Novel electromagnetic magnetic magnetic separator

An electromagnetic and magnetic separator technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of poor sealing, difficult to clean the radiator, and the feeding valve is stuck, so as to achieve convenient maintenance and heat dissipation. Good effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

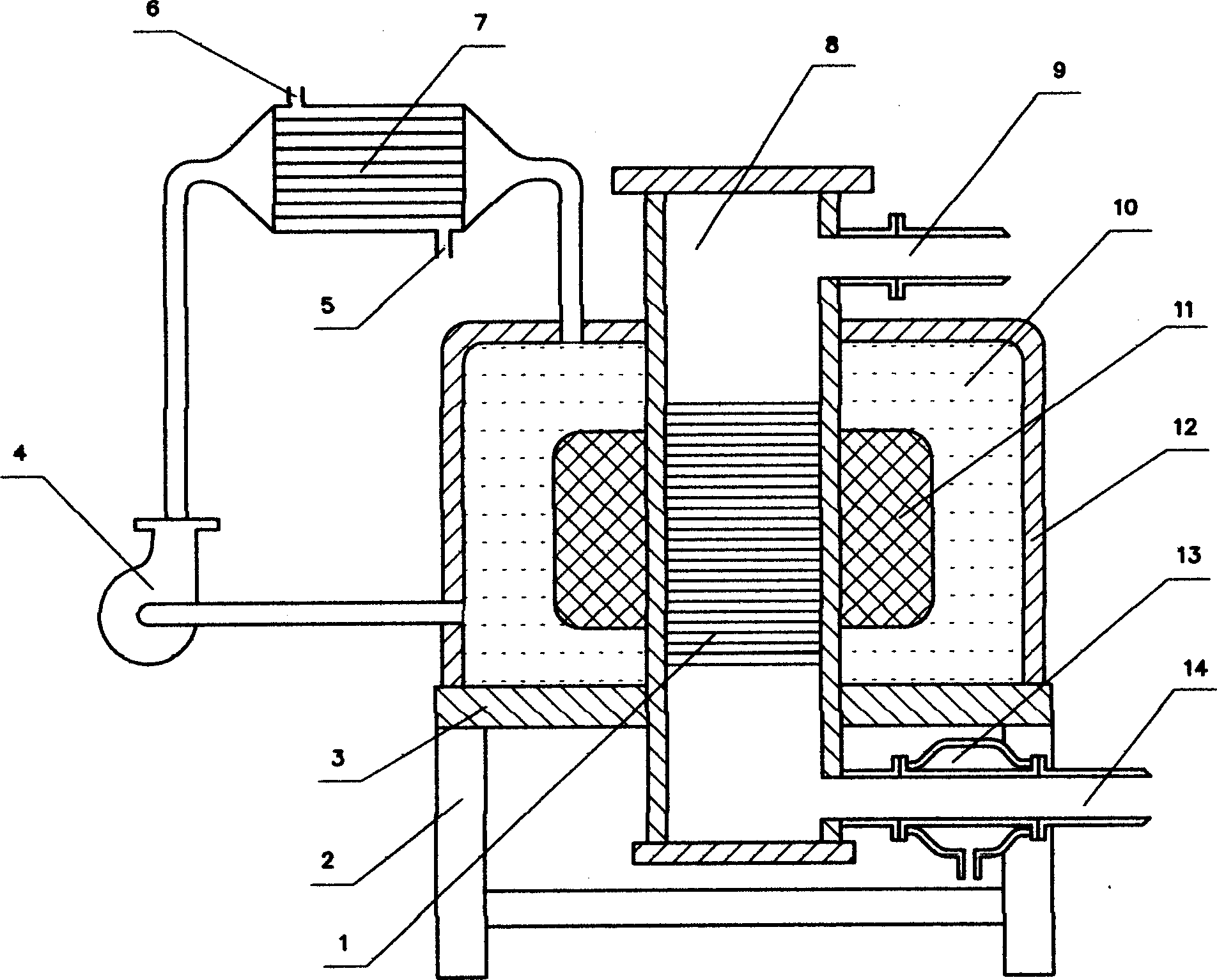

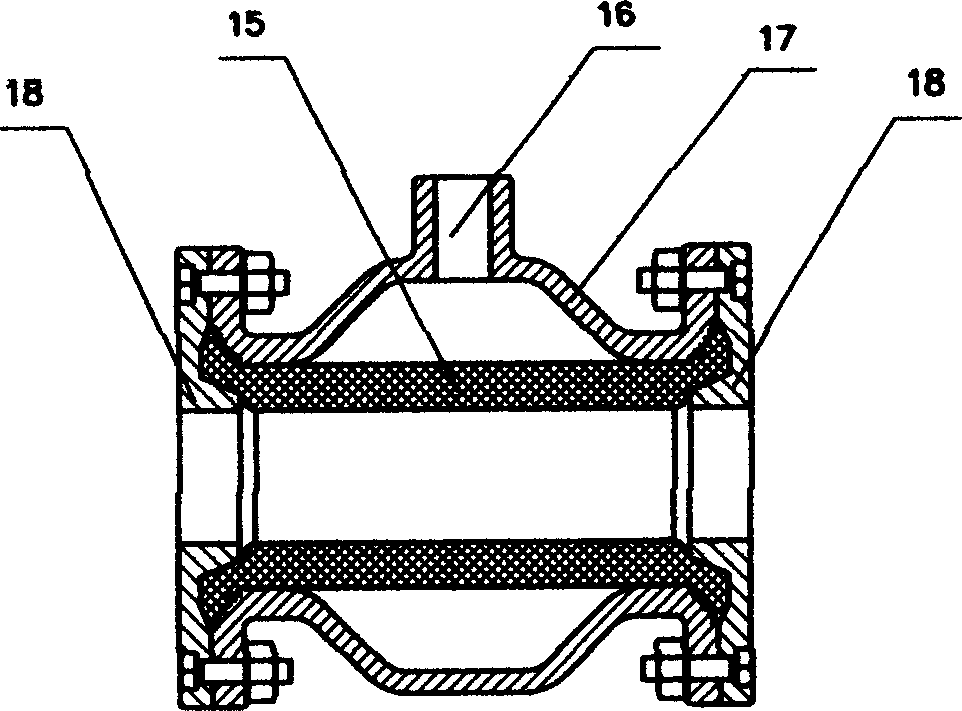

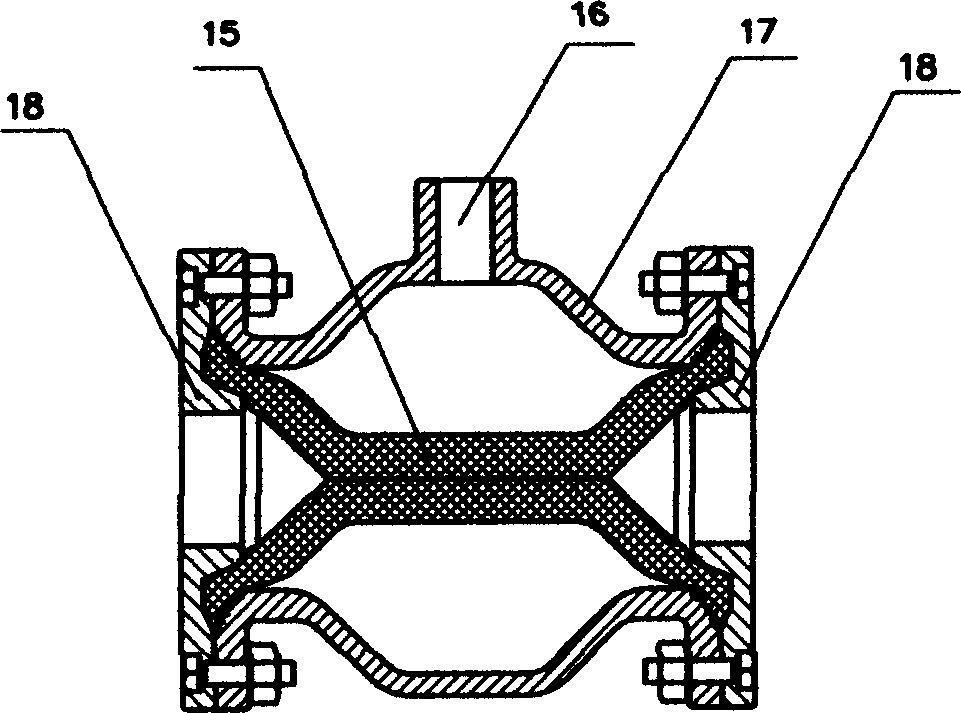

[0029] like figure 1 , figure 2 , image 3 Shown, a kind of novel electromagnetic type magnetic separator, comprises the deironing chamber (8) that magnetic intermediary network (1) is installed, on the deironing chamber (8) there is a feed port (14) and a discharge port ( 9), the middle part of the iron removal chamber (8) is covered with an electromagnetic coil (11), and the electromagnetic coil (11) is soaked in the transformer oil (10) in the oil tank (12), and the oil tank (12) and the iron removal chamber (8 ) is installed on the base plate (3), and the base plate (3) is installed on the bracket (2). During operation, the fluid raw material enters the iron removal chamber (8) through the magnetic medium net (1) from the feed port (14) to remove iron, and then is output from the discharge port (9). A pneumatic diaphragm valve (13) is connected at the feeding port (14), and the pneumatic diaphragm valve (13) is made up of a rubber diaphragm (15), a sealing shell (17) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com