Waste heat recovery device of day lily drying machine

A technology of waste heat recovery device and dryer, which is applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problems of energy waste and loss, achieve energy saving, uniform drying treatment, and avoid heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

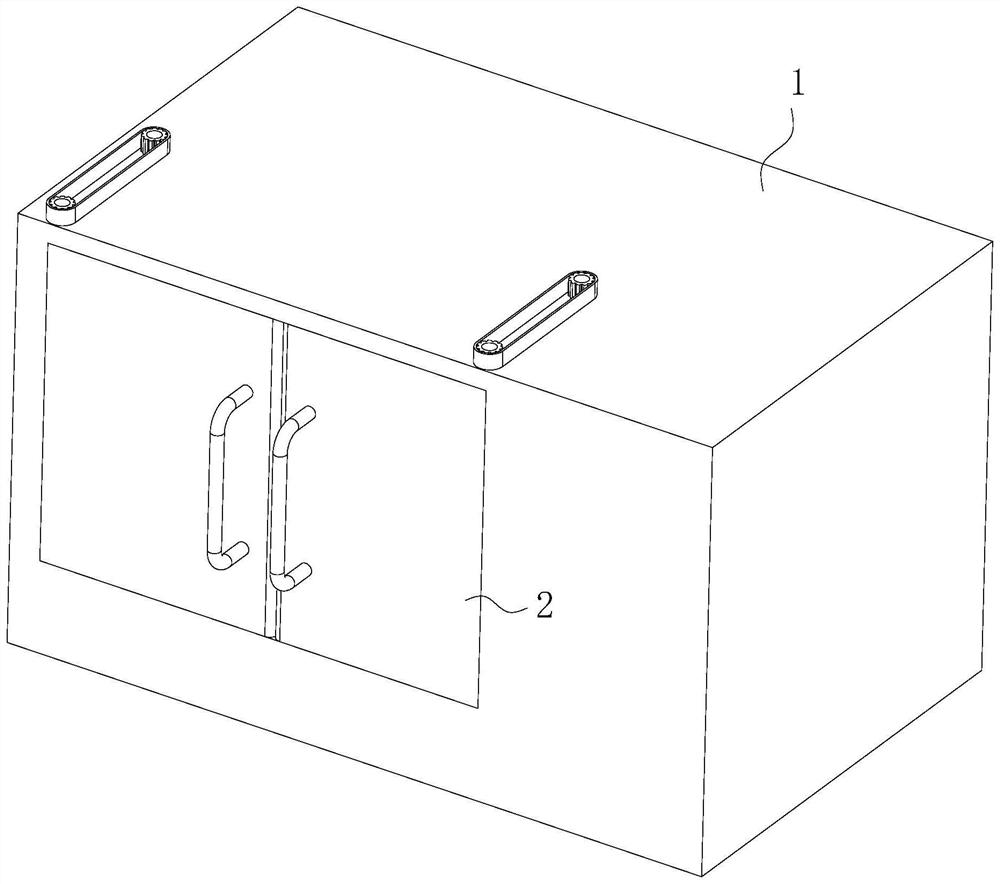

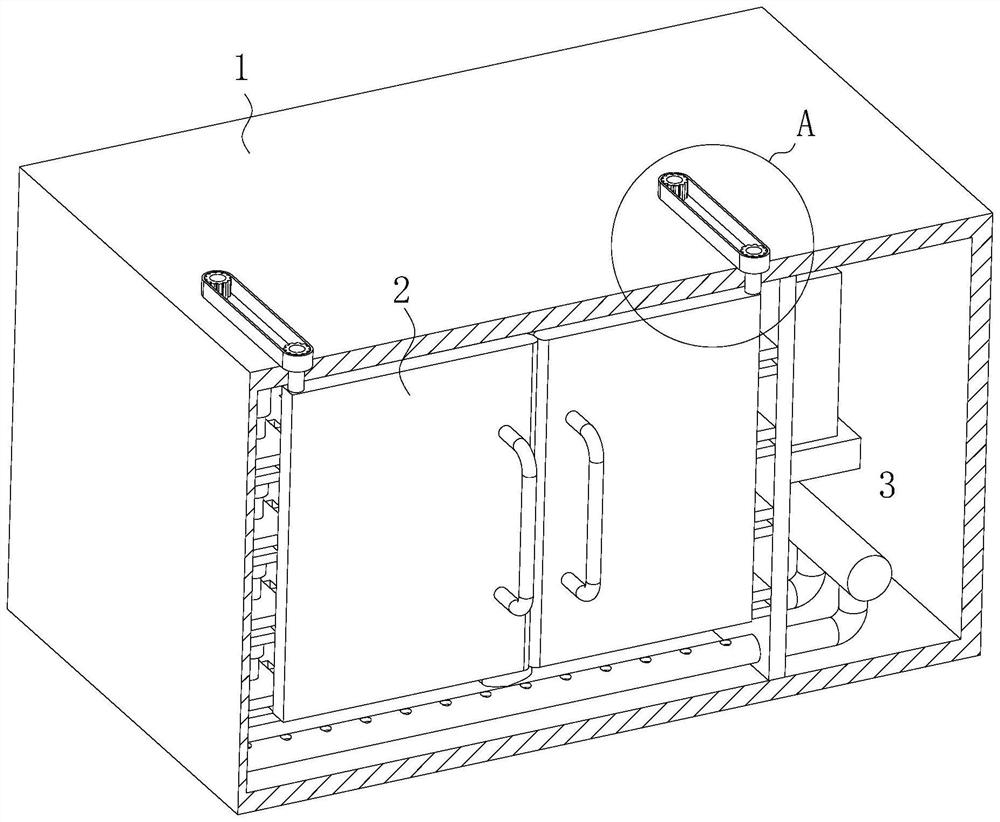

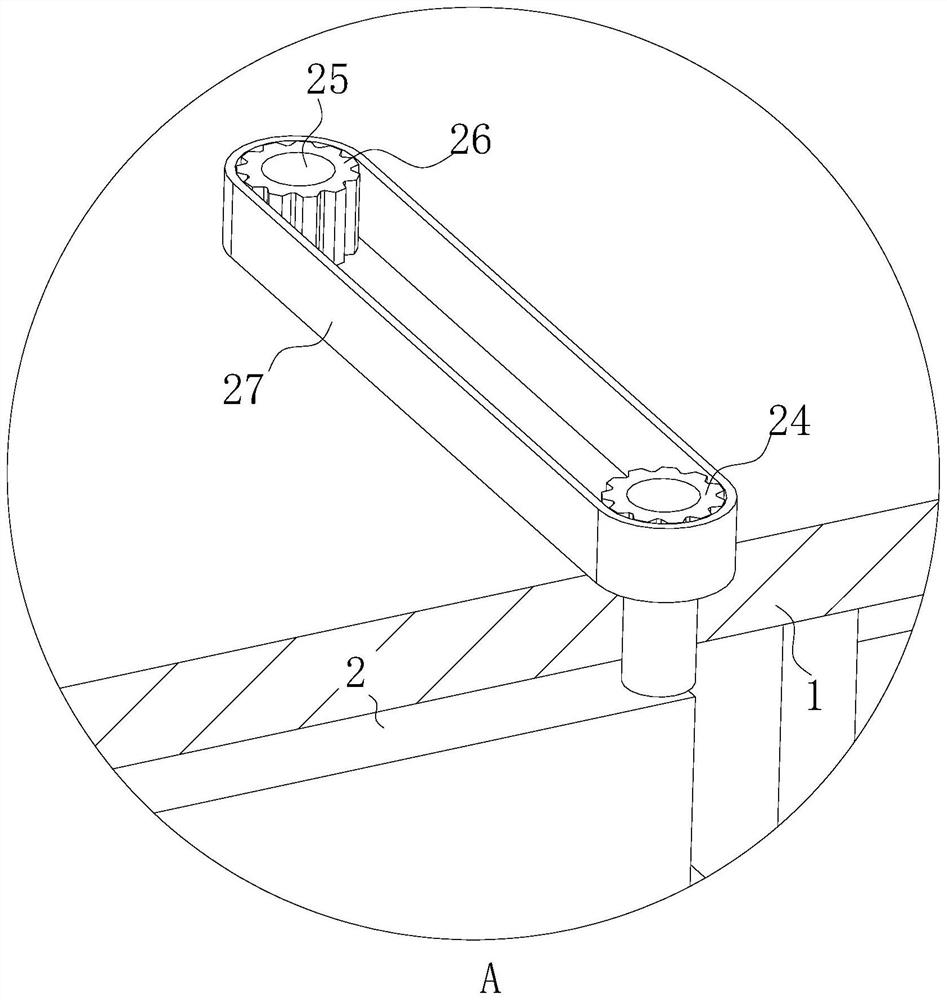

[0029] see Figure 1-9 , the present invention provides a technical solution: a yellow flower dryer waste heat recovery device, including a heat insulation shell 1, two opening and closing doors 2 are rotatably connected to the front side of the heat insulation shell 1, and the inner wall of the heat insulation shell 1 is provided with As for the discharging mechanism, a heat shield 3 is fixedly connected to the inner wall of the heat insulation shell 1, and a heat feeder 4 is fixedly connected to the right side wall of the heat shield 3, and the bottom of the heat feeder 4 is connected to a device for uniformly transporting heat to the discharge mechanism. In the heat transfer mechanism, the rear end of the heat sending machine 4 is fixedly connected with an air inlet pipe 5, and the inside of the heat shield 3 is fixedly connected with a return pipe 6, and the return pipe 6 is fixedly connected with a fan 7, and the fan 7 is fixedly connected to the inner wall of the heat ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com