A centrifugal compressor or air blower for high speed motor

A technology of centrifugal compressors and high-speed motors, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of high energy consumption and achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

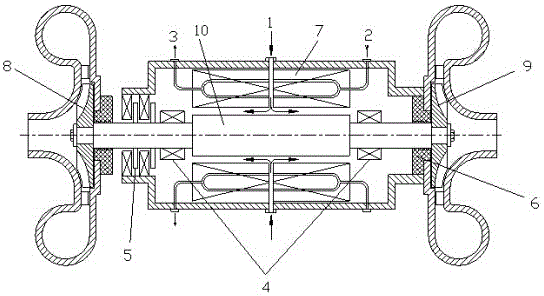

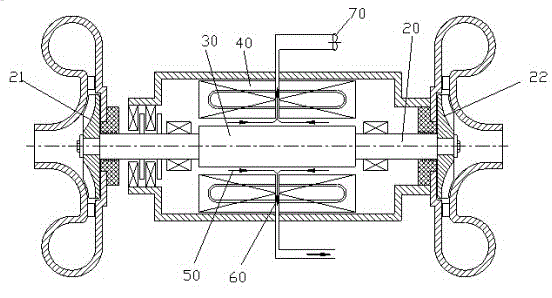

[0020] see figure 2 , the two ends of the rotor shaft 20 are respectively provided with the impeller 21 and the impeller 22, and the middle position is the motor rotor 30.

[0021] The air shown at 50 is inhaled from the atmosphere, from both ends of the motor rotor 30, the negative pressure cooling air 60 passes through the stator 40 through the middle position, is discharged through the vacuum pump 70 or the air injector, and released into the atmosphere. figure 2 As shown, the lower exhaust channel communicates with the upper exhaust channel and shares a vacuum pump 70 .

[0022] and figure 1 Compared with the cooling air pressure is low, the air friction loss is less, which can improve the overall efficiency.

Embodiment 2

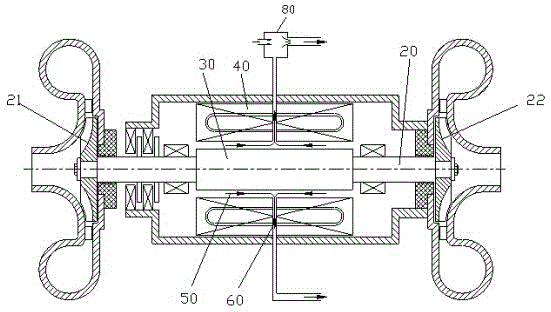

[0024] see image 3 ,and figure 2 The difference is that the air is exhausted by the air jet vacuum pump 80 and released into the atmosphere. image 3 In the figure shown, the lower exhaust channel communicates with the upper exhaust channel and shares a common space. Gas injector 80.

[0025] see Figure 4 , a blower for a high-speed motor, the impeller 21 is directly connected to the high-speed motor 23, the air shown at 50 is sucked from the atmosphere, sucked from both ends of the motor rotor 30, the negative pressure cooling air 60 passes through the stator 40 through the middle position, and passes through the vacuum pump or Air ejector exhaust, release to atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com