Novel wafer surface drying device

A surface drying and wafer technology, applied in drying, drying machines, heating devices, etc., can solve the problems that the actual yield rate of wafers cannot be effectively counted, and the quality data is difficult to obtain statistics and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

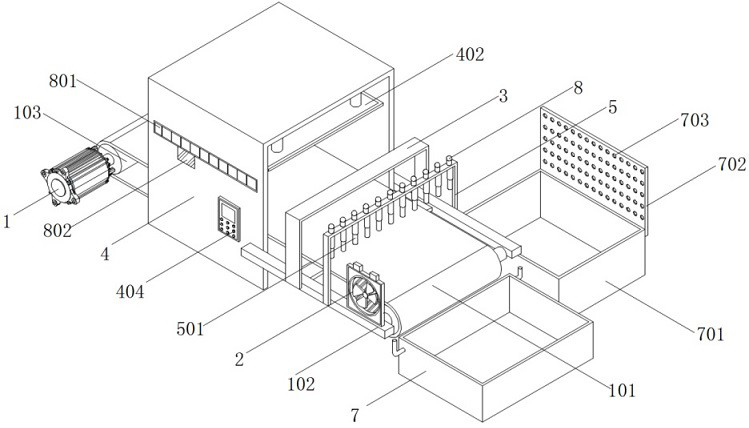

[0045] see Figure 1-Figure 3 , an embodiment provided by the present invention: a novel wafer surface drying device, comprising a drying frame 4 and a conveying fan 2, a crosspiece 102 is installed on the front and back of the drying frame 4, and the top of the front crosspiece 102 A delivery fan 2 is installed, and the delivery fan 2 is located on one side of the marking frame 5;

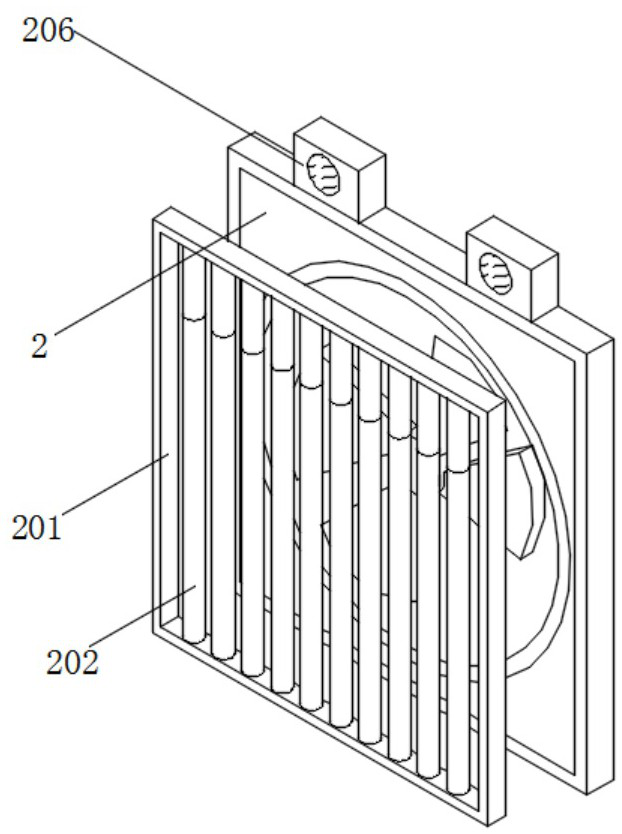

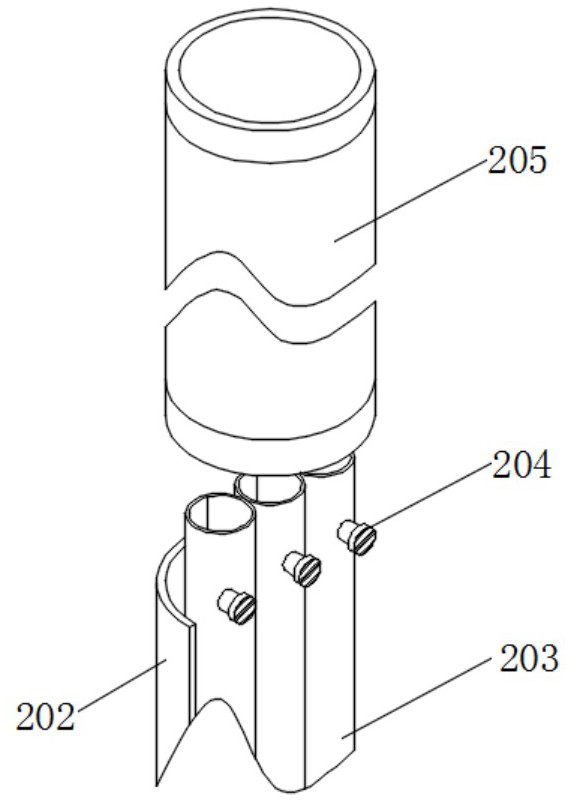

[0046] A connecting frame 201 is installed on the back of the conveying fan 2, an infrared thermometer 206 is installed on the top of the conveying fan 2, a hollow metal pipe 202 is installed on the bottom wall of the connecting frame 201, and three sets of equidistant air ducts are installed inside the metal pipe 202 203, an electronic valve 204 is installed on the surface of the air duct 203, the electronic valve 204 is electrically connected to the infrared thermometer 206, the top of the air duct 203 is fitted with a liquid nitrogen tube 205, and the top of the liquid nitrogen tube 205 is conn...

Embodiment 2

[0051] see Figure 5 , an embodiment provided by the present invention: a novel wafer surface drying device, comprising a drying frame 4, a No. 2 infrared heating plate 403 is installed on the inner wall of the drying frame 4, and the four corners of the top wall of the drying frame 4 are An electric telescopic cylinder 401 is installed, and the bottom of the electric telescopic cylinder 401 is connected with a No. 1 infrared heating plate 402, and a temperature controller 404 is installed on the front of the drying frame 4, and a control button and a temperature detector are installed on the surface of the temperature controller 404, and The temperature detector is located above the control button. The temperature detector is electrically connected to the No. 1 infrared heating plate 402 and the No. 2 infrared heating plate 403 . The No. 2 infrared heating plate 403 is located in the middle of the conveyor belt 101 .

[0052] Specifically, start the electric telescopic tube 4...

Embodiment 3

[0055] see figure 1 , an embodiment provided by the present invention: a novel wafer surface drying device, including a counter 8, a counter 8 equidistantly arranged on the top of the marking frame 5, and a No. 1 display screen 801 installed on the front of the drying frame 4 , the installation quantity of No. 1 display screen 801 is equal to the installation quantity of counter 8, No. 2 display screen 802 is installed on the front of drying frame 4, and No. 2 display screen 802 is positioned at the bottom of No. 1 display screen 801, and No. 2 display The screen 802 is electrically connected to the No. 1 display screen 801 , and the No. 1 display screen 801 is electrically connected to the counter 8 one by one. The No. 2 display screen 802 is located above the temperature controller 404 .

[0056] Specifically, since the wafers placed on the surface of the conveyor belt 101 are arranged in columns, the production batches of the wafers discharged in each column may be differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com