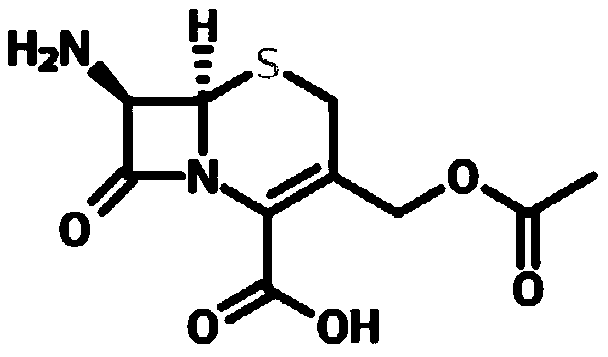

Preparation method of 7-aminocephalosporanic acid

A technology of aminocephalosporanic acid and cephalosporins, applied in organic chemistry, fermentation, etc., can solve problems such as easy blockage of membrane pores, waste acid water and resin regeneration waste liquid, and inability to perform ultrafiltration, so as to improve quality and reduce Impurities, drug safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Get 4.5L cephalosporin C fermentation liquid, pH is 4.53, contains about 25g / L cephalosporin C (supernatant liquid), uses the sulfuric acid of 15% (v / v) to adjust pH to 2.50, then at 5 ℃~10 Under the condition of ℃, after filtering through 50nm ceramic membrane and 20KD ultrafiltration membrane, 5.6L filtrate (including ceramic membrane top wash water) was obtained, the concentration of cephalosporin C was 7.14g / L, and the light transmittance at 425nm wavelength was 77%.

[0038] Add 16.8L of ethyl acetate pre-cooled to 5-10°C to the filtrate, mix thoroughly, and collect 16.3L of the light phase after standing and layering, the concentration of cephalosporin C is 2.40g / L; then, at about 5°C, add 1421mL of 1wt% sodium bicarbonate aqueous solution dropwise at a constant speed within 20min, let stand for 10min to collect the heavy phase in layers after the addition, and obtain 1450mL of cephalosporin C sodium salt solution after vacuum distillation and deesterification. T...

Embodiment 2

[0041] Take 4.5L cephalosporin C fermentation liquid, pH is 4.66, contains about 27g / L cephalosporin C (supernatant liquid), uses the sulfuric acid of 15% (v / v) to adjust pH to 3.50, then in 5 ℃~10 Under the condition of ℃, after filtering through 100nm ceramic membrane and 50KD ultrafiltration membrane, 6.0L filtrate (including ceramic membrane top wash water) was obtained, the concentration of cephalosporin C was 7.53g / L, and the light transmittance at 425nm wavelength was 65%.

[0042] Add 18.0L of ethyl acetate that has been pre-cooled to 5-10°C to the filtrate, mix well, and collect 17.3L of the light phase after standing and layering. The concentration of cephalosporin C is 2.45g / L; then, at about 5°C, add 1436mL of 1wt% sodium bicarbonate aqueous solution dropwise at a constant speed within 20min, and let stand for 10min to separate and collect the heavy phase after the feeding is completed, and obtain 1470mL of cephalosporin C sodium salt solution after vacuum distilla...

Embodiment 3

[0045] Get 4.5L cephalosporin C fermented liquid, pH is 4.59, contains about 22g / L cephalosporin C (supernatant liquid), uses the sulfuric acid of 15% (v / v) to adjust pH to 3.00, then at 5 ℃~10 Under the condition of ℃, after filtering through 50nm ceramic membrane and 30KD ultrafiltration membrane, 5.7L filtrate (including ceramic membrane top wash water) was obtained, the concentration of cephalosporin C was 7.33g / L, and the light transmittance at 425nm wavelength was 72%.

[0046] Add 17.1L of ethyl acetate that has been pre-cooled to 5-10°C to the filtrate, mix well, and collect 16.7L of the light phase after standing and layering, the concentration of cephalosporin C is 2.43g / L; then within 20min Add 1434mL of 1wt% sodium bicarbonate aqueous solution dropwise at a constant speed, let stand for 10min to separate and collect the heavy phase after the addition, and obtain 1465mL of cephalosporin C sodium salt solution after vacuum distillation and deesterification, the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com