Quantitative pump hydraulic control system of work mechanism of underground carrying scraper

A technology of hydraulic control system and working mechanism, which is applied to mechanically driven excavators/dredgers, mechanical equipment, fluid pressure actuators, etc., to achieve the effects of reducing mining costs, solving excessive energy consumption, and improving traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

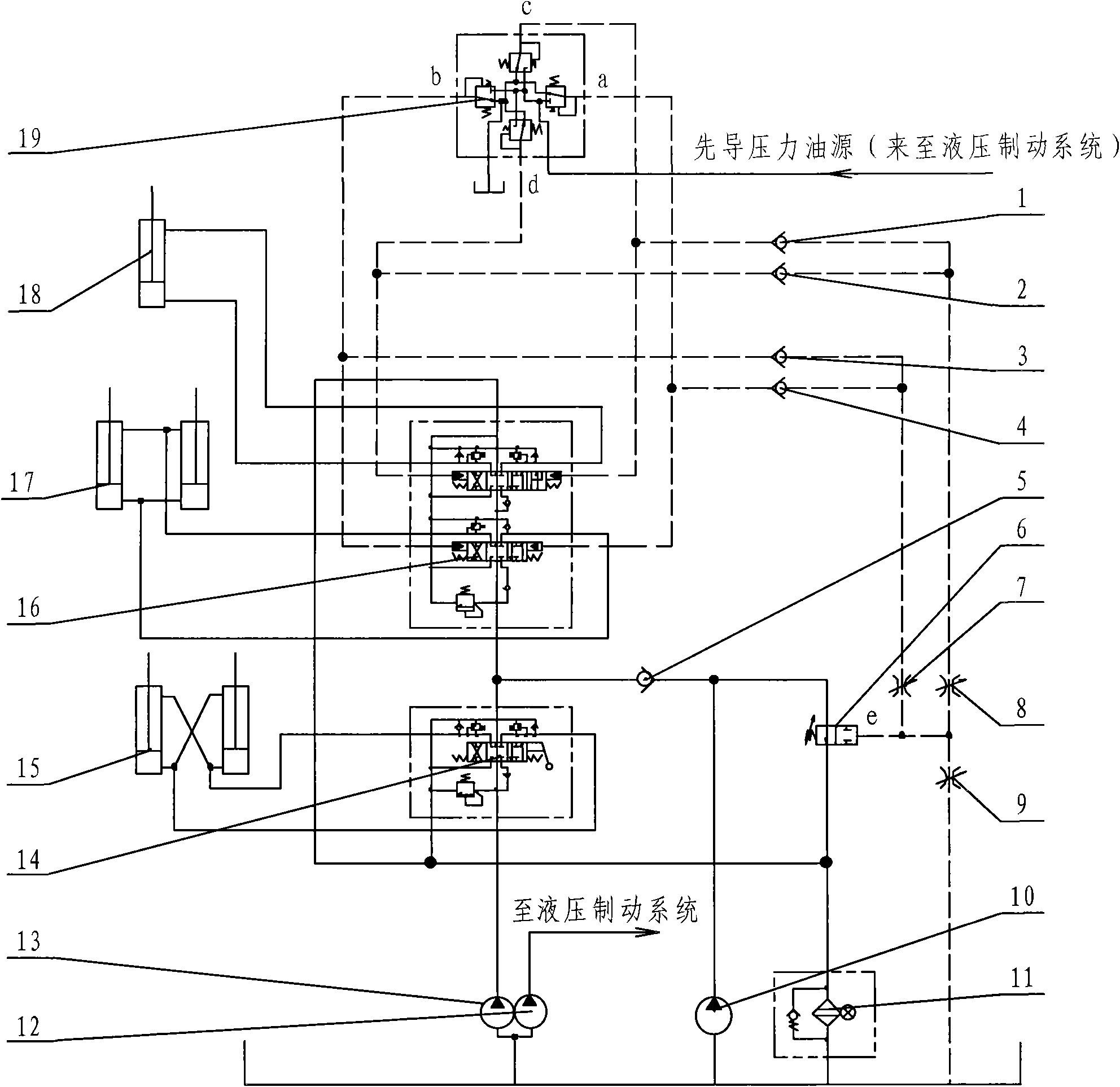

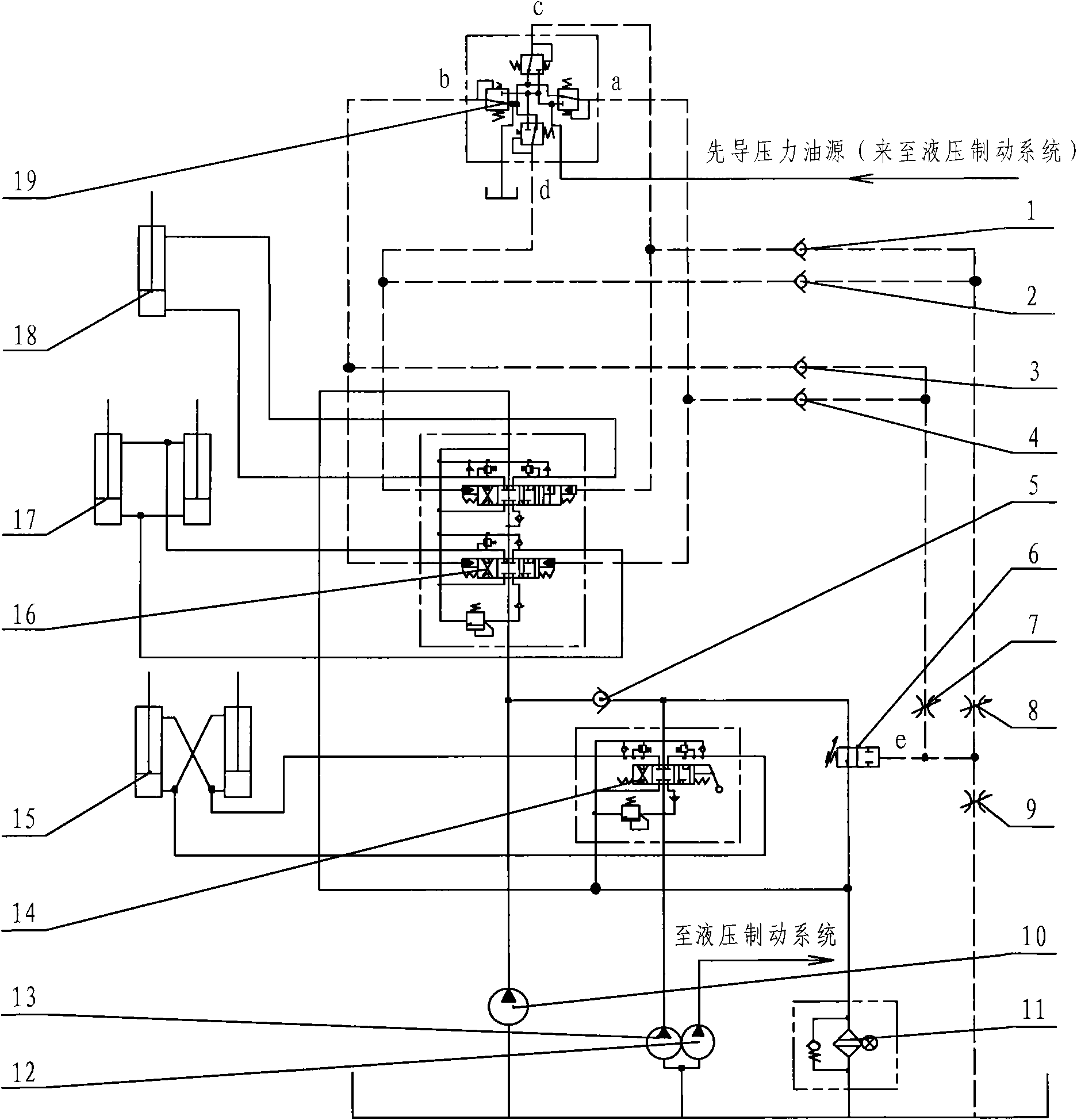

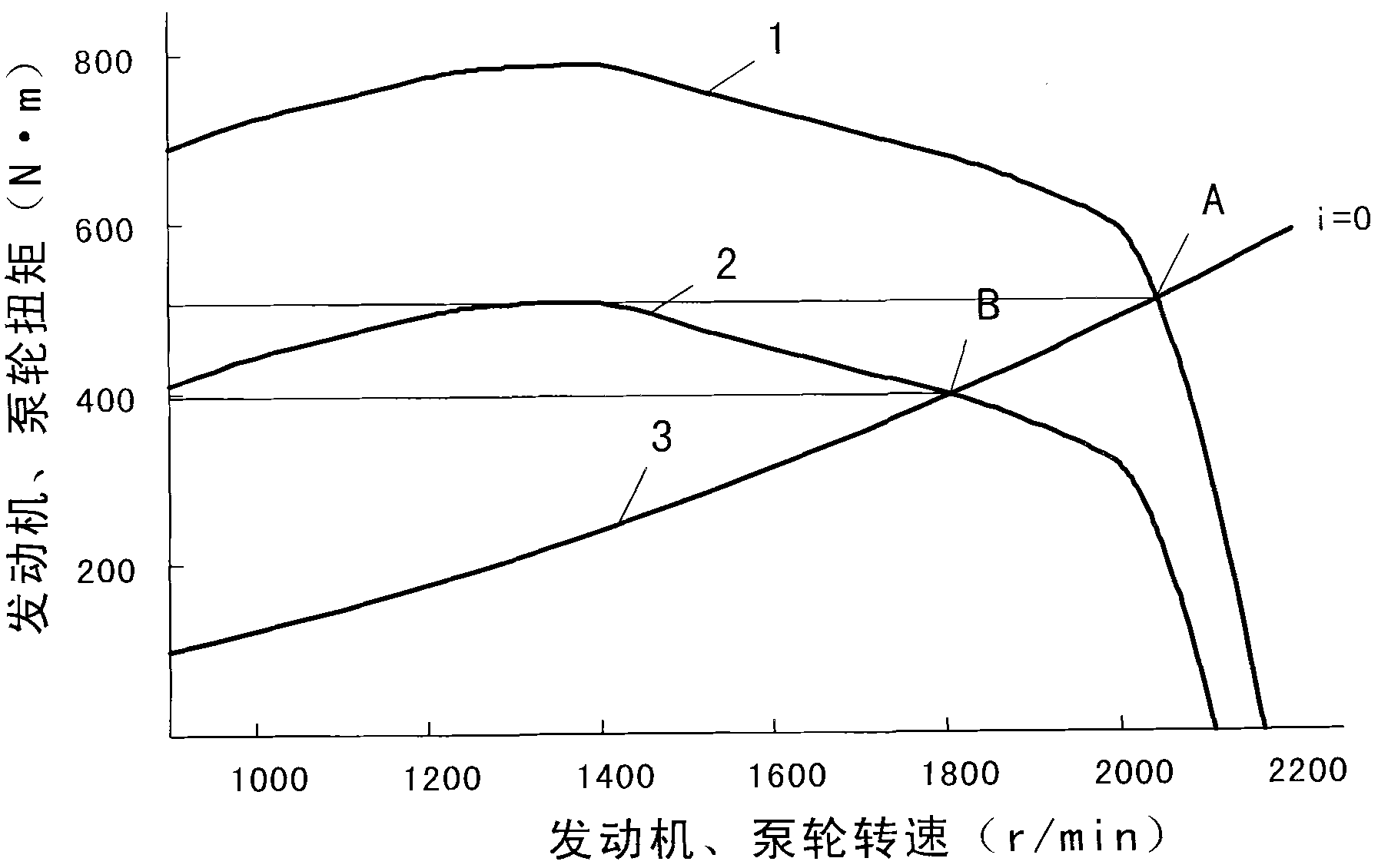

[0019] The quantitative pump hydraulic control system of the underground scraper working mechanism of the present invention, its preferred embodiment is:

[0020] It includes a steering oil pump, a steering multi-way valve, a working oil pump, a working multi-way valve, and a pilot valve. There are multiple control oil circuits between the pilot valve and the working multi-way valve. The outlet oil circuit of the steering oil pump It is connected with the inlet oil circuit of the steering multi-way valve, and the middle outlet oil circuit of the steering multi-way valve and the outlet oil circuit of the working oil pump are combined into one oil circuit and connected with the inlet oil circuit of the working multi-way valve ;

[0021] The middle outlet oil circuit of the steering multi-way valve or the outlet oil circuit of the working oil pump is provided with a pressure relief bypass, and a hydraulically controlled two-position two-way valve is arranged on the pressure relie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com