Agricultural seed sieving and drying treatment equipment

A technology for drying treatment and seeds, applied in the field of agricultural seed screening and drying treatment equipment, can solve the problems of high energy consumption of drying devices and uneven drying of seeds, avoid seed accumulation, uniform heating, and solve problems of excessive energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

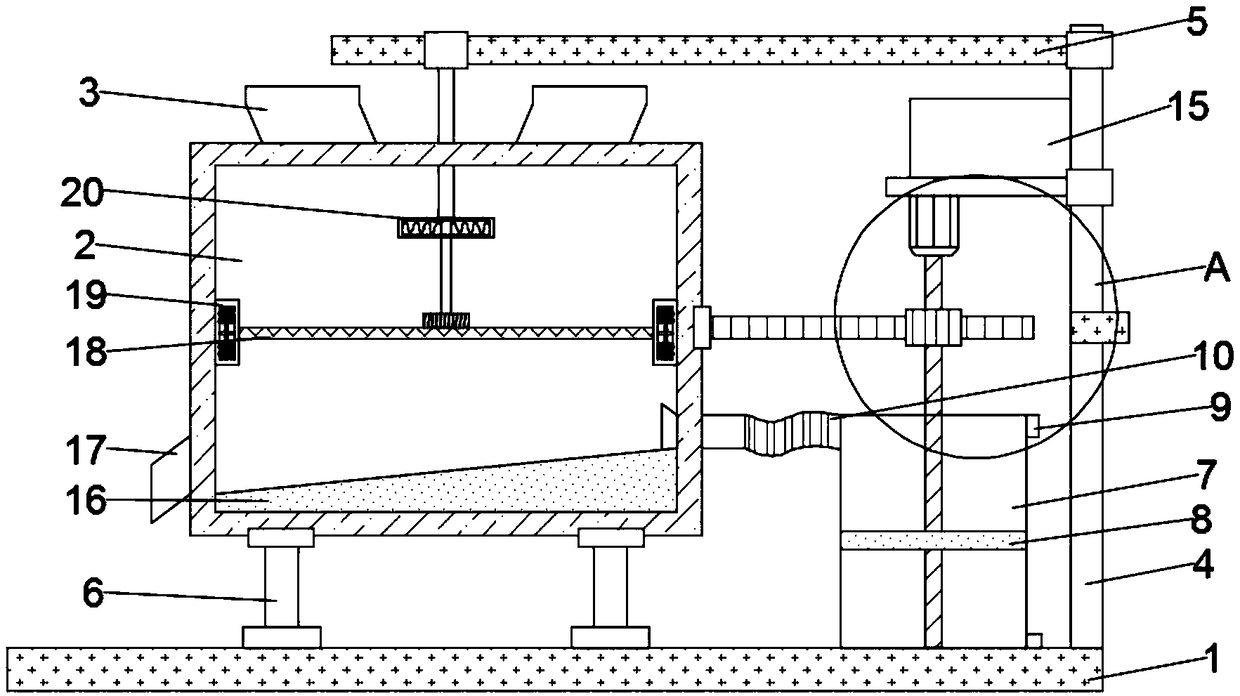

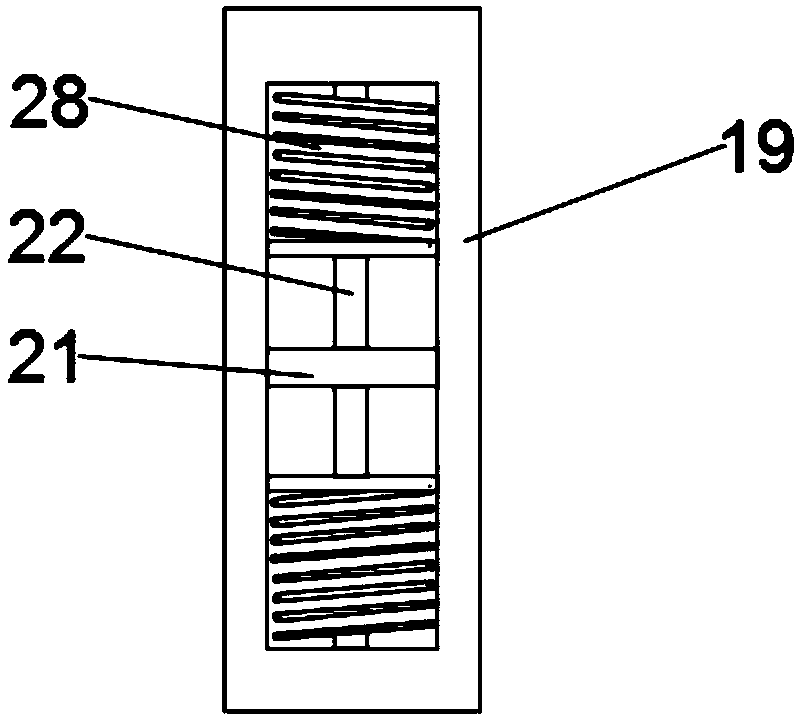

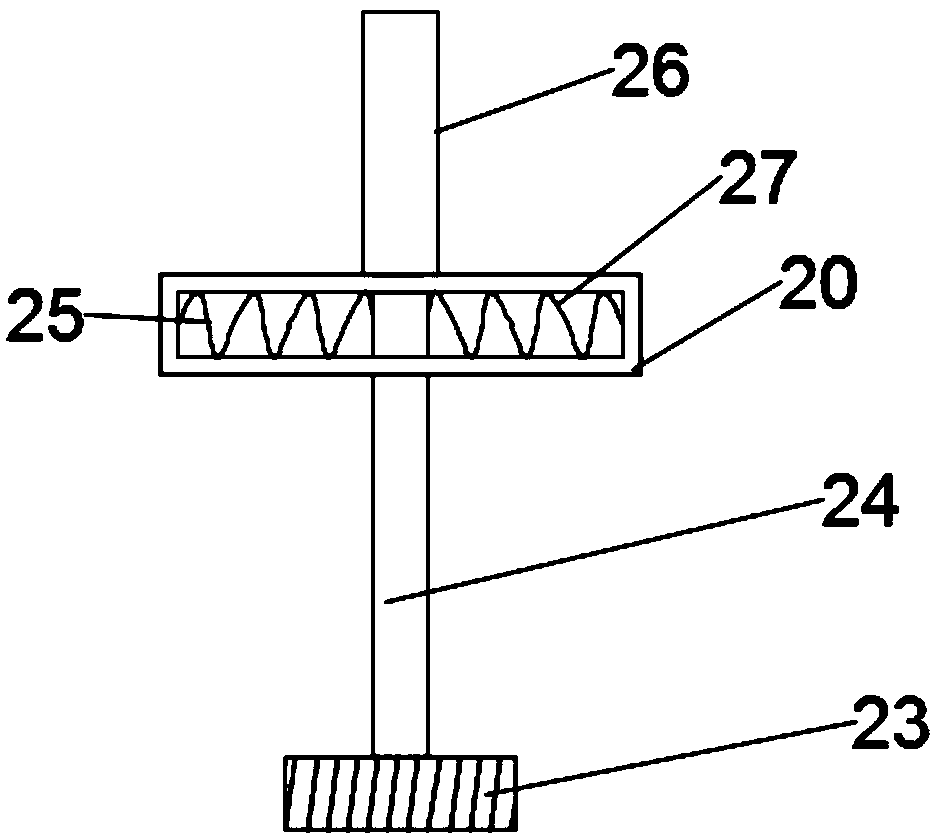

[0020] see Figure 1~4 , in an embodiment of the present invention, an agricultural seed screening and drying treatment equipment includes a drying box 2, a hot air release chamber 7, a screen 18 and a vertical guide rail 19, and a horizontal chute 1 is arranged below the drying box 2, so that The four corners of the lower surface of the drying box 2 are all welded with slide plates 6, the slide plates 6 are slidably connected to the horizontal chute 1, the right side of the horizontal chute 1 is vertically welded with a vertical column 4, and the upper end of the vertical column 4 is welded horizontally A support rod 5, a hot air release chamber 7 is provided on the lower right side of the drying box 2, and the drying box 2 and the hot air releasing chamber 7 are connected by an air guide hose 10, and a screen 18 is arranged inside the drying box 2, so that The setting of the sieve 18 can realize sufficient screening of the seeds in the drying box 2, and the air guide hose 10...

Embodiment 2

[0027] see Figure 5 , in the embodiment of the present invention, the upper end of the vertical column 4 is welded with a battery 15, the working motor 14 is installed horizontally, the working motor 14 is electrically connected to the battery 15, and the left side of the output shaft of the working motor 14 is Welding gear 13, described gear 13 rear side is provided with rack 12, and described gear 13 is meshed with rack 12, and the lower end of described rack 12 runs through described hot blast release chamber 7 upper wall, and fixed welding piston plate 8, described The piston plate 8 is slidingly connected to the two side walls of the hot air release chamber 7, the left side of the gear 13 is welded with a screw 11, and the left end of the screw 11 runs through the right side wall of the drying box 2 and extends into the drying box 2 , and two cams 29 are welded symmetrically about the vertical central axis of the drying box 2 on the screw rod 11, the cams 29 abut against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com