Method for recovering selenium from acid mud wastes of acid production with copper smelting smoke

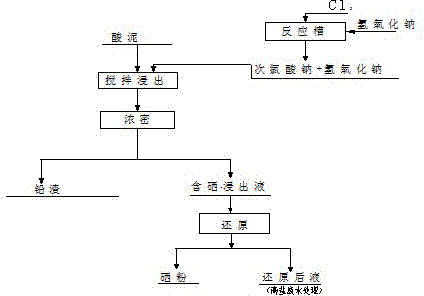

A recovery method and copper smelting technology, which is applied in the field of selenium recovery from copper smelting flue gas acid mud waste, can solve the problems of no extraction process, high leaching temperature, large equipment investment, etc., and achieve low production cost and smooth production process. Simple, high metal recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Chemical weight composition of acid mud: selenium 0.2%, lead 50%, arsenic 0.01%, bismuth 0.1%, sulfur and oxygen, carbon 50%.

[0021] Acid mud or acid mud after extracting bismuth and arsenic, add sodium hypochlorite and sodium hydroxide solution, the concentration of sodium hypochlorite solution is 8%, sodium hydroxide is 2%, the liquid-solid ratio is 15:1, and the reaction is stirred for 1.5h, and the reaction temperature is 50°C. The selenium-containing liquid is obtained by filtration, the selenium-containing liquid is combined with the existing selenium powder production process, and relatively pure lead slag is obtained after leaching.

[0022] The lead slag after deselenization is sent to the precious metal factory to recover lead and precious metals. The chemical composition of lead slag after deselenization: lead 76.88%, selenium 0.015%, arsenic 0.04%, bismuth 0.13%, silver 0.0025%, sulfur, oxygen, chlorine, sodium 23%.

Embodiment 2

[0024] Chemical weight composition of acid mud: Selenium 2%, Lead 70%, Arsenic 0.05%, Bismuth 0.5%, Sulfur and Oxygen, Carbon 27%.

[0025] Acid mud or acid mud after extracting bismuth and arsenic, add sodium hypochlorite and sodium hydroxide solution, the concentration of sodium hypochlorite solution is 12%, sodium hydroxide is 1.5%, the liquid-solid ratio is 20:1, the reaction is stirred for 1.0h, and the reaction temperature is 80°C. The selenium-containing liquid is obtained by filtration, the selenium-containing liquid is combined with the existing selenium powder production process, and relatively pure lead slag is obtained after leaching.

[0026] The lead slag after deselenization is sent to the precious metal factory to recover lead and precious metals. The chemical composition of lead slag after deselenization: lead 74.25%, selenium 0.04%, arsenic 0.02%, bismuth 0.17%, silver 0.0015%, sulfur, oxygen, chlorine, sodium 25.5%.

Embodiment 3

[0028] Chemical weight composition of acid mud: Selenium 1%, Lead 60%, Arsenic 0.05%, Bismuth 0.3%, Sulfur and Oxygen, Carbon 39%.

[0029] Acid mud or acid mud after extracting bismuth and arsenic, add sodium hypochlorite and sodium hydroxide solution, the concentration of sodium hypochlorite solution is 4%, sodium hydroxide is 4%, the liquid-solid ratio is 10:1, and the reaction is stirred for 0.5h, and the reaction temperature is 60°C. The selenium-containing liquid is obtained by filtration, the selenium-containing liquid is combined with the existing selenium powder production process, and relatively pure lead slag is obtained after leaching.

[0030] The lead slag after deselenization is sent to the precious metal factory to recover lead and precious metals. The chemical composition of lead slag after deselenization: lead 78.5%, selenium 0.15%, arsenic 0.04%, bismuth 0.17%, silver 0.0025%, sulfur, oxygen, chlorine, sodium 21.5%.

[0031] The present invention separates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com