Gas converting method and system

A gas conversion and gas technology, applied in the field of gas conversion methods and systems, can solve the problems of restricting the application of liquefied gas, unfavorable sustainable economic development of the liquefaction industry, and large energy consumption, so as to improve energy utilization, improve liquefaction efficiency, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

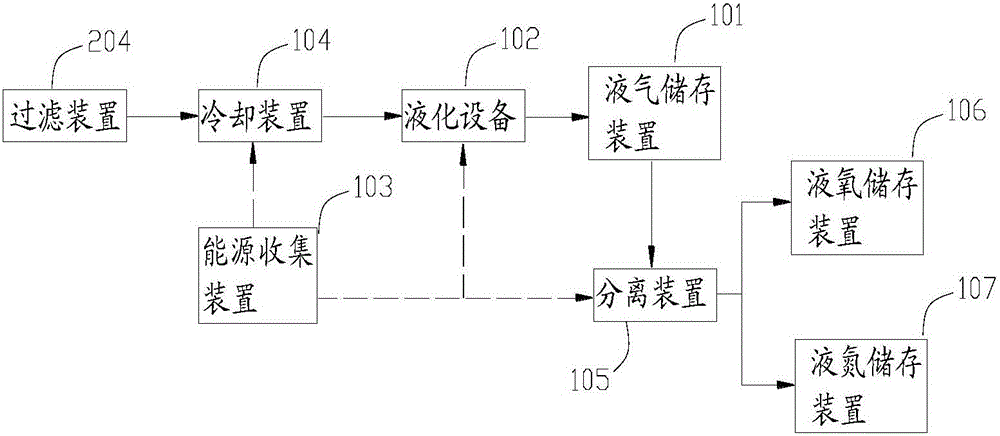

[0058] Such as figure 1 As shown, in the first embodiment, the gas conversion system of the present invention can also include a separation device 105, which can be communicated with the liquid gas outlet of the liquefaction device 102, and the outlet is communicated with the liquid gas storage device 101, and then the The substances to be separated are introduced into the separation device 105, from which liquid nitrogen and liquid oxygen are separated; meanwhile, the separation device 105 is also provided with a liquid oxygen outlet and a liquid nitrogen outlet for outputting liquid nitrogen and liquid oxygen.

[0059] In order to realize the separate storage of liquid nitrogen and liquid oxygen, a liquid oxygen storage device 106 and a liquid nitrogen storage device 107 can also be provided, wherein the liquid oxygen storage device 106 is connected with the liquid oxygen outlet of the separation device 105, and the liquid nitrogen storage device 107 is connected with the sep...

Embodiment 2

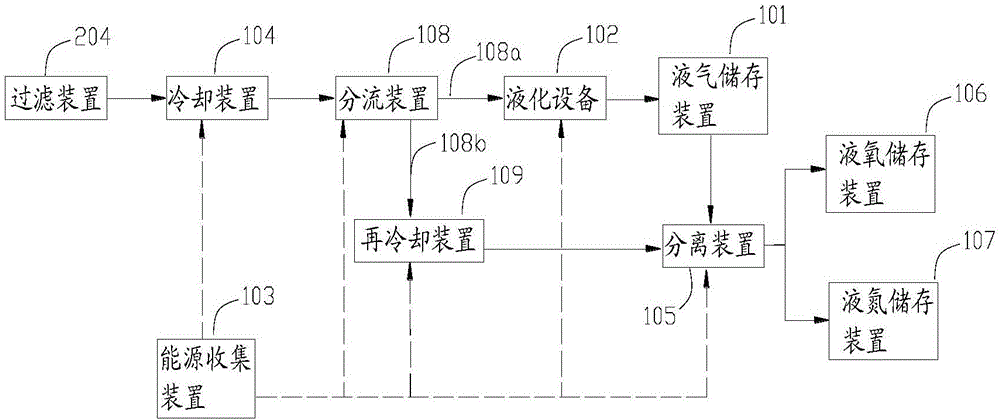

[0070] Such as figure 2 As shown, in the second embodiment, the liquefaction equipment 102 is a cryogenic device. Specifically, the separation device 105 can also be integrated with the cryogenic device, so as to separate liquid oxygen and liquid nitrogen while liquefying low-temperature air, that is At this time, the liquefaction equipment 102 is a cryogenic device with a separation function, which can directly liquefy and separate liquid oxygen and liquid nitrogen.

[0071] Compared with Embodiment 1, this embodiment can directly separate liquid oxygen and liquid nitrogen during liquefaction, which improves efficiency, and does not require a liquid-gas storage device 101, which reduces costs and saves storage space.

[0072] Specifically, the temperature of the cryogenic device can be controlled to achieve liquefaction of air. During the liquefaction process, the difference in liquefaction temperature of oxygen and nitrogen can be used to separate liquid oxygen and liquid n...

Embodiment 3

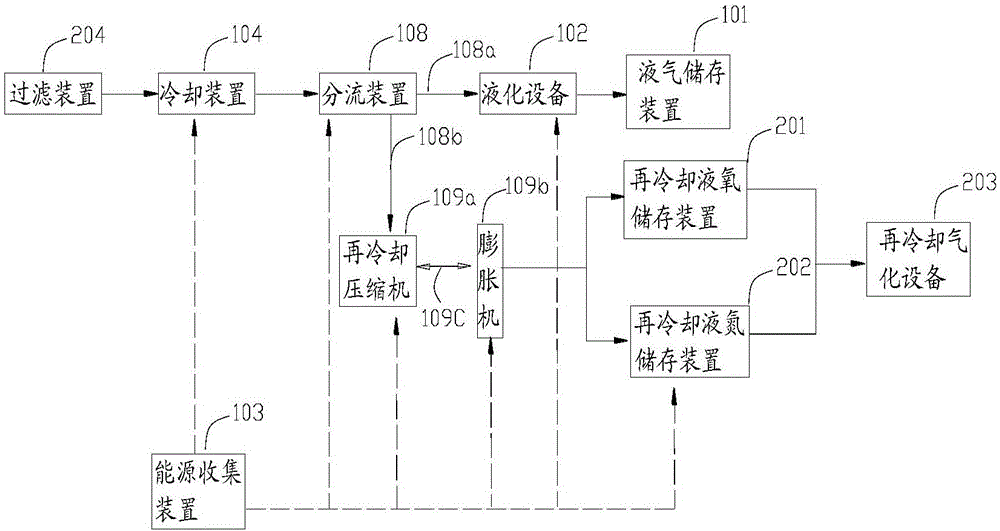

[0076] Such as image 3 As shown, in the third embodiment, a circulation air channel 109c can be provided between the expander 109b and the recooling compressor 109a to recool the low-temperature air circulation, and part of the liquid oxygen and part of liquid nitrogen; the recooling device 109 can be respectively provided with an output port for outputting liquid oxygen and an output port for outputting liquid nitrogen, and then the liquid oxygen and liquid nitrogen obtained by recooling are transported to the re-cooling system respectively through the delivery pipeline. The liquid oxygen storage device 201 is cooled and the liquid nitrogen storage device 202 is subcooled.

[0077] At the same time, the present invention may also include a subcooling gasification device 203 communicated with at least one of the subcooling liquid oxygen storage device 201 and the subcooling liquid nitrogen storage device 202, for recooling the obtained liquid oxygen and / or The liquid nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com