Liquid cleansing composition and its preparation method and application

A composition and liquid technology, which is applied in the direction of detergent composition, soap detergent composition, surface active detergent composition, etc., can solve the problems of single form, insufficient transparency, and difficulty in mass production of handmade soap, and achieve enhanced nourishment Moisturizing, speeding up the reaction rate, and good skin feel after washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

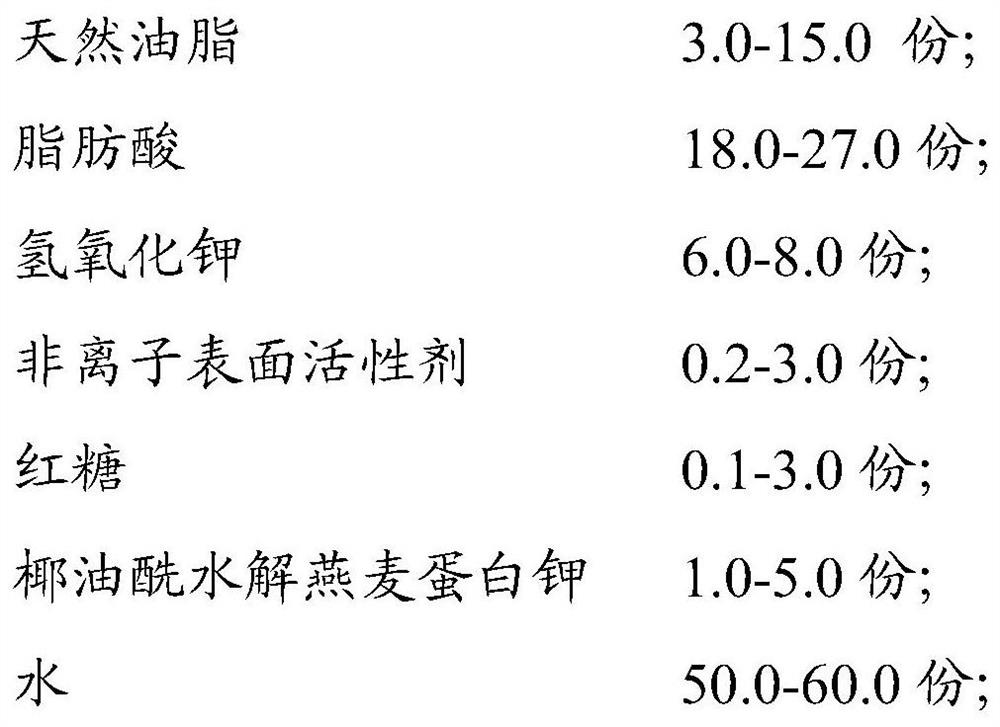

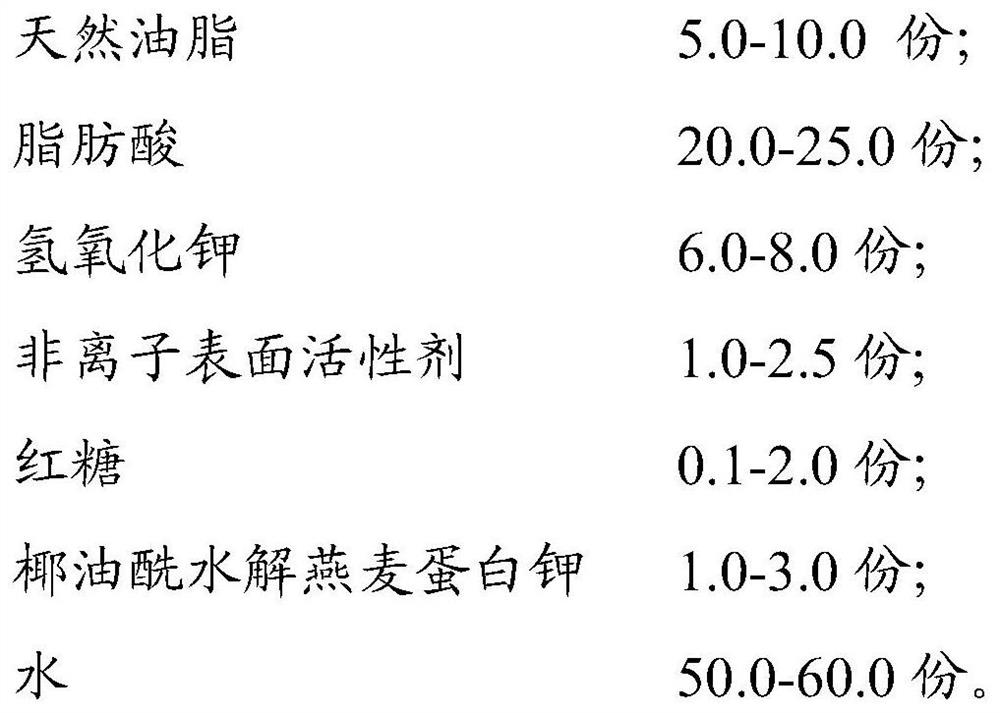

[0079] Table 1 is the formulation of the liquid skin cleansing compositions of Examples 1-6.

[0080] Its preparation method of the liquid cleansing composition of embodiment 1-6 is as follows:

[0081] The raw materials required for each embodiment were weighed in parts by weight shown in Table 1.

[0082] Mix natural oil, fatty acid, part of water, PEG / PPG-80 / 20 copolymer, PEG-32 and PEG-6, heat to 50-65°C, stir until it completely dissolves and becomes a dilute solution, and keep the vacuum degree -0.05 ~0.2Mpa;

[0083] Mix potassium hydroxide with some water to form a potassium hydroxide solution with a concentration of 40%, slowly add it dropwise to the mixture in the previous step step by step, and keep the vacuum at 0.2Mpa, the temperature is 60°C, and configure a condensation reflux device At the same time, turn on the fast dispersing device, keep the dispersing speed at 3000rpm, add cocoyl hydrolyzed oat protein potassium, brown sugar, stir until dissolved, until t...

Embodiment 1 and comparative example 1-4

[0087] Table 2 is the formula of the liquid cleansing composition of Example 1 and Comparative Examples 1-4.

[0088]

[0089]

[0090] The performance test of embodiment 1-6 and comparative example 1-4

[0091] Test 1 basic physical and chemical performance test.

[0092] Wherein, the testing method of the viscosity is: the composition is kept warm at 25° C. in advance, and the NDJ-5S / NDJ-8S rotational digital viscometer is used for measurement.

[0093] The test results are shown in Table 3.

[0094] table 3

[0095]

[0096]

[0097] It can be seen from Table 3 that the liquid cleansing compositions prepared in Examples 1-6 are clear and low-viscosity transparent aqueous solutions, which are easy to extract when used as basic cleaning materials, and can be applied to transparent and opaque products. Products in various states such as liquid, paste, and emulsion. It is easy to stir evenly during the production process, and it only takes 1 to 2 hours from th...

Embodiment 1'、 Embodiment 4'- Embodiment 6' and comparative example 1'- comparative example 4

[0100] The compositions of Examples 1, 4-6 and Comparative Examples 1-4 are prepared into shower gels, corresponding to Example 1', Example 4'-Example 6' and Comparative Example 1'-Comparative Example 4', Its formula is shown in table 4.

[0101] The shower gel is prepared as follows:

[0102] The raw materials required for each embodiment and comparative example were weighed in parts by weight shown in Table 4.

[0103] Add disodium edetate and sodium chloride to water at a temperature of 25°C and stir until dissolved to obtain a transparent solution A;

[0104] Add the corresponding liquid cleansing composition, sodium cocoamphoacetate, 1,2 propylene glycol, ethylene glycol distearate, cocamidopropyl betaine, sodium lauroyl sarcosinate, PEG into the transparent solution A -14M, and methylparaben and propylparaben, heated up to 50-60°C, stirred until dissolved to obtain solution B;

[0105] Add citric acid aqueous solution to solution B, cool down to 45°C, add cocoyl dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com