Plant plastic and preparation method thereof

A technology of plastics and plants, which is applied in the field of artificial microstructure materials, ecological materials and their preparation, can solve the problems such as the difficulty in realizing the strong interaction between plant microfibers, and achieve the effects of low cost, increased productivity, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

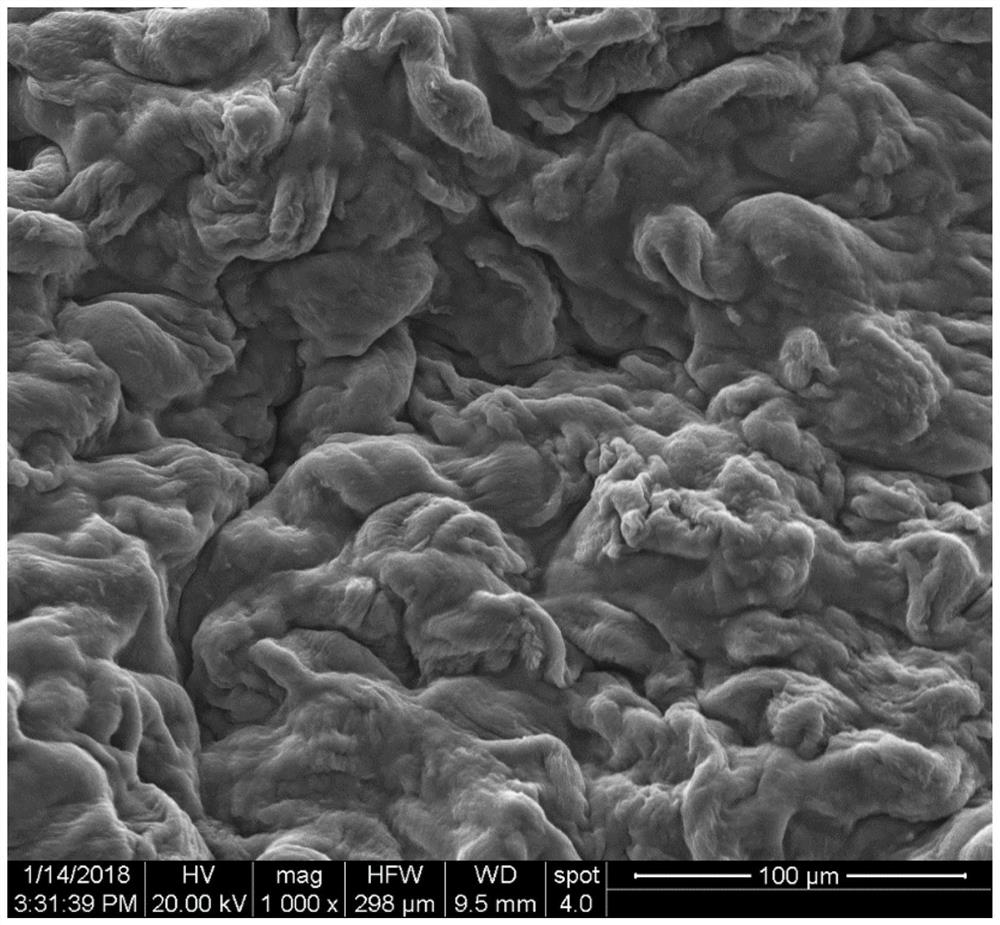

[0029] Mix 10g of cellulose fibers derived from cotton with 7% NaOH and 12% urea aqueous solution, and fully stir evenly. The required volume of sodium hydroxide urea aqueous solution is 100ml, and take it out after freezing at -18°C for 1 hour. The shape changes from straight to distorted, the surface of the fiber is slightly dissolved, and the fresh surface is exposed. After taking it out, it is immersed in dilute hydrochloric acid for 10 hours, and then washed with deionized water for many times, and then the washed sample is dried. During the process of dehydration, the fiber Actively shrink to form a dense structure, and finally get a new plant plastic material. Its scanning electron microscope picture is as figure 1 As shown in the figure, the plant plastic is composed of micron-scale plant fibers, which are bent, deformed and tightly wound to form a very dense structure.

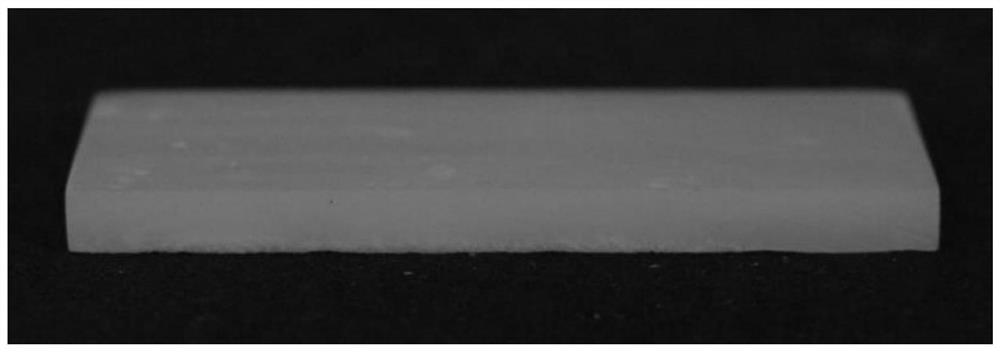

[0030] From figure 2 It can be seen that the plant plastic (white block) of this embodiment is ...

Embodiment 2

[0032] Mix 8g of cellulose fibers derived from wood with 7% NaOH and 12% urea aqueous solution, and stir well, the volume of the required aqueous solution is 100ml, and the resulting mixed system is frozen at -13°C for 3 hours, and the fiber shape From straight to distorted, the surface of the fiber is slightly dissolved to reveal a fresh surface. After taking it out, it is immersed in dilute sulfuric acid for 72 hours, then cleaned with deionized water, and then the washed sample is dried. During the process of dehydration, the fiber actively shrinks. A dense structure is formed and finally plant plastics are obtained.

Embodiment 3

[0034] Mix 10g of cellulose fibers derived from rice straw with lithium chloride / DMAc=8g:100ml solution, react at a temperature of 140°C for 30min, then let the resulting mixed system stand for 10 hours, the surface of the cellulose is slightly dissolved, exposing the fresh The surface was washed several times with deionized water, and then the washed samples were dried to obtain plant plastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com