Water level sensor as well as water container and beverage dispenser comprising same

A water level sensor and water container technology, applied in beverage preparation devices, liquid level indicators for physical variable measurement, household appliances, etc., can solve the problems of short life, failure, and high cost of use, and achieve low cost, long life, and circuit simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

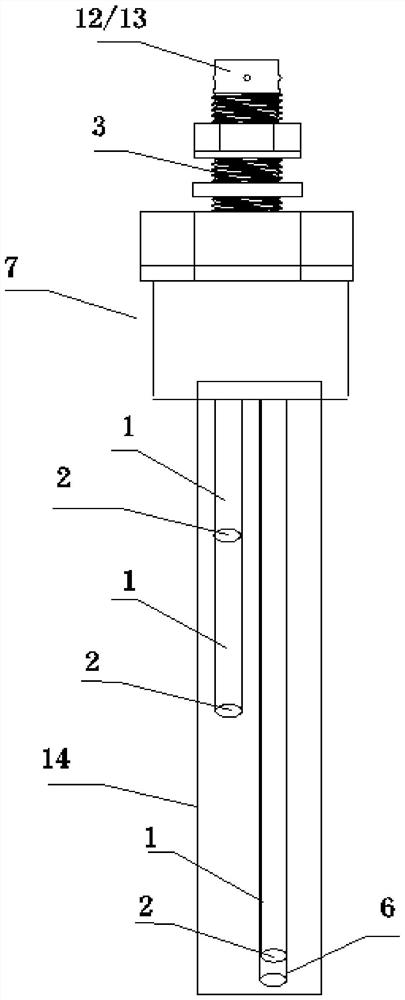

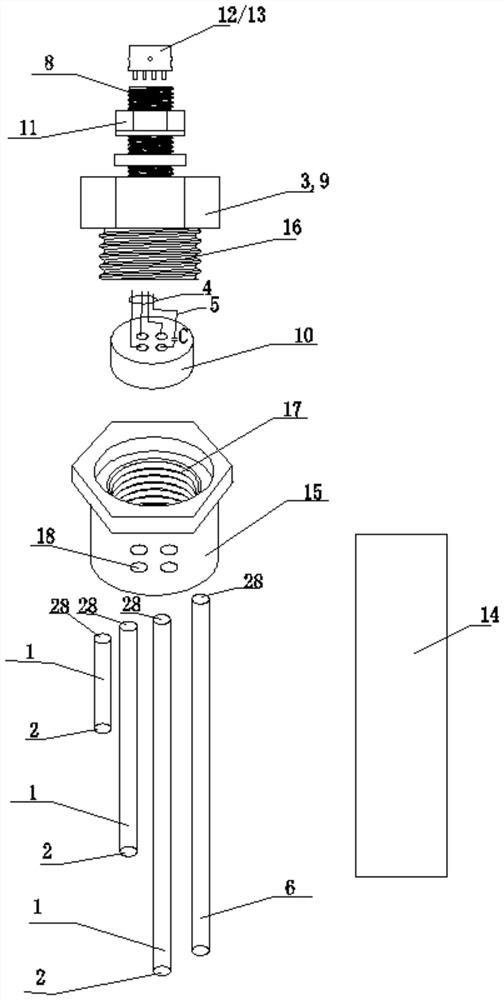

[0033] Example 1: A water level sensor, such as figure 1 , 2 As shown, it includes 3 metal electrodes. One end of each metal electrode is exposed as the detection terminal 2, and the other end 28 is fixed in an insulating fixing member 3, and is connected to the signal output wiring harness 4 in the insulating fixing member 3. The signal output wiring harness 4 is further composed of an aviation connector. The core connector 12 is connected to realize a wired connection with an external controller. Or, the other end 28 is connected to a radio frequency wireless communication device 13 based on a SoC computer system on a chip (such as Zigbee) for realizing a wireless connection with an external controller.

[0034] The whole metal electrode, including its detection end 2, is made of a stainless steel rod of 1-6 mm; or only the detection end 2 is made of stainless steel rod or block or tube, and the rest is made of copper wire.

[0035] The metal electrode 1 of the present invention...

Embodiment 2

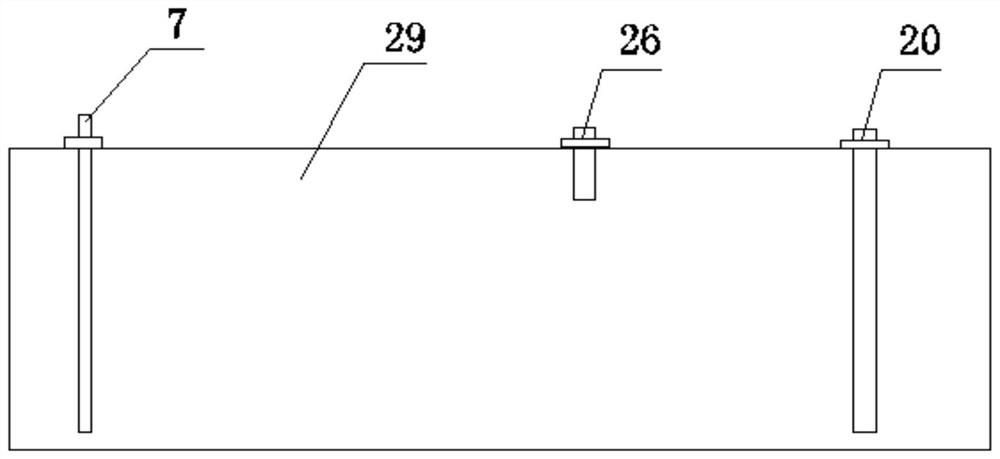

[0048] A container with a water level measurement and control device formed by using the above-mentioned water level sensor 7: The above-mentioned water level sensor 7 is installed on the top or upper side of the water container 29.

Embodiment 3

[0050] The beverage machine with a liquid level measurement and control device composed of the above-mentioned water level sensor 7 includes 12 beverage boxes 19 in 3 rows and 4 rows. A water level sensor 7 is installed on the top or upper side of the beverage box 19, and a liquid outlet 20 is connected to the beverage box 19.

[0051] There are 12 beverage boxes 19 in 3 rows and 4 columns, which are arranged horizontally and vertically in the freezer 21. The electronically controlled liquid outlet device 23 controls each liquid outlet 20 to output selected beverages with different tastes.

[0052] Each beverage box 19 is provided with a solid beverage mixing and / or homogenizing device 22, which can stir, mix and homogenize the newly added solid or concentrated liquid beverage (such as tea powder, concentrated juice, etc.).

[0053] A self-priming pump 24 is connected to each liquid outlet 20 for extracting the beverage in the beverage box 19. The liquid outlet 25 of the self-primin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com