Efficient grain drying box

A drying box and grain technology, applied in grain drying, drying, dryer and other directions, can solve problems such as inconvenience for users, uneven grain drying, and grain not meeting drying standards, and reduce drying Drying time, improve drying efficiency and effect, easy to collect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

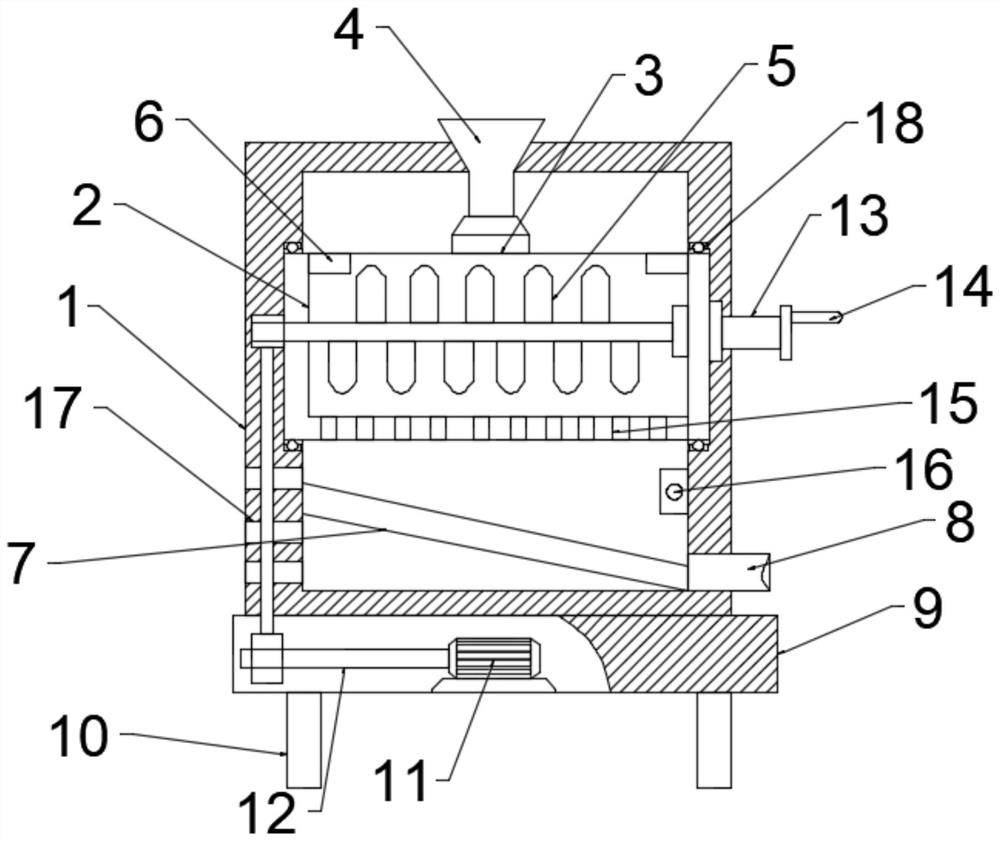

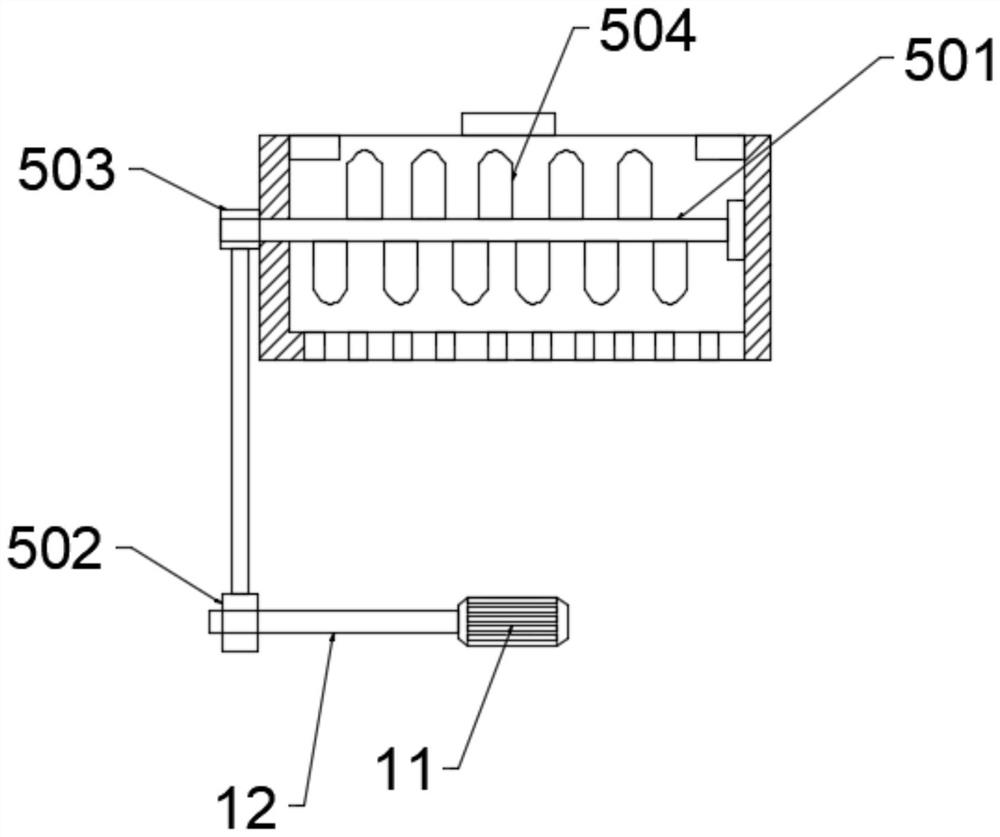

[0021] see Figure 1-2 , in the embodiment of the present invention, a high-efficiency grain drying box includes a box body 1, a material barrel 2 is arranged inside the box body 1, and a feed inlet 3 is opened on the upper surface of the material barrel 2, and the box body 1 The top of the body 1 is fixed with a feed funnel 4, the bottom of the feed funnel 4 communicates with the feed port 3, the barrel 2 is provided with a drying mechanism 5, and the inner wall of the barrel 2 is fixed around A heater 6 is provided, and a deflector 7 is fixedly connected between the inner walls of the box 1 close to the bottom, and the deflector 7 is obliquely arranged inside the box 1, and the side of the box 1 close to the deflector 7 The inclined surface is provided with a discharge port, the discharge port is fixedly provided with a discharge pipe 8, the bottom end of the box body 1 is fixedly provided with a base 9, and the lower surface of the base 9 is fixedly connected with a support...

Embodiment 2

[0025] see Figure 1-2 , in this embodiment, the outer wall of the barrel 2 close to the bearing ring is fixedly connected with a fixed block, the right surface of the fixed block is fixedly connected with a connecting rod 13, and one end of the connecting rod 13 is fixedly provided with a turntable, and on the turntable Fixedly be provided with turning handle 14, described turning handle 14 is provided with non-slip groove, by rotating turning handle 14, turning handle 14 drives barrel 2 to rotate through rotating disk, fixed block, makes the grain in barrel 2 constantly turn over, in Cooperating with the toggle of the toggle plate 504 during the flipping process, the grains are evenly dispersed, which is beneficial to even drying.

[0026] In this embodiment, the bottom end of the barrel 2 is provided with multiple groups of leakage holes 15, and the inner wall of the box 1 close to the discharge pipe 8 is fixed with a fan 16, and the box 1 is far away from the fan 16. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com