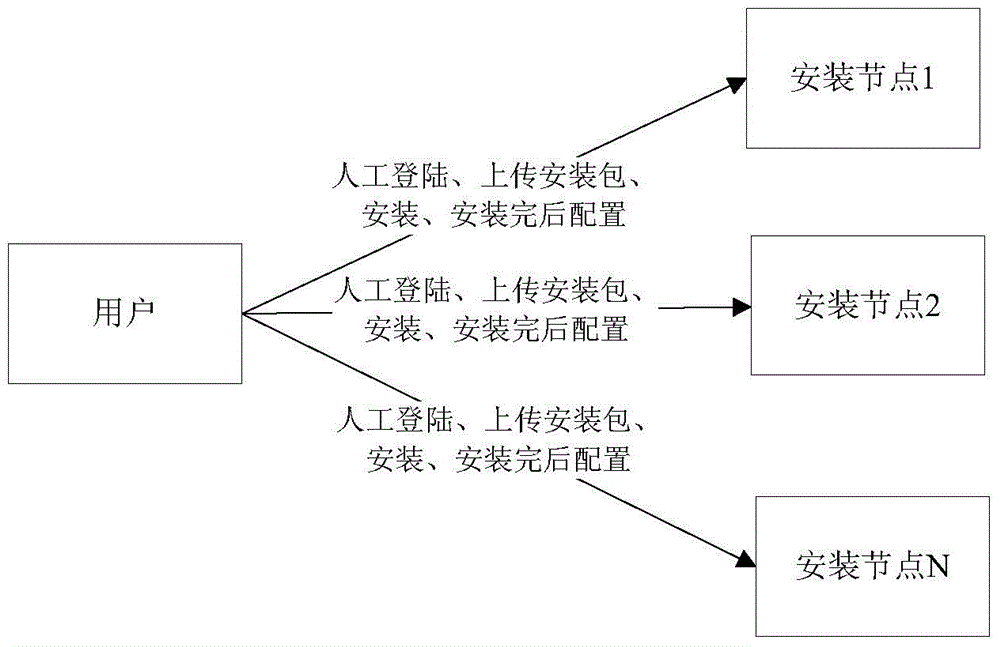

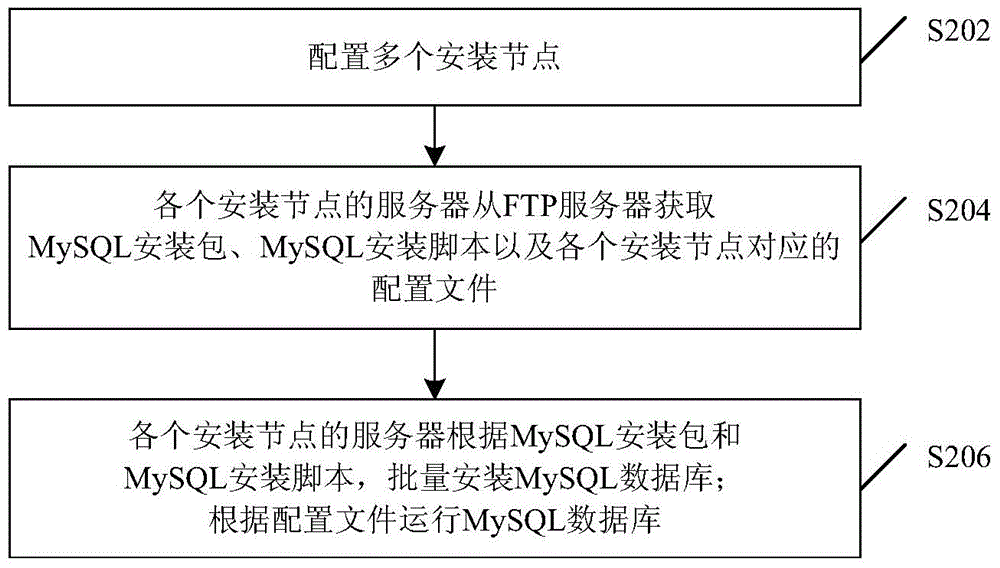

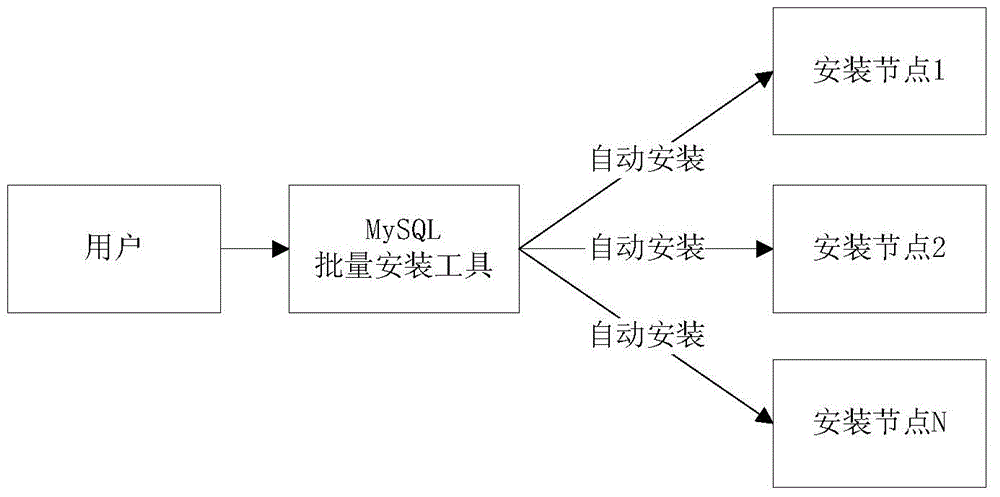

Method and device for installing MySQL database

InactiveCN105224348ASolve excessive energy consumptionResolution timeProgram loading/initiatingQuery languageOperating system

The invention discloses a method and device for installing a MySQL (Structured Query Language) database. The method comprises the following steps: a plurality of installation nodes are configured; a server on each installation node obtains a MySQL installation package, a MySQL installation script and a configuration file corresponding to each installation node from a reservation server, and the MySQL database is subjected to batch installation; the server on each installation node carries out the batch installation on the MySQL database according to the MySQL installation package and the MySQL installation script; and according to the configuration file, the MySQL database runs. The quick batch installation of the MySQL database is realized, the problem in the relevant prior that an installation method of the MySQL database consumes excessive vigor and time is solved, the complicated degree and the complexity of the large-scale installation of MySQL are lowered, installation time is greatly shortened, misoperation possibility is greatly lowered, and installation success rate and correctness can be guaranteed.

Owner:ZTE CORP

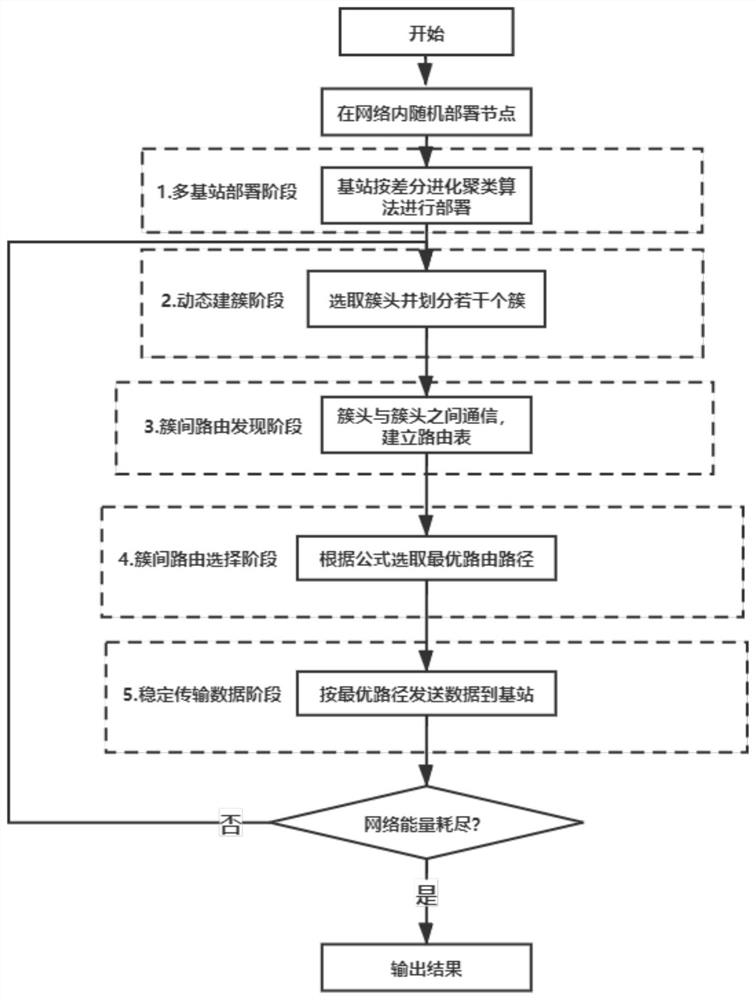

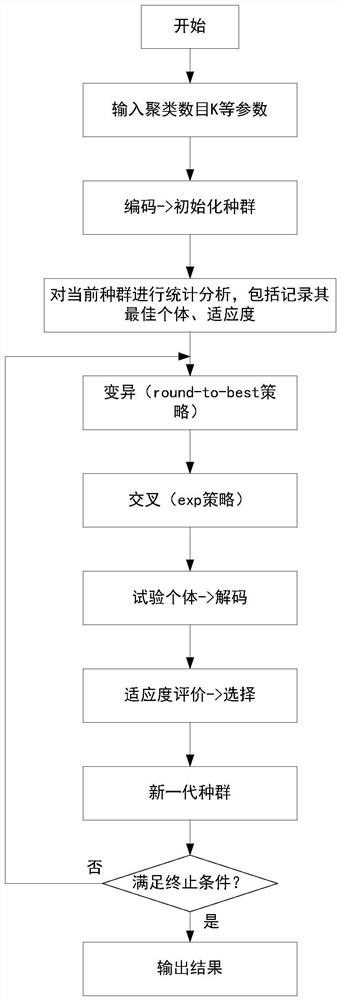

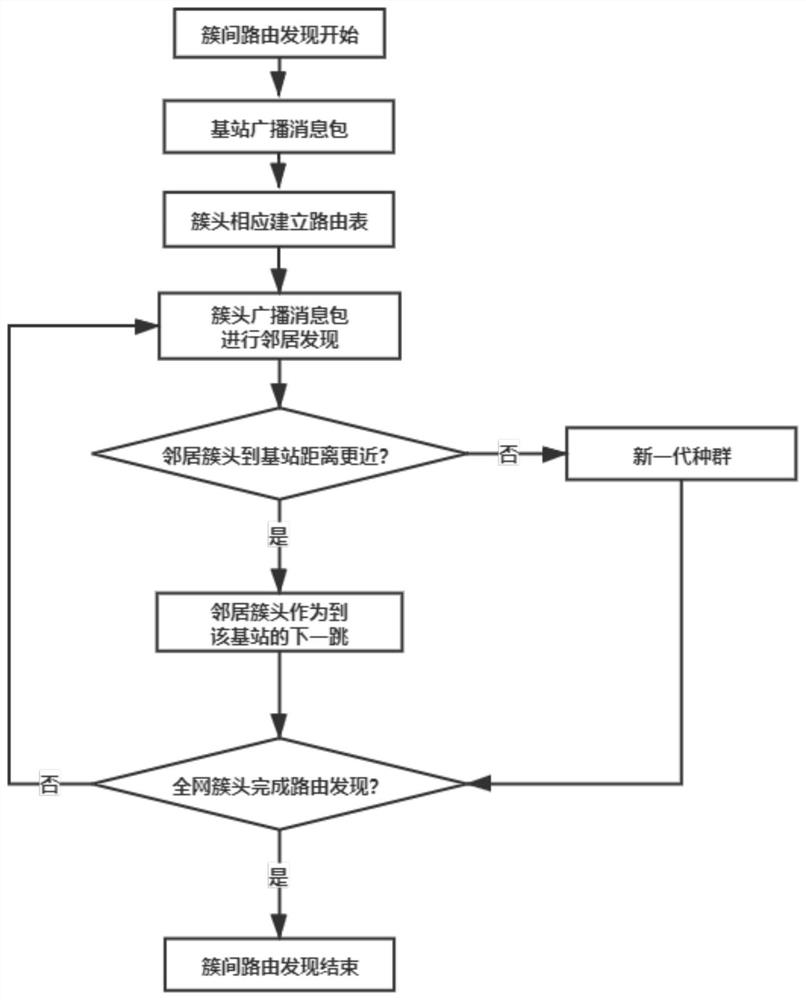

Hierarchical routing algorithm based on rechargeable multi-base-station wireless heterogeneous sensor network

ActiveCN112469100AExtend the life cycleReduce distancePower managementNetwork topologiesBalancing networkAlgorithm

The invention discloses a hierarchical routing algorithm based on a rechargeable multi-base-station wireless heterogeneous sensor network, which comprises the following steps of: deploying and optimizing the positions of base stations in a multi-base-station deploying stage; in the cluster establishment stage, adopting a dynamic clustering mode and selecting luster heads and automatically adjusting clustering by calculating thresholds according to information such as node residual energy and the distance between the node residual energy and a base station; in an inter-cluster route discovery stage, searching for an inter-cluster multi-hop route; in the inter-cluster routing selection stage, selecting an optimal routing path according to factors such as the minimum node residual energy of the path, the hop count from the node to the base station and the total energy consumption of the path; in a data acquisition and transmission stage, enabling a cluster head to transmit data to the base station through an optimal routing path, after a plurality of periods, enabling the whole network to rebuild clusters, carrying out inter-cluster routing discovery and inter-cluster routing selection and cyclically carrying out the steps in this way until the energy of the whole sensor network is exhausted. According to the invention, the network energy consumption can be better balanced, the network life cycle is prolonged, and the hot zone problem is effectively solved.

Owner:GUANGZHOU UNIVERSITY

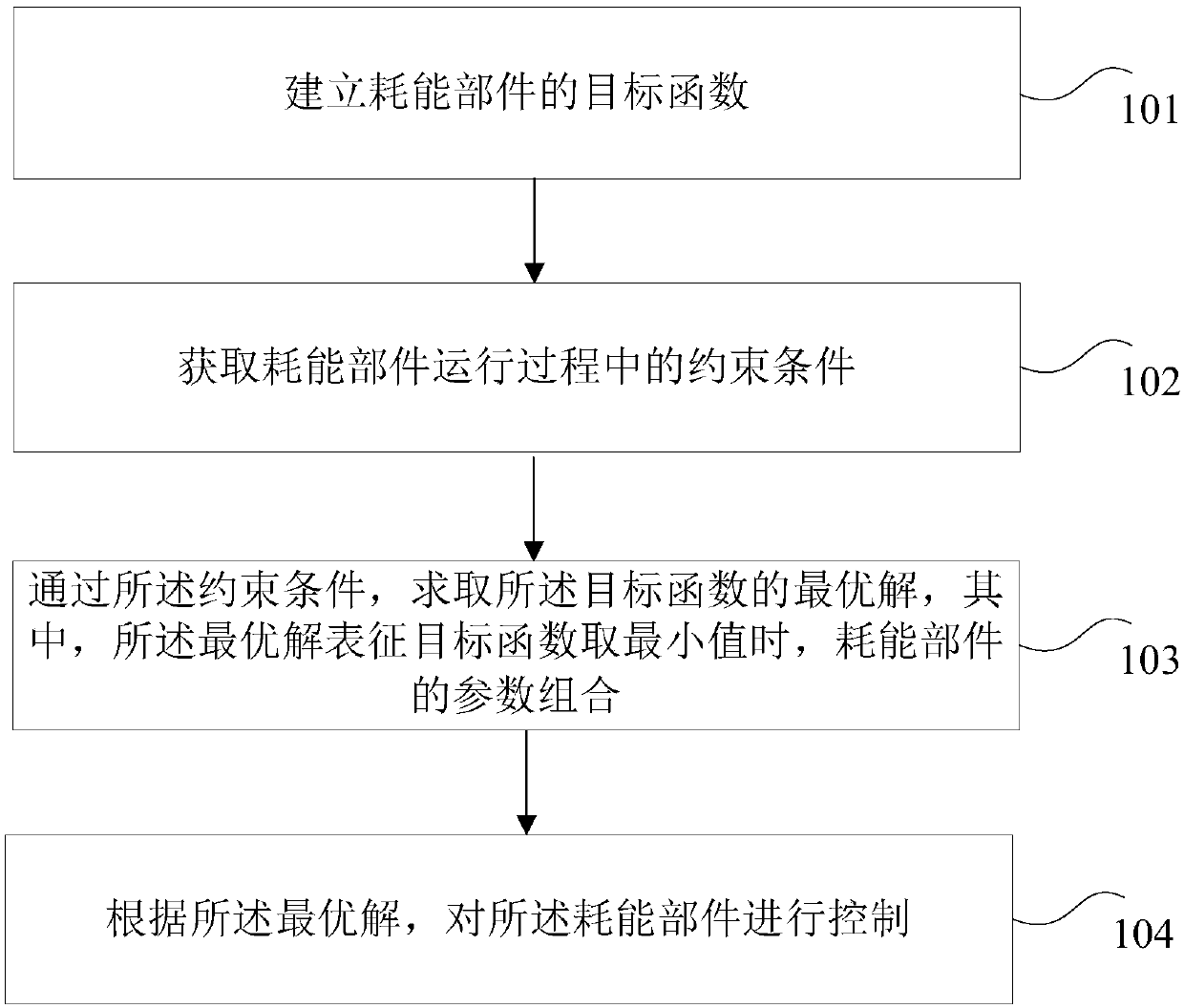

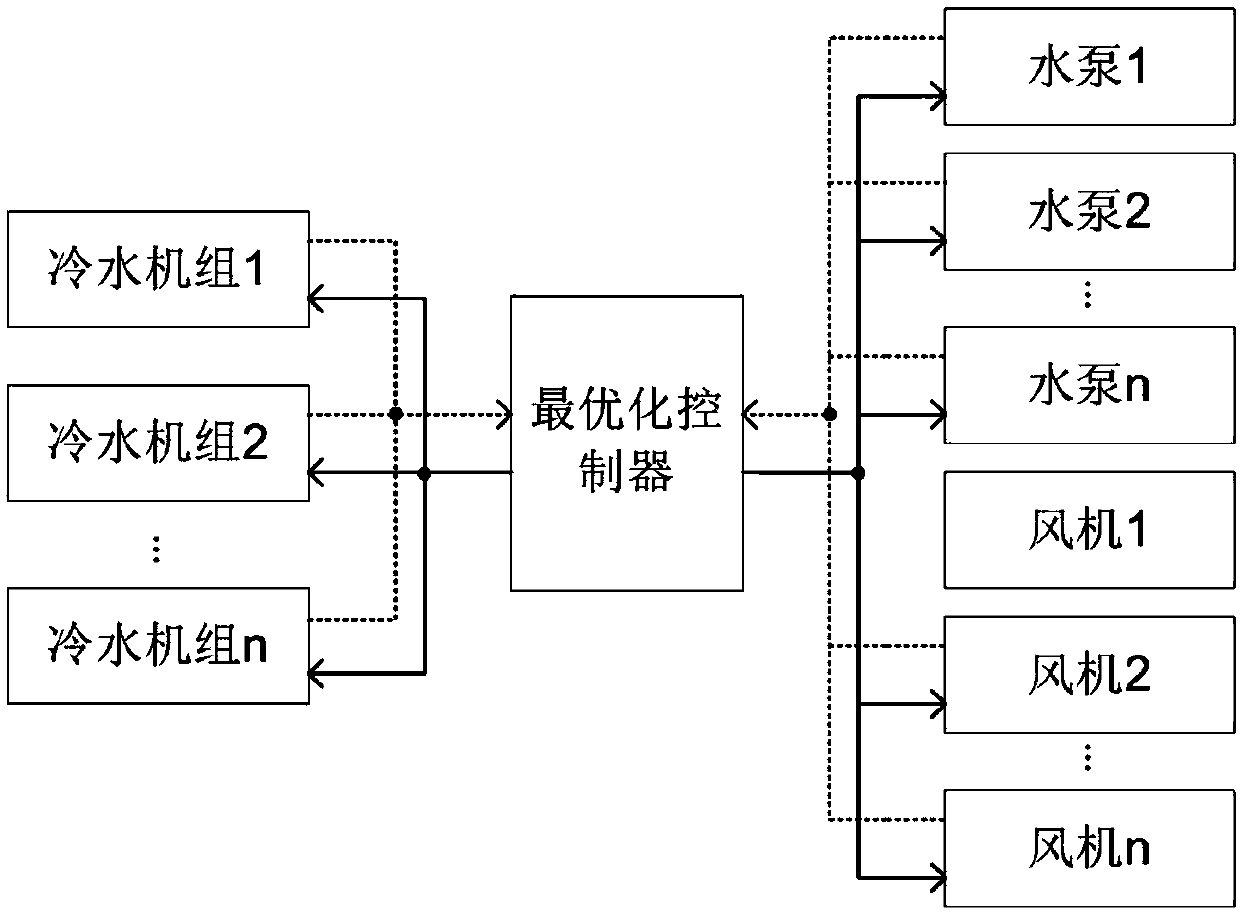

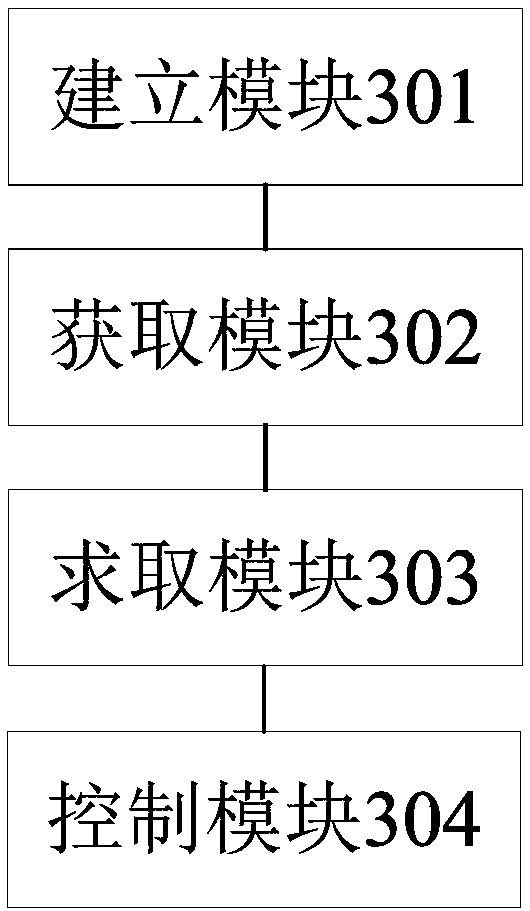

Energy efficiency control method and device

ActiveCN109556236AReduce wasteReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsEngineeringProcess engineering

The invention provides an energy efficiency control method and device. The energy efficiency control method comprises the steps: the objective function of energy consumption parts is built; the constraint conditions of the energy consumption parts in the operating process are obtained; through the constraint conditions, the optimal solution of the objective function is obtained, wherein the optimal solution represents the parameter combination of the energy consumption parts when the minimum value of the objective function is taken; and according to the optimal solution, the energy consumptionparts are controlled. Through the energy efficiency control method and device, the technical problems that energy consumption is too large, and resources are wasted are solved, and the technical effects that the energy efficiency is improved, and resource waste is reduced are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

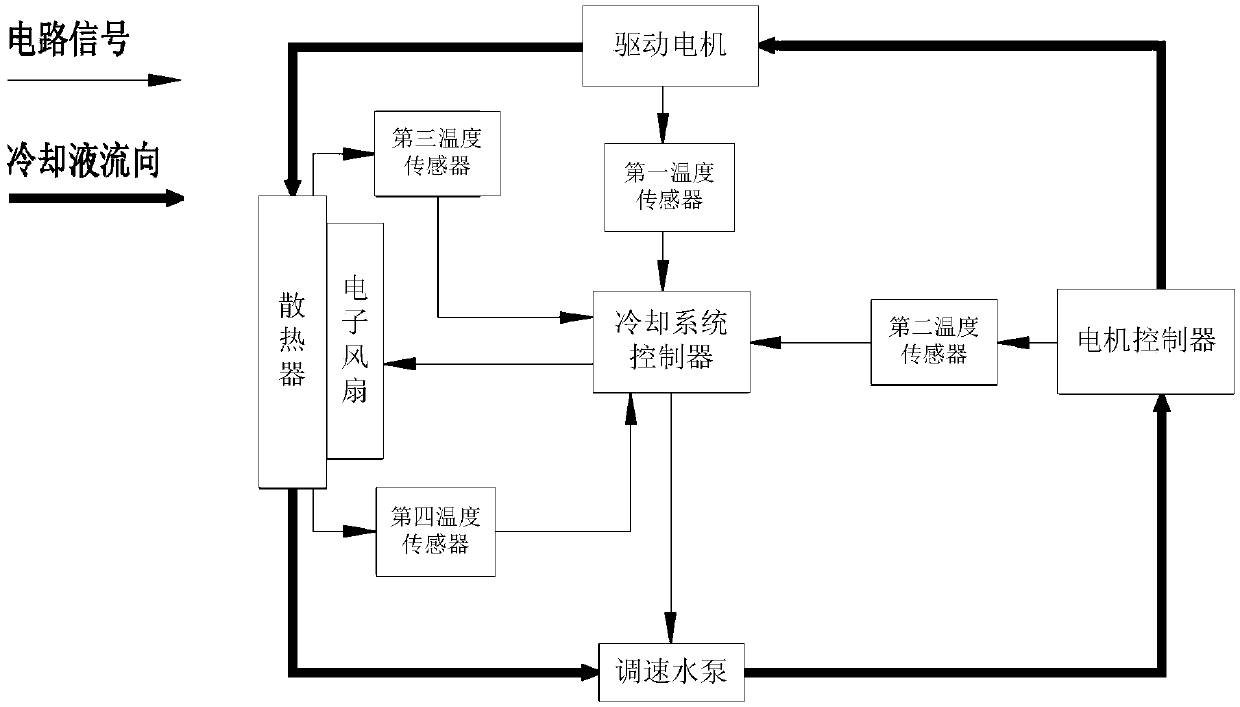

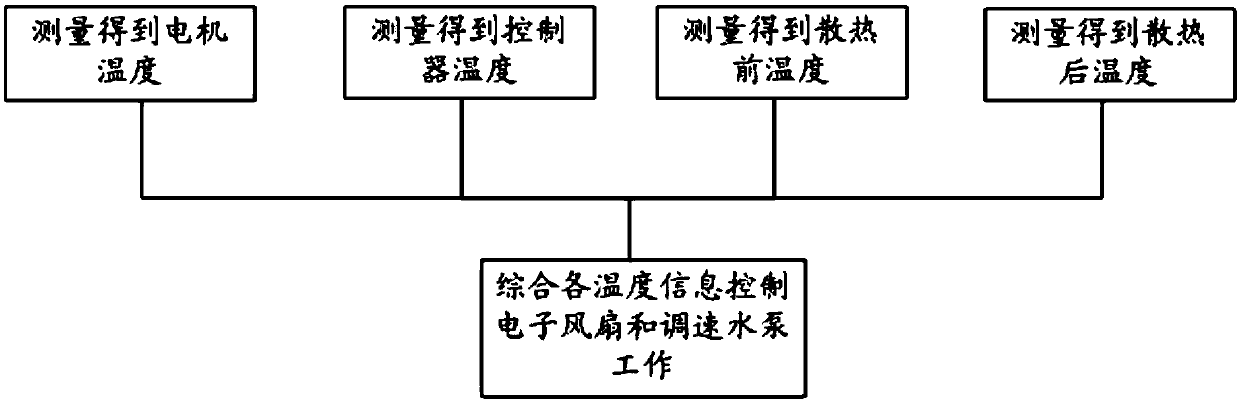

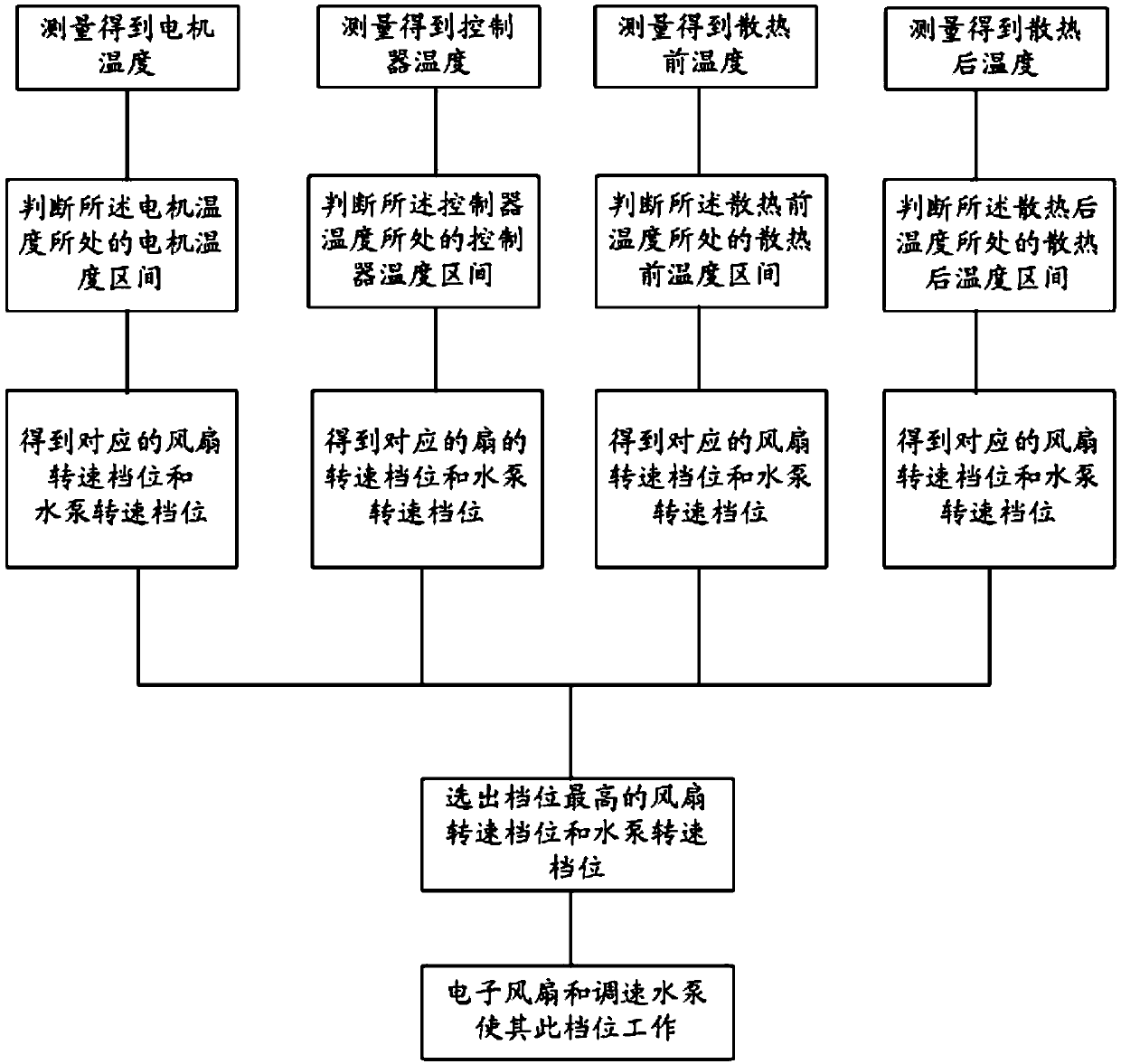

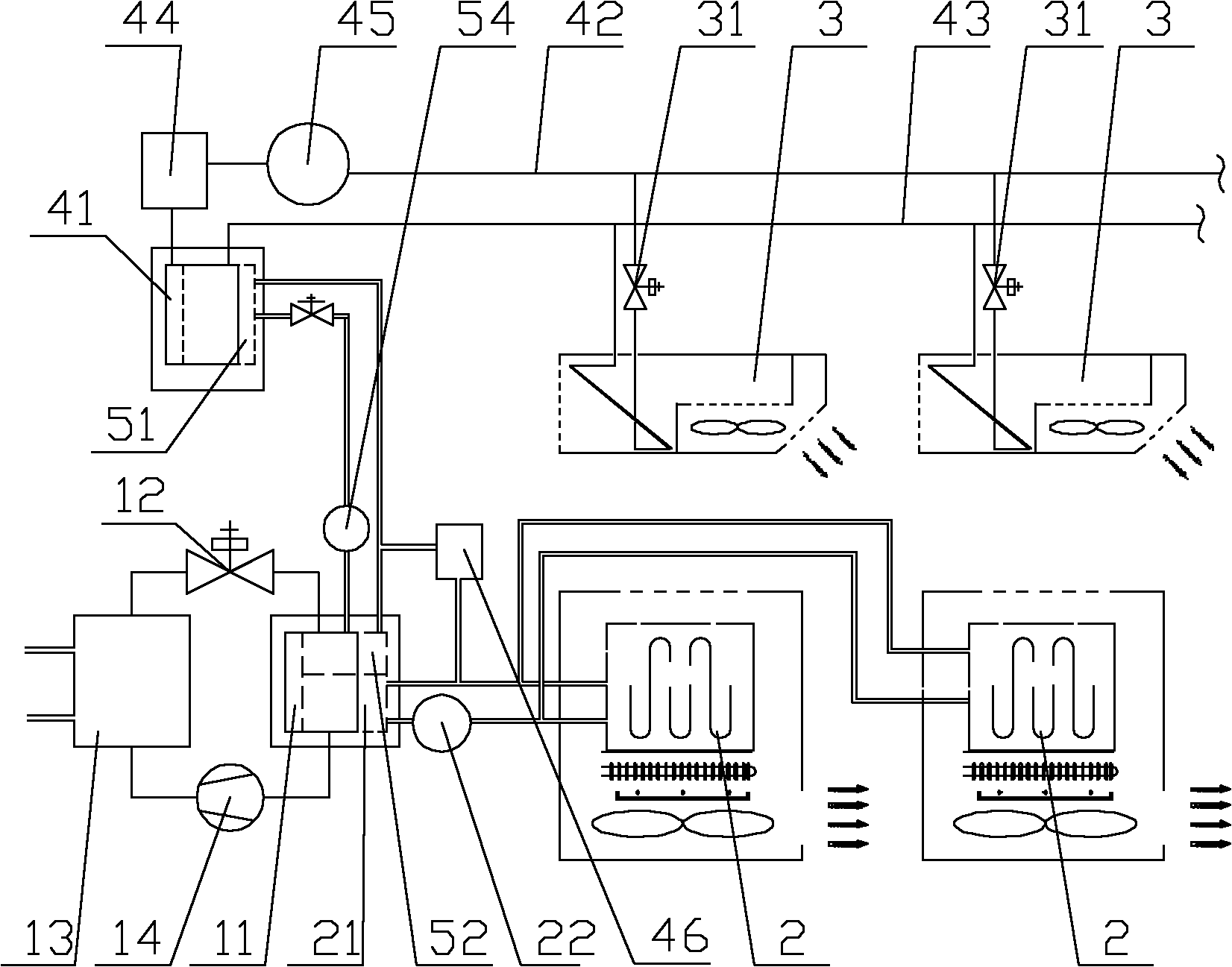

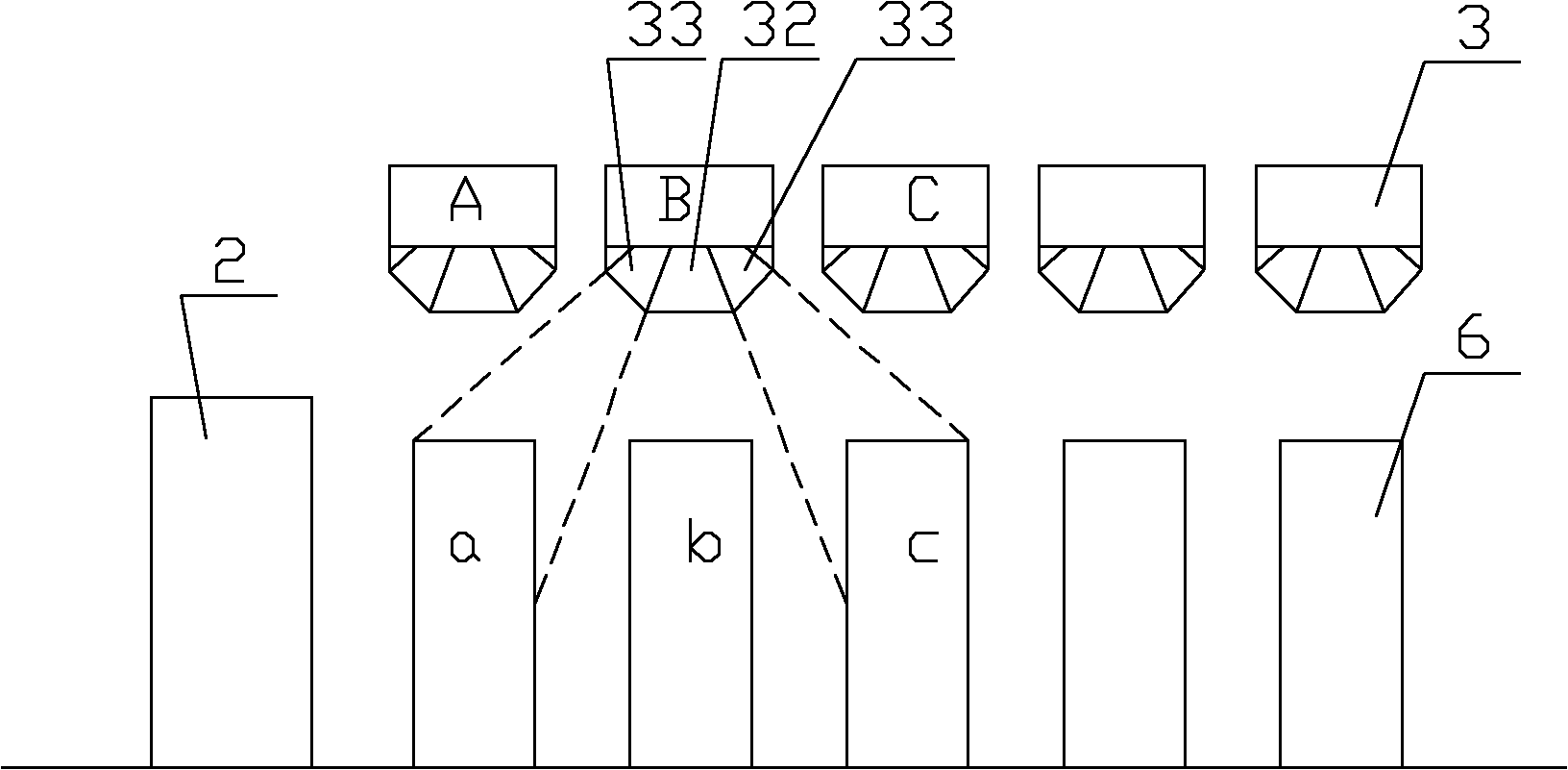

Cooling control system, cooling control method, cooling controller and electric automobile

InactiveCN109552021AImprove cooling efficiencyReduce energy consumptionElectric propulsion mountingPropulsion coolingElectric machineControl system

The invention discloses a cooling control system, a cooling control method, a cooling controller and an electric automobile. The cooling control system comprises a cooling pipeline, a heat radiator, an electronic fan, a first temperature sensor, a second temperature sensor, a third temperature sensor, a fourth temperature sensor and a cooling controller, wherein the cooling pipe is used for conveying a cooling fluid to pass through a speed regulating water pump, a motor controller, a driving motor and the heat radiator in sequence and enabling the cooling fluid to flow in circulation; the heatradiator is used for cooling the cooling fluid; the electronic fan is used for ventilation of the heat radiator; the first temperature sensor is used for measuring a temperature of the driving motor;the second temperature sensor is used for measuring a temperature of the motor controller; the third temperature sensor is used for measuring the temperature of the cooling fluid in an inlet of the heat radiator; the fourth temperature sensor is used for measuring the temperature of the cooling fluid in an outlet of the heat radiator; the cooling controller is independently arranged relative to avehicle control unit; an input end of the cooling controller is used for receiving temperature signals of the four temperature sensors; and an output end of the cooling controller is connected with the electronic fan and the speed regulating water pump. According to the cooling control system, the cooling control method, the cooling controller and the electric automobile, the cooling efficiency of the driving motor and the cooling efficiency of the motor controller can be enhanced, and the energy consumption is low.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

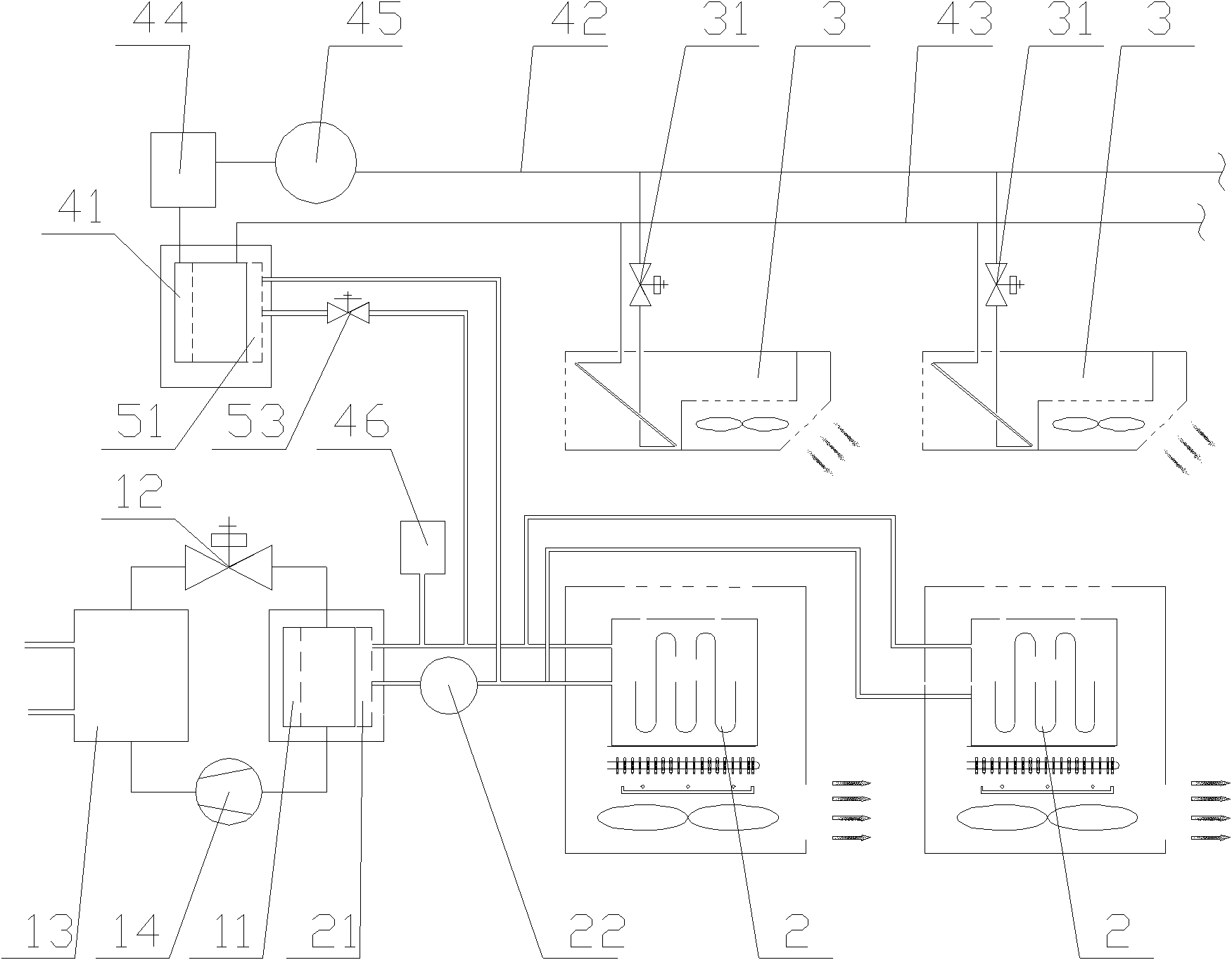

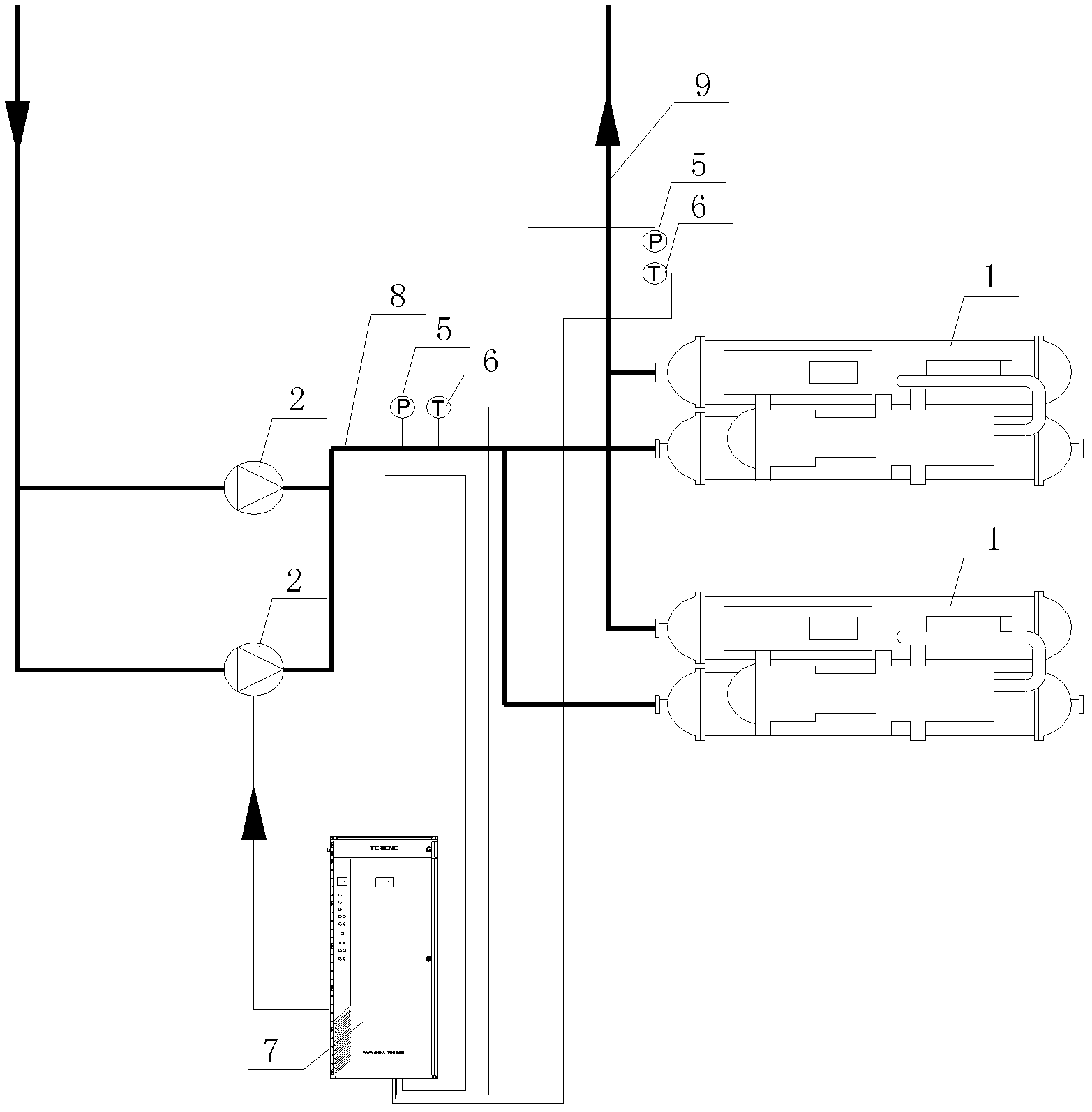

Improved structure of distributed air-conditioning system for data centre

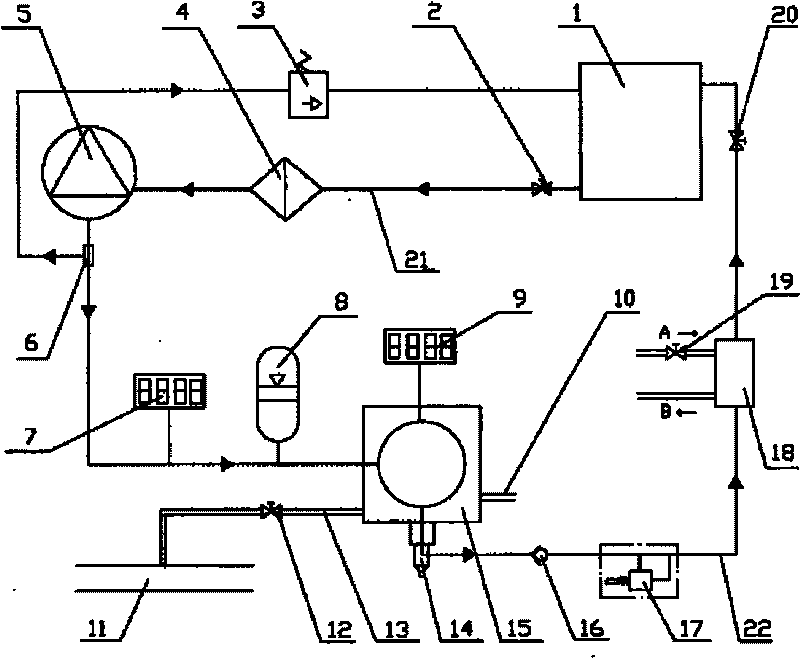

InactiveCN102128489ASolve excessive energy consumptionReduce cooling wasteSpace heating and ventilation detailsFluid circulation arrangementEvaporatorEngineering

The invention discloses an improved structure of a distributed air-conditioning system for a data centre, wherein the improved structure comprises a plurality of precise air-conditioning heat exchangers and a plurality of cabinet top air-conditioning evaporators; a chilled water condensing end 1 of each precise air-conditioning heat exchanger exchanges heat with a heat exchanging evaporator of anoutdoor refrigerating system; the improved structure further comprises a refrigerant circulation system; the plurality of cabinet top air-conditioning evaporators are connected in parallel in the refrigerant circulation system; an inlet end of each cabinet top air-conditioning evaporator is provided with a valve; a condensing end 2 of the refrigerant circulation system exchanges heat with an evaporating end of an intermediate heat exchanger; and a chilled water condensing end 3 of the intermediate heat exchanger exchanges heat with the heat exchanging evaporator of the outdoor refrigerating system. By means of the improved structure disclosed by the invention, problems of local overheating and overhigh energy consumption of cabinets in a machine room are solved better, and the distributedair-conditioning system is better optimized and has a simpler structure and reduced invested cost.

Owner:浙江榛果实业发展有限公司

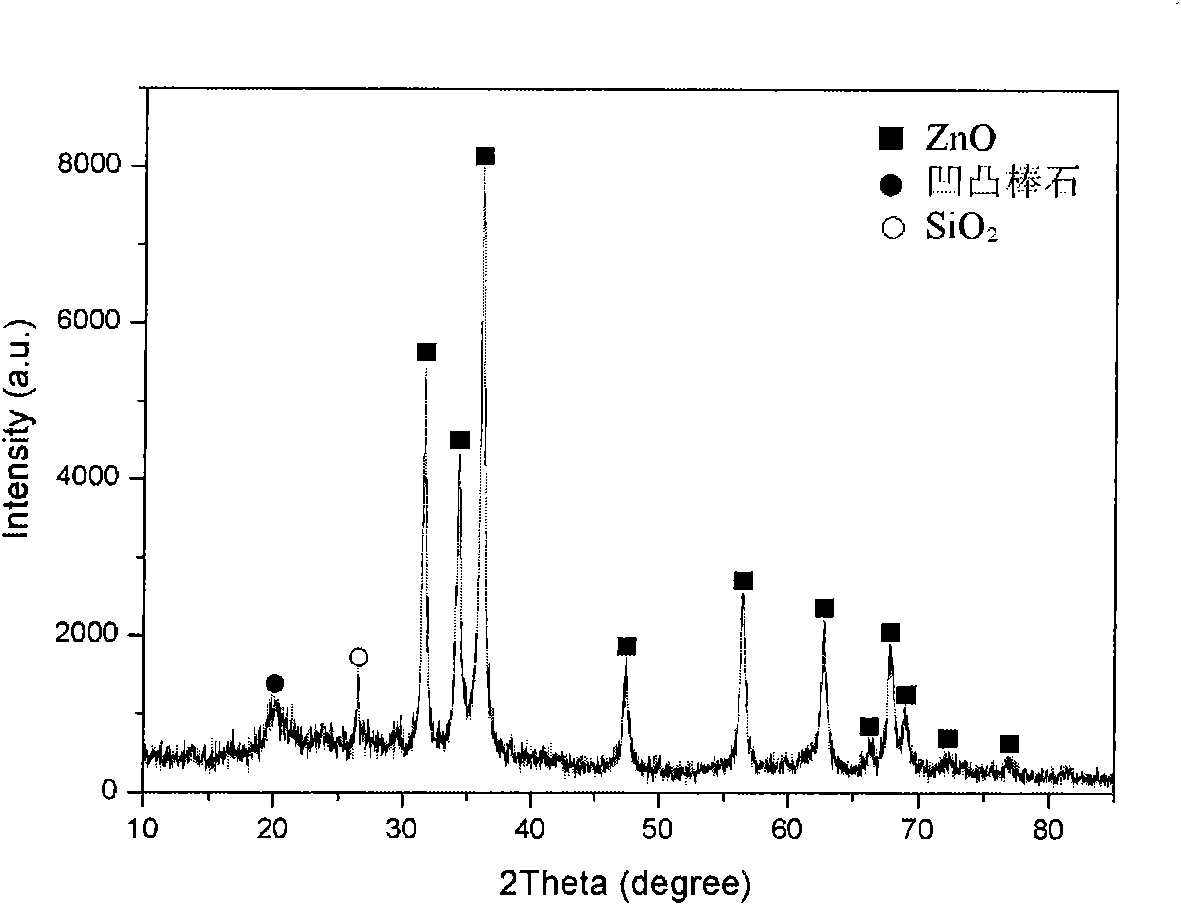

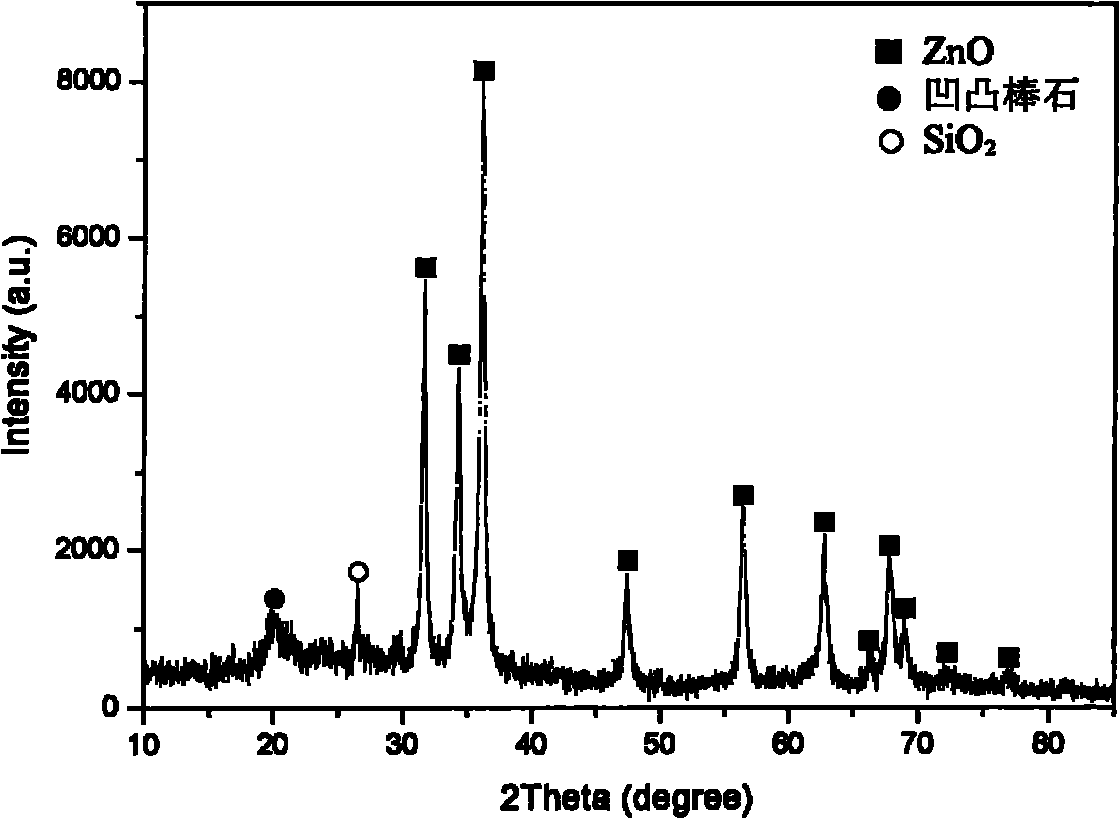

Method for preparing ZnO/attapulgite composite antibacterial agent

The invention discloses a method for preparing a ZnO / attapulgite composite antibacterial agent, comprising the following steps: dissolving water-soluble inorganic zinc salt in distilled water, adding attapulgite powder in the solution, stirring and dispersing for 15min by ultrasonic wave at the same time, and continuing stirring to obtain turbid liquid consisting of the attapulgite and the water-soluble inorganic zinc salt; and adding NaOH solution in the turbid liquid, stirring till fully mixing to obtain turbid liquid of zinc hydroxide and the attapulgite, filtering the turbid liquid, taking filter residue and drying, calcining, and naturally cooling to the room temperature to obtain the ZnO / attapulgite composite antibacterial agent. The invention has the advantages of simple preparation process, convenient operation and low cost, takes the attapulgite with larger specific surface area as a carrier to absorb a certain amount of ZnO, thus being capable of effectively improving the antibiosis property of ZnO; and the prepared material can be widely used in fields such as antibiotic plastics, antibiotic ceramics, cosmetics packaging materials and the like.

Owner:杨倩

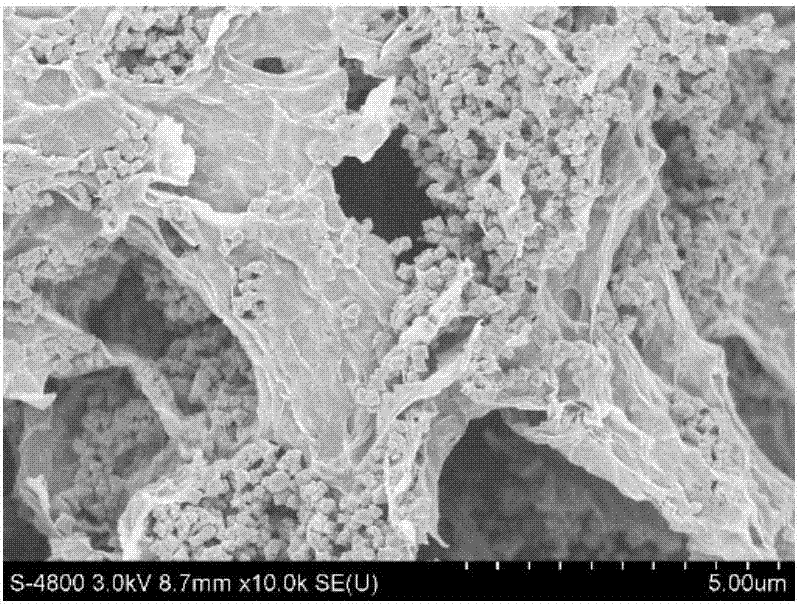

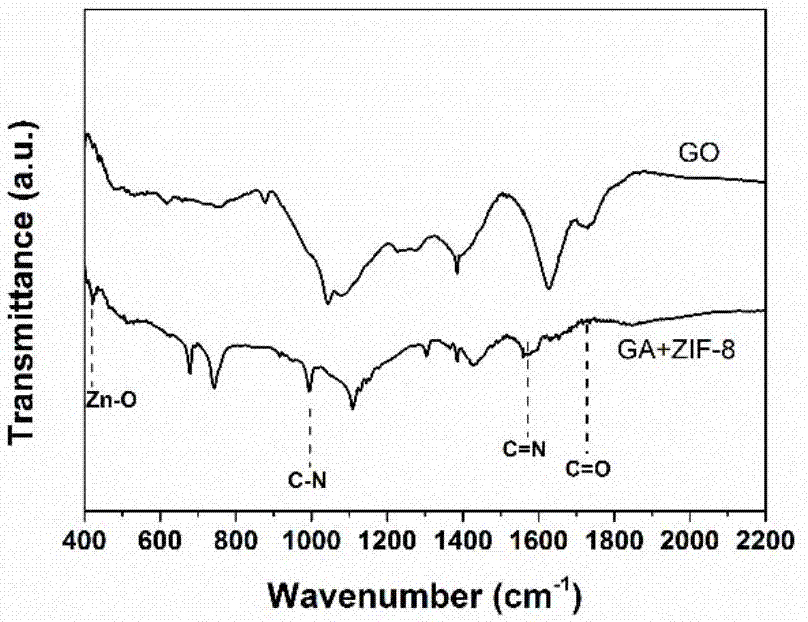

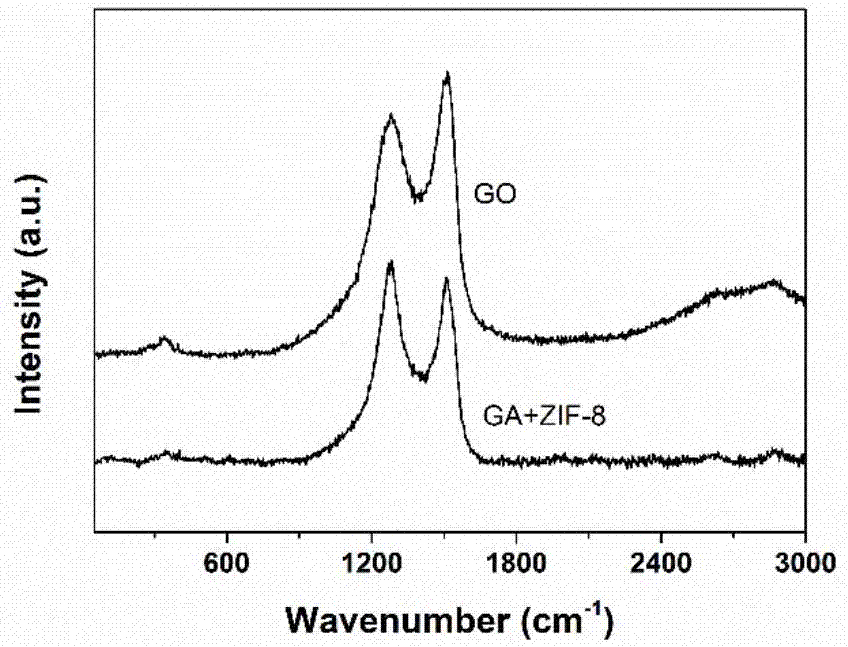

Rapid preparation method of graphene/nanoparticle aerogel

InactiveCN107381560AConducive to speed upIncreased ability to self-assembleCarbon compoundsAerogel preparationOxygenPolymer

The invention discloses a rapid preparation method of graphene / nanoparticle aerogel. The rapid preparation method comprises the steps that an aqueous solution of graphene oxide and a reducing agent are ultrasonically mixed to prepare a mixed solution; an organic metal frame / metallic oxide nanoparticle solution is added into the mixed solution I, ultrasonic mixing is carried out, and a mixed solution II is prepared; and the mixture II is dried to prepare hydrogel, and continues to be frozen and dried to prepare aerogel. An oxygen-containing group in oxidized graphene is removed through the reducing agent, and the formed aerogel has the properties of hydrophobicity, flame retardance and conductivity. Due to the fact that the organic metal frame such as 2-methylimidazole is of a porous polymer and hydrophobic and coarse structure, the aerogel has the properties of super-hydrophobicity and the high specific area; and aerogel can have magnetism through the metallic oxide such as ferroferric oxide.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

S460G2+QT steel plate for fixed offshore platform and production method of steel plate

The invention discloses an S460G2+QT steel plate for a fixed offshore platform and a production method of the steel plate. The production method comprises the following process steps: smelting, continuous casting, heating, rolling, cooling, quenching and tempering, wherein the continuous casting billet obtained in the continuous casting process comprises the following chemical components in percentage by mass: 0.08-0.10 percent of C, 0.20-0.50 percent of Si, 1.40-1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.15-0.20 percent of Cr, less than or equal to 0.25 percent of Mo, 0.30-0.35 percent of Ni, 0.020-0.045 percent of Al, less than or equal to 0.10 percent of Cu, less than or equal to 0.008 percent of N, 0.035-0.040 percent of Nb, less than or equal to 0.025 percent of Ti, 0.040-0.050 percent of V and the balance of Fe and inevitable residual elements and impurities. According to the method, low-cost chemical components and a quenching and tempering process with low energy and time consumption are adopted, so that the S460G2+QT steel plate with the advantages of high strength, high toughness, fatigue resistance, lamination crack resistance and excellent weldability is produced.

Owner:WUYANG IRON & STEEL

Propolis flavonoid extracting method

InactiveCN102935091ABitter tasteAstringent Active IngredientsAnthropod material medical ingredientsAntineoplastic agentsRotary evaporatorPropolis

The invention provides a propolis flavonoid extracting method which is characterized by including steps of (1), mixing propolis with ethanol solution, soaking at the temperature of 70-85 DEG C for 16-24 hours; (2), refluxing and extracting the solution to obtain leaching liquid; (3) concentrating the leaching liquid to recover ethanol; (4) cooling and centrifuging condensed liquid without ethanol; and (5), extracting supernatant obtained by centrifuging twice by chloroform to obtain water phase, extracting the water phase twice by ehyl acetate, evaporating off the ehyl acetate from the ehyl acetate extract through a rotary evaporator so as to obtain flavonoid compounds. By the method, flavonoid effective components are complete, damage to active components is reduced, ethanol can be recovered easily, the process is simple, and time and energy consumption is low; further, the method is quite suitable for industrial production; and the prepared high-purity propolis flavonoid has high application value in medical healthcare, and has unique special function in cancer resistance.

Owner:广西蜜博士蜂业有限责任公司

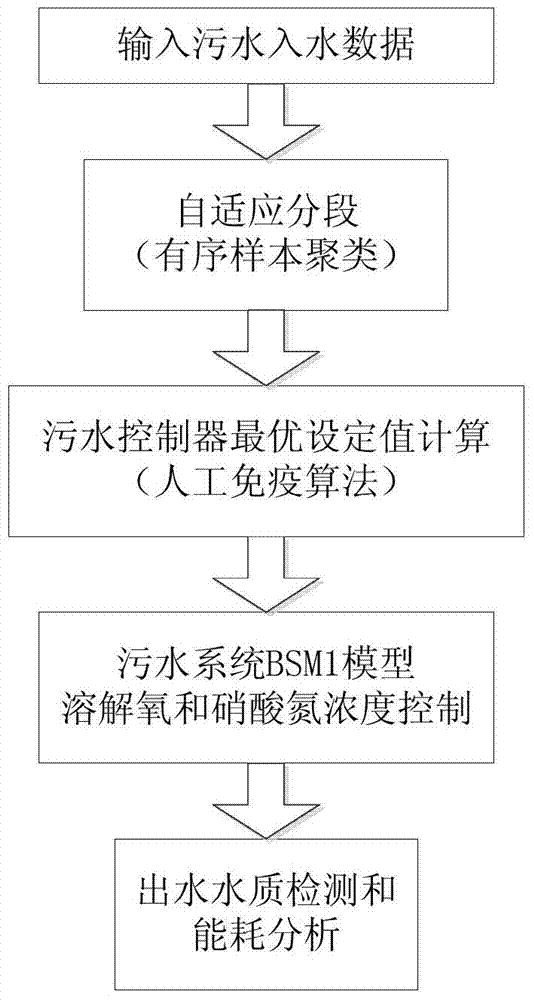

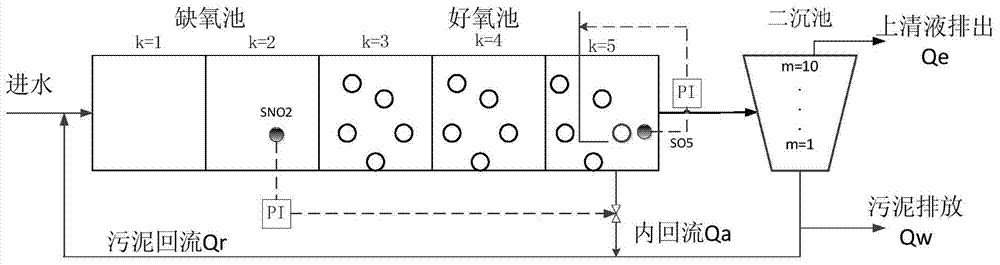

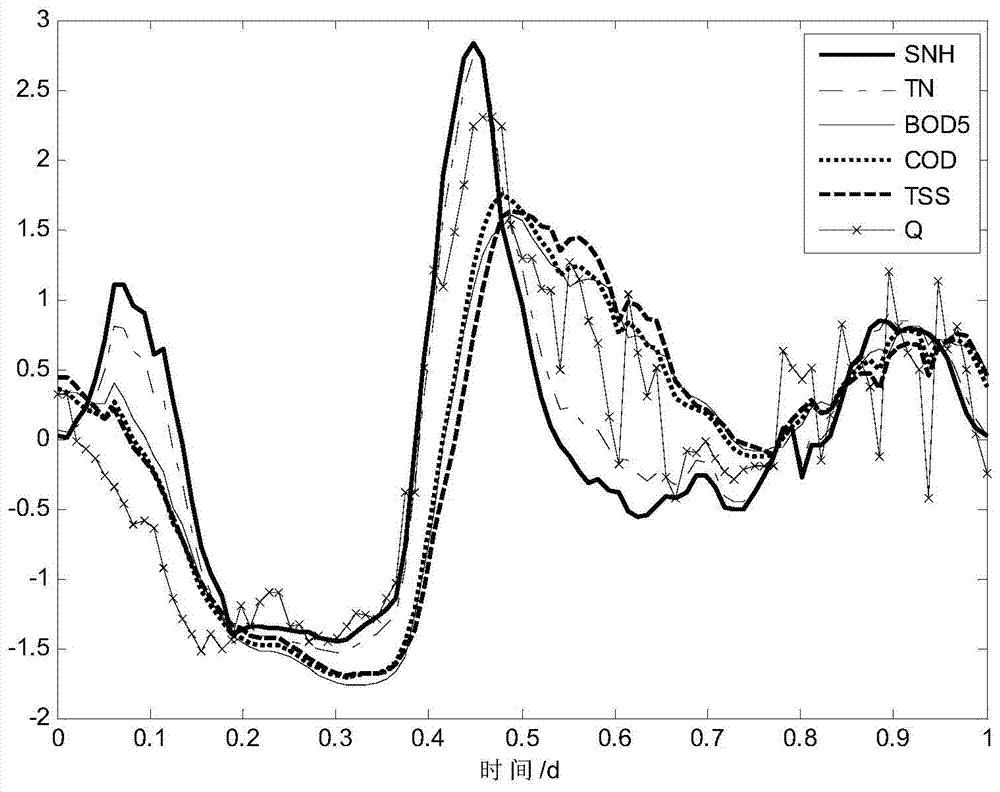

Sewage treatment control method based on sequential clusters

ActiveCN103792844AGuaranteed energy savingRealize energy saving and consumption reductionAdaptive controlOxygen deficiencyOxygen transfer coefficient

The invention discloses a sewage treatment control method based on sequential clusters. The method includes the steps that control time periods are divided for changing conditions of sewage inlet quality and amount in a self-adaptive mode by the adoption of the sequential sample clusters; water outlet quality, aeration energy consumption and pumping energy consumption are considered comprehensively, the optimal set values of the concentration of dissolved oxygen in an aerobiotic pool and the concentration of nitrate nitrogen in an oxygen deficiency pool at each period are determined by the adoption of an artificial immune algorithm with a global searching ability, and the oxygen transfer coefficient and inner reflux quantity are adjusted in real time for a sewage system at different periods. According to the sewage treatment control method, operation energy consumption for sewage treatment is reduced on the premise of ensuring the water outlet quality.

Owner:SOUTH CHINA UNIV OF TECH

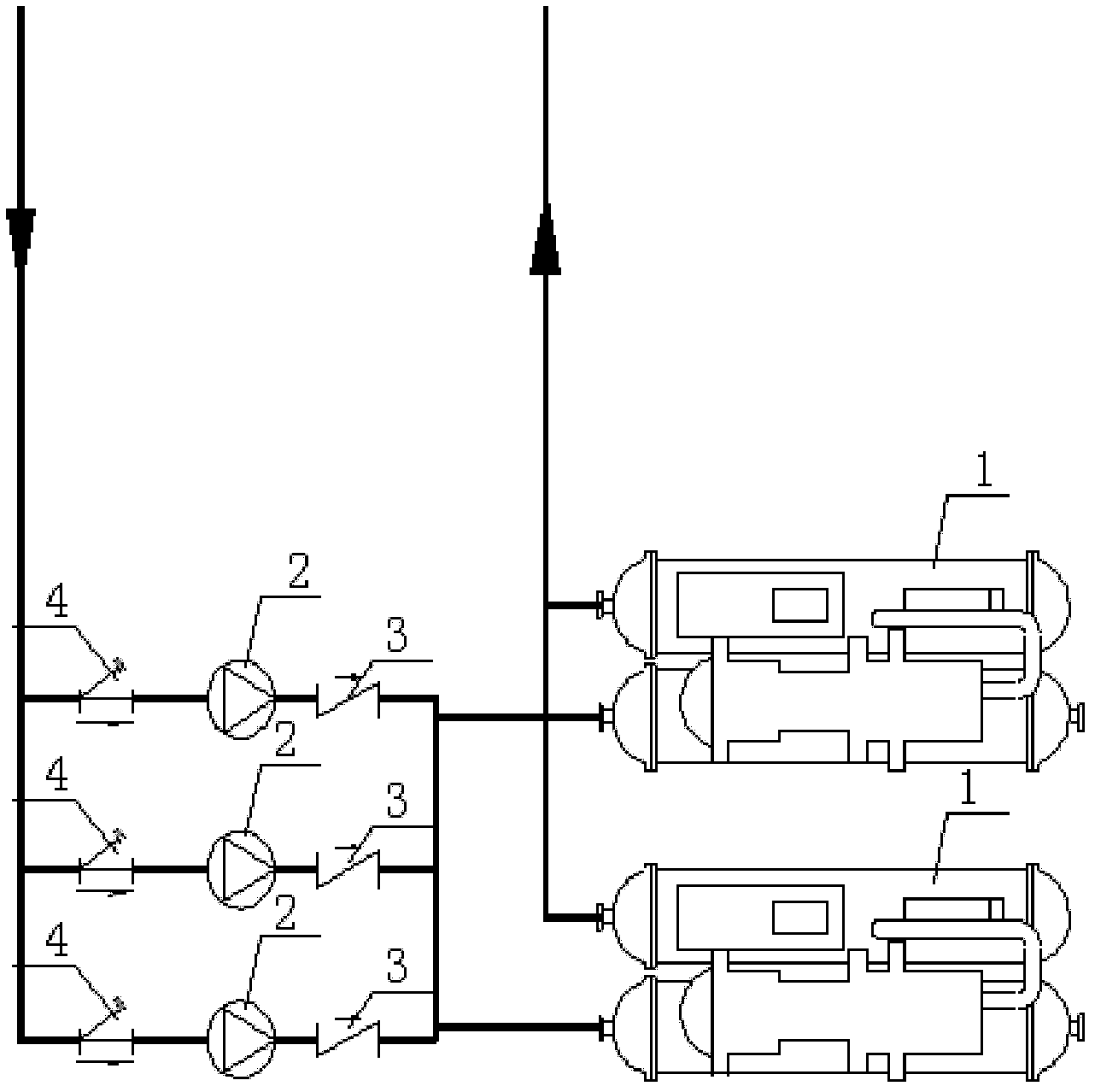

Matching system for pump head flow of central air-conditioning water system and resistance flow of air-conditioning pipeline system

InactiveCN103032937ASolve excessive energy consumptionSolve problems that don't matchSpace heating and ventilation safety systemsLighting and heating apparatusThermodynamicsControl signal

The invention relates to a matching system for a pump head flow of a central air-conditioning water system and a resistance flow of an air-conditioning pipeline system. The matching system comprises at least one water pump, a plurality of water-cooling air-conditioning host machines, two pressure detectors and a controller, wherein the water pumps are in parallel connection; water outlets of the water pumps are connected with corresponding water inlets of the water-cooling air-conditioning host machines through a water inlet header pipe; the two pressure detectors are respectively mounted on the water inlet header pipe and water outlet header pipe of the water-cooling air-conditioning host machines; signal output ends of pressure difference detectors are connected with a pressure detecting signal input end of the controller; and a control signal output end of the controller is connected with control signal input ends of the water pumps and is used for controlling the rotating speeds of the water pumps. The matching system provided by the invention utilizes an inlet and outlet water pressure difference and a frequency converter to control the rotating speeds of the water pumps so as to control the pump head flow; the problem of oversize head at local flowing moment of the water pumps is solved; the rotating speeds of the water pumps are adjusted by the controller according to the requirement; and the problem of ultrahigh energy consumption of the water pumps is effectively solved.

Owner:WUXI YONGXIN ENERGY TECH

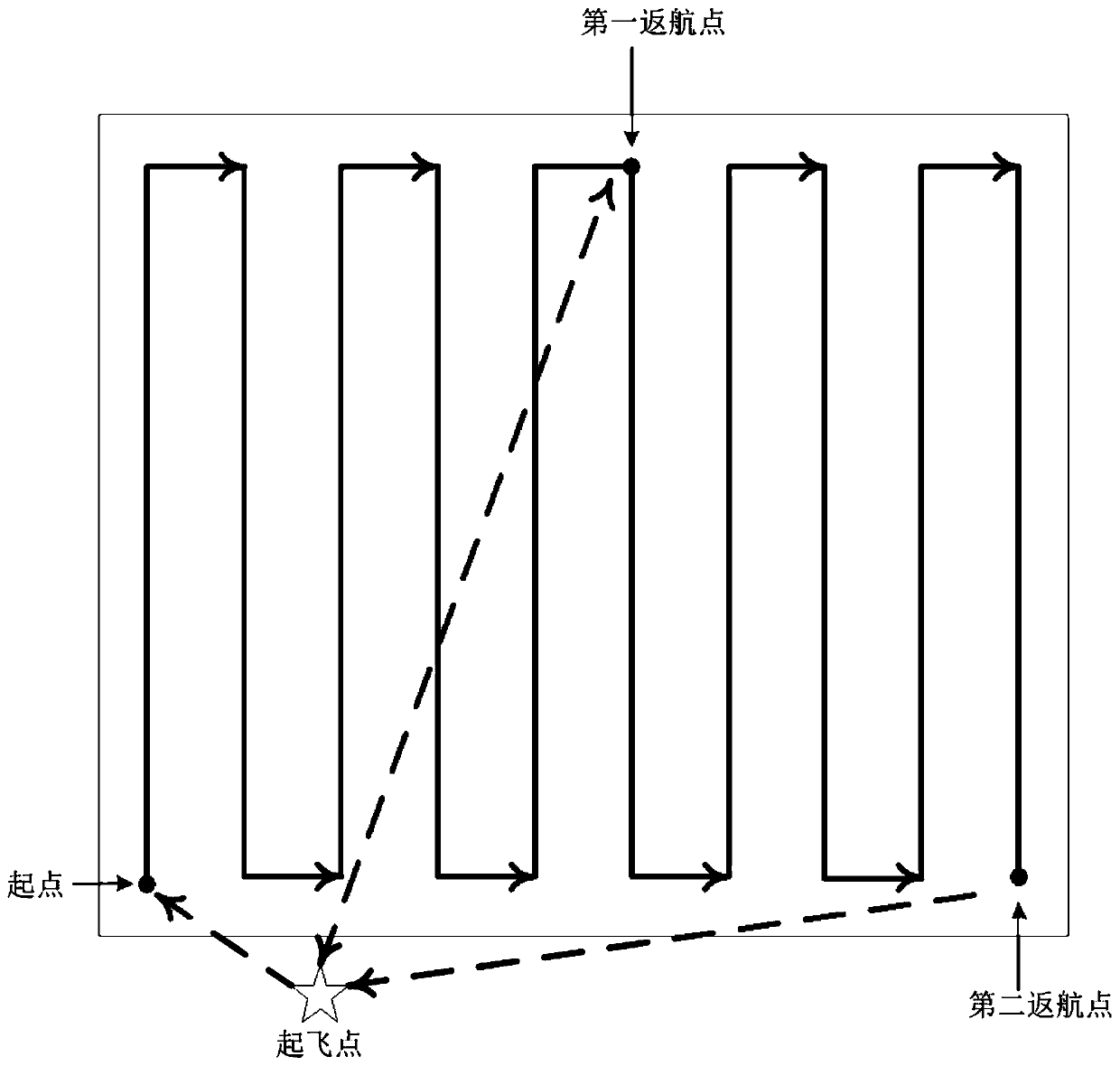

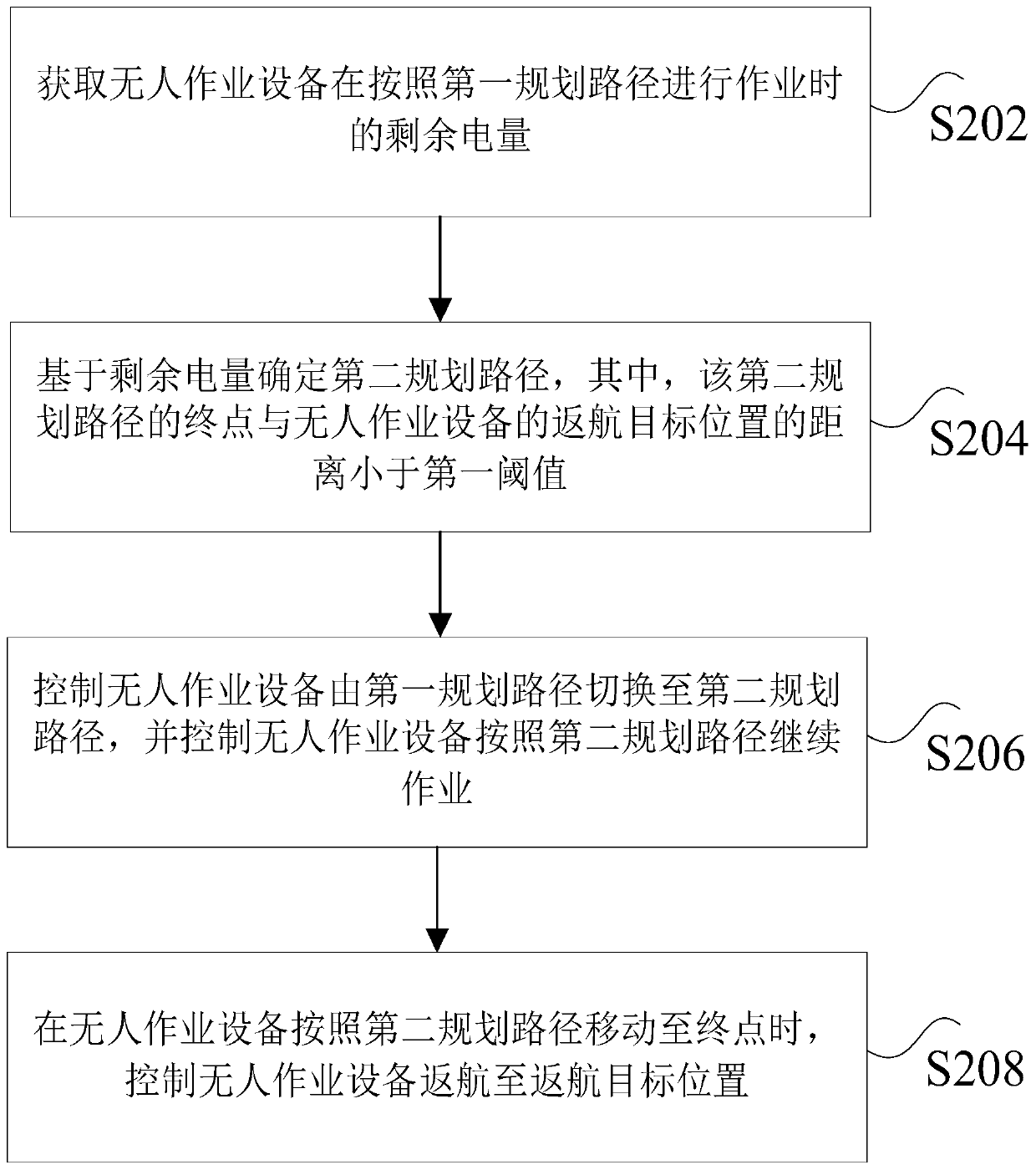

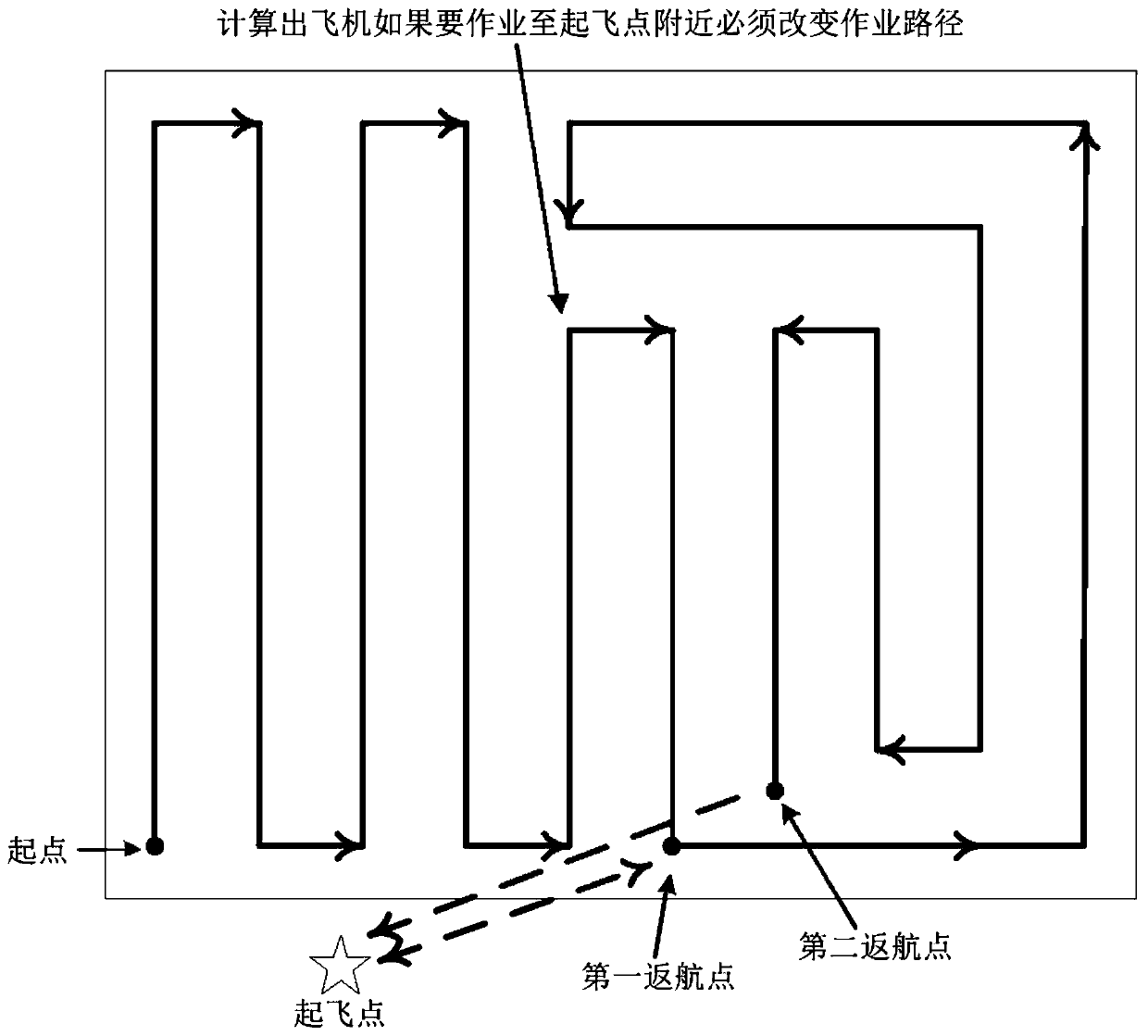

Return voyage control method, device and equipment of unmanned operation device, and non-volatile storage medium

ActiveCN111324144AEffective use of the return pathSolve excessive energy consumptionPosition/course control in three dimensionsTerminal pointElectrical and Electronics engineering

The invention discloses a return voyage control method, device and equipment of unmanned operation device and a non-volatile storage medium. The method comprises the following steps: acquiring the residual electric quantity of the unmanned operation device during operation according to a first planned path; determining a second planned path based on the remaining electric quantity, and the distance between the terminal point of the second planned path and the return target position of the unmanned operation device being smaller than a first threshold value; controlling the unmanned operation device to switch from the first planned path to the second planned path, and controlling the unmanned operation device to continue to operate according to the second planned path; and when the unmannedoperation device moves to the terminal point according to the second planned path, controlling the unmanned operation device to return to the return target position. According to the invention, the technical problems of excessive energy consumption and low operation efficiency caused by a relatively long back-and-forth invalid operation path of the operation device are solved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

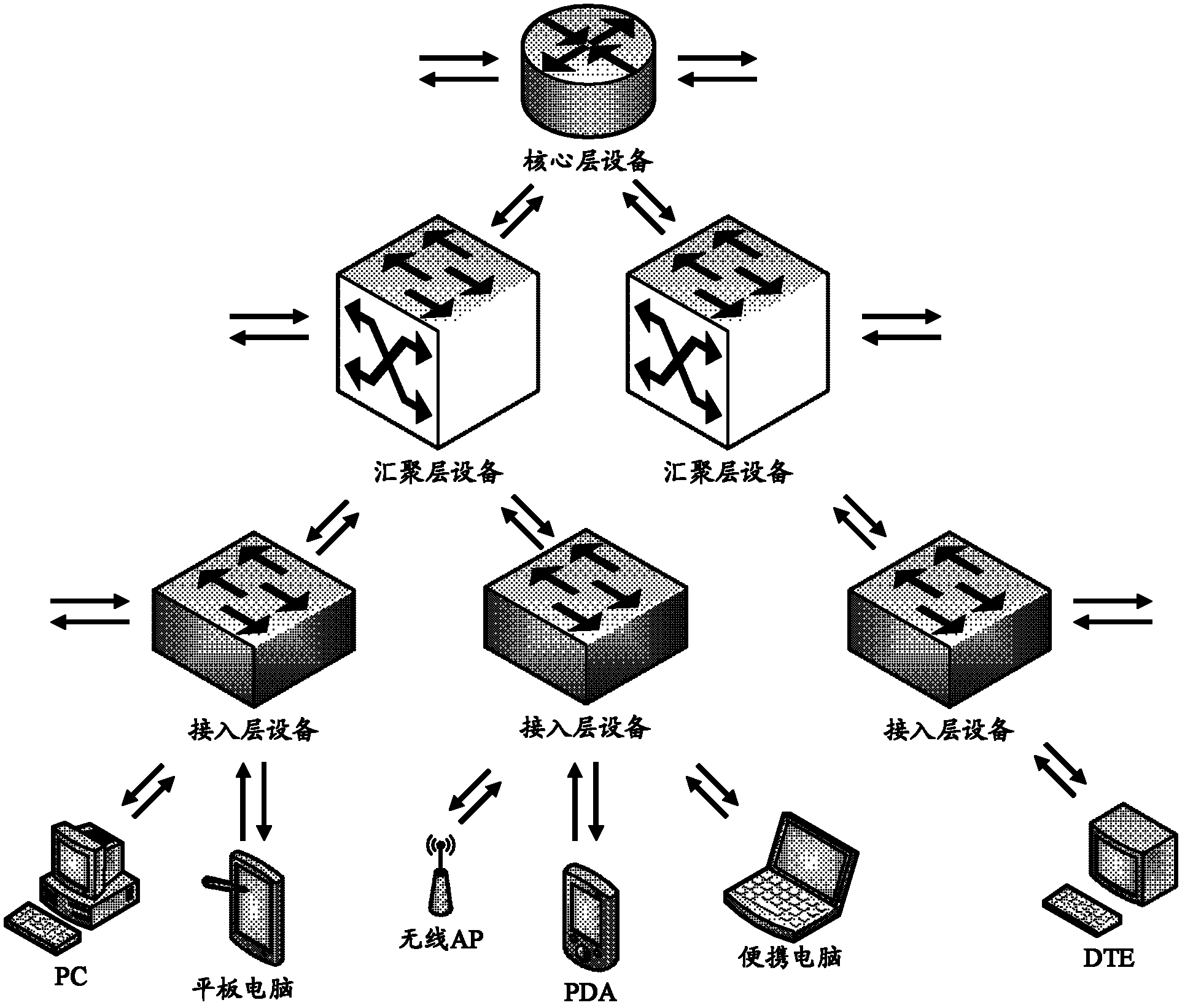

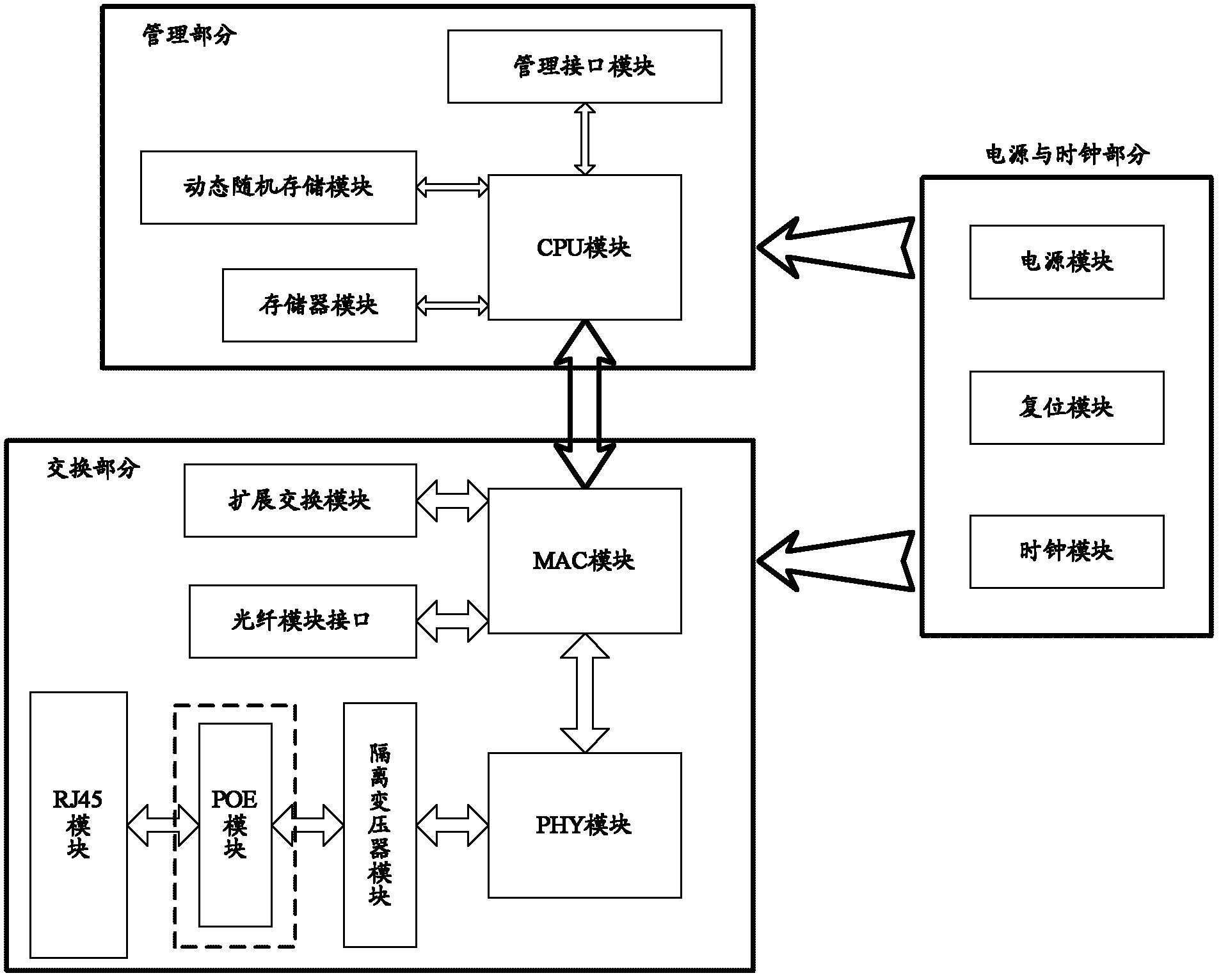

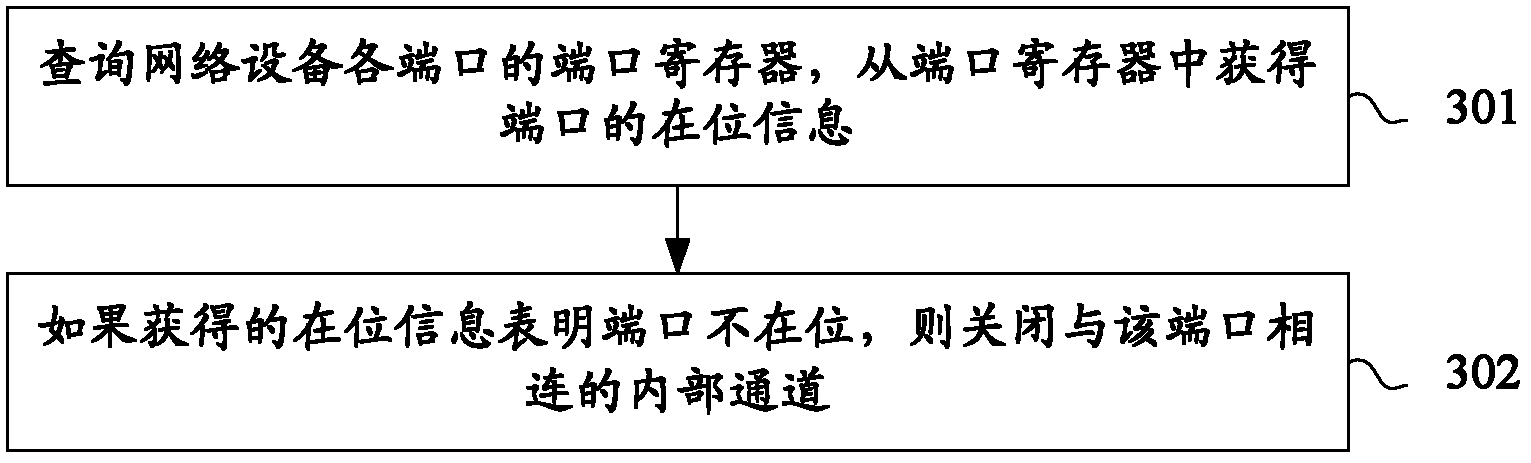

Energy saving method of network equipment, apparatus thereof and equipment

ActiveCN102571367ASolve excessive energy consumptionEffective energy savingEnergy efficient ICTSubstation remote connection/disconnectionProcessor registerResource consumption

The invention provides an energy saving method of network equipment, an apparatus thereof and equipment. The method comprises the following steps: inquiring a port register of each port of the network equipment and acquiring on-position information of the port from the port register; and if the obtained on-position information shows that the port is not on a position, closing an internal channel connected with the port. The apparatus comprises an inquiry module used for inquiring the port register of each port of the network equipment and acquiring the on-position information of the port from the port register, and a closure module used for closing the internal channel with the port if the obtained on-position information shows that the port is not on the position. The network equipment comprises the above apparatus. Terminal equipment comprises an on-position characteristic circuit. When the terminal equipment is connected with the port of the network equipment, the on-position characteristic circuit and an on-position detection circuit of the network equipment form a closed loop. According to a scheme provided by the invention, on the basis of reducing software resource consumption, energy saving of the network equipment is realized simply and conveniently.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

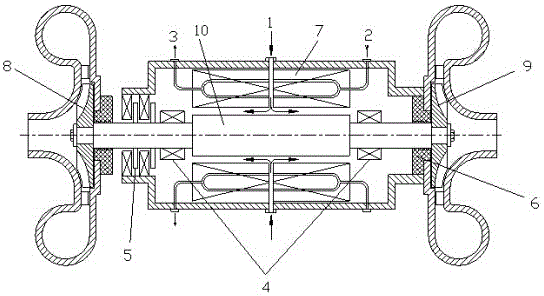

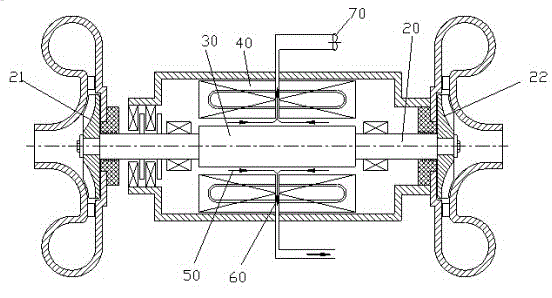

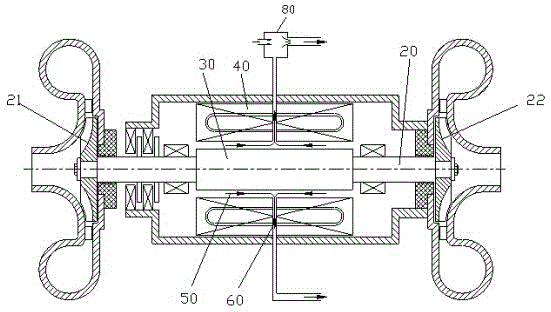

A centrifugal compressor or air blower for high speed motor

InactiveCN104806542AReduce friction lossSolve excessive energy consumptionPump componentsPump installationsEngineeringAir blower

The circumferential speed of a traditional centrifugal compressor or an air blower for a high speed motor is high, frictional loss between the surface of a rotor and air is high, so as to cause the rotor to generate heat, and the rotor is always cooled by a large amount of compressed air. By such a way, the consumption rate is high, and the overall efficiency of equipment is reduced. The invention discloses a centrifugal compressor or an air blower for the high speed motor, the surface of the rotor is positioned under a negative pressure environment, so as to use a negative pressure air cooling method to cool instead of cooling by the comprised air, and the efficiency is improved by reducing the frictional loss. Equipment such as vacuum pump or an air ejector is needed for making the negative pressure environment. The main aim of the centrifugal compressor or the air blower for the high speed motor is to reduce the loss caused by the traditional method that cooling air is used for cooling the rotor.

Owner:SHANGHAI UNITED COMPRESSOR

Agricultural seed sieving and drying treatment equipment

InactiveCN109290184AUniform drying treatmentPlay the role of buffer resetSievingSeed and root treatmentAgricultural engineeringSlide plate

The invention discloses agricultural seed sieving and drying treatment equipment and belongs to the field of agricultural tools. The problem that a seed drying device is high in energy consumption, and seeds are dried unevenly are solved. The agricultural seed sieving and drying treatment equipment comprises a drying box, a hot air releasing cavity, a sieving net and a vertical guide rail. Horizontal sliding grooves are formed below the drying box, the four corners of the lower surface of the drying box are all provided with welding sliding plates in a welded manner, and the sliding plates areconnected with the horizontal sliding grooves in a sliding manner. Vertical stand columns are vertically welded on the right sides of the horizontal sliding grooves. The upper ends of the vertical stand columns are provided with horizontal supporting rods in a welded manner. The hot air releasing cavity is formed on the lower part of the right side of the drying box. The drying box is internallyprovided with the sieving net. A drive device is arranged on the upper part of the right side of the drying box. According to the agricultural seed sieving and drying treatment equipment, large granular impurities can be sieved out, meanwhile, uniform heating of the seeds can be achieved, the problem that the existing seed drying device is too high in energy consumption is solved, and the agricultural seed sieving and drying treatment equipment is capable of saving energy, environmentally friendly and suitable for being applied to agricultural seed processing processes.

Owner:马骏

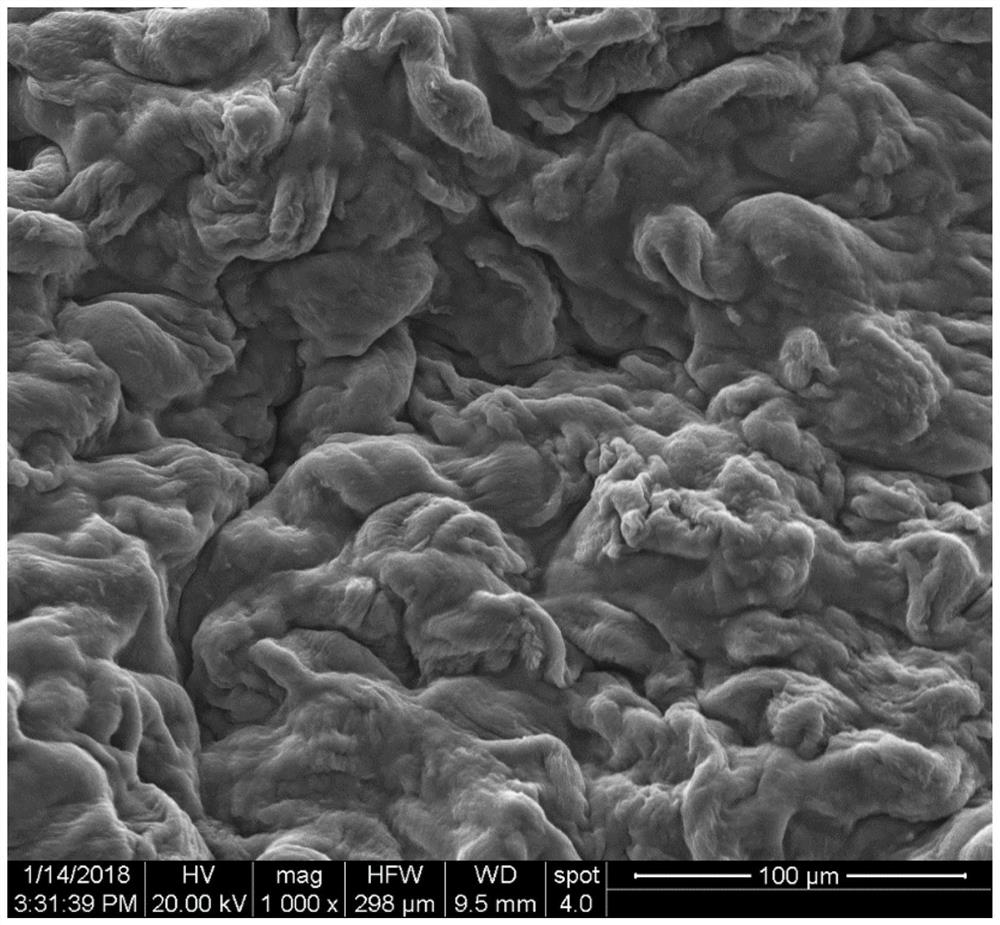

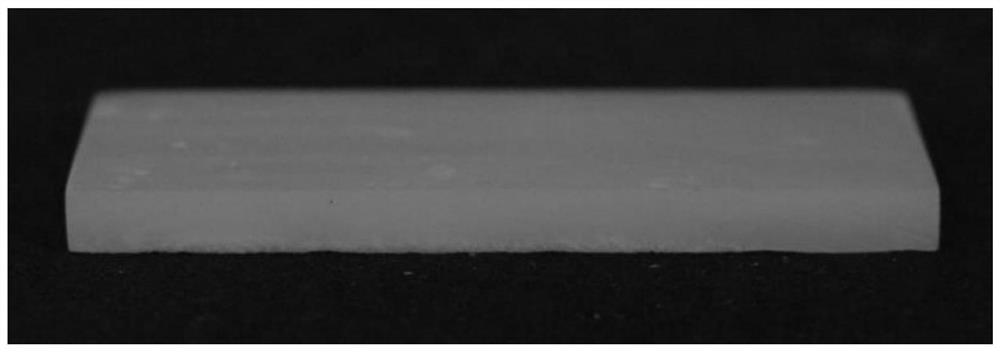

Plant plastic and preparation method thereof

ActiveCN112778578AWith mechanical propertiesRetain performanceFibre treatment to obtain bast fibreCellulosePolymer science

The invention discloses a plant plastic and a preparation method thereof. The plastic is only composed of micron-sized plant fibers, and the plant fibers are bent, deformed and tightly wound to form a compact microstructure. The appearance property of the plant plastic is similar to that of common plastic, the plant plastic is optically semitransparent, hard in texture and high in strength, and the density (about 1.2-1.6 g / cm<3>) of the plant plastic is close to the theoretical density (about 1.6g / cm<3>) of cellulose; the component is natural cellulose, is free of thermoplasticity and can be completely biodegraded. The preparation method comprises the following steps of: treating the surfaces of the plant fibers with a chemical solution; then performing treatment with acid or an aqueous solution; and finally, conducting cleaning with water to remove chemical residues in the sample, and conducting drying to obtain the plant plastic. The plant plastic prepared by the invention is a brand new material, and the preparation method has the characteristics of wide raw material source, low cost, simple preparation steps and the like, and has a wide application range.

Owner:NANJING UNIV

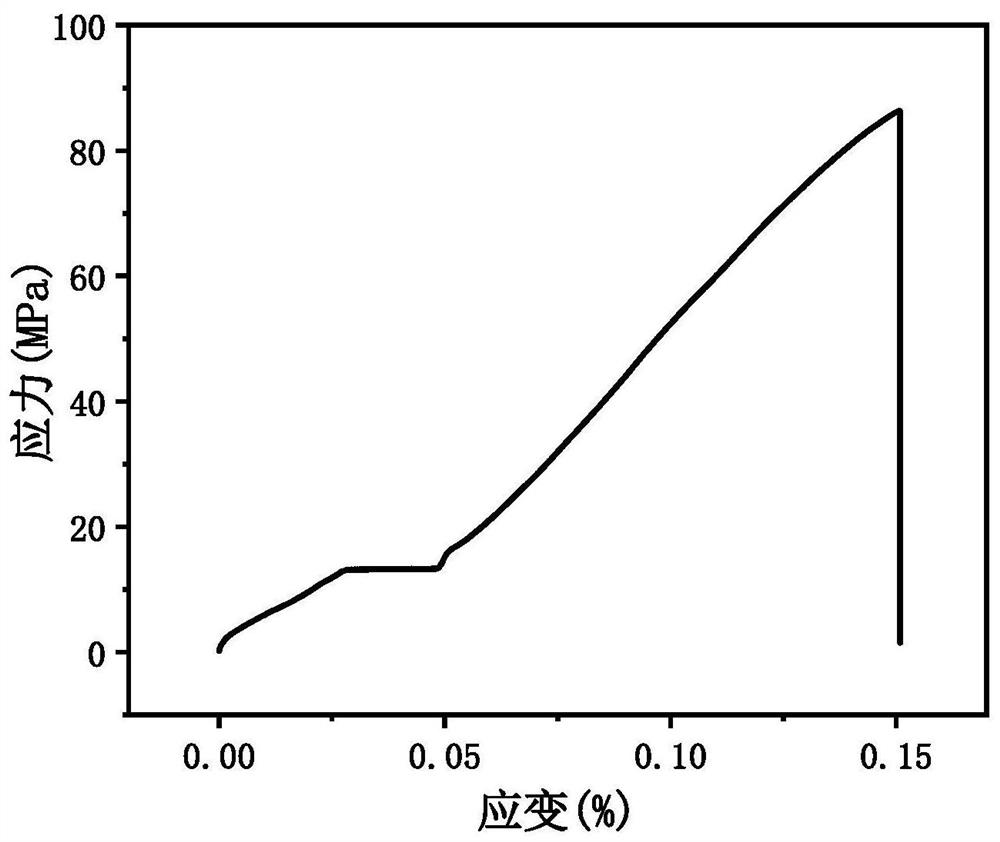

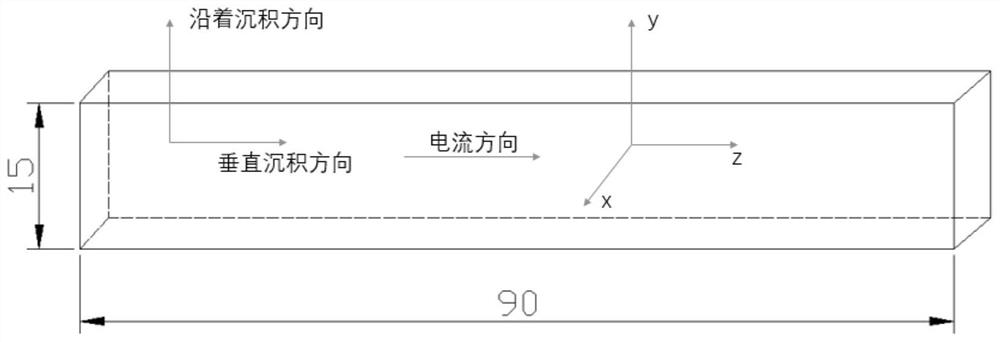

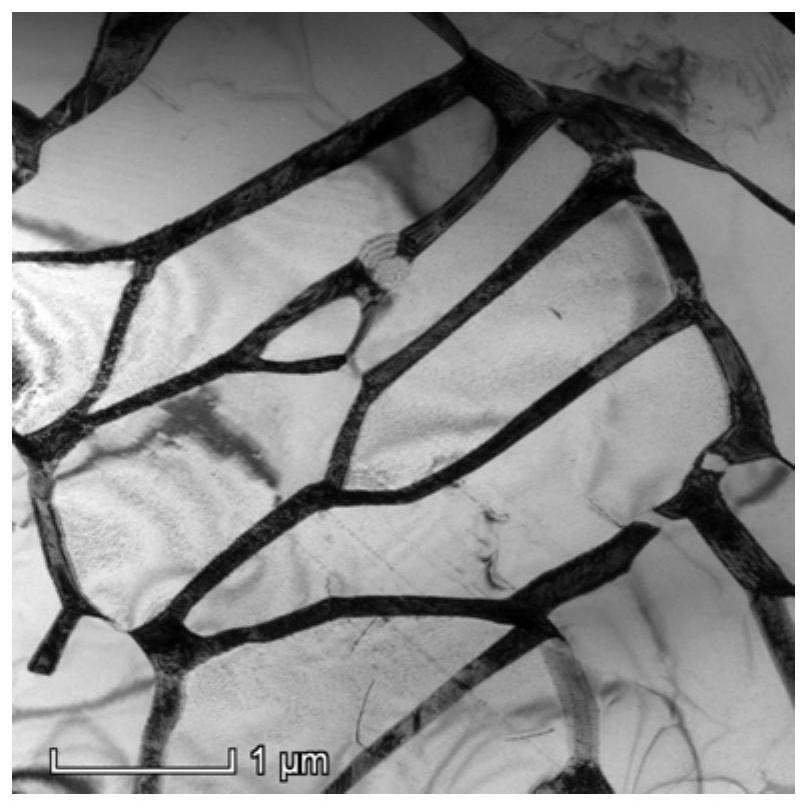

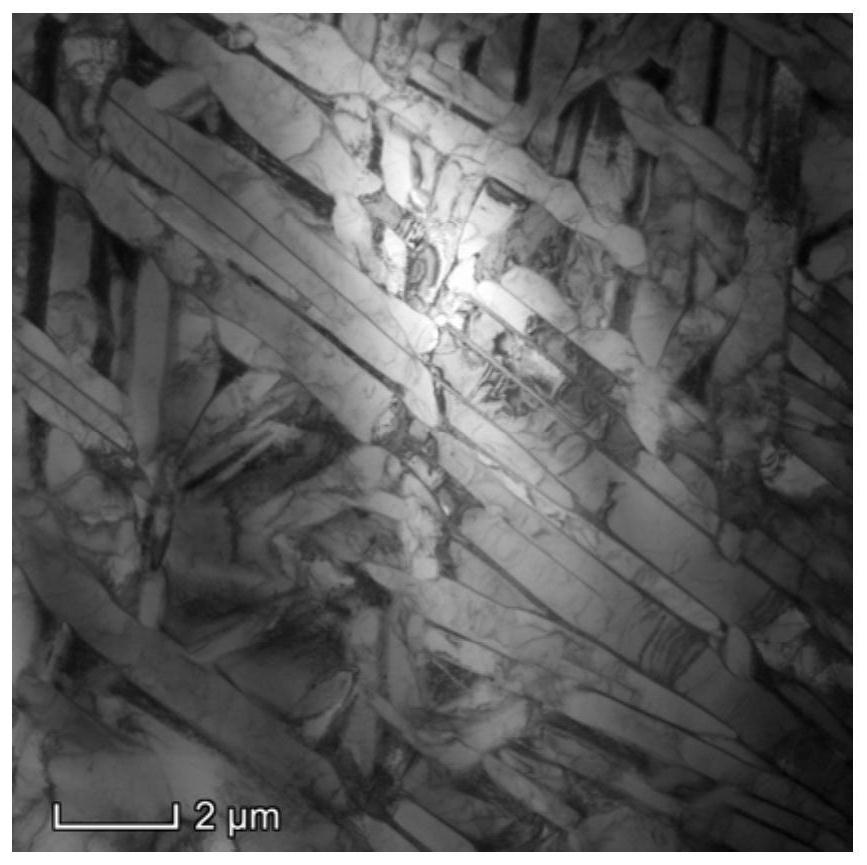

Method for improving anisotropy of additive manufacturing titanium alloy through pulse current

ActiveCN113249668AIncreased anisotropyEliminate anisotropyAdditive manufacturing apparatusIncreasing energy efficiencyHigh energySS - Stainless steel

The invention provides a method for improving anisotropy of an additive manufacturing titanium alloy through pulse current, and solves the problems of high energy consumption, high time consumption, difficulty in popularization and poor effect on large components in an existing post-treatment technology. The method comprises the following steps: (1) the surface of the additive manufacturing alloy component is cleaned; (2) the alloy is fixed through a clamp and then connected to the two ends of a pulse power source, and the clamp and the workpiece keep complete contact; (3) the clamped component is horizontally placed on a specific device, and is kept horizontal; (4) the voltage, the frequency and the action time are adjusted, and the additive manufacturing titanium alloy is treated through pulse current; and (5) the pulse power source is turned off, and the component is taken down after being cooled to the room temperature. The method has the advantages of being simple in process, rapid in implementation, capable of easily achieving batch production, capable of being applied to large workpiece treatment, wide in application range and the like, and can be applied to additive manufacturing of the titanium alloy, stainless steel, an aluminum alloy, a high-temperature alloy and the like and corresponding components.

Owner:HARBIN ENG UNIV

Making method of novel puffed pet snack food

InactiveCN104982653AWithout prejudice to reservationWith bactericidal functionAnimal feeding stuffSnack foodMicrowave technology

The invention relates to a making method of novel puffed pet snack food. The making method of the novel puffed pet snack food comprises the steps that fresh hide of pigs, cattle, fishes and the like are used as raw materials, the raw materials are pre-boiled to remove odor and oil, the raw materials are cut into pieces and dices and then placed in a high-temperature kneading machine to be decocted and kneaded, and meanwhile the needed fresh meat paste, natural gourmet powder and related nutrient matter are added; the decocted hide paste is placed in a mold to be formed and cooled, and then slicing and drying are conducted; puffing is conducted through a creative microwave technology, and after sterilization and packaging, the high-protein low-fat puffed snack food for pets is obtained. The finally obtained product has thick meat fragrance, is easy to digest and absorb, maintains the nutrient of fresh hide collagen type food, has the health-care function on the skin and hair of the pets and can be used as meat type snack food and a nutritional supplement for the pets.

Owner:高鸿立 +1

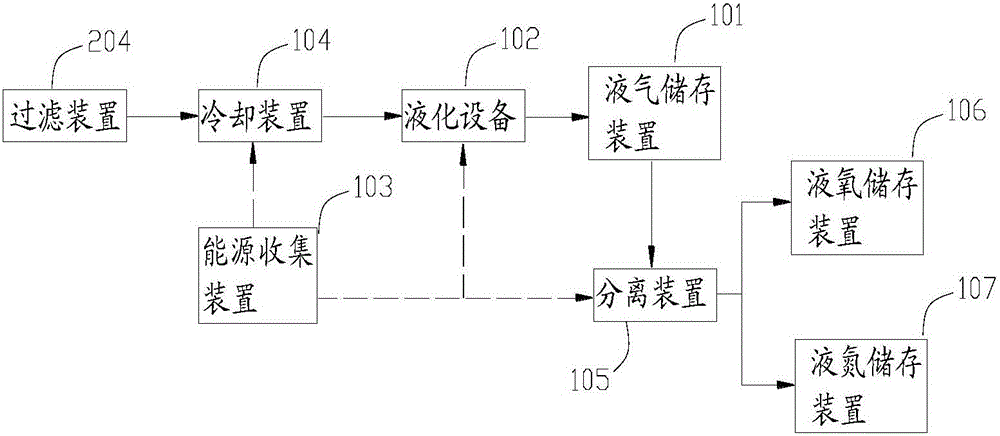

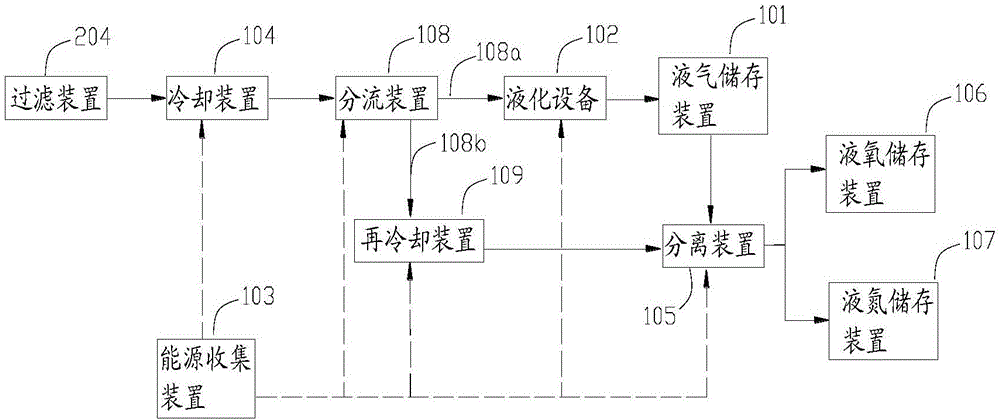

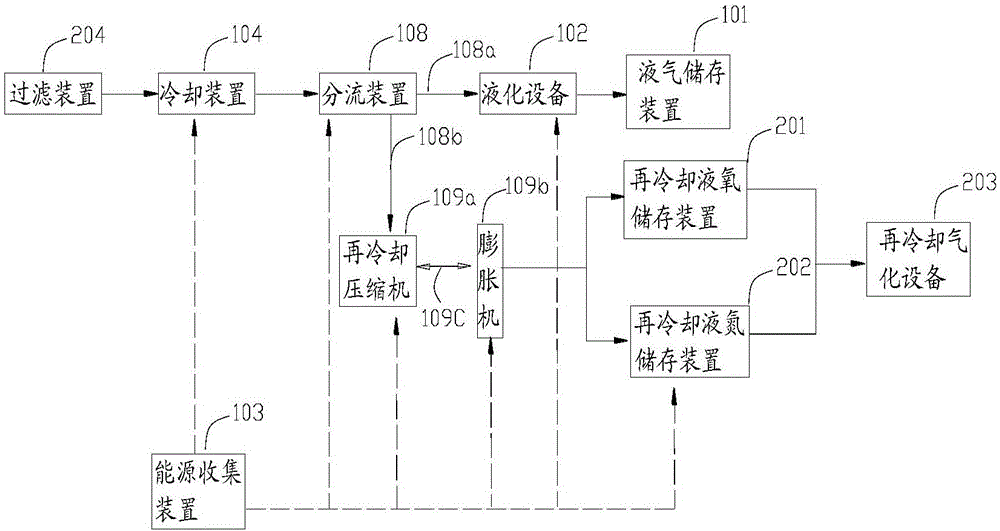

Gas converting method and system

ActiveCN106247757AImprove energy efficiencyImprove liquefaction efficiencySolidificationLiquefactionProcess engineeringHigh pressure

The invention provides a gas converting method and system capable of storing and converting clean energy and improving the liquefying benefits. The gas converting system comprises a liquid gas storage device and a liquefying device. The liquefying device is provided with an air inlet and a liquid gas outlet. The liquid gas outlet communicates with the liquid gas storage device. The gas converting system further comprises an energy collecting device and a cooling device, wherein the energy collecting device is used for collecting pushing energy, the cooling device communicates with an air source, compression and stepped cooling are conducted on air through the pushing energy, low-temperature air is formed, and a low-temperature air outlet is formed. The liquefying device is used for liquefying the low-temperature air through the pushing energy, so that liquid air is manufactured and output through the liquid gas outlet, high-pressure gas obtained after liquid gas gasification is used for conducting power generation and / or external acting, and cold energy generated through gasification is recycled. The gas converting method comprises the steps that the energy is collected to conduct compression and stepped cooling on the air, the low-temperature air is formed and further liquefied, liquid air is manufactured, and the high-pressure gas obtained after liquid gas gasification is used for conducting power generation and / or external acting.

Owner:陈正洪

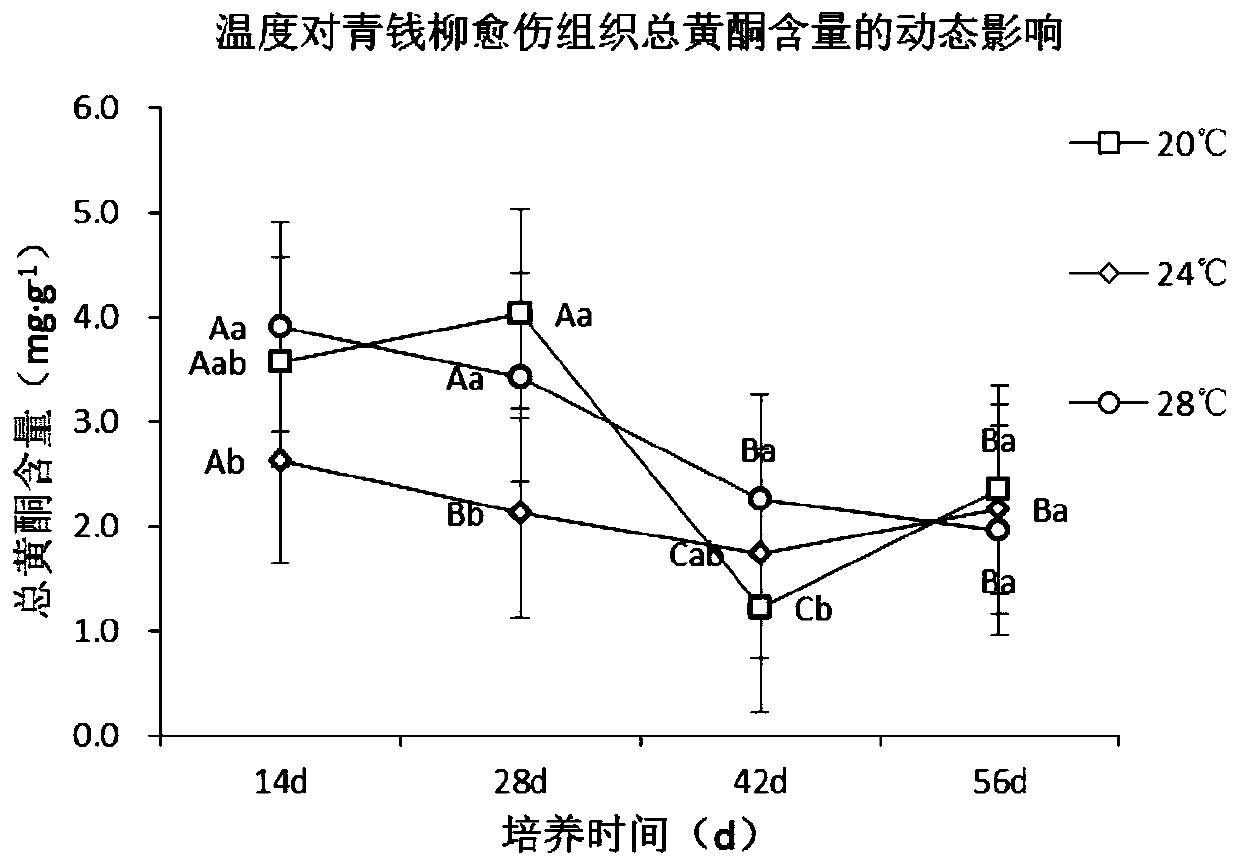

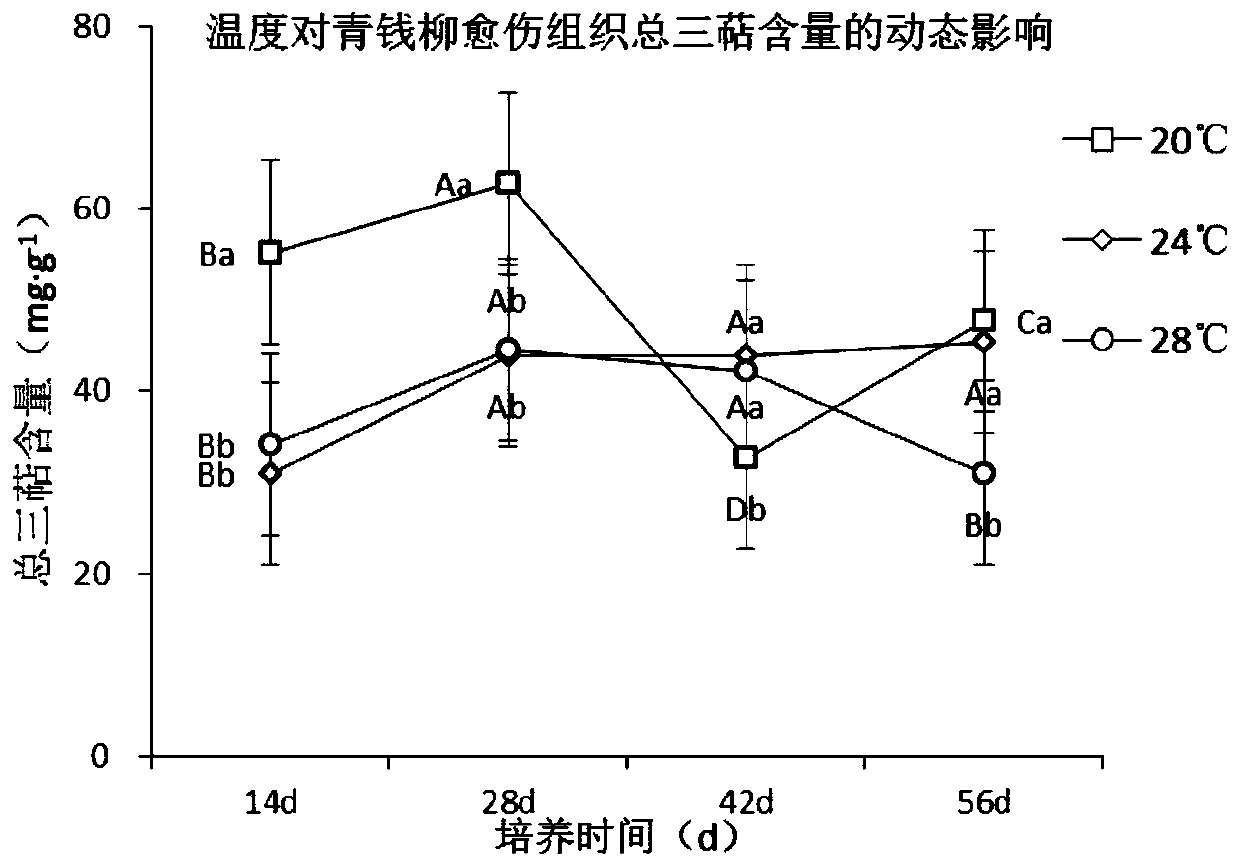

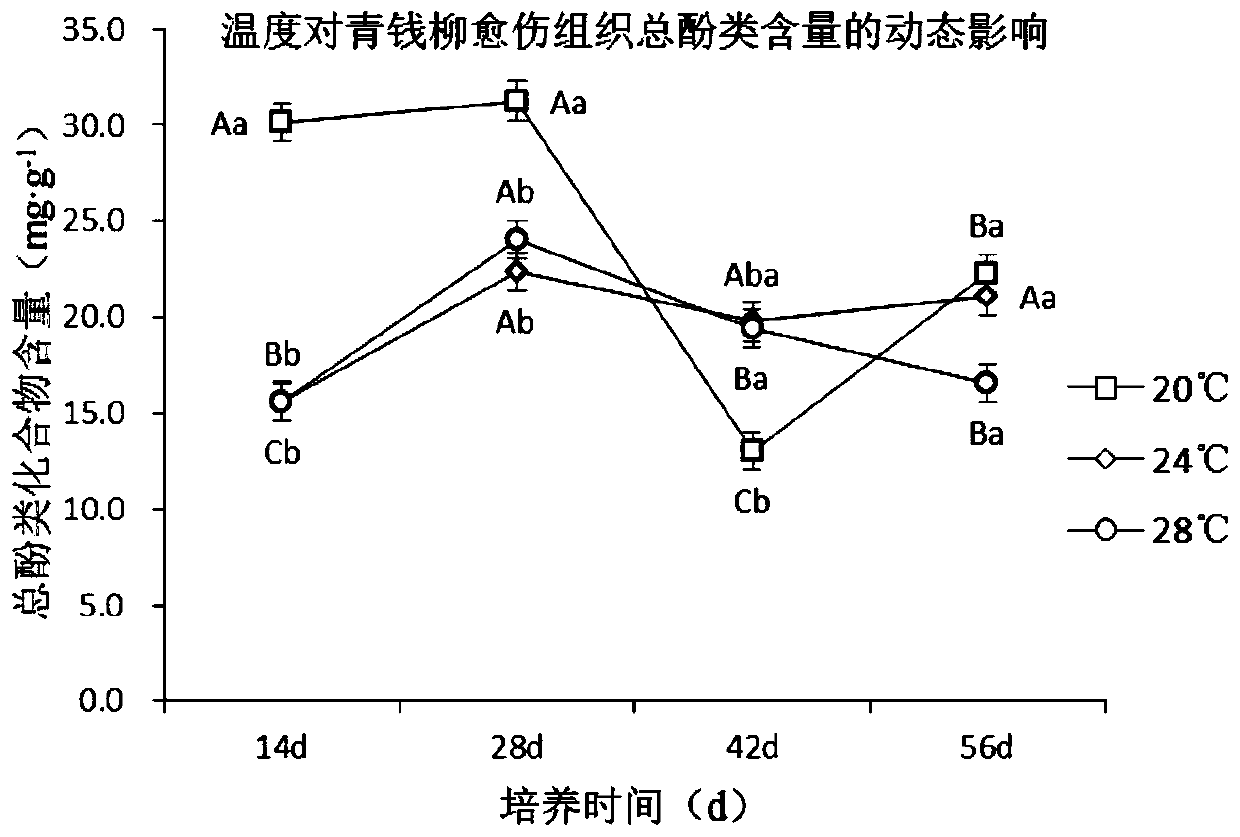

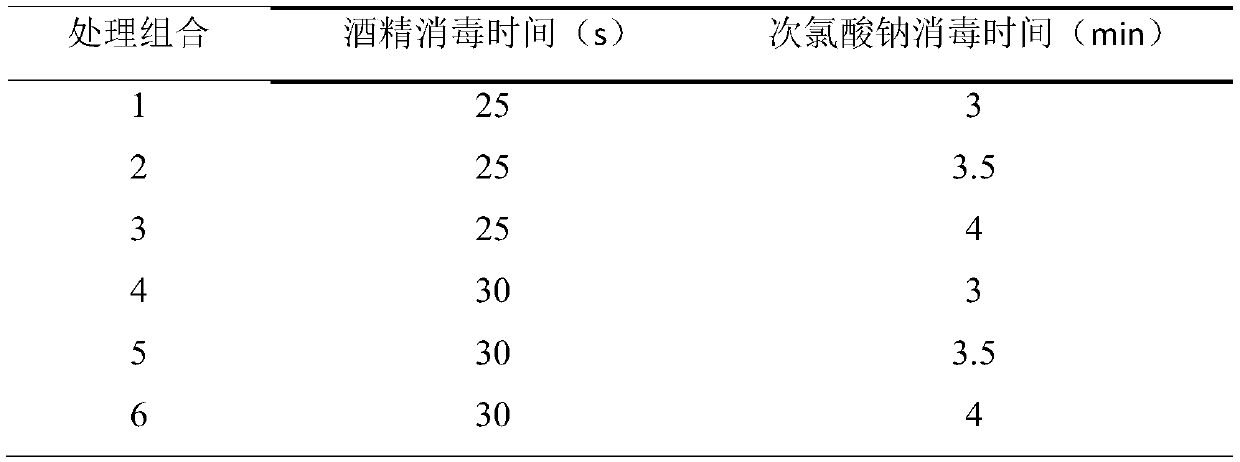

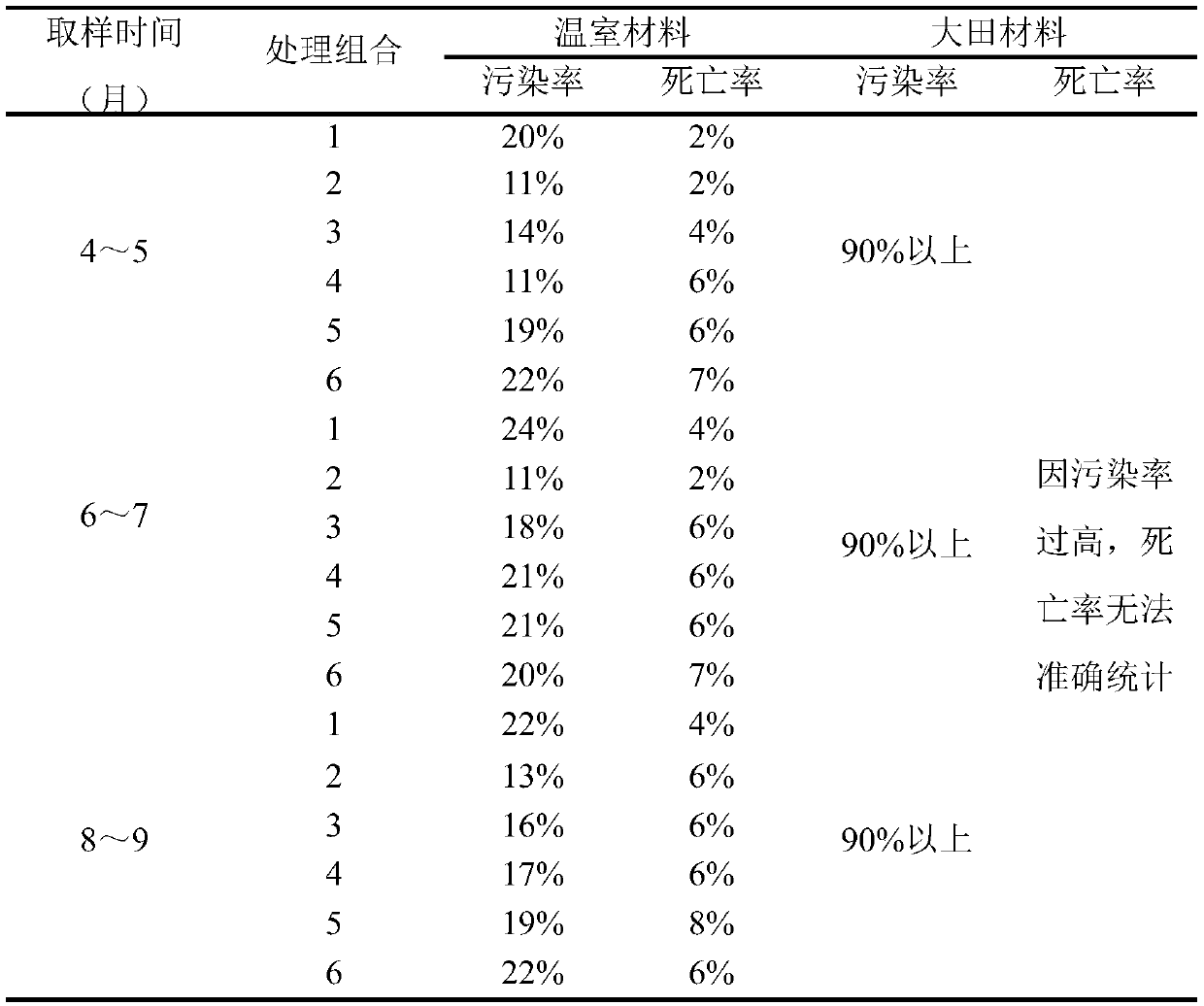

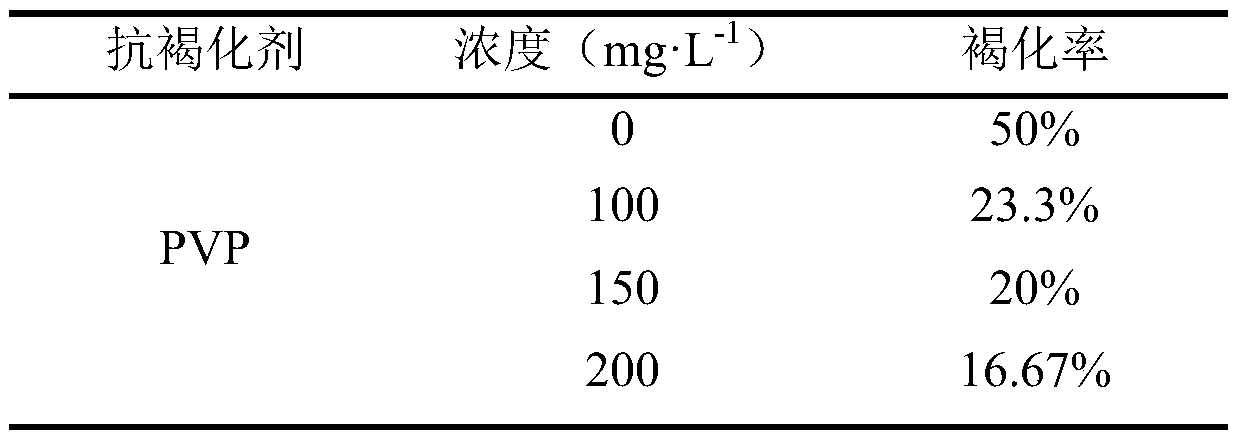

Culture method capable of promoting cyclocarya paliurus callus growth and secondary metabolite accumulation

ActiveCN110432145APromote growthPromote accumulationHorticulture methodsPlant tissue cultureSecondary metaboliteNormal growth

The invention discloses a culture method capable of promoting cyclocarya paliurus callus growth and secondary metabolite accumulation. The culture method includes: taking materials, and disinfecting;selecting semi-lignified stems with buds and top-end leaflets of cyclocarya paliurus, and disinfecting; performing callus induced culture: culturing stems and leaves in an induced culture medium to generate callus, wherein culture conditions are continuous dark treatment, and culture temperature is set at 20 DEG C; performing callus multiplication culture: transferring the callus into a transgenerational multiplication culture medium for transgenerational multiplication culture, and using a sealing film to sea, and putting into a culture chamber for culture, wherein culture conditions are continuous dark treatment, and culture temperature is set at 20 DEG C. Induction and multiplication culture of the callus are performed at temperature of 20 DEG C, so that generation of phenolic substances is inhibited while normal growth of cyclocarya paliurus is ensured, and callus growth and secondary metabolite accumulation are promoted at low temperature.

Owner:NANJING FORESTRY UNIV

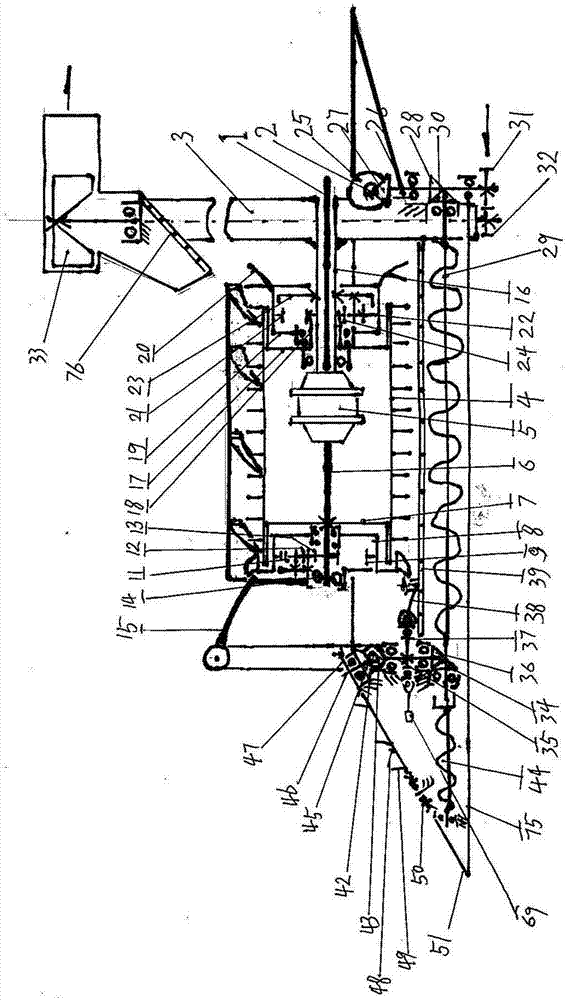

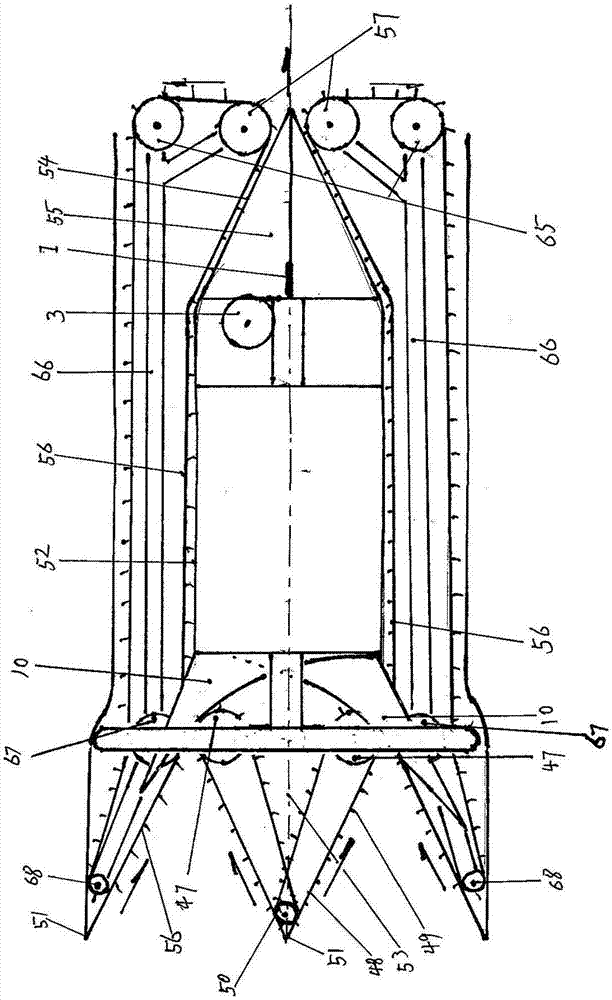

Preceding reaping threshing combined cereal harvester

ActiveCN106888675ASolve the problems that can't be solved by grain wasteLow costMowersThreshersCropping systemEngineering

The invention discloses a preceding reaping threshing combined cereal harvester. The preceding reaping threshing combined foxtail millet harvester comprises a threshing structure, a cereal cleaning, conveying and combined transmission structure, a straw conveying mechanism and a mowing structure. The preceding reaping threshing combined foxtail millet harvester which makes straws stand still or fallen straws erected to stand still, and only makes grains stripped off, subjected to dreg removal and then collected is adopted to replace an existing whole-feed type harvester and an existing half-feed type harvester. The problems are solved that by means of the existing half-feed type harvester, grains are missed and wasted before threshing, the structure is complex, the cost is high and the energy consumption is too high; the special requirement that in an actual cropping system, only the straws which are not cut off can be buried into soil to serve as a fertilizer is met; the preceding reaping threshing combined foxtail millet harvester can operate in a paddy field, a muddy field, a hill area and a mountainous area and walk with no difficulties in a road-free sloping field within 45 degrees; even working in the paddy field deep muddy surface, the preceding reaping threshing combined cereal harvester does not sink; moreover, only one third of power of an existing harvester is needed, the preceding reaping threshing combined cereal harvester can complete the same amount of work; by means of the preceding reaping threshing combined cereal harvester, the bad manners that farming cannot be conducted, so that farmers set fire to burn up the straws are avoided.

Owner:向青茂

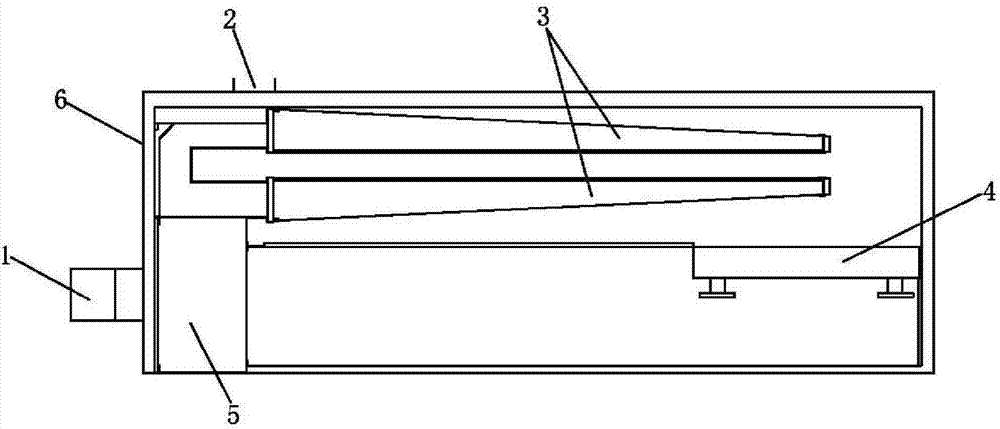

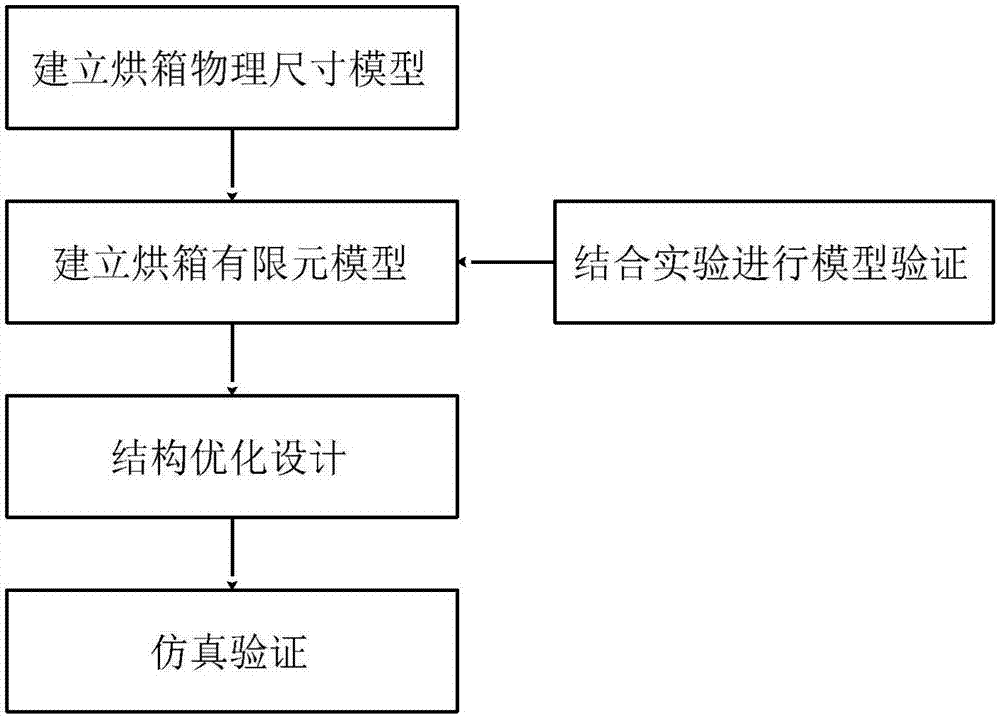

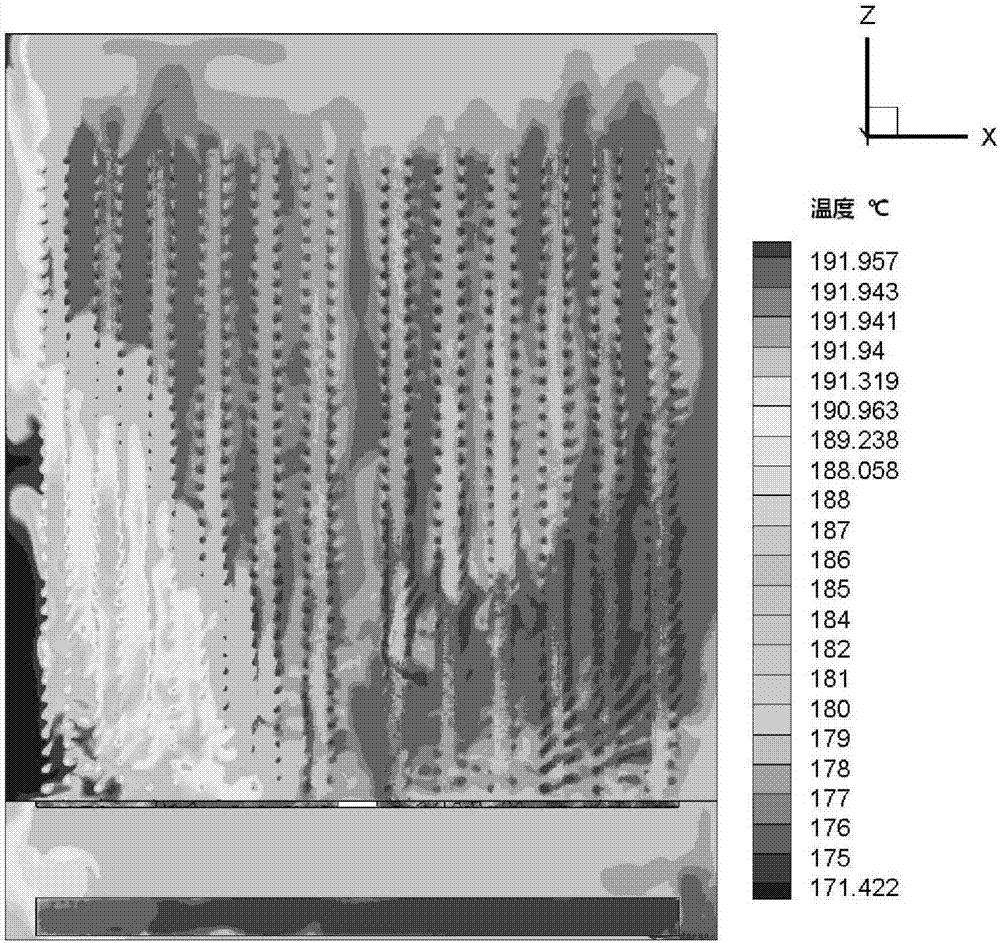

Tentering and heat-setting machine oven structure optimization method

ActiveCN107977482AAddressing Fluid Mechanical PropertiesOptimize the local flow fieldGeometric CADSpecial data processing applicationsEngineeringHeat setting

The invention discloses a tentering and heat-setting machine oven structure optimization method. Through the method, hydrodynamic performance in the operating process of a traditional setting machineoven is realized, the situation that an original structure is unreasonable and a vortex structure exists is relieved, a local flow field is optimized, vortex strength is obviously lowered, the problems that energy is excessively consumed and a fire hidden danger is generated because exhaust is unsmooth and fiber dust is prone to accumulation at the vortex structure are solved, and a basis is provided for energy-saving, environment-friendly and safe production of a setting machine.

Owner:ZHEJIANG SCI-TECH UNIV

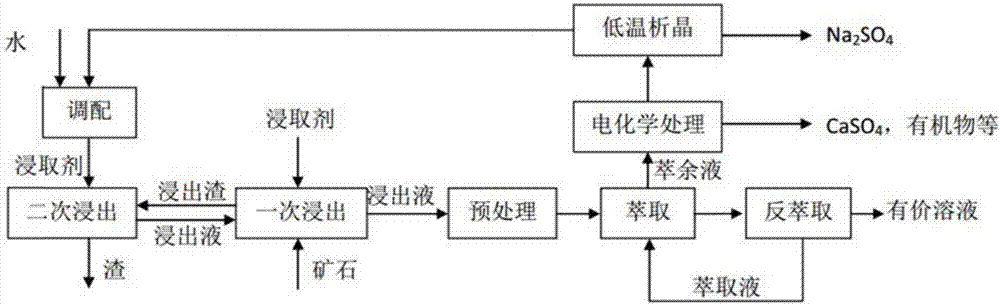

Comprehensive utilization method for waste water containing high-concentration sodium sulfate based on wet metallurgy process

InactiveCN107881341AAchieve recyclingSolving Wastewater ProblemsProcess efficiency improvementAlkali metal sulfites/sulfatesHigh concentrationSlag

The invention provides a comprehensive utilization method for waste water containing high-concentration sodium sulfate based on the wet metallurgy process. The comprehensive utilization method at least comprises the following steps that (1) an appropriate quantity of leaching agent is added into an ore raw material, wherein the leaching agent at least comprises sulfate ions and sulfite ions, thensolid-liquid separation is conducted, and leaching slag and leaching liquid are obtained correspondingly; (2) the leaching liquid is pre-treated, namely still standing for sediment is conducted, the leaching liquid is subjected to organic solvent extraction, and an extraction agent and extraction liquid are obtained; (3) the extraction agent is subjected to saponification to obtain a sediment, theextraction liquid is subjected to electrochemical treatment, after calcium ions and organic matter are removed, cooling for crystallization is conducted, and crystals and clear liquid are obtained; (4) at least part of the clear liquid is dosed to obtain a leaching agent, the leaching agent and the leaching slag in the step (1) are mixed and reacted again, and thus reaction slag and secondary leaching liquid are obtained; and (5) at least part of the secondary leaching liquid is utilized to return to the step (1) to be mixed and reacted with to-be-treated ore. The comprehensive utilization method is low in cost and high in efficiency.

Owner:SHANGHAI IND TECH INST

Callus induction and subculture medium for cyclocarya paliurus, and culture method thereof

ActiveCN109997692ALow pollution rateNot easy to pollutePlant tissue cultureHorticulture methodsTriterpeneSecondary metabolite

The invention discloses a callus induction and subculture medium for cyclocarya paliurus, and also discloses a culture method based on the callus induction and subculture medium for the cyclocarya paliurus. The culture method includes explant selection, explant sterilization, establishment of a sterile anti-browning system, and proliferation culture. The callus induction and subculture medium andthe culture method have the advantages that the anti-browning abilities of calluses of the cyclocarya paliurus can be effectively improved, a large quantity of non-browning calluses with high growth speeds can be obtained in a short time, the problem of resource shortage of the cyclocarya paliurus can be solved through biotechnological measures, and accordingly, the foundation is laid for industrial extraction of secondary metabolites of the cyclocarya paliurus, such as triterpenes, flavonoids and polysaccharides, in later period.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com