Patents

Literature

117results about How to "For subsequent recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

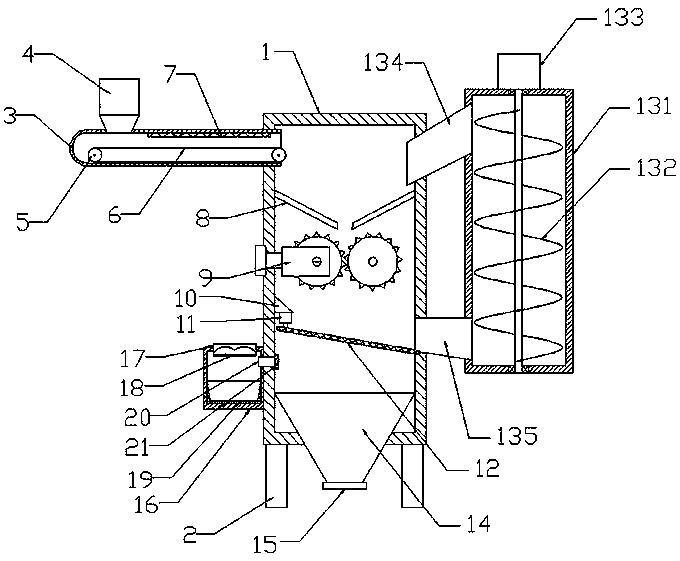

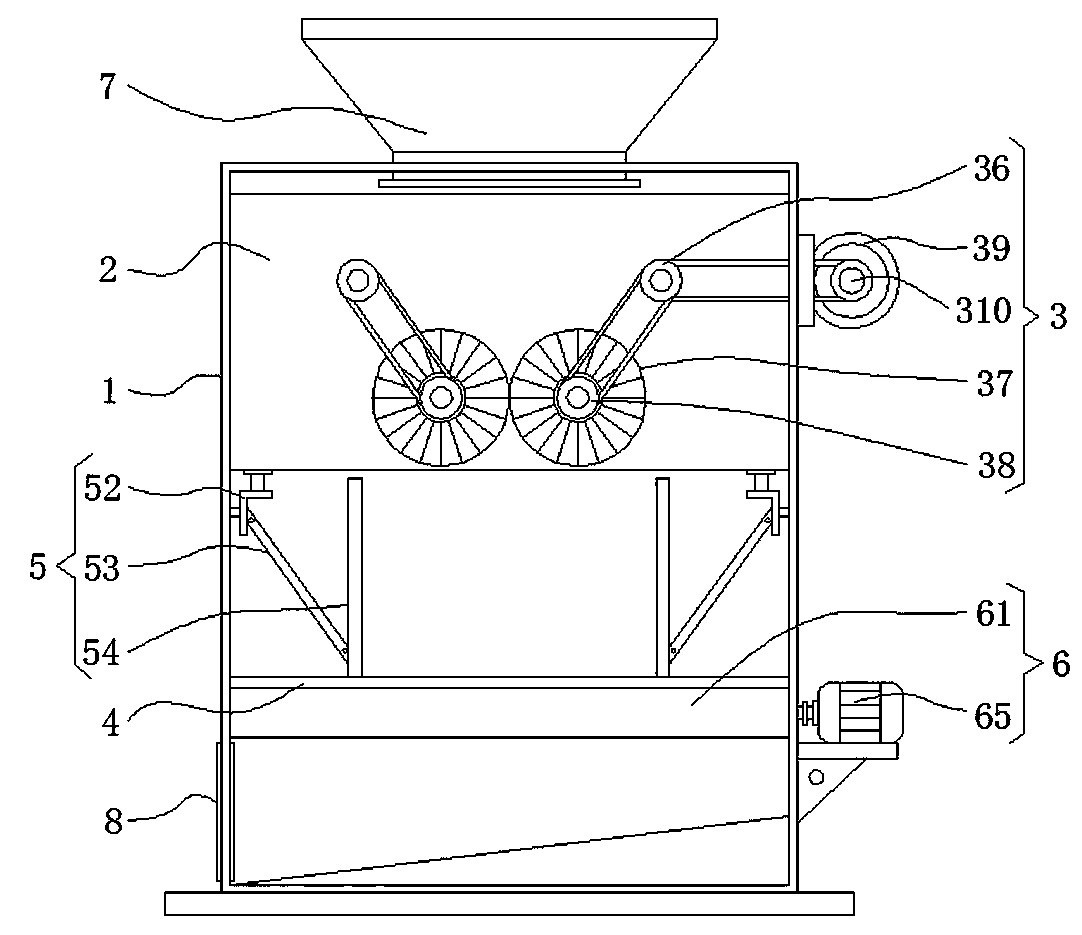

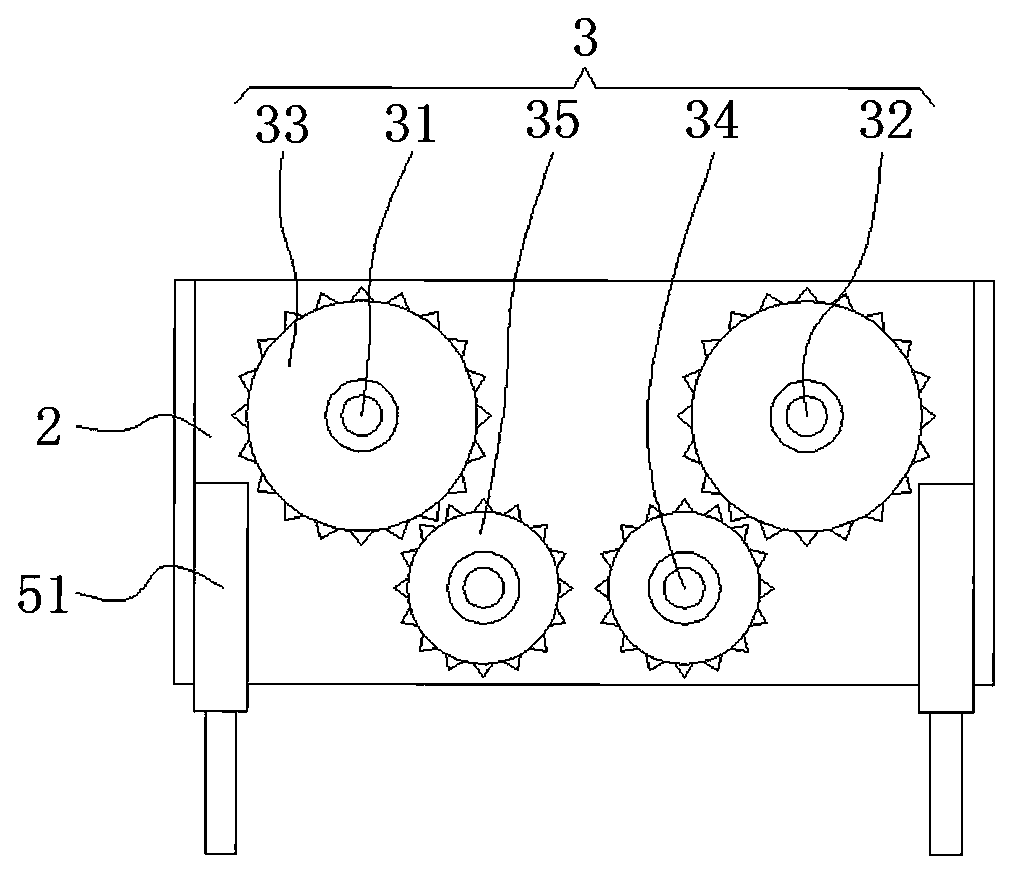

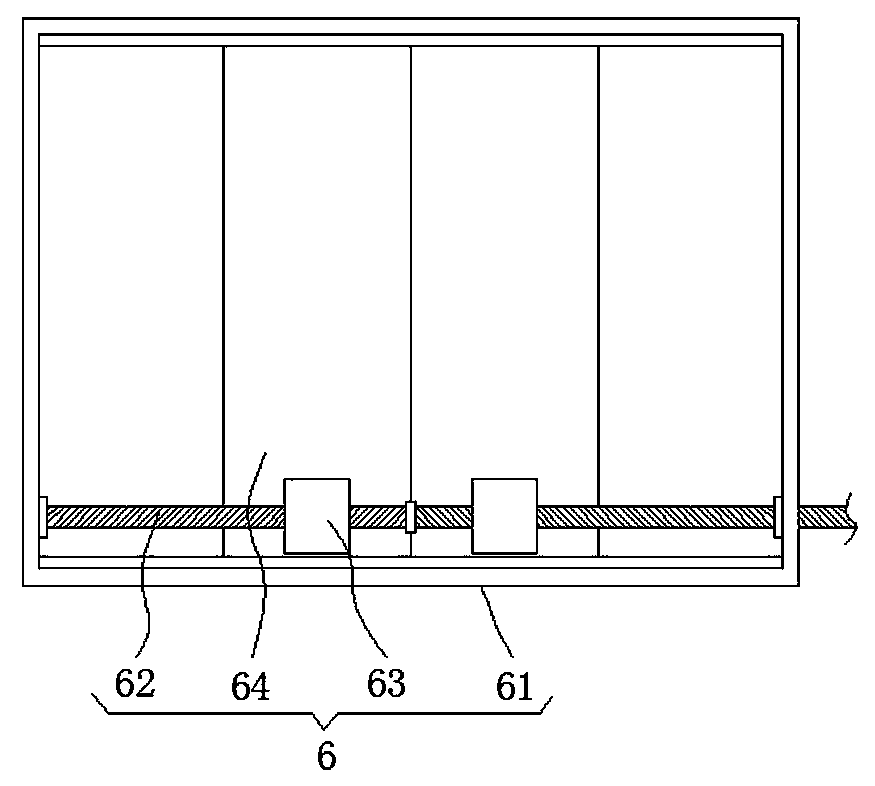

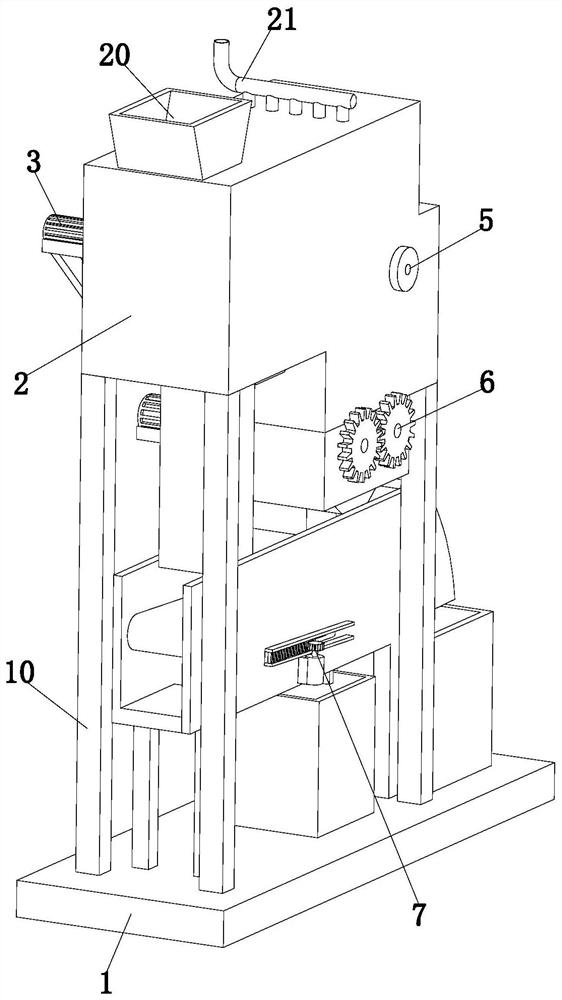

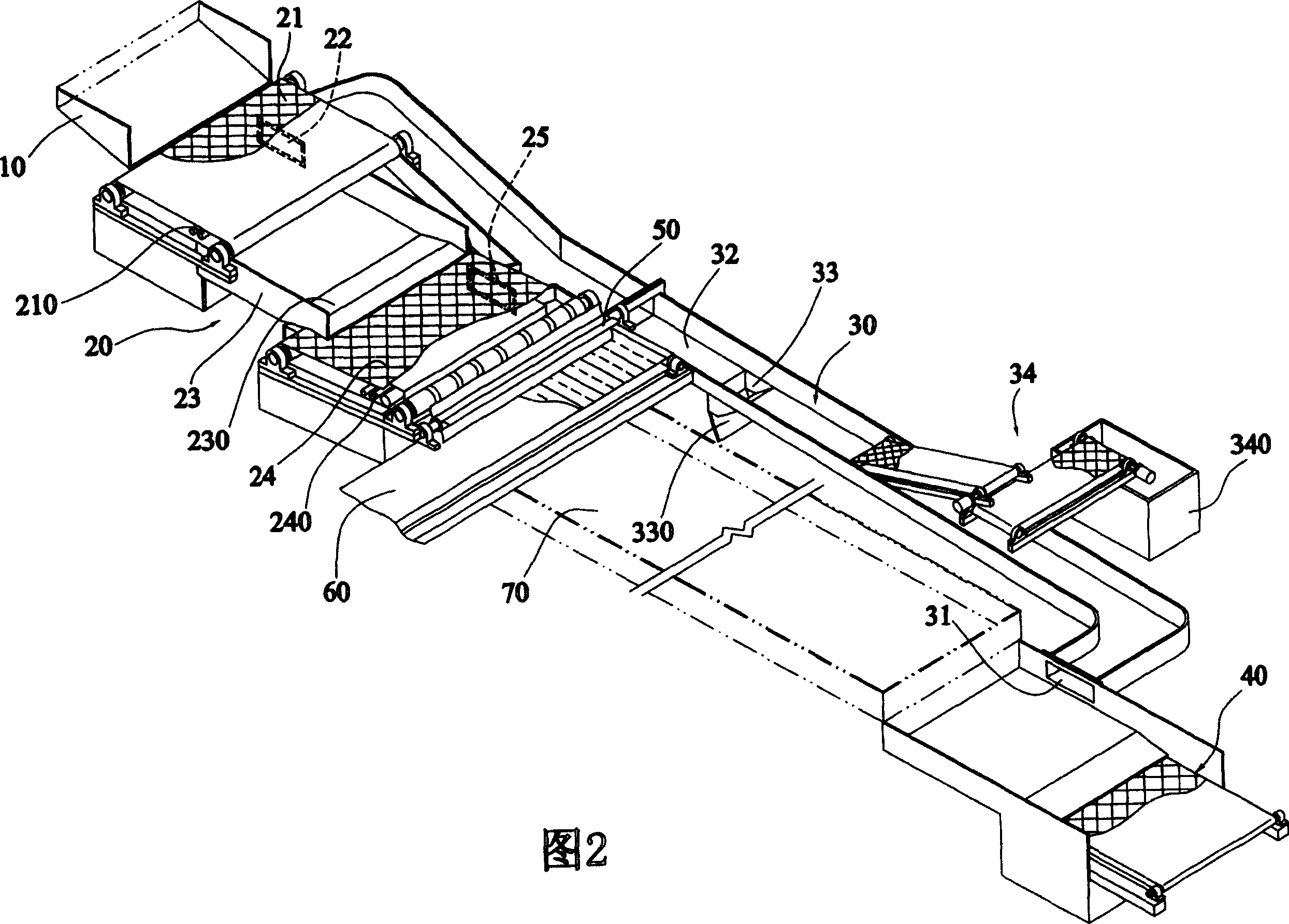

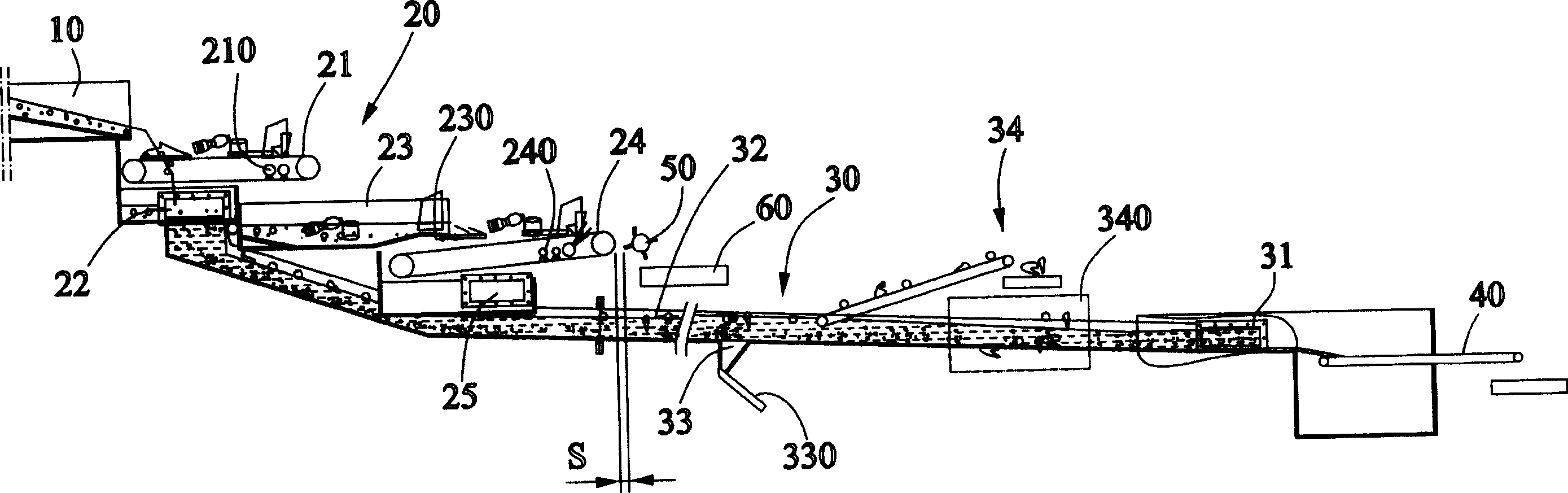

Household garbage crushing sorting system

ActiveCN104874582AThere will be no stuckStuck situation solvedSolid waste disposalGrain treatmentsSocial benefitsLitter

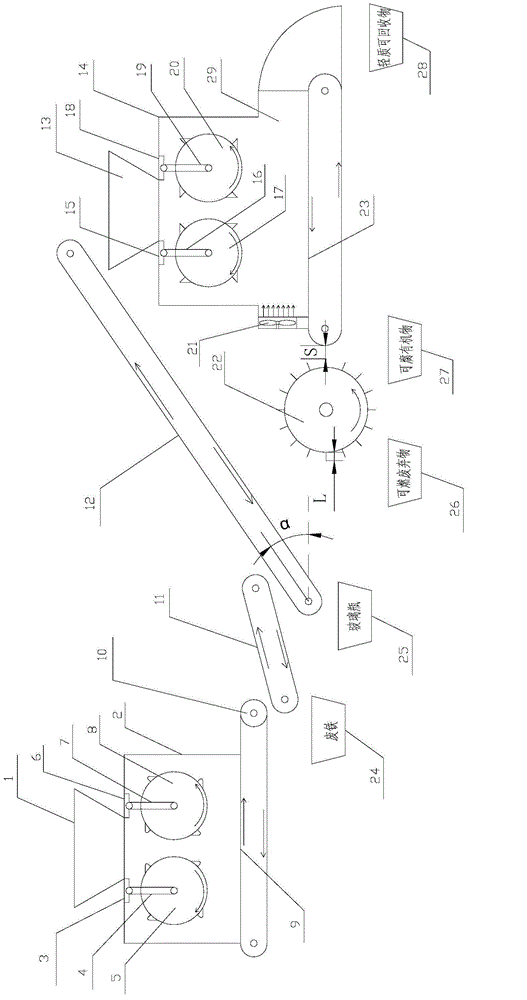

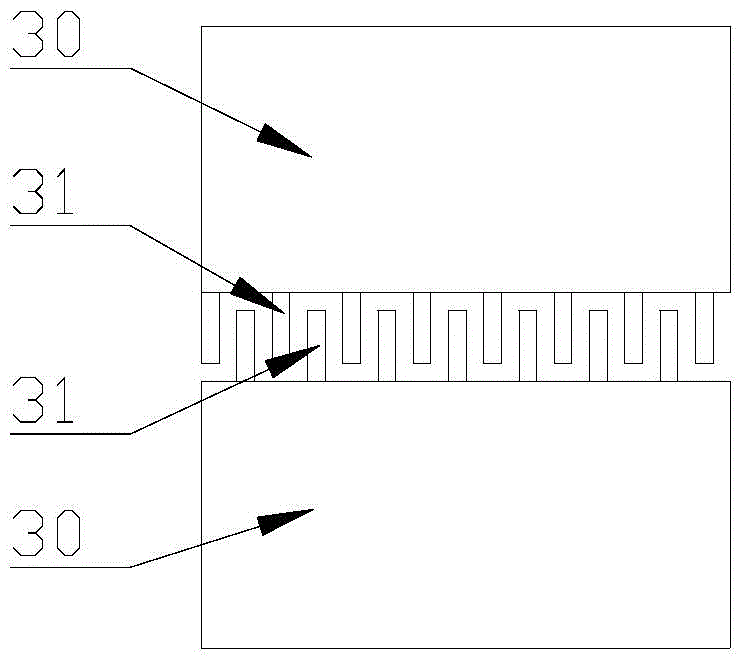

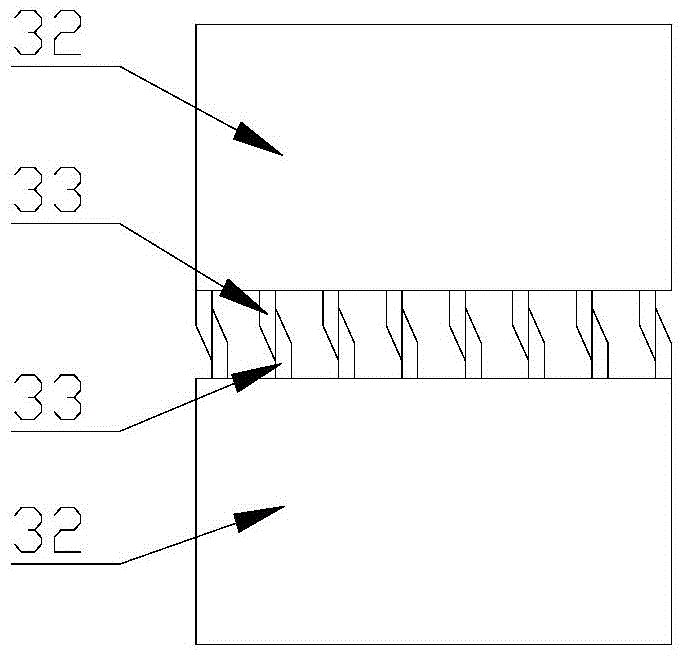

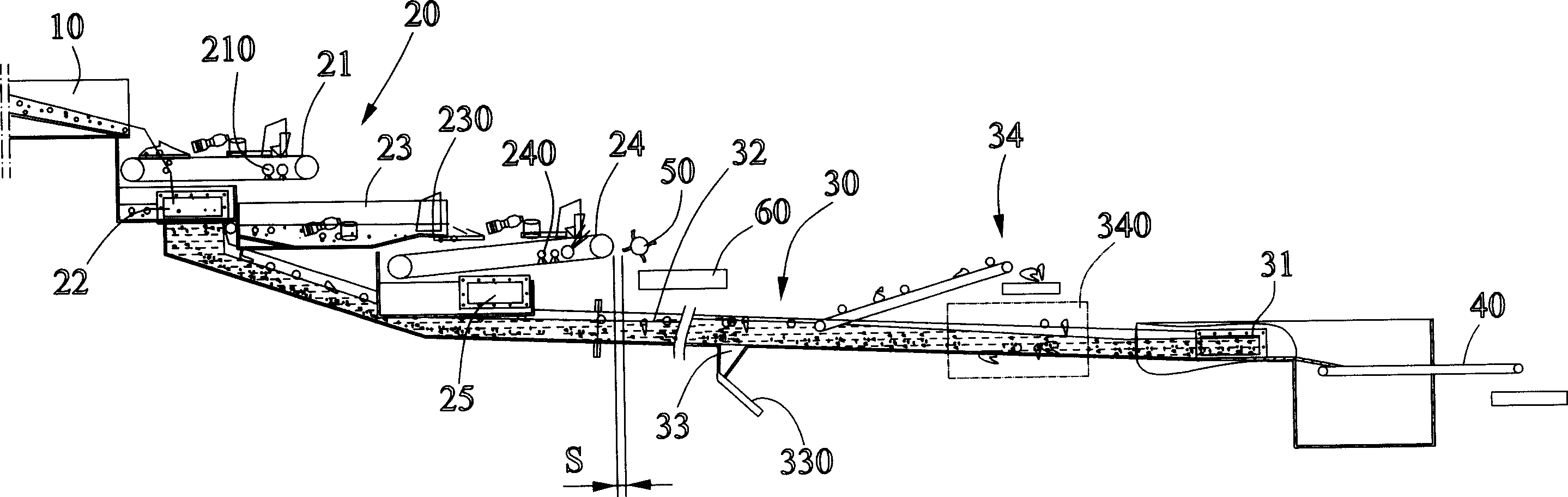

The invention discloses a household garbage crushing sorting system. The sorting system consists of a quantitative feeding device, a magnetic separation device, a gravity gradient sorting device, a pendulum type crushing device, an air separation device, a needle selection device and a material conveying device. The sorting system is compact in structure, can achieve continuous production, is high in production efficiency, simple to operate, safe and reliable, and can divide urban household garbage into decayable organic matter, combustible wastes, metal, glass and light recoverable matter, so that the urban household garbage can be sufficiently utilized as a resource, and the sorting system has very high environmental benefit and social benefit simultaneously.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

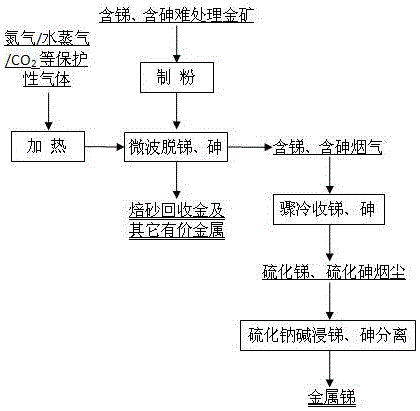

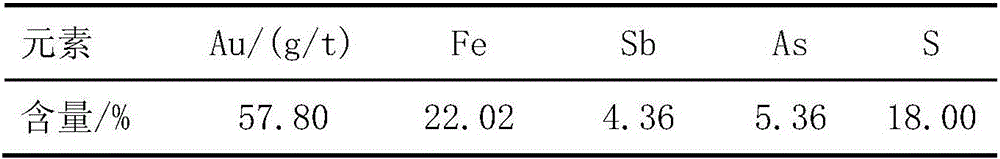

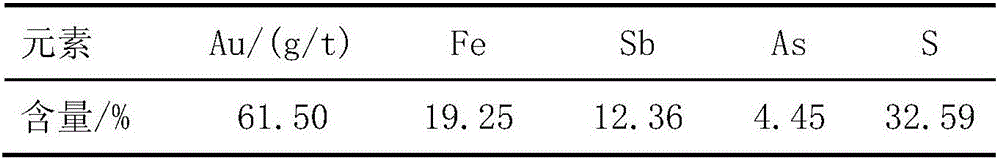

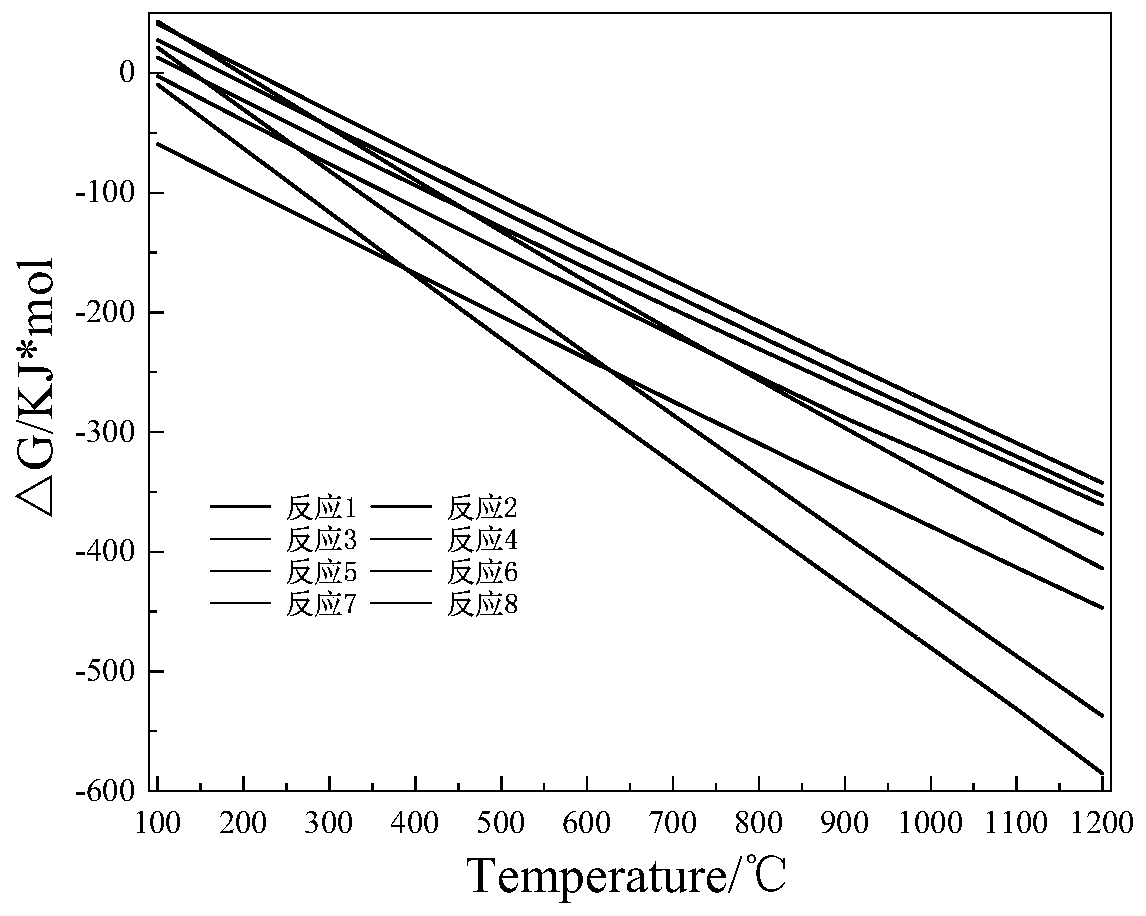

Pretreatment method for refractory gold ore with antimony and arsenic

The invention relates to the technical field of metallurgy, in particular to a pretreatment method for refractory gold ore with antimony and arsenic. The method comprises the steps that 1, the refractory gold ore with antimony and arsenic is broke and subjected to ball milling to form powder; 2, the powder obtained in the step 1 is added into a hermetic vertical pipe type heating furnace, neutral protective gas is introduced in, roasted ore is obtained after roasting and cooling are carried out, produced tail gas enters a tail gas collection device, collected smoke dust is leached through a mixed solution of Na2S with the concentration of 50-200 g / L and NaOH with the concentration of 20-100 g / L, solid-liquid separation is carried out, a filter residue with arsenic and a leaching solution with antimony are obtained, and the leaching solution is electrodeposited to produce metal antimony, wherein leaching time is 30-180 min, and leaching temperature is 20-95 DEG C. The pretreatment method has the advantages that the technological process is simple, operation is flexible, roasting time is short, energy consumption is low, antimony and arsenic can be synchronously removed, smoke gas is low in toxicity and small in amount, and economic and social benefits are good.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

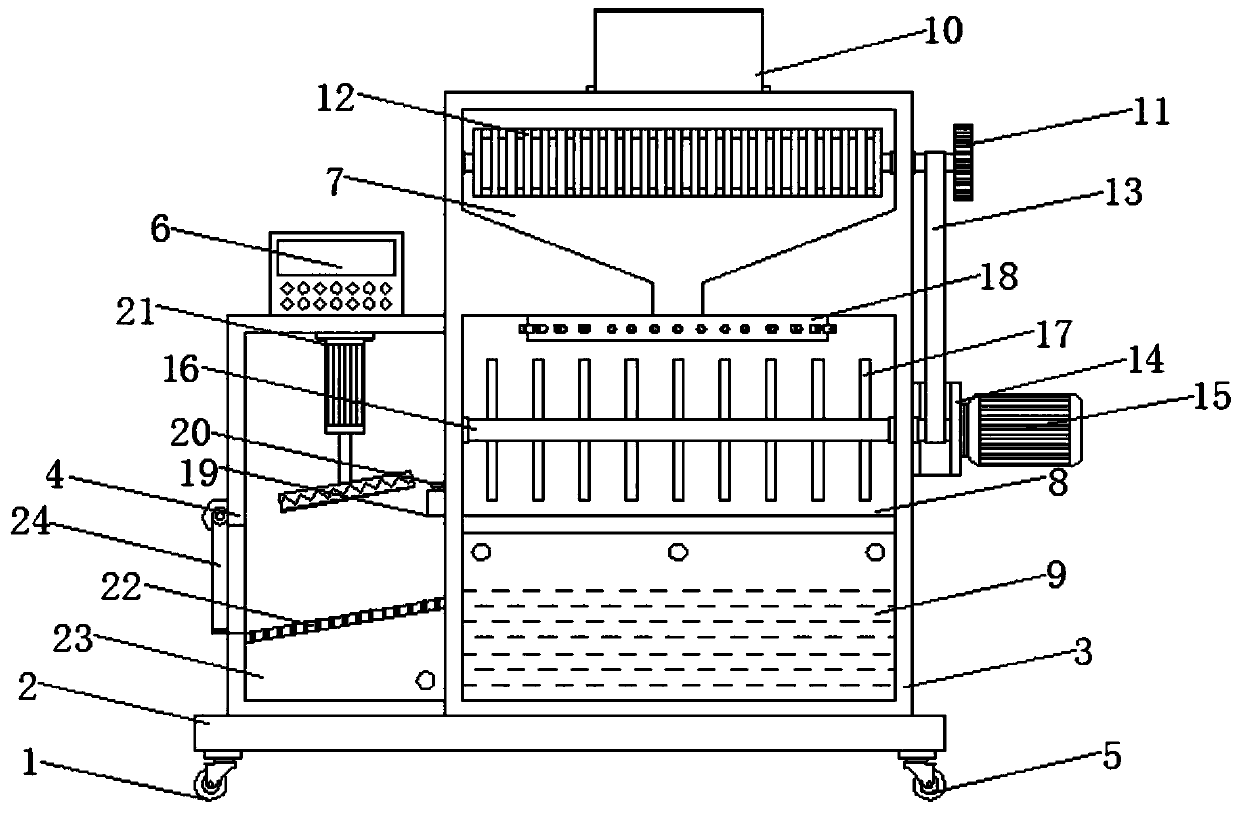

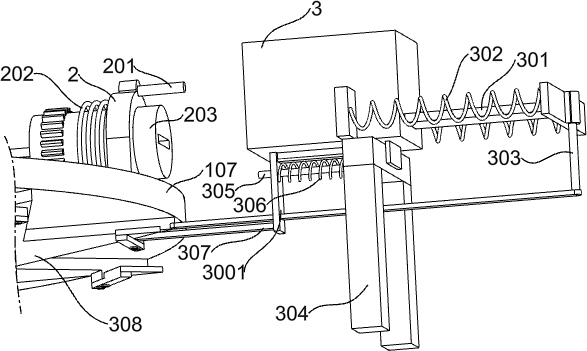

Paper shredder achieving cyclic utilization

InactiveCN109772541AReduce crushing costsImprove practicalityRotary stirring mixersGrain treatmentsCartonHand held

The invention discloses a paper shredder achieving cyclic utilization. A base is arranged at the bottom of a paper shredder body. A paper shredding box is mounted at the top of the base. A crushing chamber is arranged at the top end in the paper shredding box. A soaking chamber is arranged at the bottom of the crushing chamber. A water box is arranged at the bottom of the soaking chamber. An extrusion box is mounted on the left side of the paper shredding box. An extruder is mounted at the top end in the extrusion box. An electric push rod is arranged at the top end of the extruder. A press plate is mounted at the bottom end of the electric push rod. An electric heating wire is mounted in the press plate. A water collection trough is arranged at the bottom of a filter plate. Trundles are mounted at the bottom of the base. According to the paper shredder, baffles are hinged to the two sides of a check block, the baffles and the check block are used in cooperation, a certain guide function can be achieved on waste paper, and the situation that hands hold paper all the time is avoided; the work intensity is reduced, and meanwhile smoothness of paper discharging is also guaranteed; andthrough the baffles in hinged design, the inclination degree can be adjusted at any time according to needs, and containing and storage are also facilitated.

Owner:WENZHOU SHENGMIAO IND DESIGN CO LTD

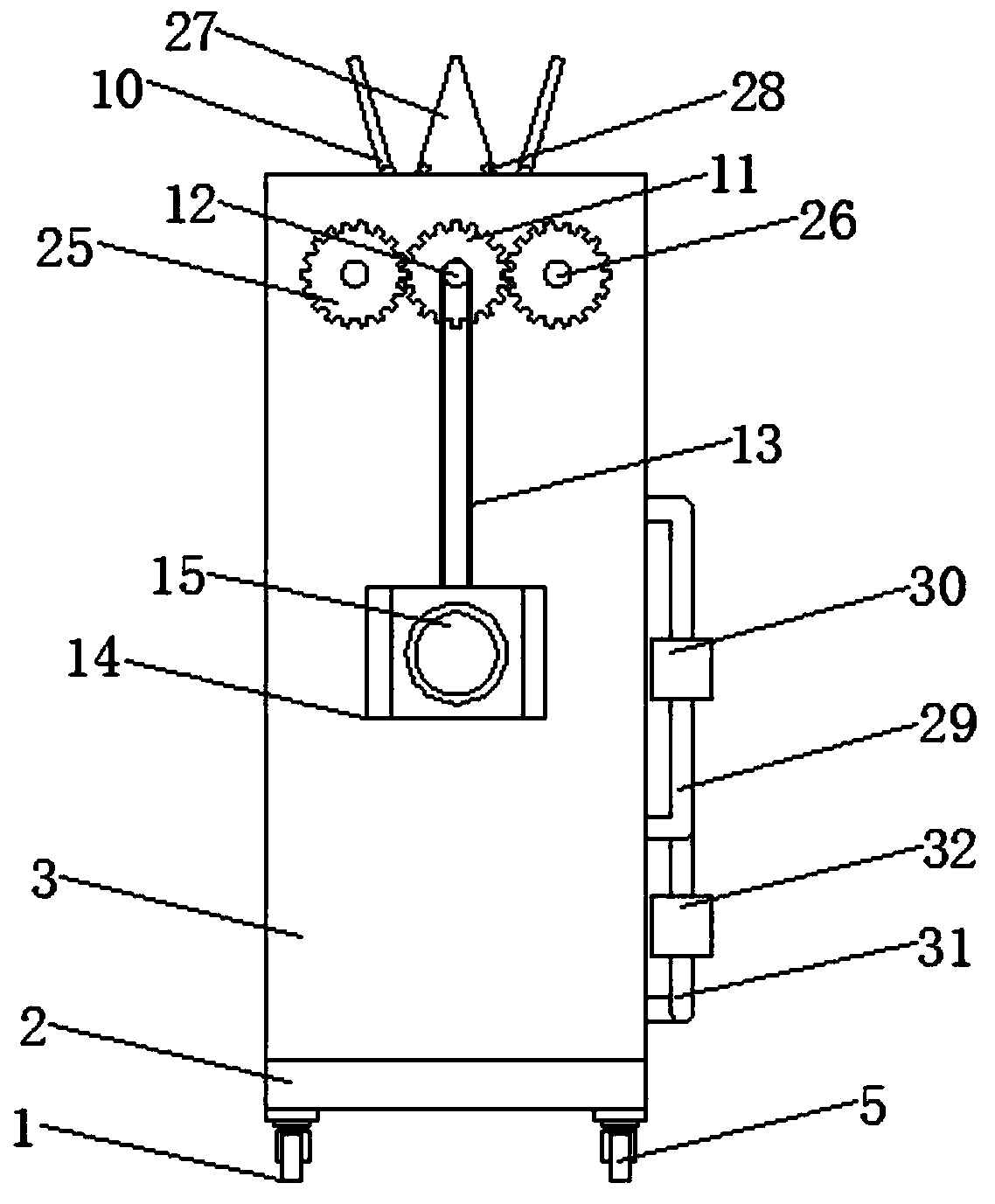

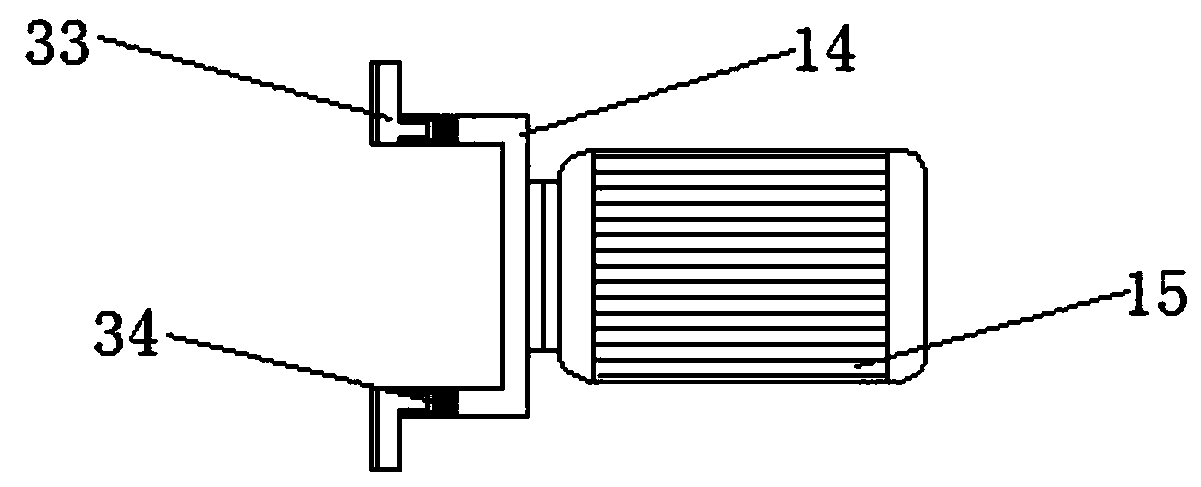

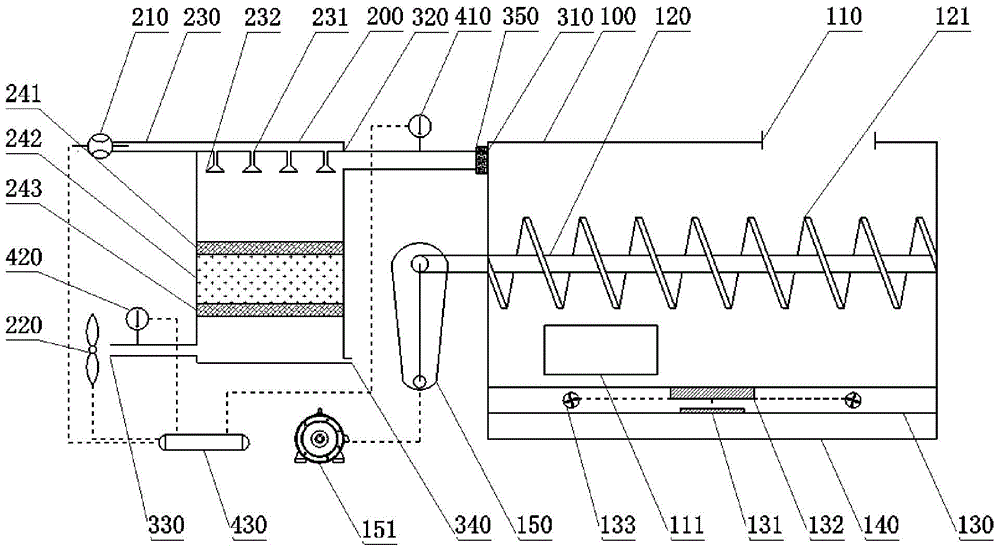

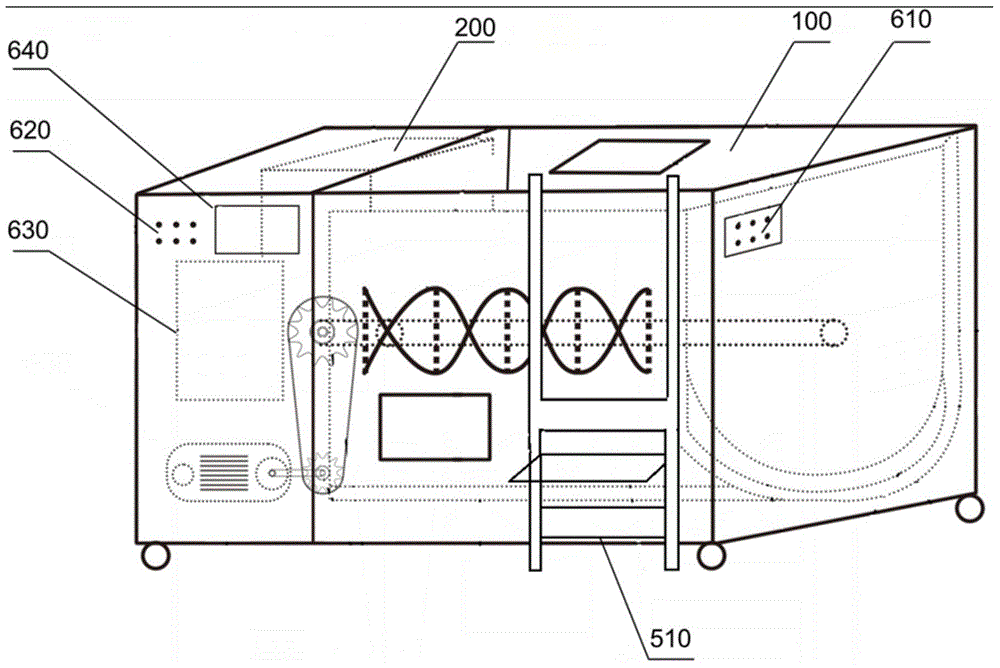

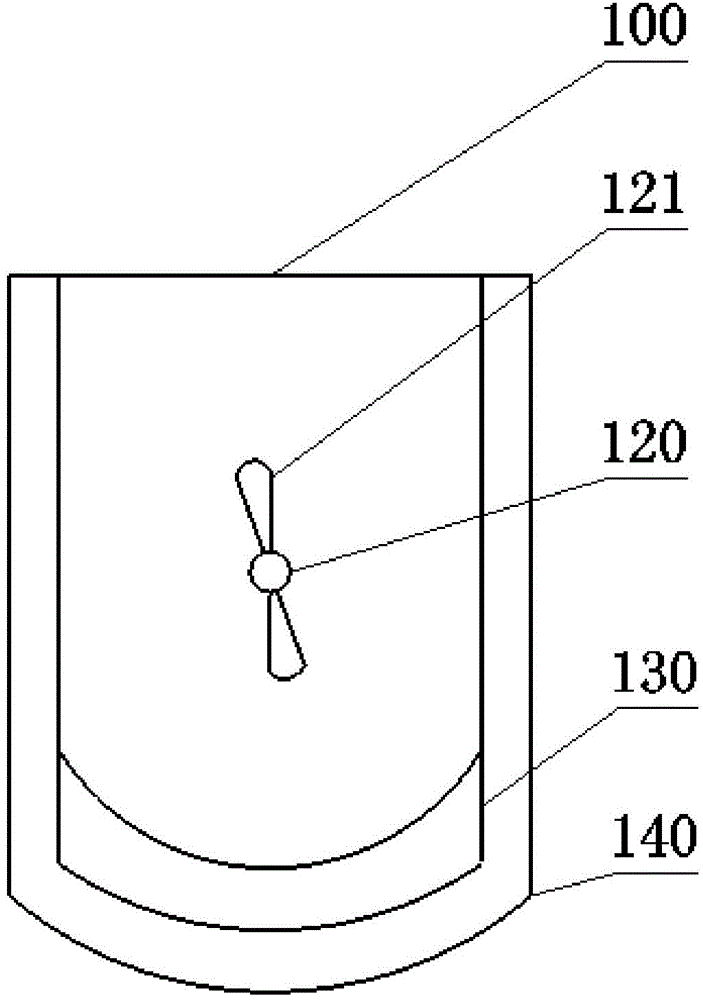

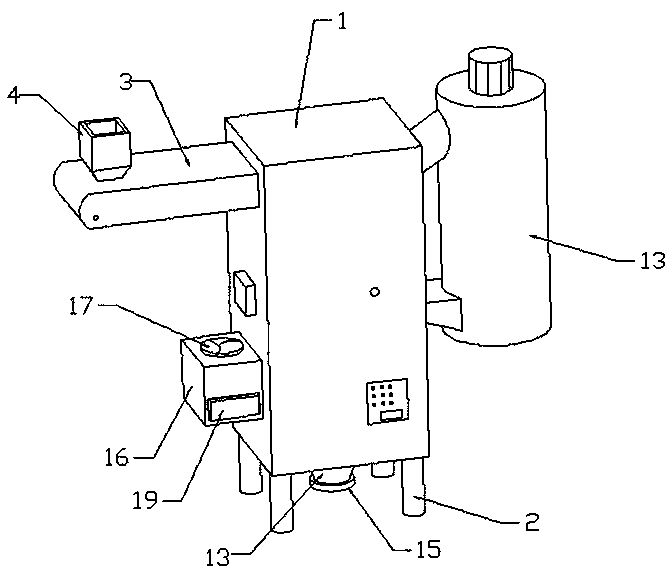

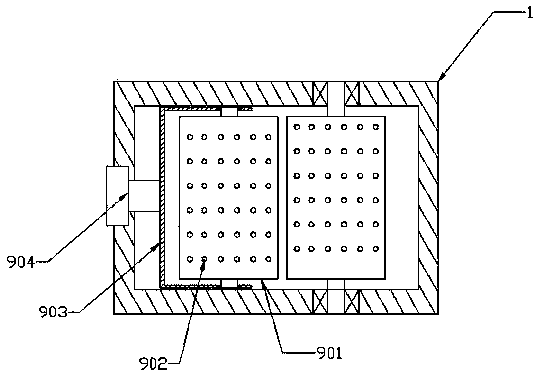

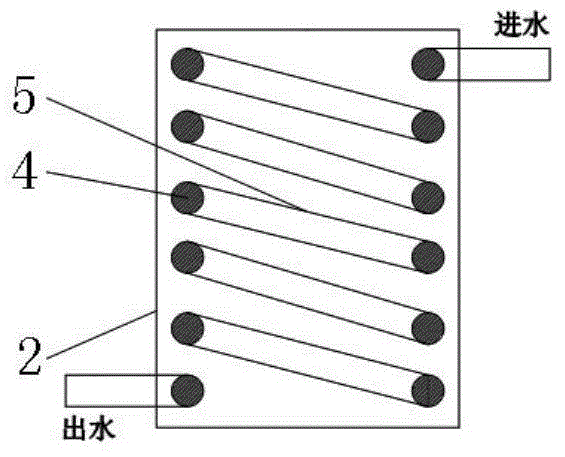

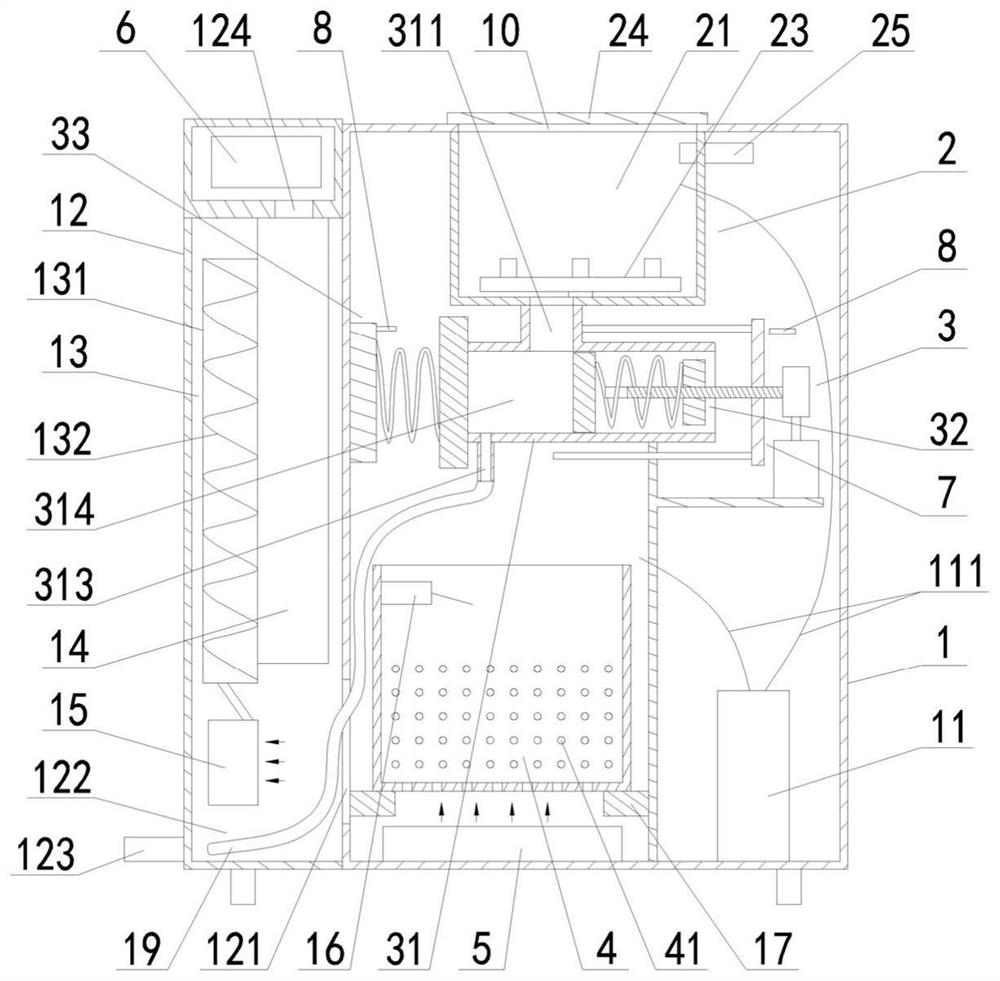

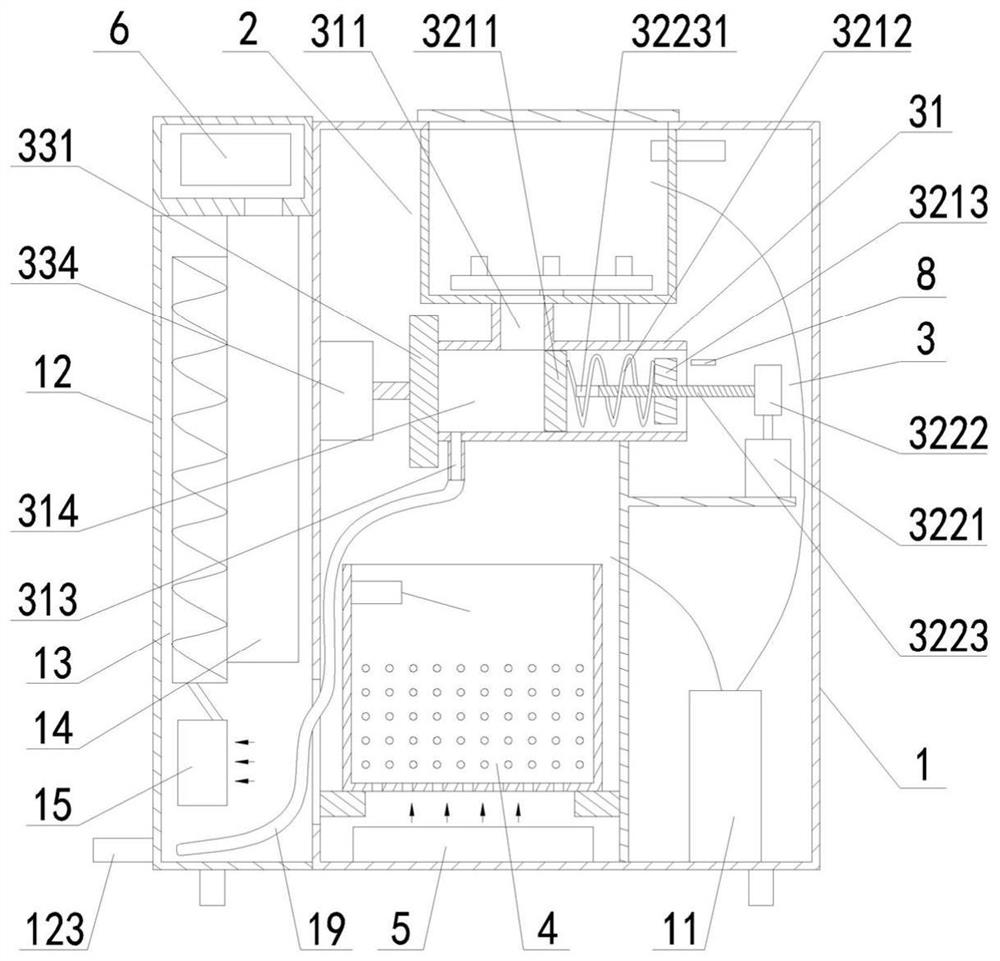

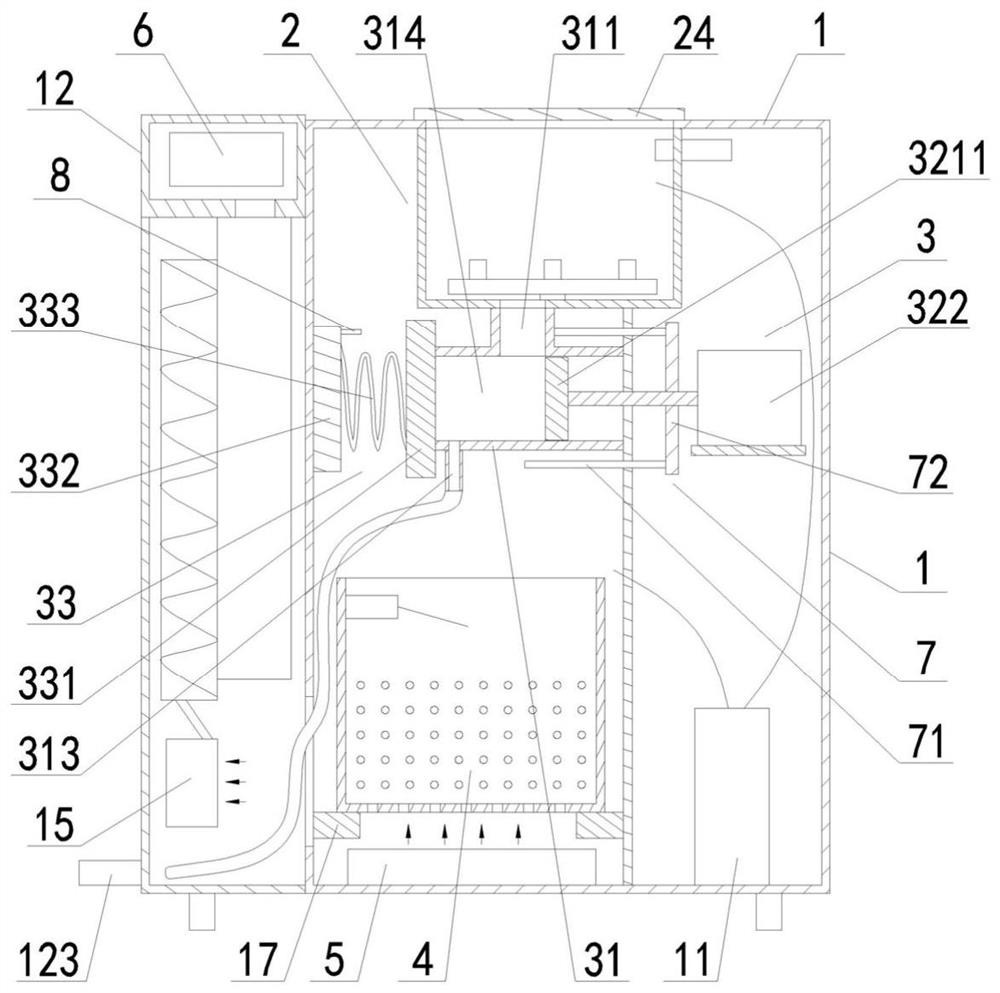

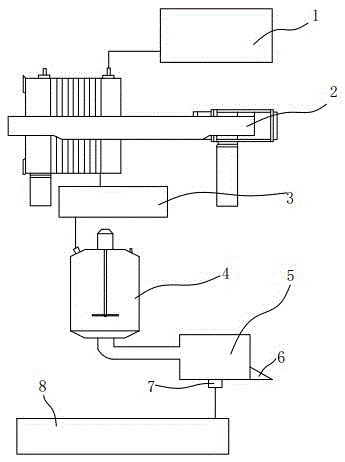

High-temperature biochemical processing machine for kitchen waste and control method thereof

ActiveCN104907320AHigh concentration rateFor subsequent recyclingSolid waste disposalActivated carbonSlag

The invention discloses a high-temperature biochemical processing machine for kitchen waste and a control method thereof. The high-temperature biochemical processing machine comprises a fermentation bin, a dust-removal deodorization purifying tower, temperature sensors and a controller, wherein a feeding hole is formed in the top of the fermentation bin, and a discharging hole is formed in the front face of the fermentation bin; a heating interlayer and a thermal insulation layer are sequentially arranged on the outer side of the fermentation bin, and a waste gas outlet is formed in one end of the fermentation bin; the dust-removal deodorization purifying tower is connected with a water pipe, the water pipe is connected to a plurality of spraying pipes which are arranged on the top end in the dust-removal deodorization purifying tower, and a filter layer, a spraying layer and an activated carbon layer are sequentially arranged in the dust-removal deodorization purifying tower from top to bottom; a waste gas inlet is formed in one end of the top of the dust-removal deodorization purifying tower, an air outlet is formed in one end of the bottom of the dust-removal deodorization purifying tower, a water outlet is formed in the other end of the bottom of the dust-removal deodorization purifying tower, and a draught fan is connected to the air outlet; the temperature sensors are mounted on a gas pipeline and the air outlet; the controller is connected with the temperature sensors and a water pump. The high-temperature biochemical processing machine has the characteristics that the kitchen waste can be processed by virtue of biological fermentation, and the processed waste slag resource can be recycled.

Owner:TIANJIN LINGJUN ENVIRONMENTAL PROTECTION TECH

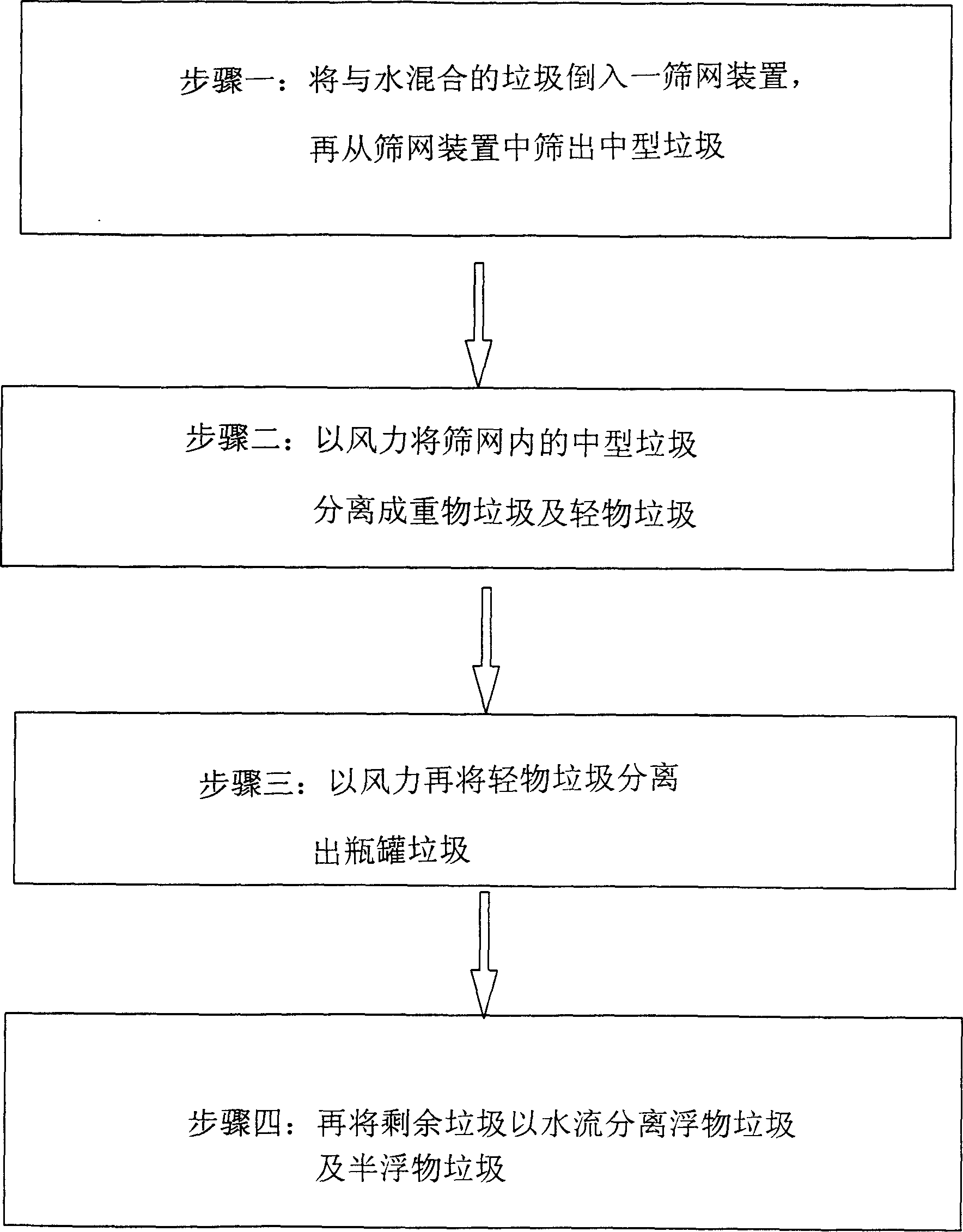

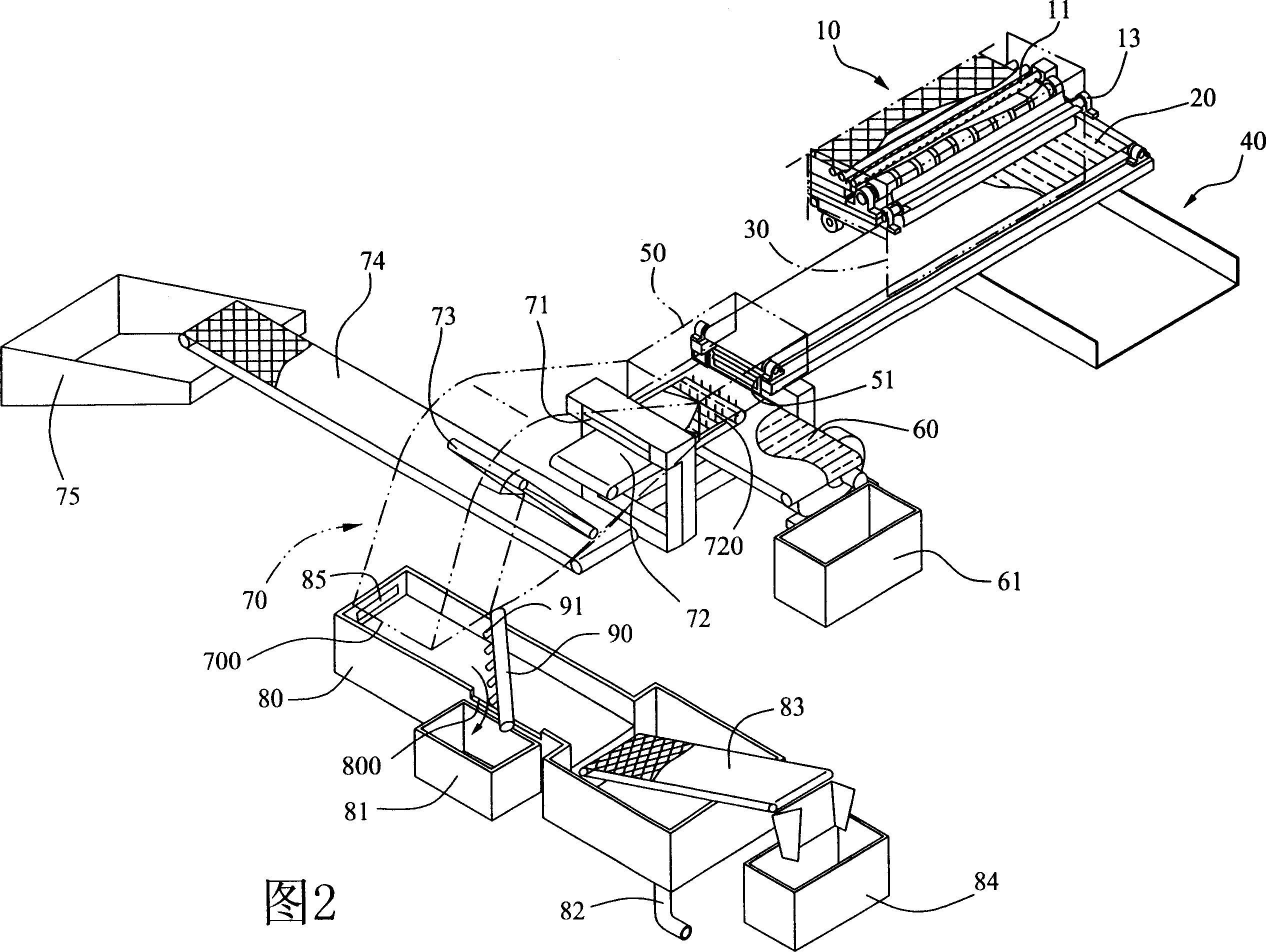

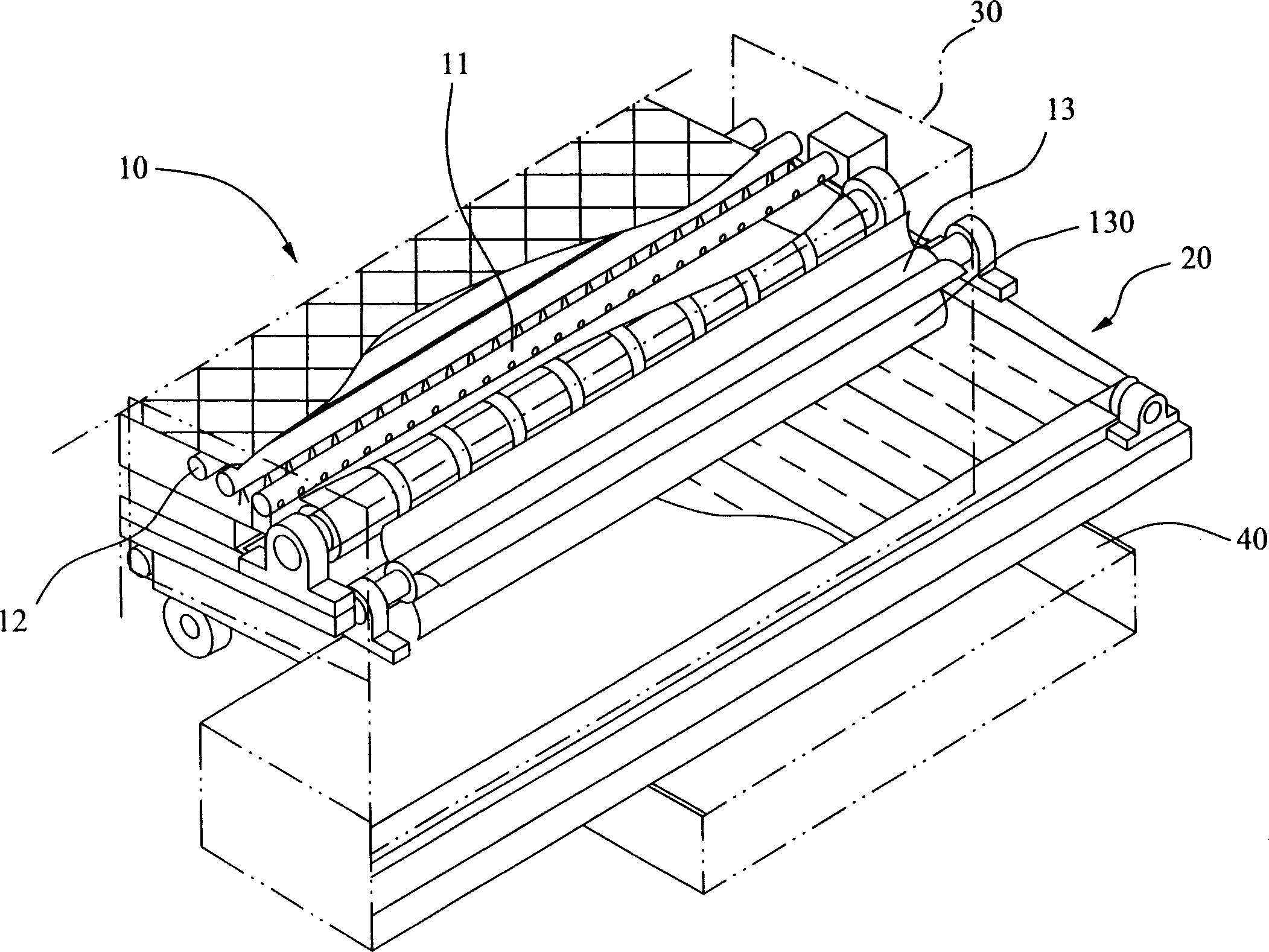

Method and device for separate collecting middle sized garbage

InactiveCN1520932AEffective classification and collectionConvenienceWet separationLitterEnvironmental engineering

The present invention is one kind of middle-sized garbage sorting and recovering method and apparatus. Wind force and water power are utilized to separate bottle and jar, floated matter, semi-floated matter, etc. from garbage while washing garbage.

Owner:无锡市长江机电有限公司

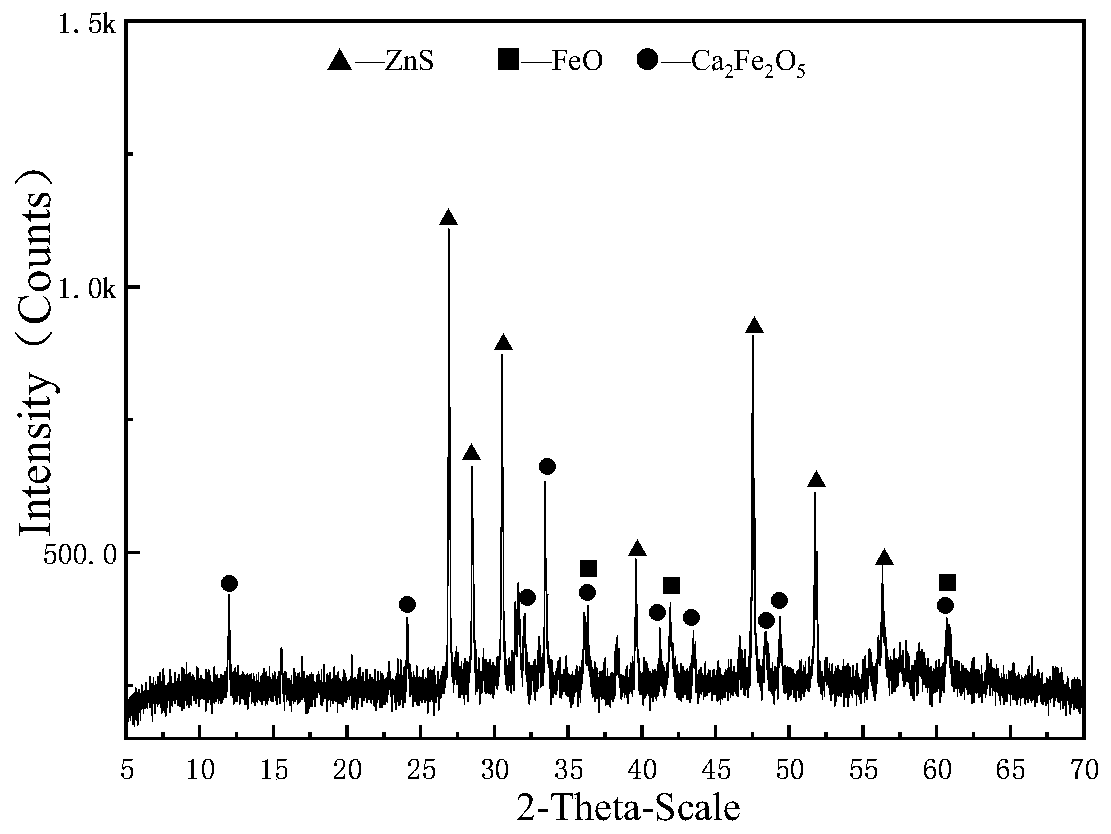

Method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag

ActiveCN110983029AAchieving clean co-processingAchieve recyclingFlotationCalcium silicateSulfidation

The invention discloses a method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag. The method comprises the following steps of: mixing lead-zinc smelting slag, gypsum slag and a carbonaceous reducing agent for reducing sulfurization roasting, using the gypsum slag as a vulcanizing agent to directionally convert lead, zinc and other heavy metals in the lead-zinc smelting slag into metal sulfides easy for flotation separation, enabling calcium in the gypsum slag to react with iron and silicon compounds in the lead-zinc smelting slag to generate calcium ferriteand calcium silicate compounds which can be used for manufacturing building materials and cement, and enabling arsenic in the gypsum slag to be volatilized and enriched in smoke dust to be recycled. The method has the advantages of being low in energy consumption and environmentally friendly, can solve the problem of environmental pollution caused by existing gypsum slag and lead-zinc smelting slag treatment, and has good application and popularization prospects.

Owner:CENT SOUTH UNIV

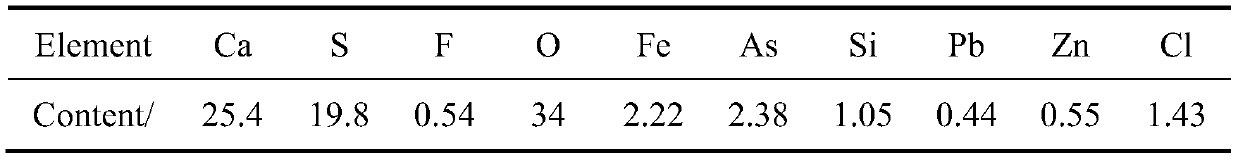

Method for recovering selenium from acid mud wastes of acid production with copper smelting smoke

InactiveCN103496676ASolving Recycling ProblemsHigh recovery rateElemental selenium/telluriumSlagSodium hydroxide

The invention discloses a method for recovering selenium from acid mud wastes of acid production with copper smelting smoke. The method comprises the steps of adding the acid mud into a solution containing sodium hypochlorite and sodium hydroxide, carrying out a selenium leaching reaction, filtering to obtain selenium removed slag and a sodium selenate containing solution, recovering lead, precious metals and valuable metals from the selenium removed slag, and carrying out acidification reduction on the sodium selenate solution to obtain rough selenium powder. Before recovering the selenium from the acid mud, arsenic and bismuth are separated from the selenium and lead in the acid firstly, the selenium removing rate is higher than 95%, the lead content in the slag is increased to 70-80%, the enrichment of the valuable metal lead in the slag is beneficial for a subsequent recovering process, the process is simple, the purpose of treatment of wastes with processes of wastes against one another is realized, the circular economy is realized, the production cost is low, and the metal recovering rate is high. In particular, residual chlorine in a production process is used for absorbing sodium hypochlorite in the waste solution, and then the selenium is directly removed from the acid mud wastes, so that the selenium recovering problem is solved, and meanwhile, the sodium hypochlorite wastewater problem is also solved.

Owner:JINCHUAN GROUP LIMITED

Cleaning device for textile processing

ActiveCN108239830ATake away in timeAvoid affecting the cleaning effectLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringRack and pinion

The invention relates to the technical field of textile processing and discloses a cleaning device for textile processing. The cleaning device comprises a rack, wherein a feeding roller and a receiving roller are rotationally connected to the rack; a first cleaning mechanism and a water removal mechanism are arranged on the rack; the first cleaning mechanism comprises a first roller and a second roller, the first roller is coaxially connected to a first gear, a second gear is rotatably connected to the rack, the second roller is coaxially connected to a third gear, a first cavity is fixedly connected to the rack, a first worm wheel is rotatably connected in the first cavity, and the first worm wheel is connected to a fan gear coaxially; a fourth gear is also engaged to the fan gear, the fourth gear is coaxially connected to a fifth gear, a first rack is engaged to one side of the fifth gear, a second rack is engaged to the other side of the fifth gear, a first pull rod is fixedly connected to the first rack, a second pull rod is fixedly connected to the second gear, and the water removal mechanism comprises a third roller and a fourth roller. The cleaning device provided by the invention can clean textiles quickly thoroughly.

Owner:NINGBO WENZE TEXTILE CO LTD

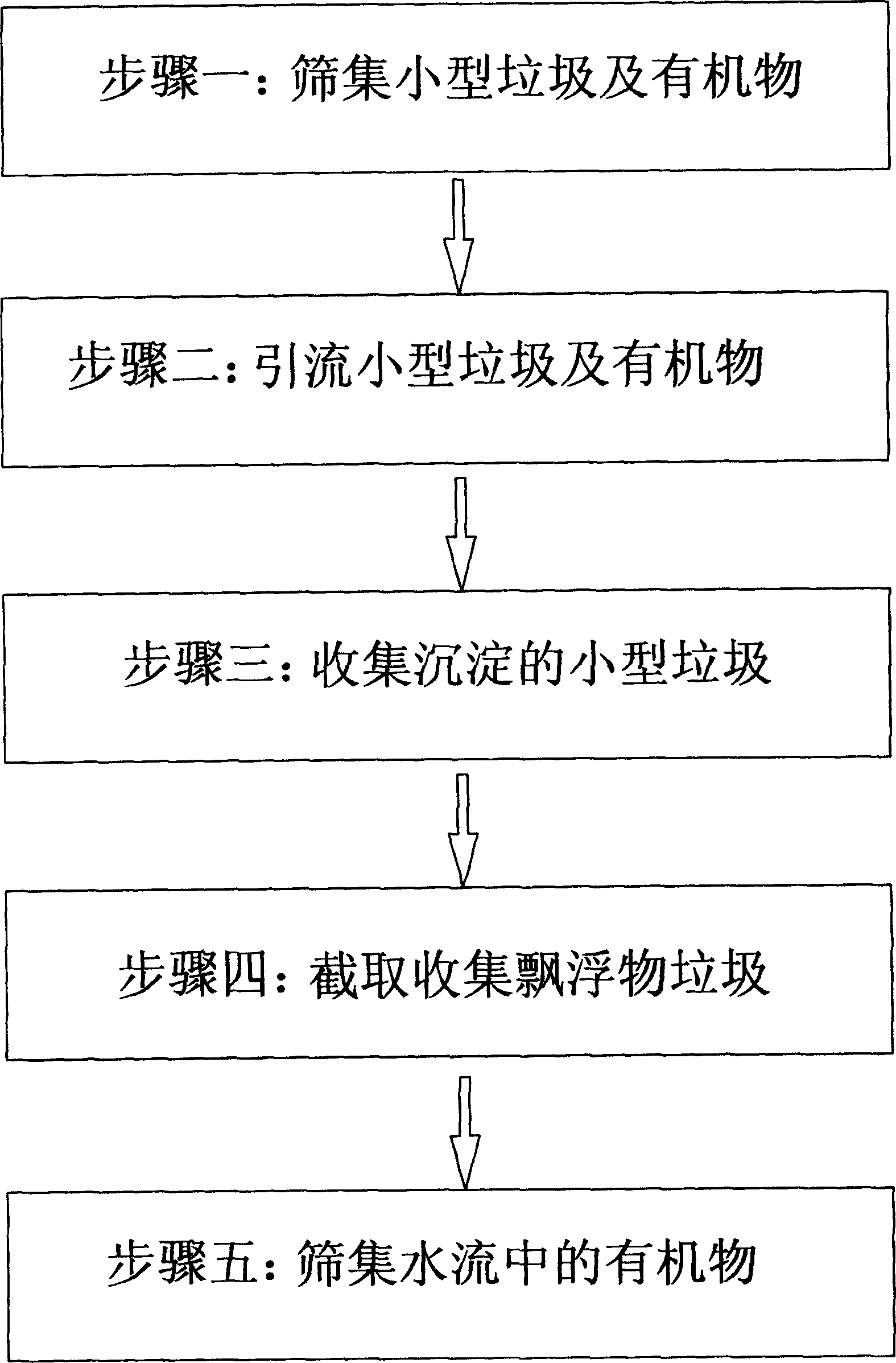

Method and device for separate collecting small sized garbage and organic matters

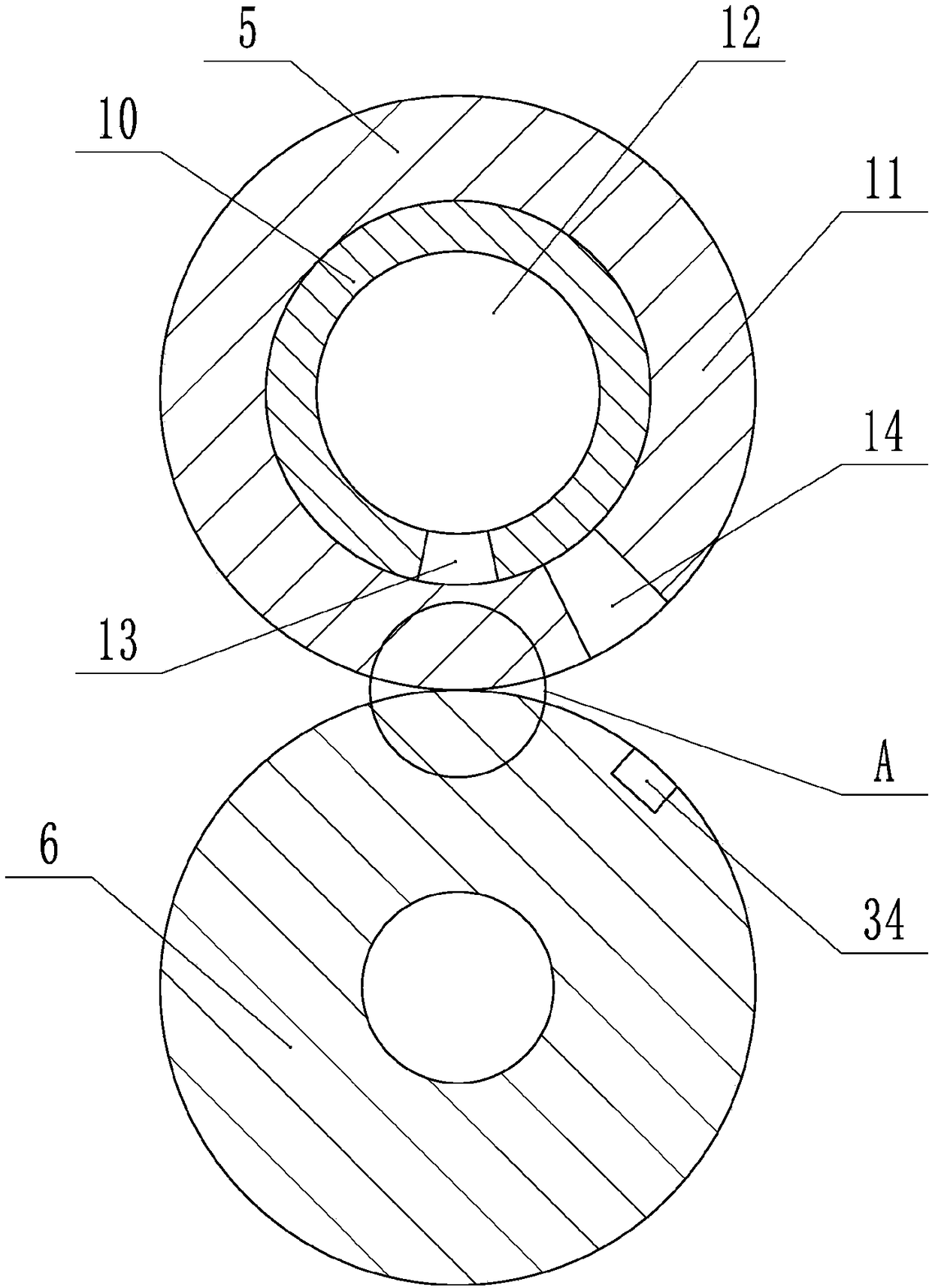

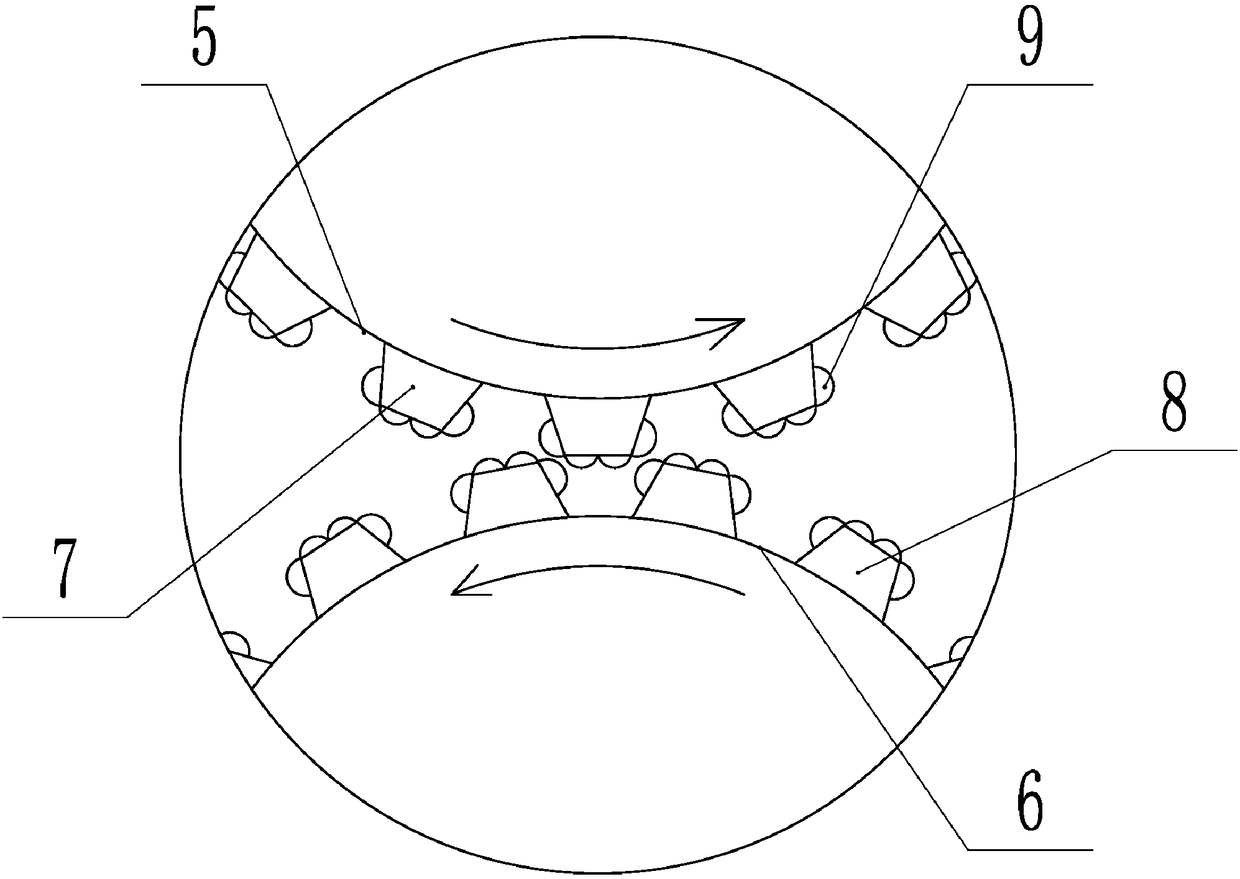

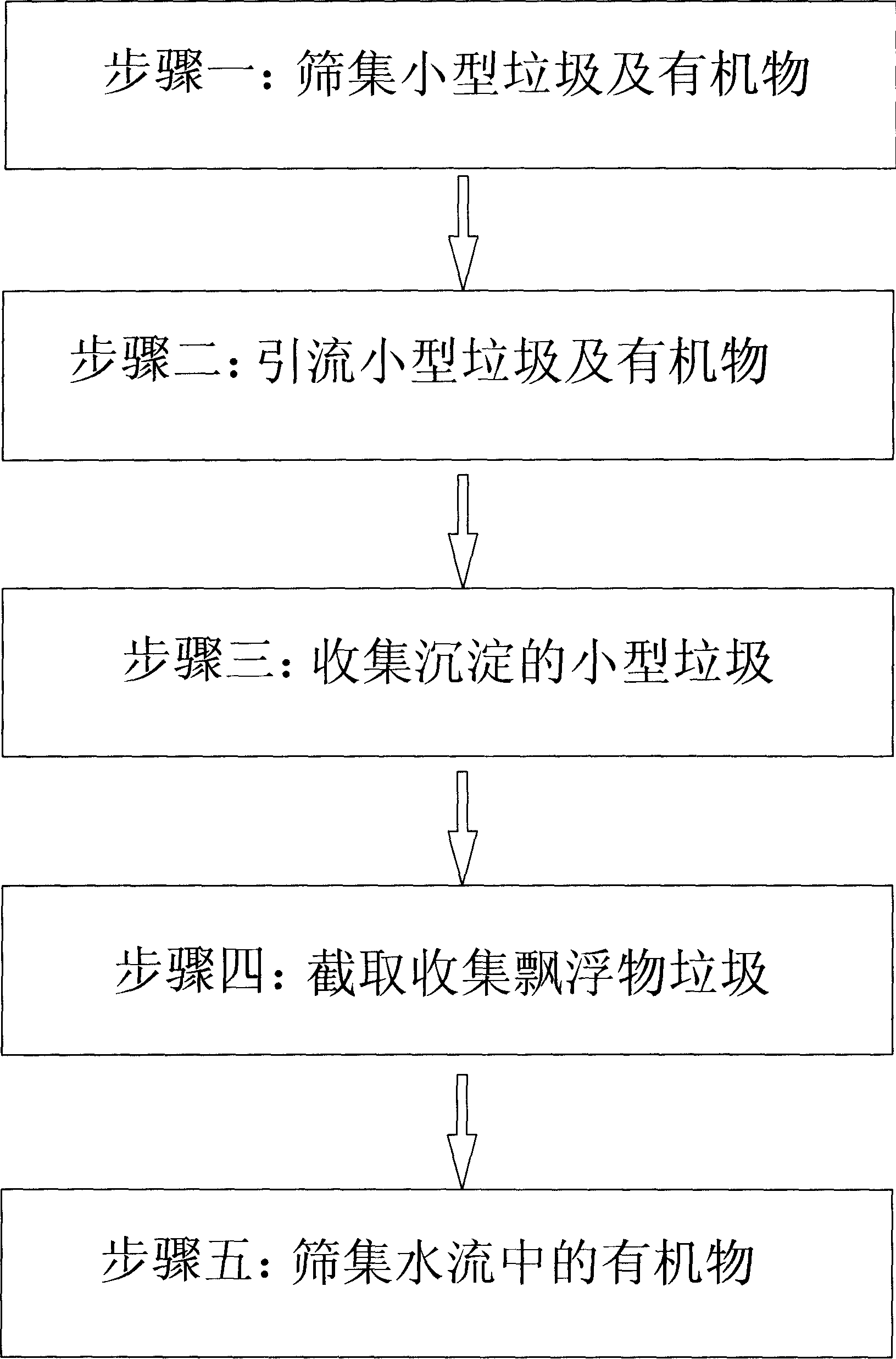

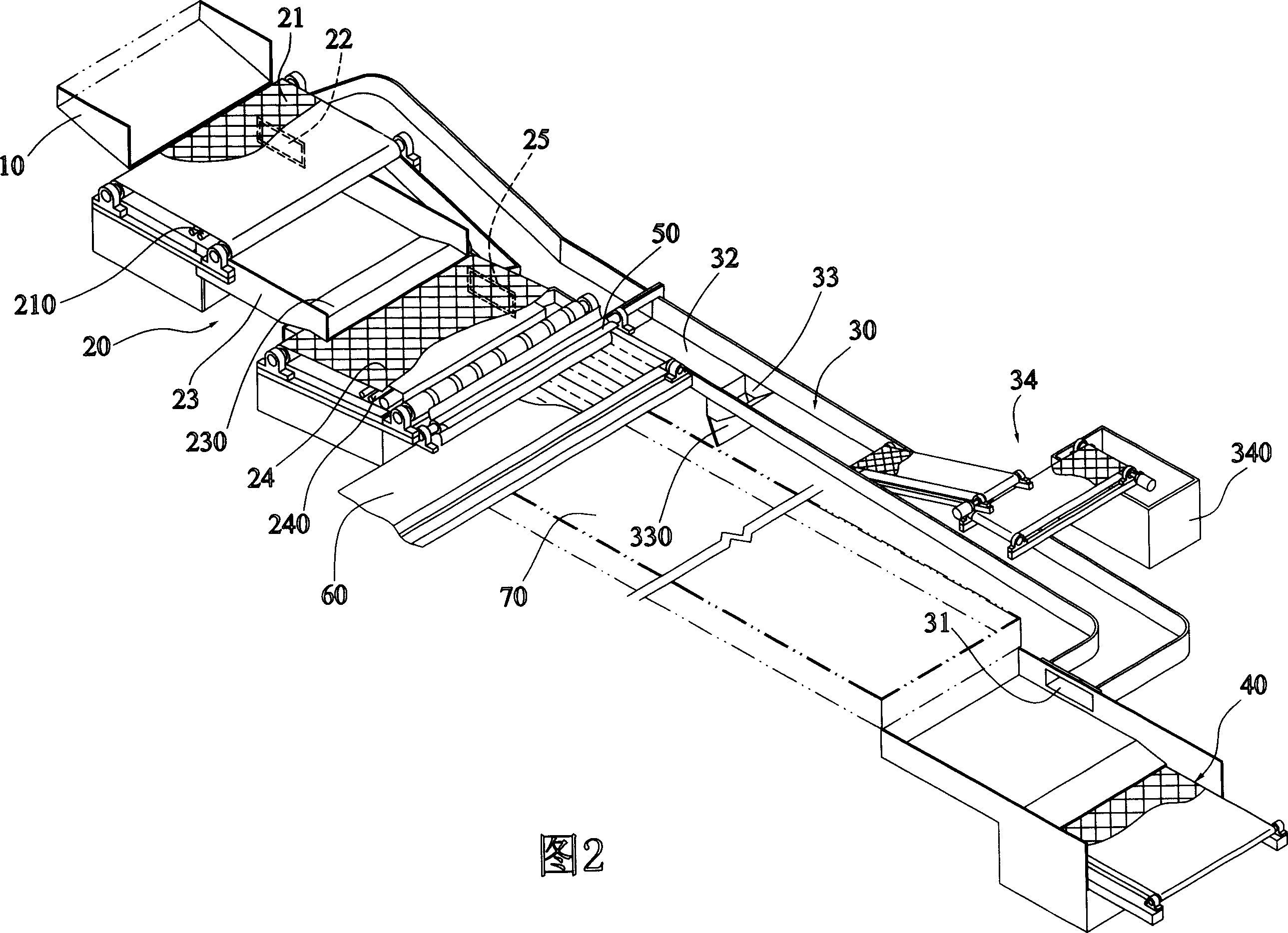

InactiveCN1520931AReduce the likelihood of infecting the human bodyEffective separation and collectionSolid waste disposalWet separationSpecific weightOrganic matter

The present invention discloses one kind of small garbage sorting and collecting method and apparatus. Water with certain specific weight, flowability and buoyancy is used as medium and several sieving, filtering and intercepting mechanisms are adopted to separate floated matter, organic matter and deposited matter effectively from garbage.

Owner:无锡市长江机电有限公司

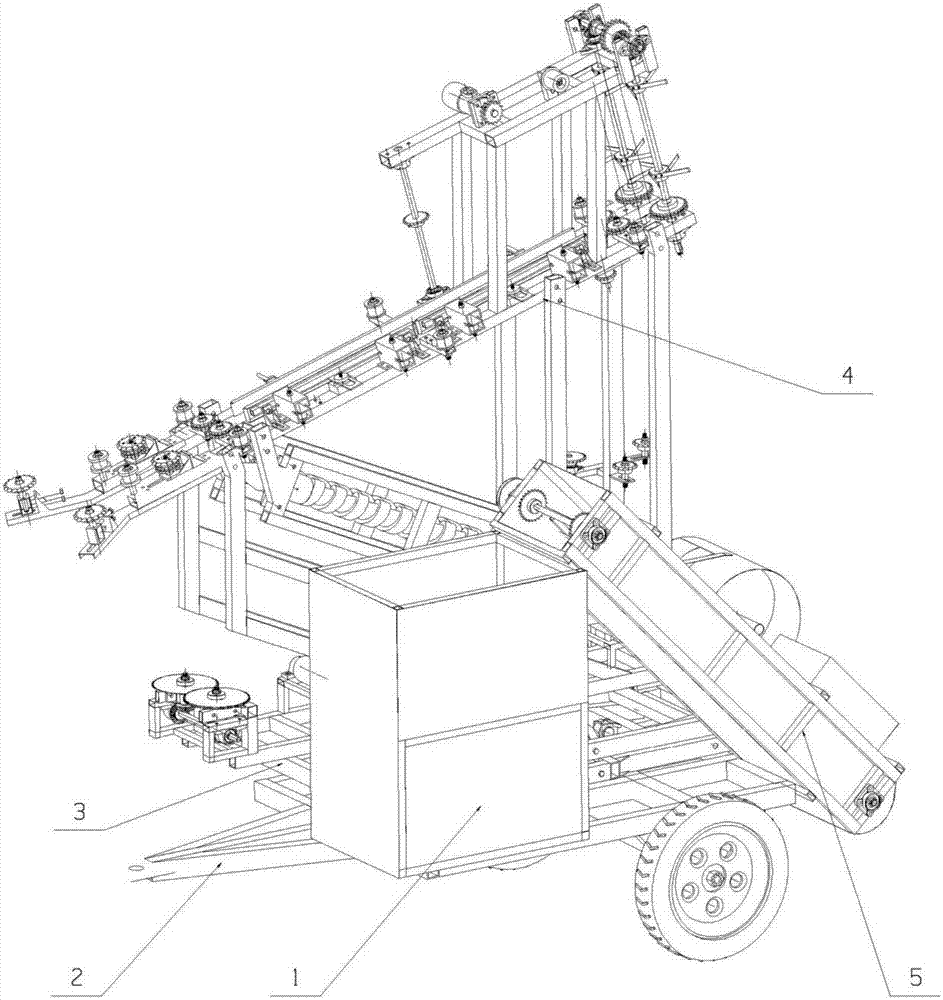

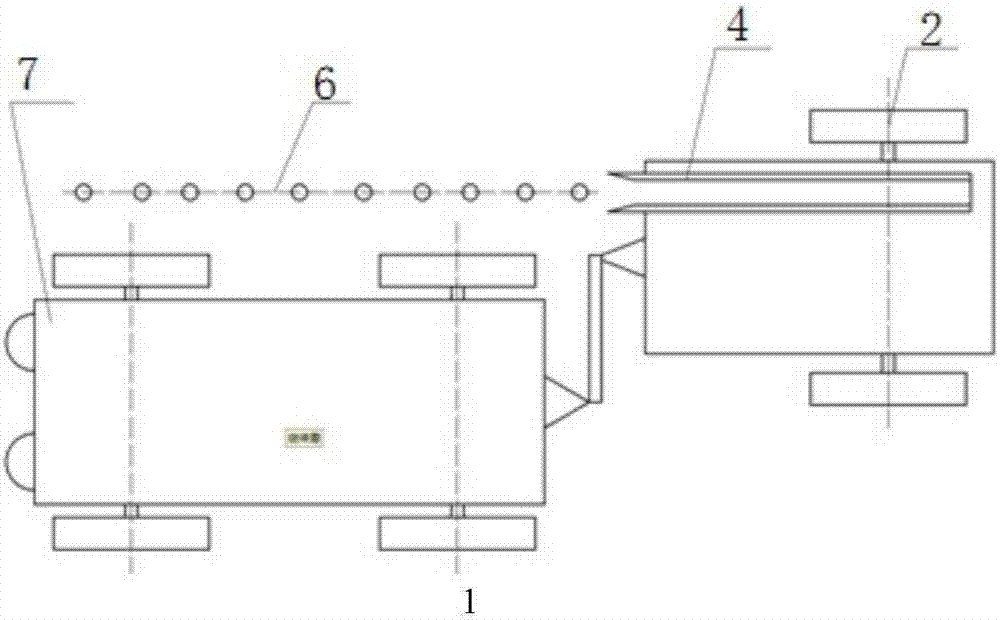

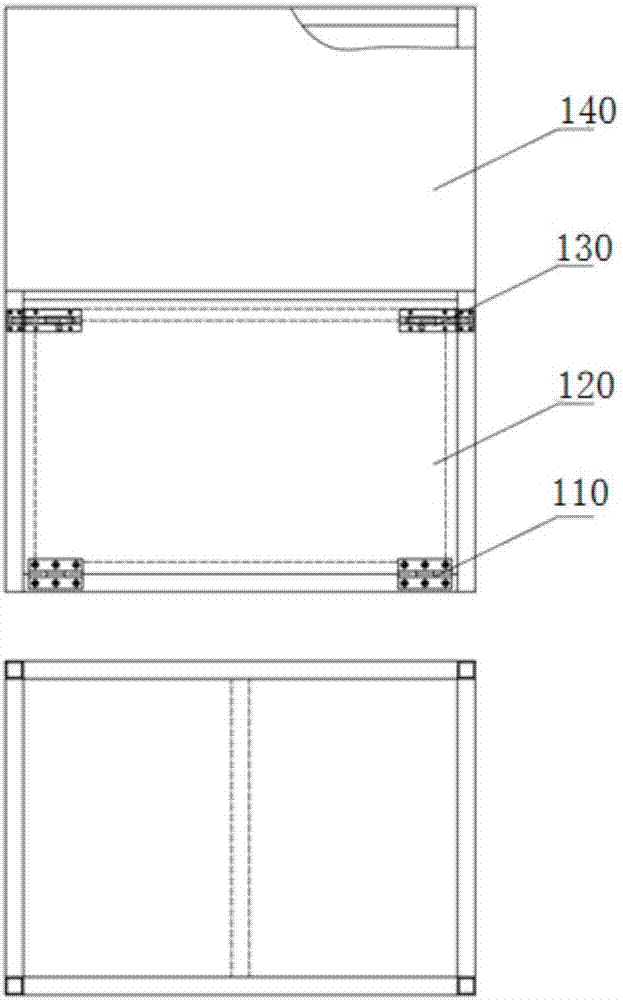

Pull-type fresh maize bionic ear-picking harvesting bench

Owner:JILIN UNIV

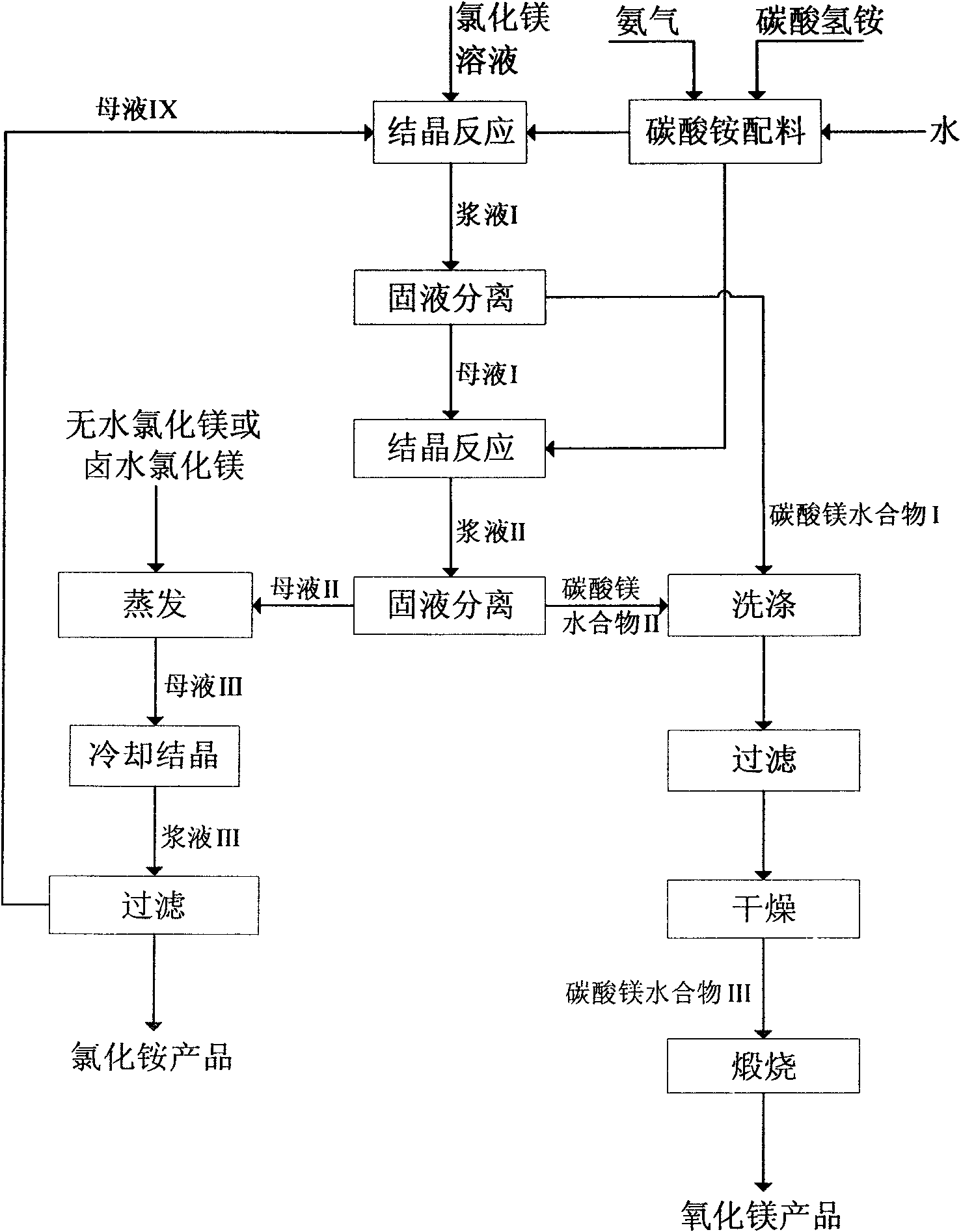

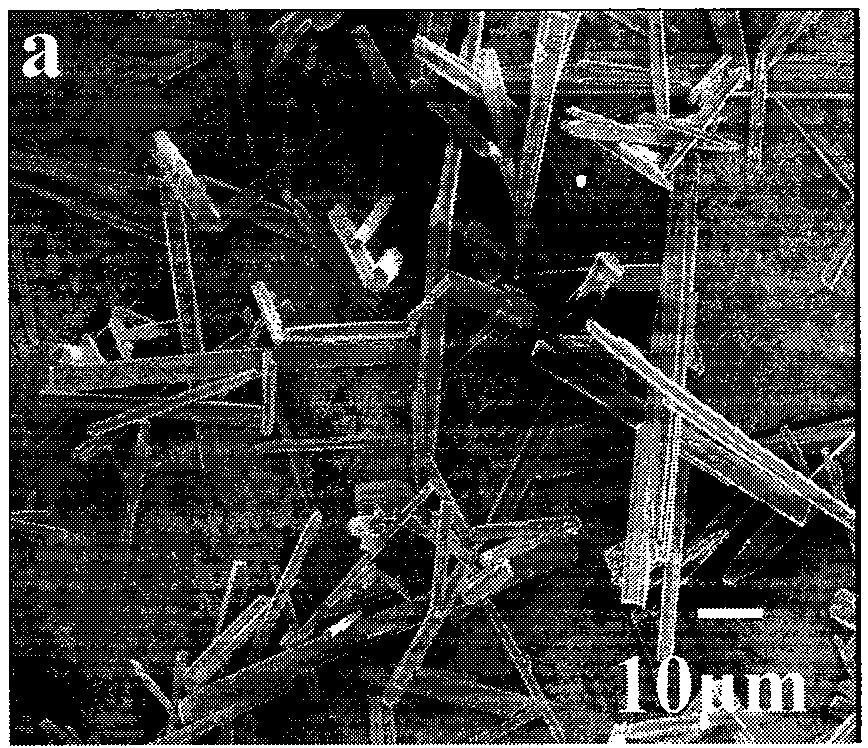

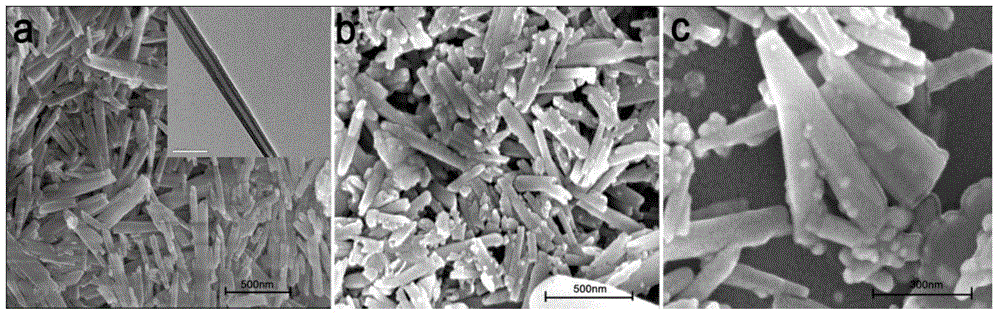

Method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as intermediate

InactiveCN101993097AHigh purityGood filtration propertiesMagnesium carbonatesAmmonium halidesMagnesium saltSeawater

The invention belongs to the field of inorganic salt chemical industry and fertilizer production, particularly relates to a method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as an intermediate. The method comprises the following steps of: with anhydrous magnesium chloride or bittern magnesium chloride as a raw material and with ammonia and ammonium bicarbonate as precipitating agents, obtaining the magnesium carbonate hydrate intermediate (the purity reaches 97-99 percent) with favorable crystal form by controlling process conditions; calcining the obtained magnesium carbonate hydrate intermediate to prepare magnesium oxide (the purity reaches 95-99 percent); adding salt to mother liquor enriched with ammonium salts and evaporating, salting out and cooling to separate out ammonium chloride, and filtering to obtain the ammonium chloride, wherein the mother liquor is circularly taken as a raw material. The method aims at producing needle-shaped or spherical magnesium carbonate hydrate by utilizing rich magnesium chloride brine from salt lakes, or magnesium chloride brine from seawater, or anhydrous magnesium chloride used for producing titanium sponge by-products, and other magnesium salt materials, thereby preparing high-purity magnesium oxide with the simultaneous co-production of ammonium chloride fertilizer. The method of the invention has strong maneuverability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

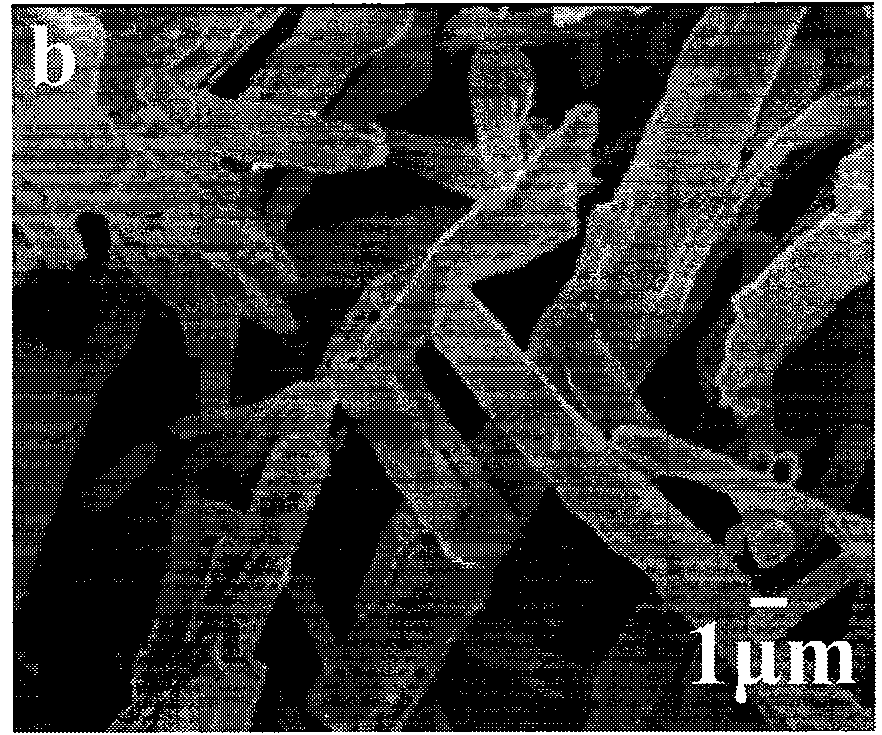

Wet-process open treatment method of arsenic in copper ashes

ActiveCN103233129AHigh recovery rateSolve the open circuit problemProcess efficiency improvementLiquid wasteImpurity

The invention discloses an open treatment method of arsenic in copper ashes and relates to a method for open pre-treatment of harmful arsenic impurities in intermediate material ashes in a copper smelting process. The wet-process open treatment method is characterized in that the treatment process comprises the following steps of: adding copper ashes to a solution containing sodium hypochlorite and sodium hydroxide; carrying out arsenic leaching reaction and filtering to obtain arsenic-removed slag and arsenic-removed solution; and recycling valuable metals including copper, lead, zinc and bismuth of the arsenic-removed slag. The wet-process open treatment method disclosed by the invention can be used for carrying out open treatment on the arsenic in the copper ashes before recycling the valuable metals, so that the subsequent recycling process of valuable metals is facilitated. Meanwhile, a utilization way for residual chlorine absorption liquid waste is found, so that the secondary pollution is avoided. Besides, the wet-process open treatment method for arsenic in the copper ashes is low in process cost and high in arsenic removal rate, and has great significance of improving environment protection, resource control and economical benefits.

Owner:JINCHUAN GROUP LIMITED

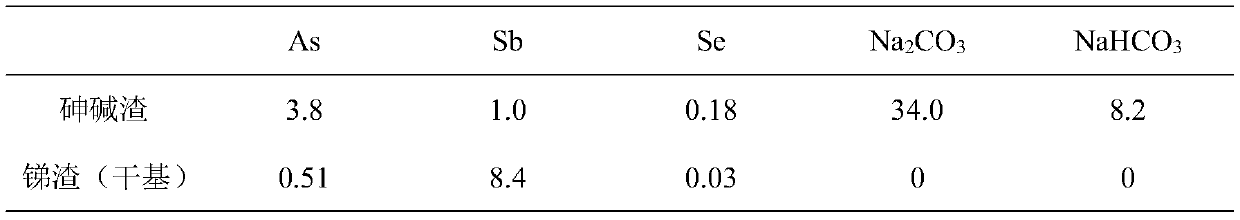

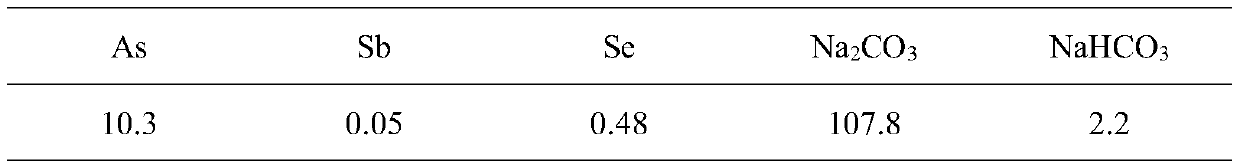

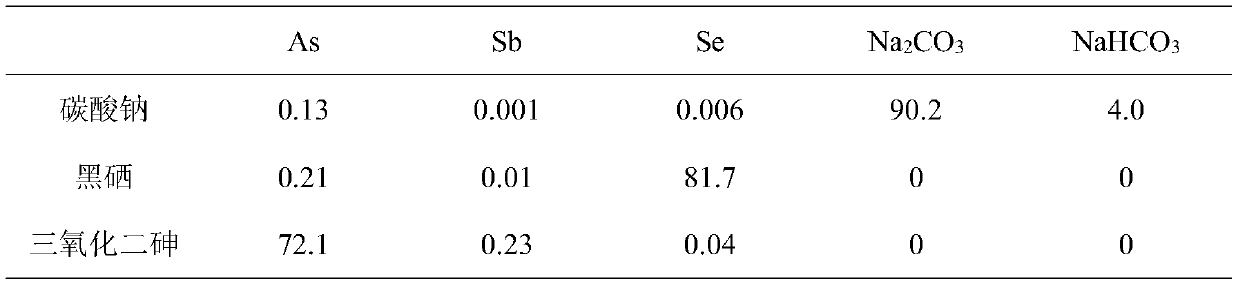

Method for recovering alkali, selenium and arsenic in arsenic-alkali residue from antimony smelting

ActiveCN110143604ASimple processReduce manufacturing costArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementSlagMother liquor

The invention discloses a method for recovering alkali, selenium and arsenic in arsenic-alkali residue from antimony smelting, comprising the following steps: (1) immersing arsenic-alkali residue in water, filtering and washing to obtain antimony slag and an arsenic-alkali solution; (2) concentrating the arsenic-alkali solution until concentration of arsenic is 12-17 g / L, introducing CO2 to obtainsodium hydrogen carbonate and primary crystallization mother liquor, concentrating the primary crystallization mother liquor until concentration of arsenic is 48-60 g / L, and introducing CO2 to obtainsodium hydrogen carbonate and secondary crystallization mother liquor; (3) using acid to regulate pH of the secondary crystallization mother liquor to 1-4, heating and reacting to obtain black selenium and a selenium-removed solution; and (4) carrying out SO2 reduction on the selenium-removed solution, conducting evaporation and concentration, cooling for crystallization and filtering to obtain arsenic trioxide and an arsenic-removed solution. By the above method, efficient recovery of alkali, selenium and arsenic in arsenic-alkali residue is realized, and effective enrichment of antimony isalso realized, oxidation for deep antimony removal is not required, arsenic-alkali separation is thorough, no sodium arsenate composite salt is generated, and acid consumption and use amount of a reducing agent are low. In addition, the process is concise, and the method has good economic and environmental benefits.

Owner:CENT SOUTH UNIV

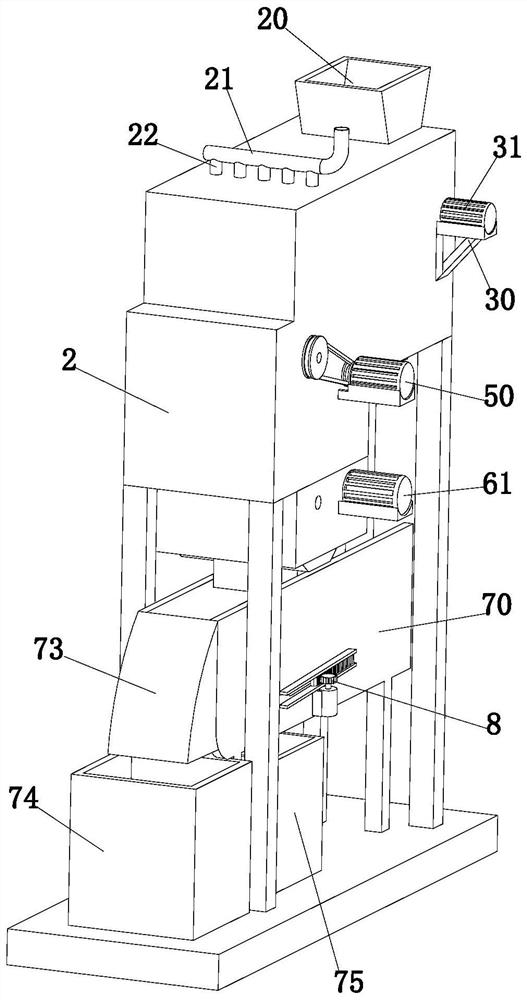

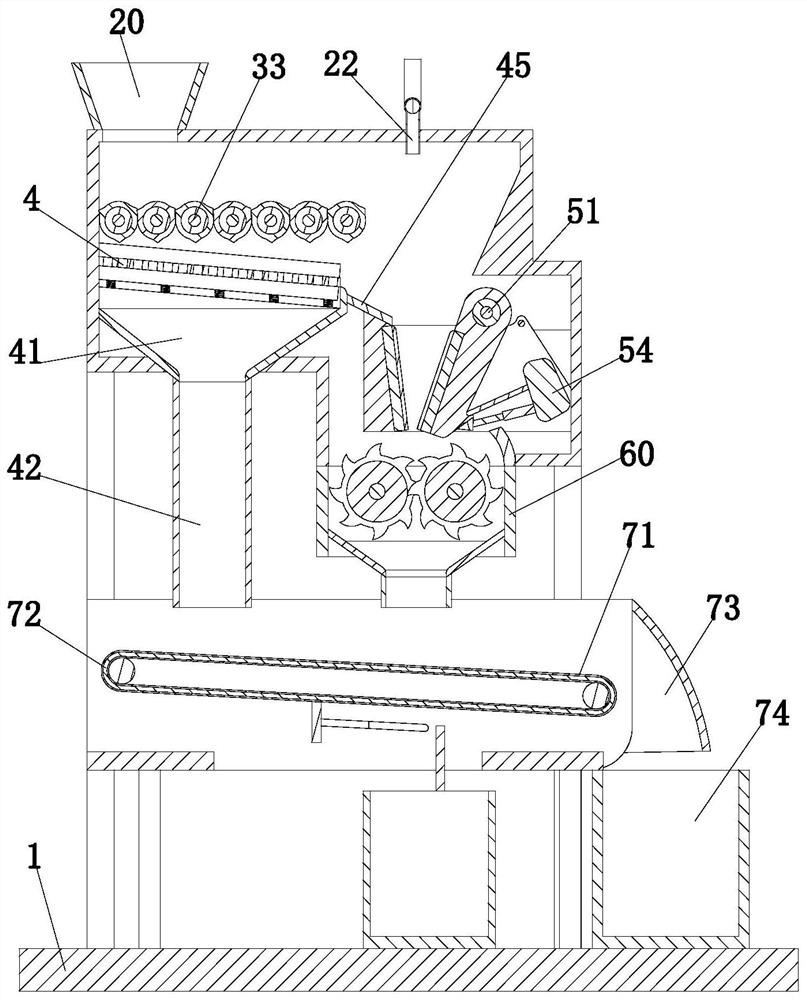

Cloth waste treatment device for spinning

InactiveCN111545289AReasonable structural designImprove crushing effectDirt cleaningGrain treatmentsWaste treatmentElectric heating

The invention discloses a cloth waste treatment device for spinning. The cloth waste treatment device comprises an outer shell, wherein the four corners of the bottom of the outer shell are connectedwith stand columns; the left upper part of the outer shell communicates with a feeding channel; the left side of the top of the feeding channel communicates with a hopper; the left end and the right end of the feeding channel are rotatably connected with conveying rollers; a conveyor belt is arranged between the two groups of conveying rollers in a sleeving mode; the top of the inner cavity of thefeeding channel is connected with an electric heating wire; the upper part of the inner cavity of the outer shell is symmetrically connected with guide inclined plates left and right; a crushing mechanism is arranged below the guide inclined plates; the left side wall of the inner cavity of the outer shell is connected with a mounting base; the bottom of the mounting base is connected with a vibrating motor; the lower end of the vibrating motor is in power connection with a screen; the right side wall of the outer shell is equipped with a reflux mechanism; and the bottom of the inner cavity of the outer shell is connected with a discharge bin. The cloth waste treatment device is reasonable in structural design, can dry cloth waste, is beneficial for improving the crushing effect, and introduces unqualified fragments into the outer shell again to crush through the reflux mechanism, so that the cloth waste treatment effect is improved.

Owner:湖北延昌纺织股份有限公司

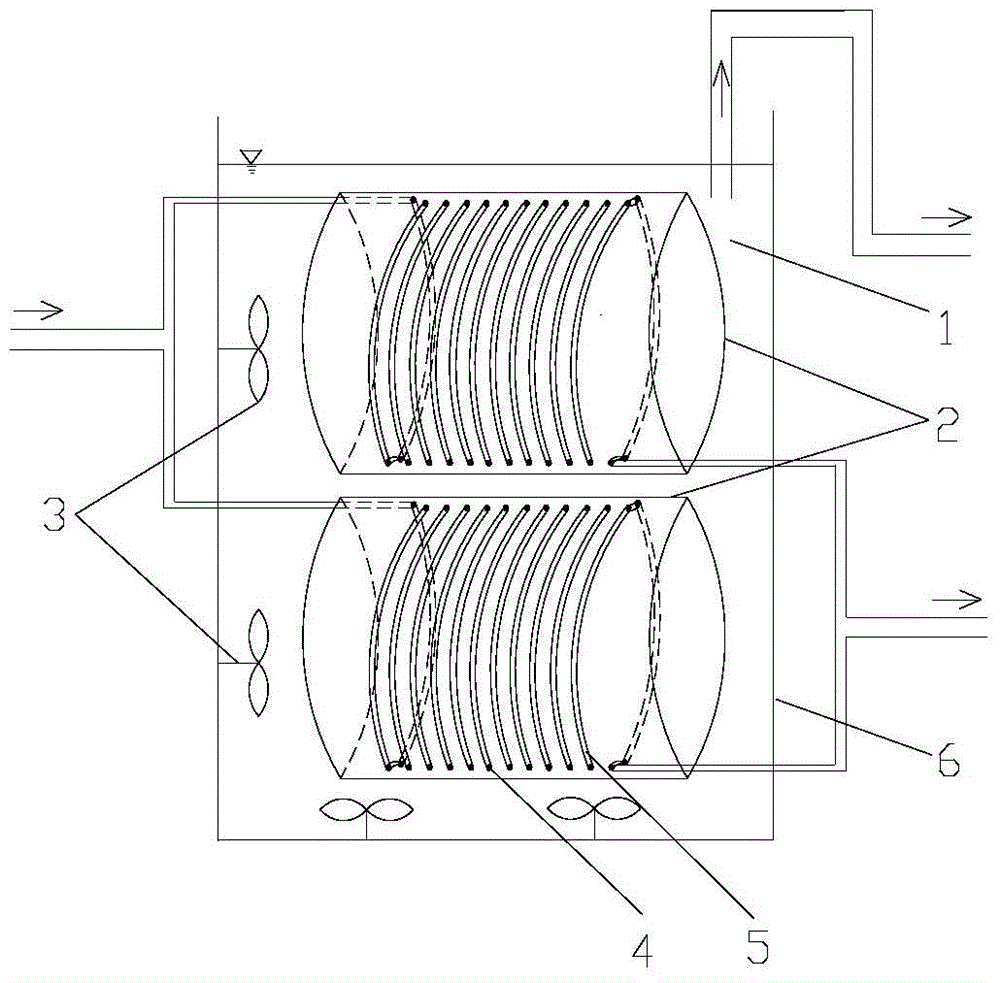

Device and method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction

InactiveCN105013210AReduce concentrationImprove absorption efficiencyAmino compound purification/separationLiquid solutions solvent extractionWastewaterOrtho-Toluidine

The invention relates to a device and a method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction. The method comprises: conveying wastewater containing ortho-toluidine to a silicon rubber extraction membrane tube, wherein the silicon rubber extraction membrane tube is put in an acidic extraction solution, ortho-toluidine in the wastewater can penetrate through the tube wall of the silicon rubber extraction membrane tube, enter into the extraction solution and react to generate ortho-toluidine ions, and the rest of the wastewater is discharged from the outlet of the silicon rubber extraction membrane tube with standard level or post-treatment; and taking out the extraction solution when the concentration of the ortho-toluidine ions in the extraction solution exceeds a predetermined value, and adding alkali liquor into the extraction solution to obtain recovered and concentrated ortho-toluidine. According to the device and method provided by the invention, the extraction solution is acidic and is reacted with alkalescent ortho-toluidine to generate the ortho-toluidine ions which cannot penetrate through the silicon rubber extraction membrane tube so as to prevent the ortho-toluidine from returning to the wastewater again. A lot of ortho-toluidine can be separated and concentrated, the mass transfer velocity is relatively rapid, industrial treatment and concentration and recovery of the ortho-toluidine are facilitated, and the use level of the extraction solution is extremely little.

Owner:SHAANXI UNIV OF SCI & TECH

Waste paper light residue recovering and processing technology

ActiveCN110409207AFor subsequent recyclingImprove bindingRaw material divisionAfter treatmentIntegrated processing

The invention relates to the technical field of comprehensive processing methods of waste residues, and concretely relates to a waste paper light residue recovering and processing technology. The technology comprises the following steps: (1) light residues are magnetically separated; (2) the magnetically separated light residues are fed into a pulp disintegrator, and are disintegrated to obtain afirst-stage accepted stock and a first-stage residue pulp; (3) the first-stage residue pulp is processed by a defibrizer, a re-crusher and a cylinder screen to an accepted stock, the accepted stock returns into the pulp disintegrator, and is disintegrated again, and the first-stage accepted stock goes through a residue remover and a pressure screen to obtain a second accepted stock and a second-stage residue pulp; (4) the second-stage accepted stock enters an OCC line heavy residue remover and is recovered, and the second-stage residue pulp enters a flotation light residue machine to obtain athird-stage accepted stock and a third-stage residue pulp; (5) the third-stage accepted stock enters the pulp disintegrator, and is disintegrated, and the third-stage residue pulp enters an impurity separator, and undergoes flotation to obtain a fourth-stage accepted stock and a fourth-stage residue pulp; and (6) the fourth-stage accepted stock enters the pulp disintegrator, and is disintegrated again, and the fourth-stage residue pulp and the residue pulp which is obtained after treatment using the cylinder screen are mixed, and then undergo sludge pressing treatment. Valuable components in the light residue of the waste paper pulping workshop are recycled to the greatest extent, and recycled metal and plastic granules which are the externally transported have single composition, and canbe conveniently recycled subsequently.

Owner:SHANYING INT HLDG CO LTD

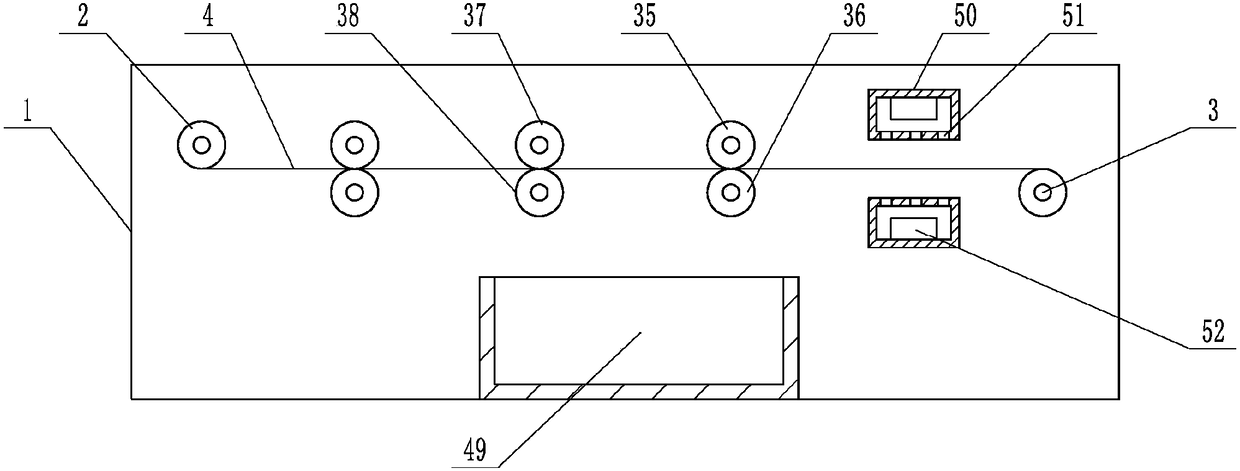

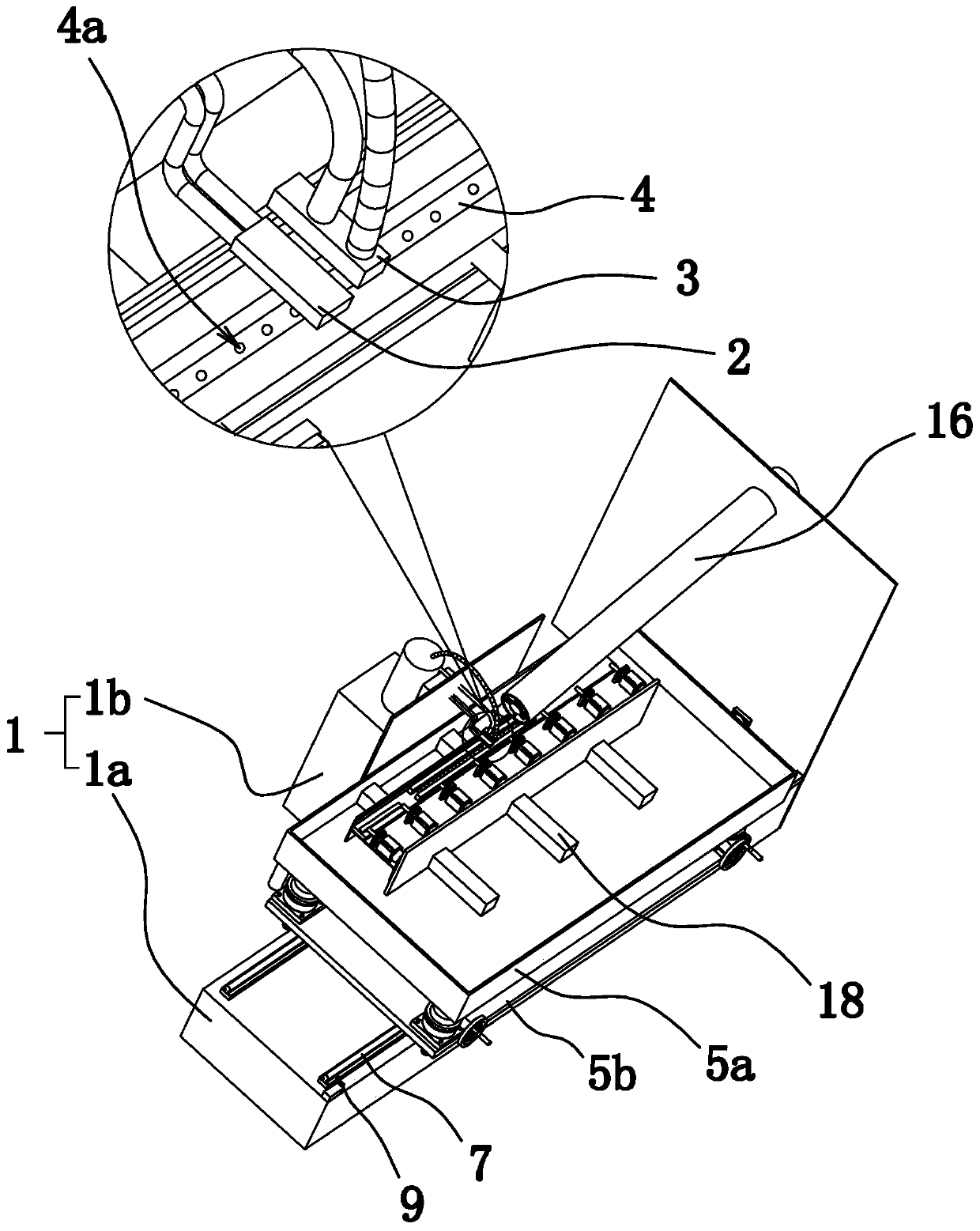

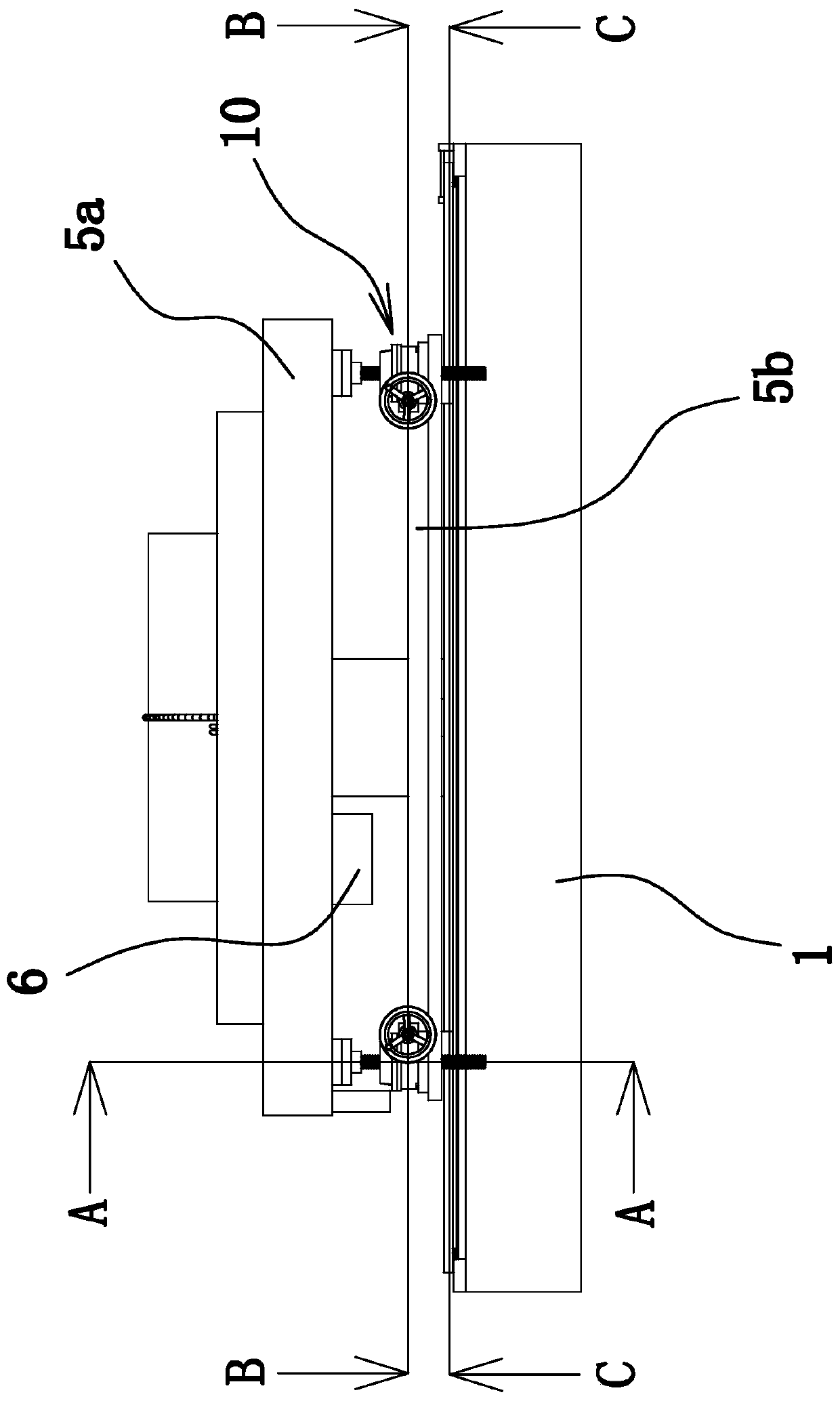

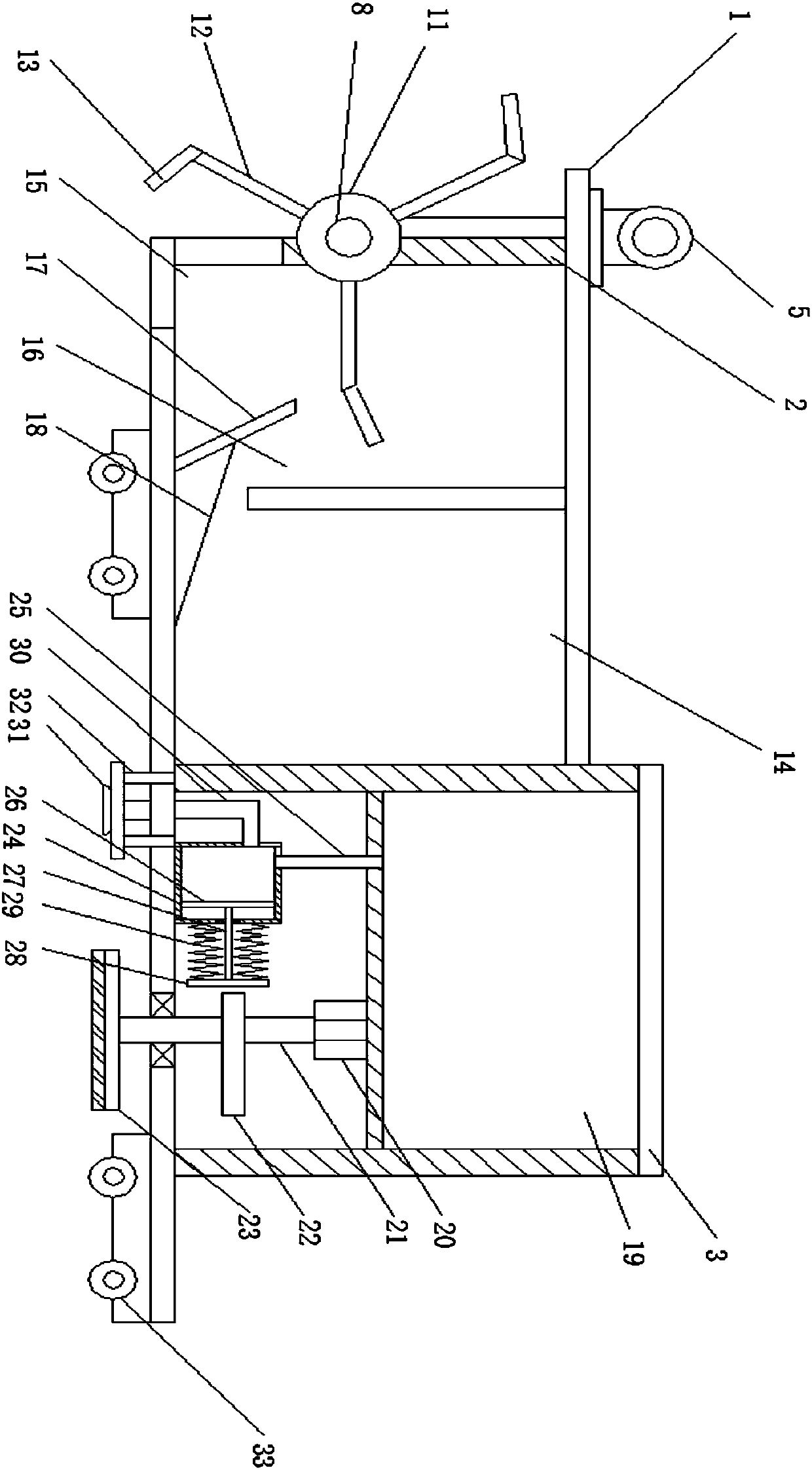

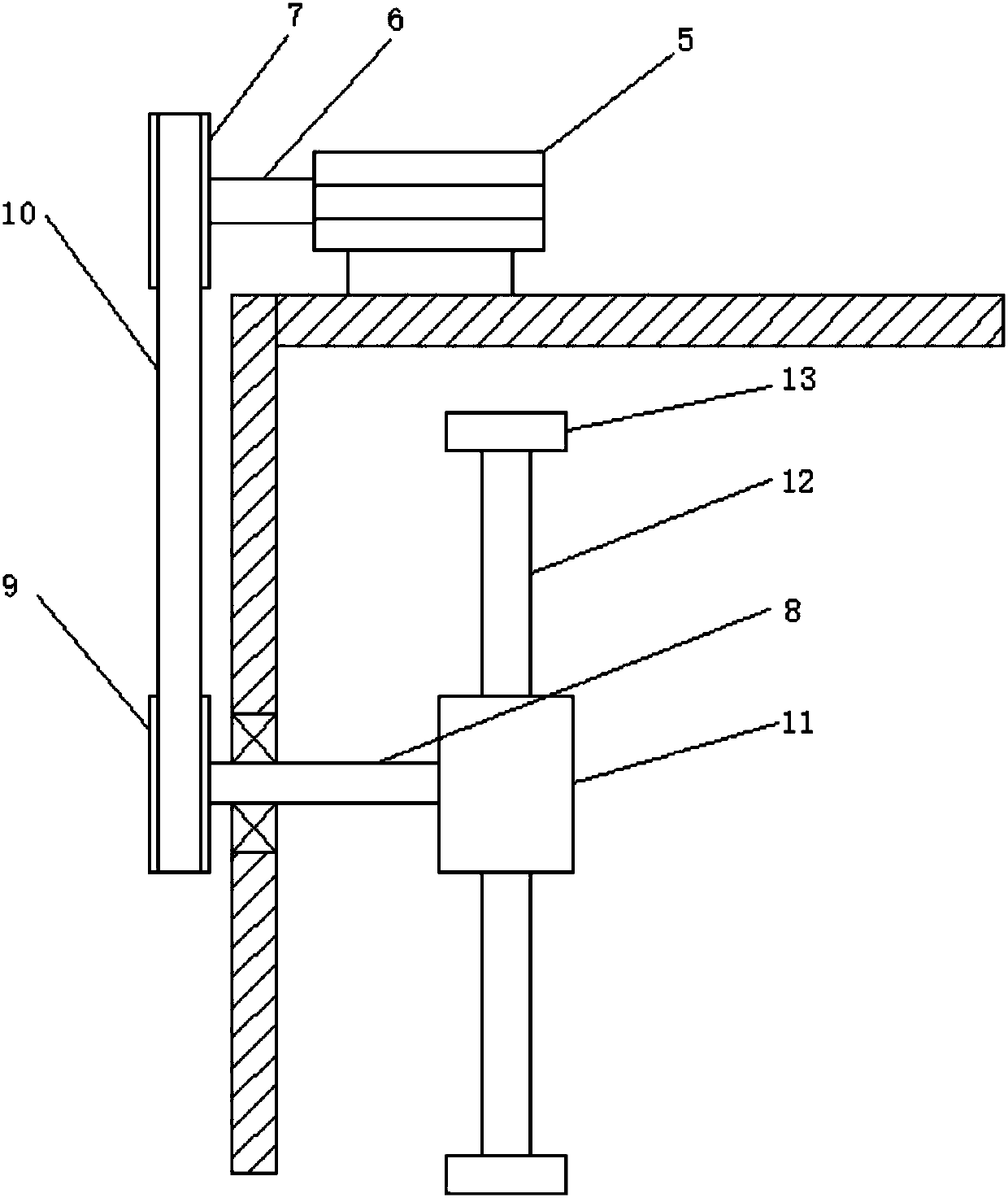

Metal scrap collecting and briquetting integrated device for machining

ActiveCN110757232AEasy to bond and pressFor subsequent recyclingMaintainance and safety accessoriesPressesMachiningMaterials science

The invention discloses a metal scrap collecting and briquetting integrated device for machining. A scrap collecting mechanism is utilized, wherein metal scraps can be conveniently collected in an electromagnetic adsorption manner; the collected scraps can be automatically placed into a scrap briquetting mechanism; manual operation is not needed; and the scraps are prevented from generating adverse effects on the body. Meanwhile, the scrap briquetting mechanism can achieve briquetting treatment on the scraps under the heating condition, briquetting is carried out under the heating condition, bonding and pressing between the scraps can be facilitated, pressing treatment is facilitated, subsequent transportation and storage are facilitated after briquetting, and meanwhile subsequent recycling of the scraps is facilitated. According to the metal scrap collecting and briquetting integrated device, automatic discharging after collecting, briquetting and briquetting can be greatly improved,and the metal scraps are prevented from generating large adverse effects on the body during collecting.

Owner:XUCHANG UNIV

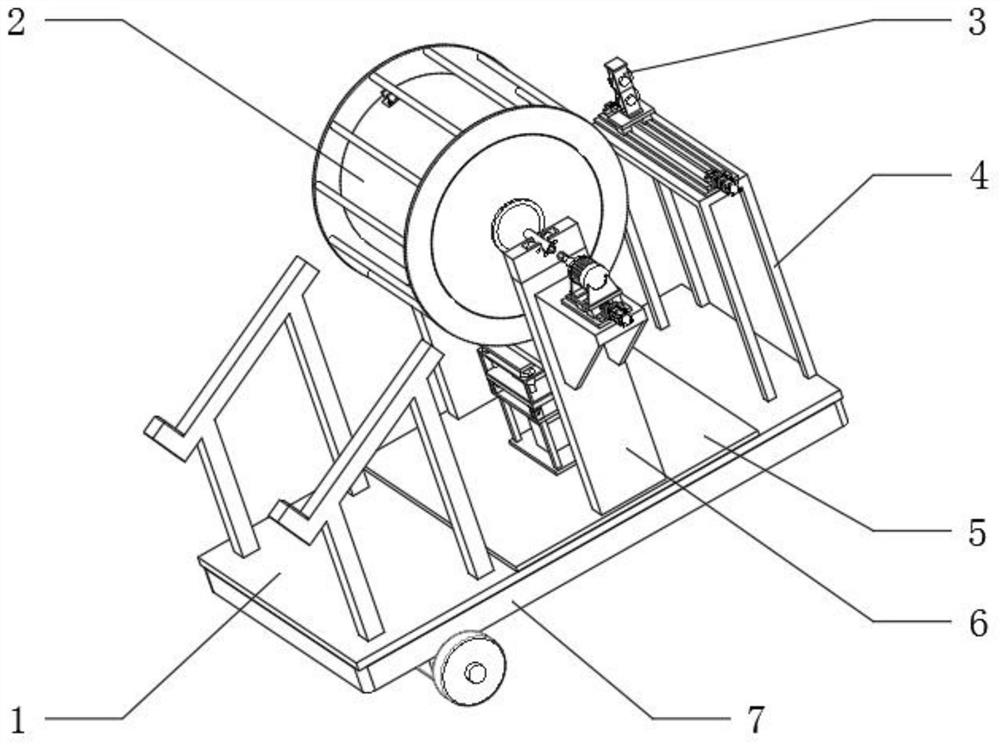

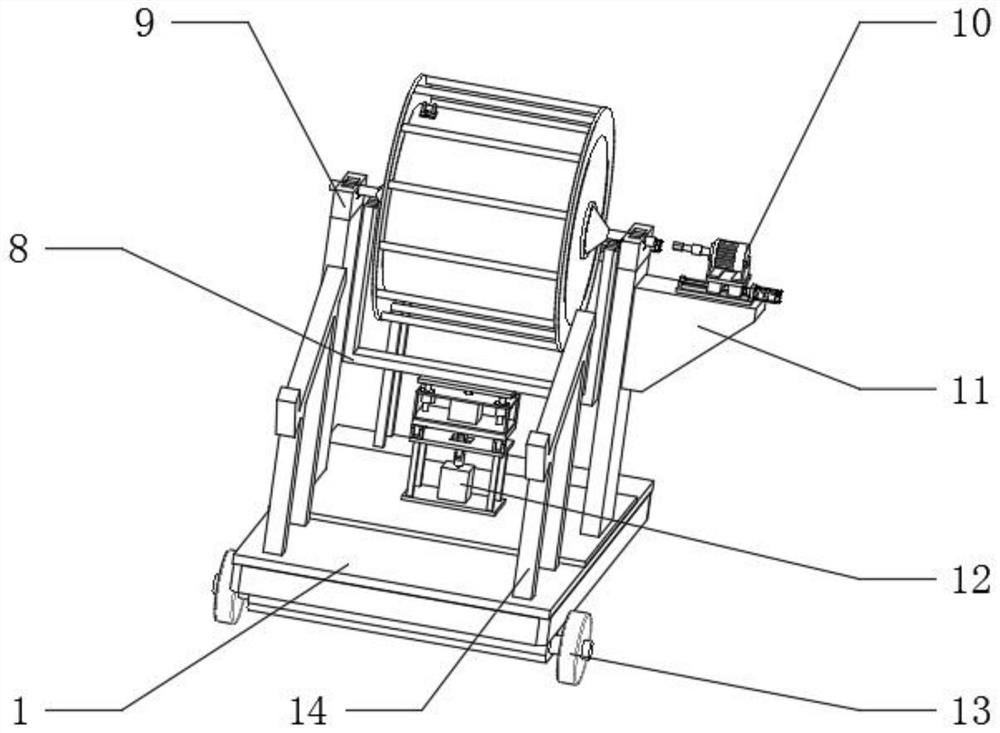

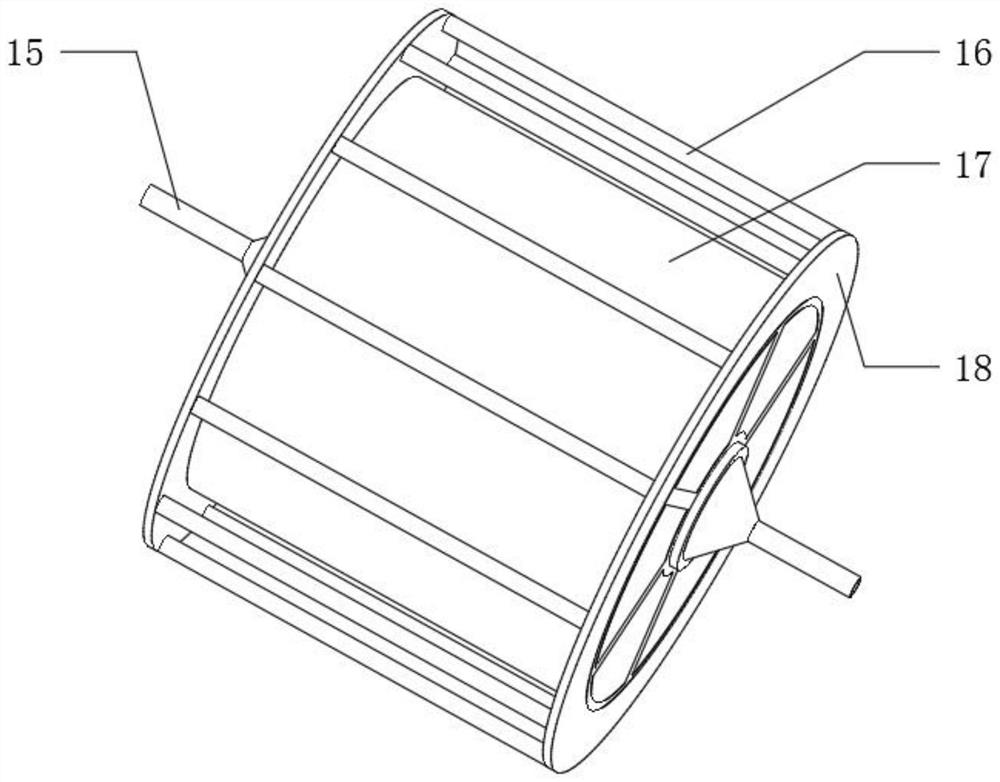

Coiling device for cable production

The invention discloses a coiling device for cable production, and relates to the technical field of cable processing equipment. The coiling device for cable production is used for achieving the purpose that a roller assembly can be independently taken out. The device specifically comprises a bottom plate. A supporting plate is fixedly connected to the outer wall of the top of the bottom plate, acantilever crane is fixedly connected to the outer wall of the top of the supporting plate, a supporting assembly is fixedly connected to the outer wall of the top of the cantilever crane, and a roller assembly is rotationally connected to the outer wall of the top of the supporting assembly. A stand frame is fixedly connected to the outer wall of the top of the bottom plate, a feeding assembly isfixedly connected to the top outer wall of the stand frame, and a connecting assembly is fixedly connected to the outer wall of the top of the bottom plate. According to the coiling device for cableproduction, because the supporting assembly is arranged, and a U-shaped groove is formed in the outer wall of the top of a fixed base, the roller assembly can conveniently go in and out of a device body vertically; and furthermore, because a first rotating wheel and a second rotating wheel are used in cooperation with trunnions, the roller assembly rotates on the outer wall of the top of the supporting assembly, and the roller assembly can be conveniently recycled after coiling work is completed.

Owner:湖南新耒传导材料科技有限公司

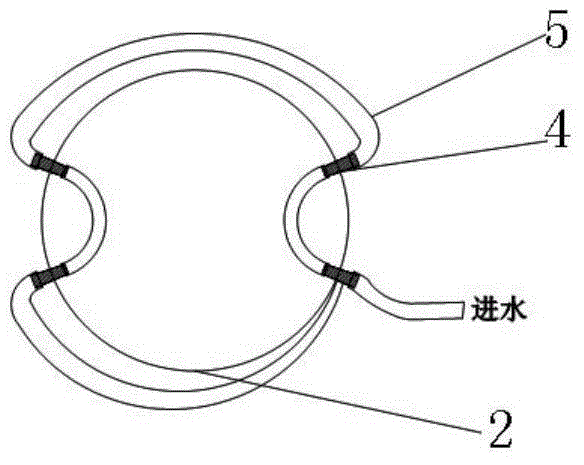

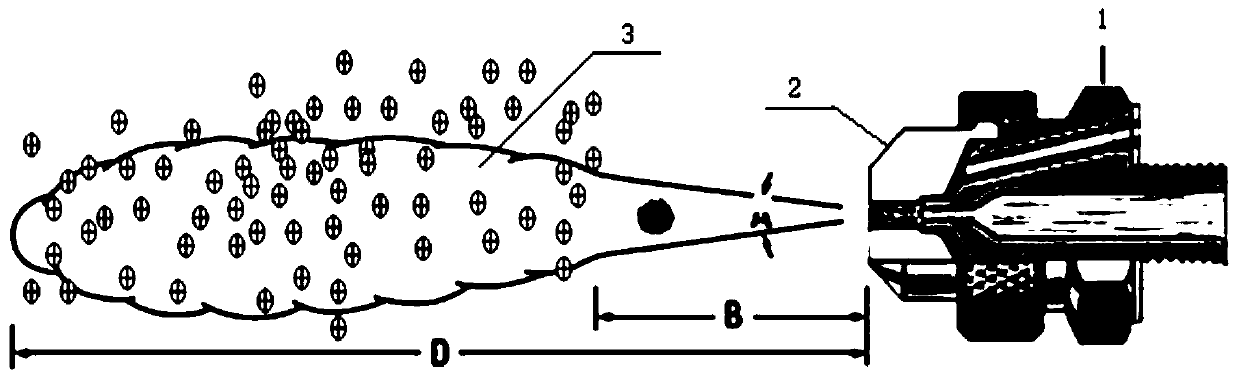

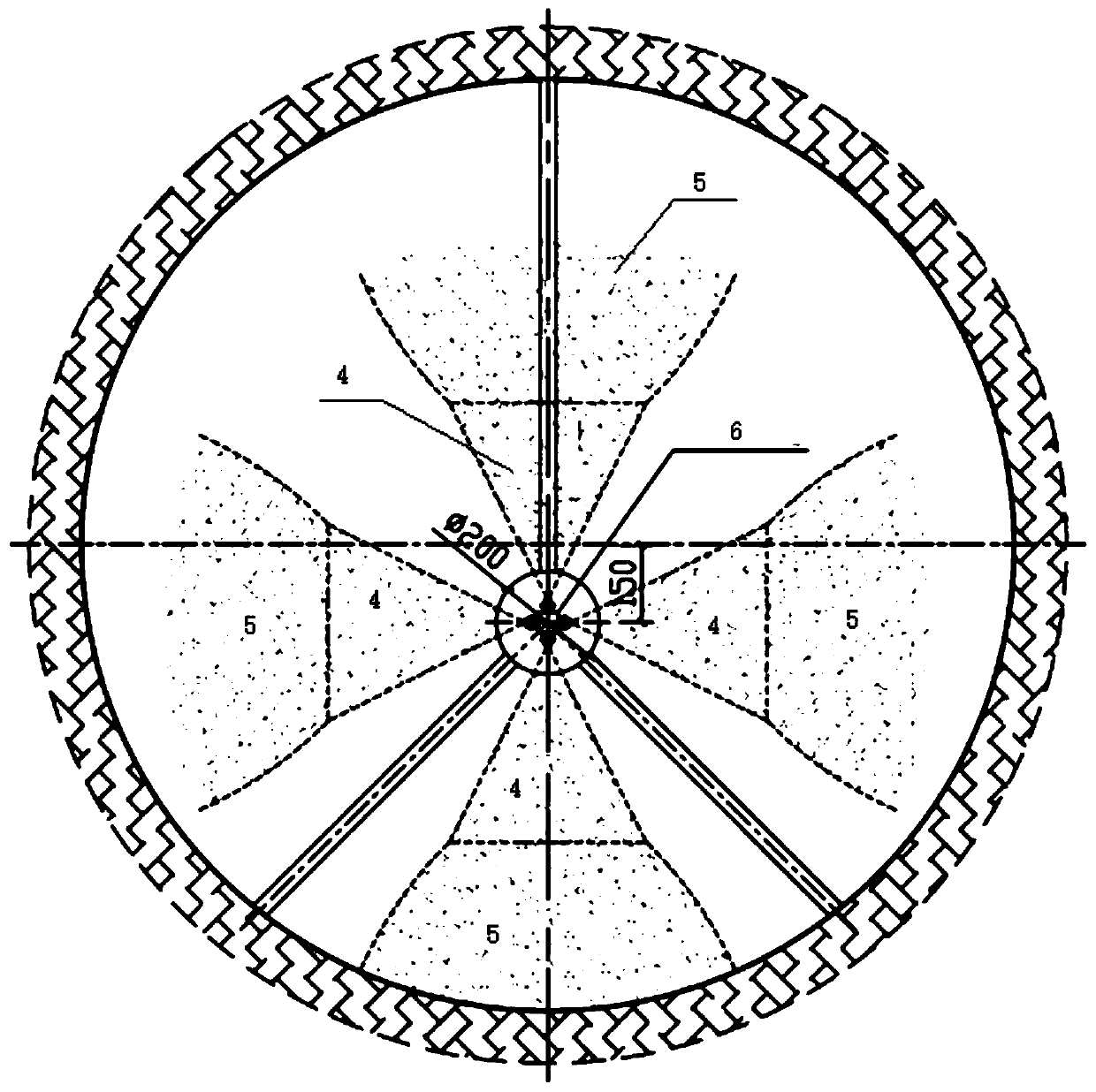

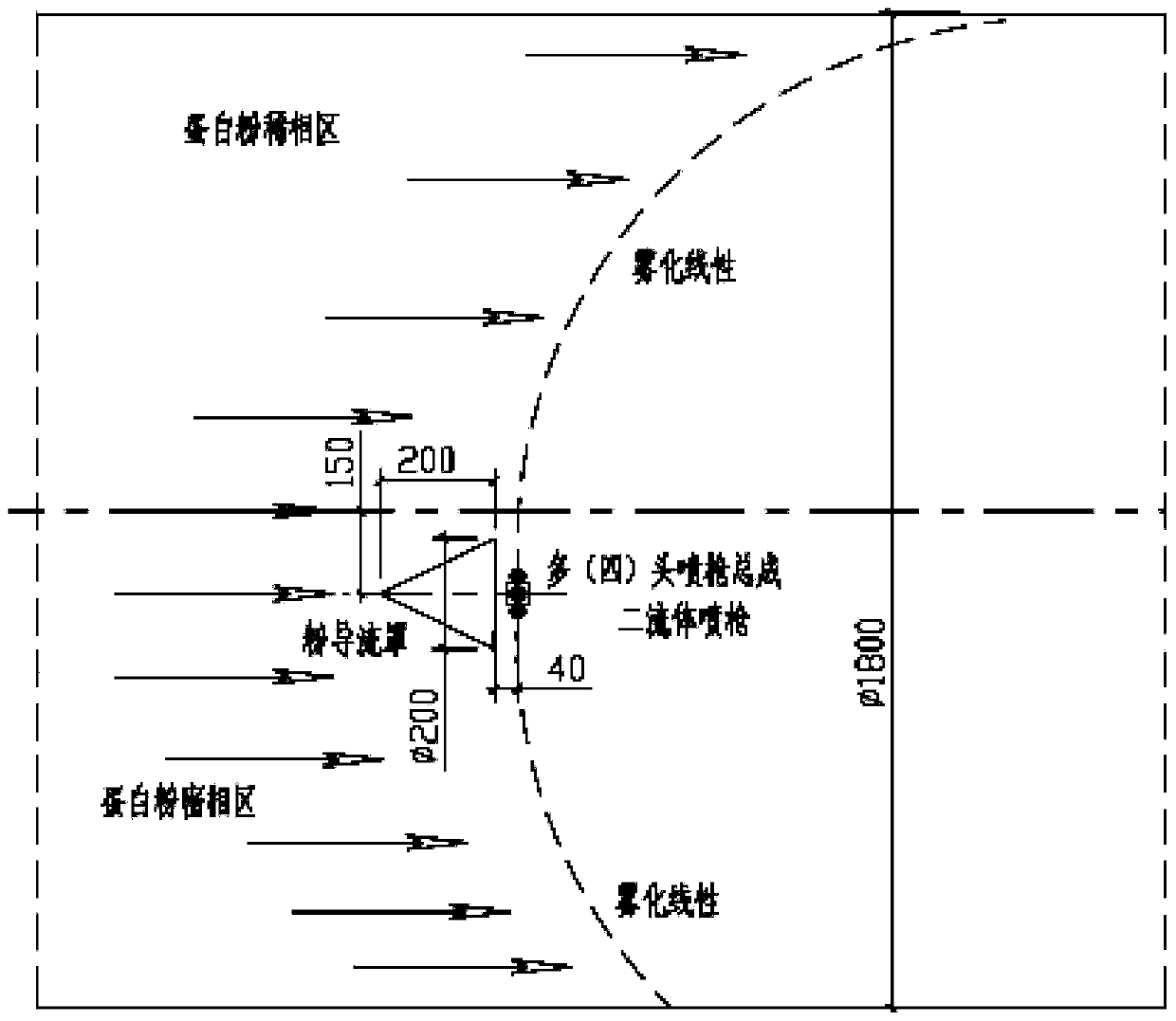

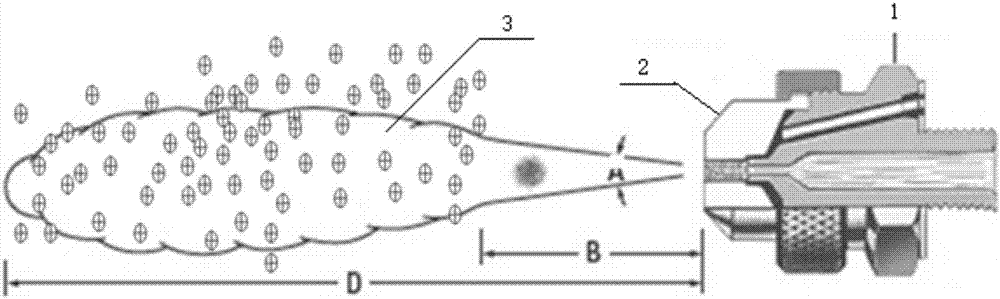

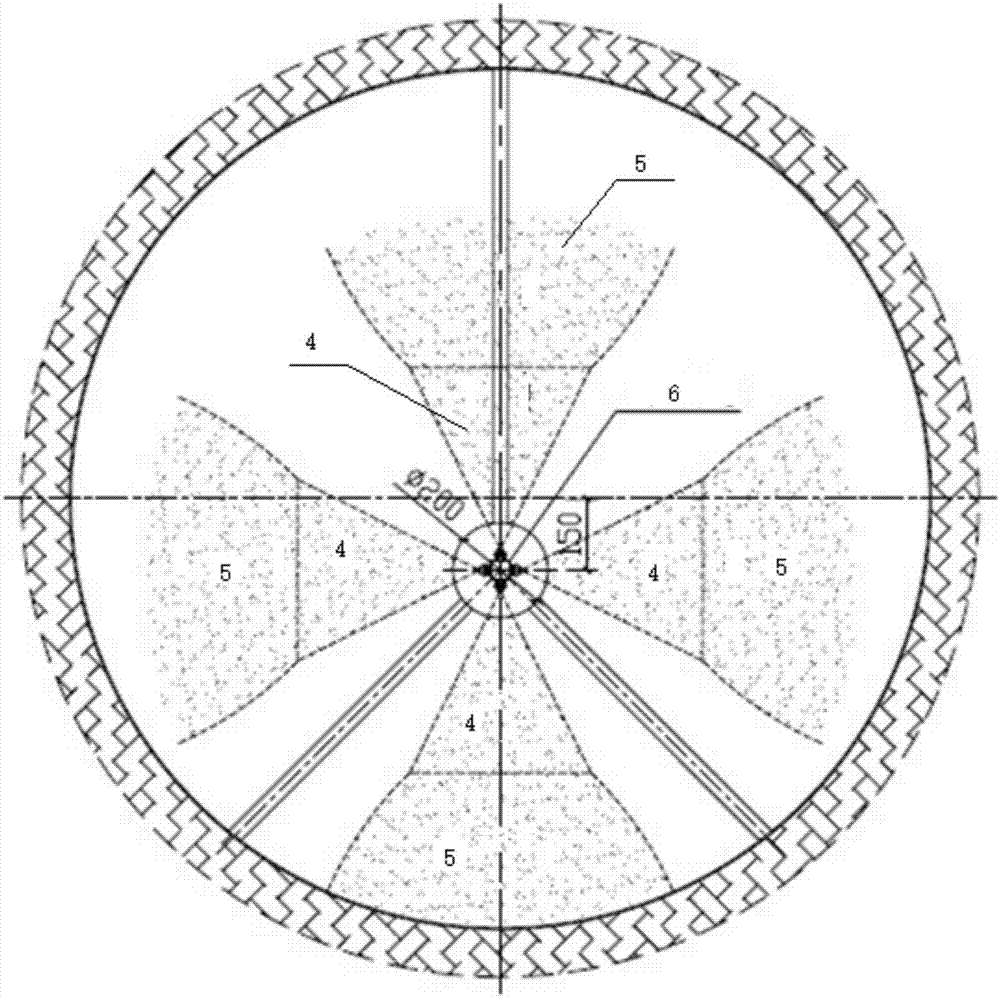

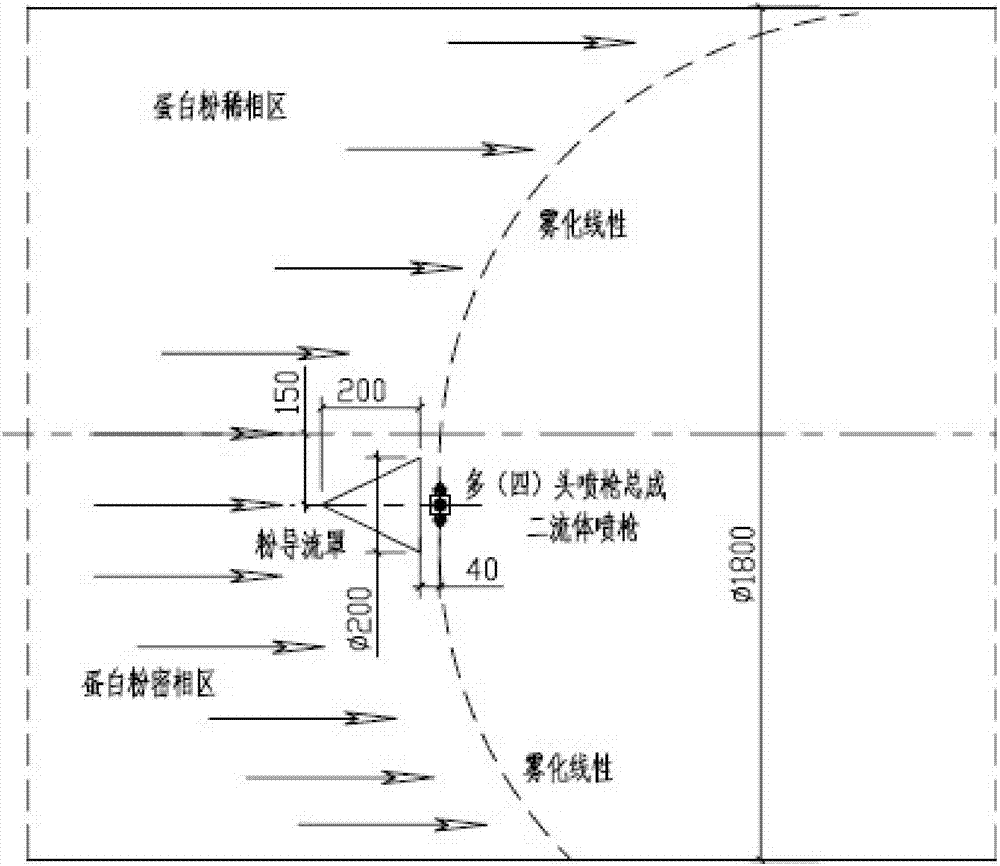

A kind of soybean protein spraying equipment and soybean protein spraying method

ActiveCN107297295BIncrease contact areaImprove spray uniformitySpray nozzlesLiquid spraying apparatusSoybean ProteinsNozzle

Soy protein spraying equipment comprises a soy protein recycling barrel and a multi-nozzle spray gun. The multi-nozzle spray gun is located between the central axis and the lower barrel wall of the recycling barrel, and the number of nozzles of the multi-nozzle spray gun is N which is a natural number greater than 1; the included angle between the two neighboring nozzles is 360 degrees / N. The soy protein spraying equipment is controllable in spraying quantity, even in spraying angle and reasonable in atomization coverage.

Owner:山东禹王生物技术有限公司

Kitchen garbage recycling processor

InactiveCN113857205AReduce generationReduce volumeSolid waste disposalPressesRefuse collectionOrganic manure

A kitchen waste recycling processor comprises a box body with a waste throwing opening in the upper portion, a waste smashing device arranged in the box body and communicating with the waste throwing opening, a waste collecting barrel arranged in the box body and located below the waste smashing device, and a drying device and a circuit control device which are arranged in the box body. And meanwhile, a quantitative extrusion forming device for separately compressing kitchen garbage crushed in the waste smashing device into small blocks is arranged in the box body and is positioned between the garbage smashing device and the waste collecting barrel. The quantitative extrusion forming device is used for performing certain-amount extrusion forming on the kitchen garbage crushed in the waste smashing device each time, so that the kitchen garbage crushed in the waste smashing device can be separately compressed into small solid blocks, and the small solid blocks are turned into pet feed, or organic fertilizer and biofuel for use; and in addition, the extrusion forming size of the kitchen garbage is effectively reduced, and subsequent recycling and reutilization treatment of the kitchen garbage are facilitated.

Owner:文明华

Soy protein spraying equipment and soy protein spraying method

ActiveCN107297295ASpray volume controllableUniform spraying angleLiquid spraying apparatusEngineeringSpray method

Soy protein spraying equipment comprises a soy protein recycling barrel and a multi-nozzle spray gun. The multi-nozzle spray gun is located between the central axis and the lower barrel wall of the recycling barrel, and the number of nozzles of the multi-nozzle spray gun is N which is a natural number greater than 1; the included angle between the two neighboring nozzles is 360 degrees / N. The soy protein spraying equipment is controllable in spraying quantity, even in spraying angle and reasonable in atomization coverage.

Owner:山东禹王生物技术有限公司

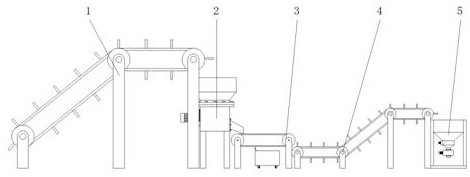

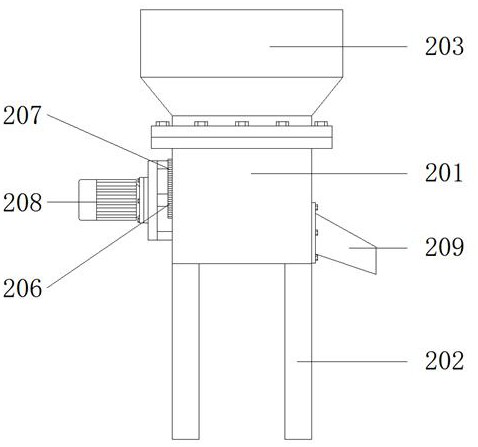

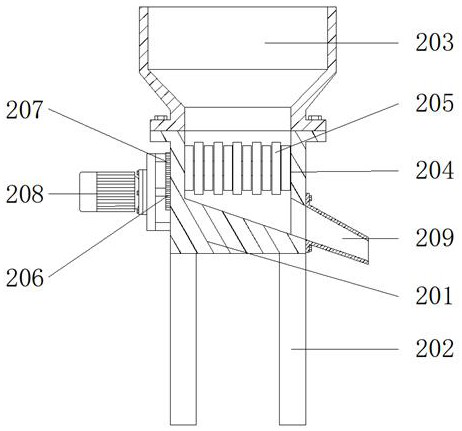

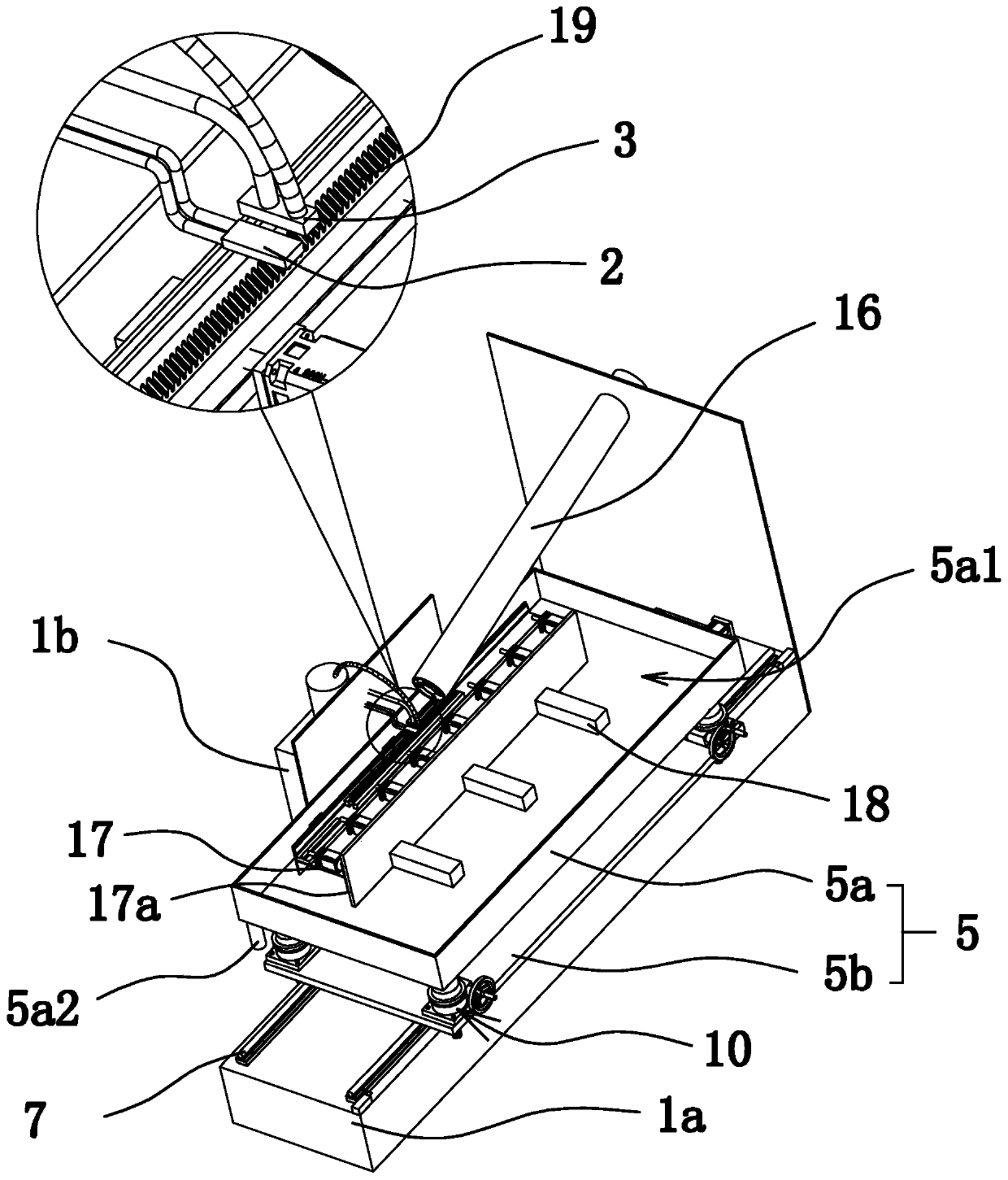

Casting waste residue recycling device

InactiveCN112371908AAchieve separationFor subsequent recyclingMould handling/dressing devicesMagnetic separatorEnvironmental engineering

The invention discloses a casting waste residue recycling device, and relates to the technical field of waste residue recycling . The casting waste residue recycling device comprises a first conveyingbelt, wherein a crushing mechanism is arranged at the output end of the first conveying belt and has a crushing function; a magnetic separation mechanism is arranged at the output end of the crushingmechanism; a second conveying belt is arranged at the output end of the magnetic separation mechanism; a sorting mechanism is arranged at the output end of the second conveying belt; the sorting mechanism has a screening function; the magnetic separation mechanism comprises a magnetic conveying belt; the conveying belt of the magnetic conveying belt has magnetism; and a material collecting vehicle is placed at the bottom of the magnetic conveying belt. According to the casting waste residue recycling device provided by the invention, through the arrangement of the crushing mechanism, blocky casting waste residues can be crushed into a granular mixture; and in combination with the arrangement of the magnetic separation mechanism, iron alloy-containing particles and casting sand particles in the granular mixture can be separated, so that subsequent recycling is facilitated.

Owner:含山县永帮再生资源利用有限公司

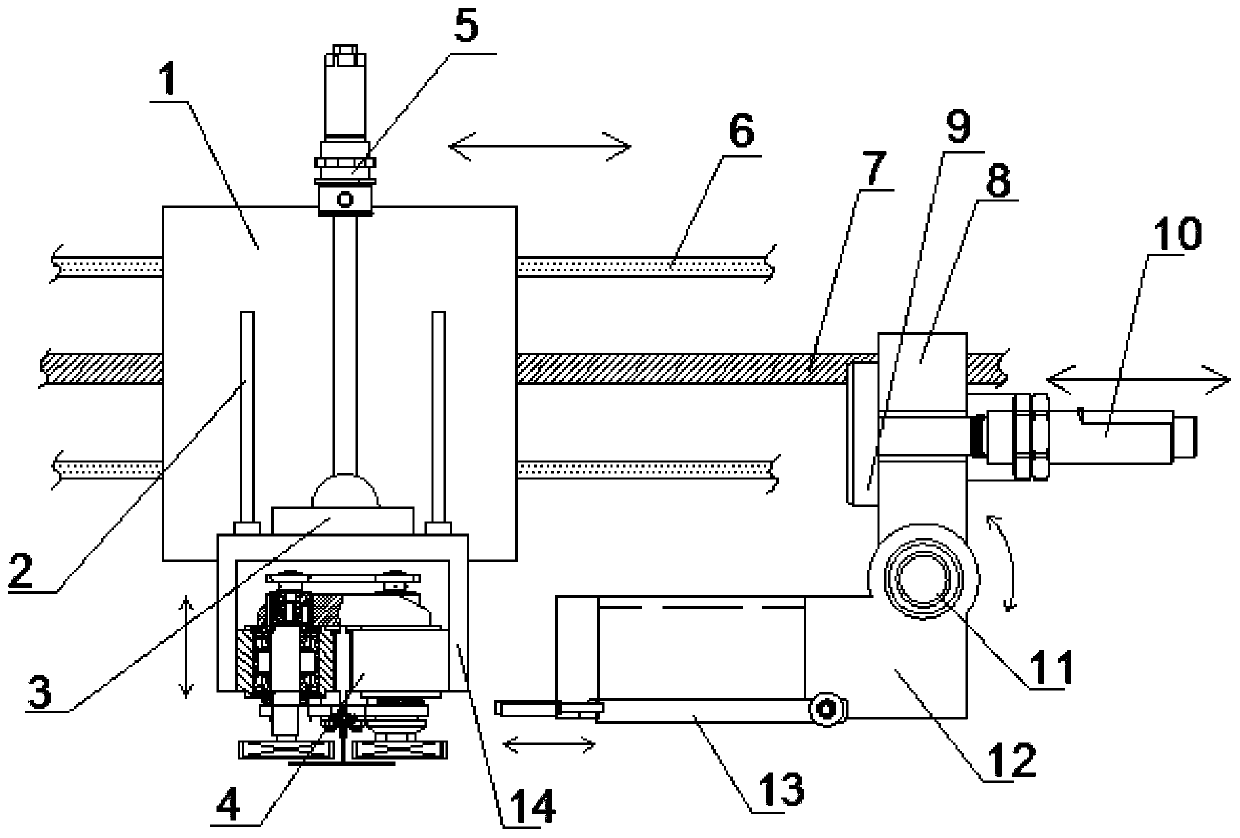

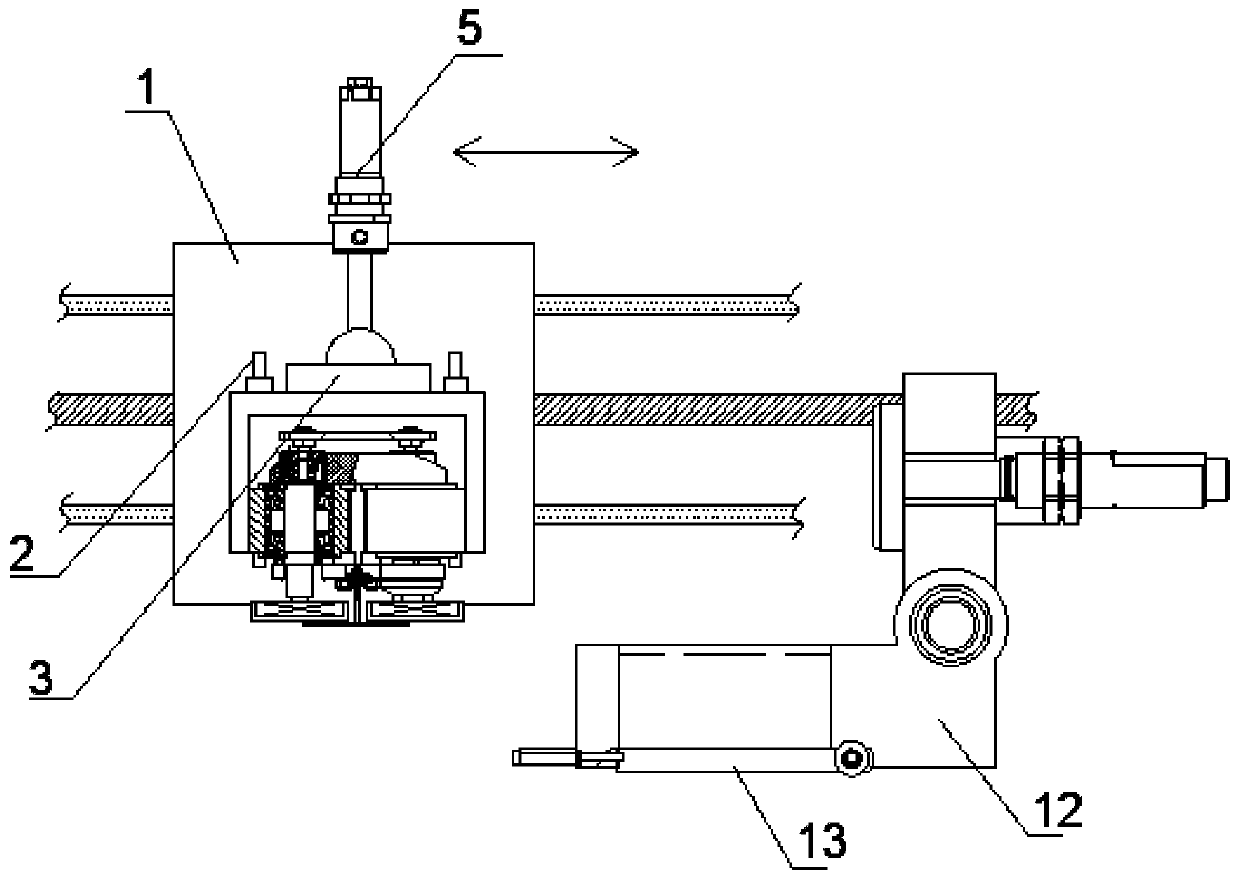

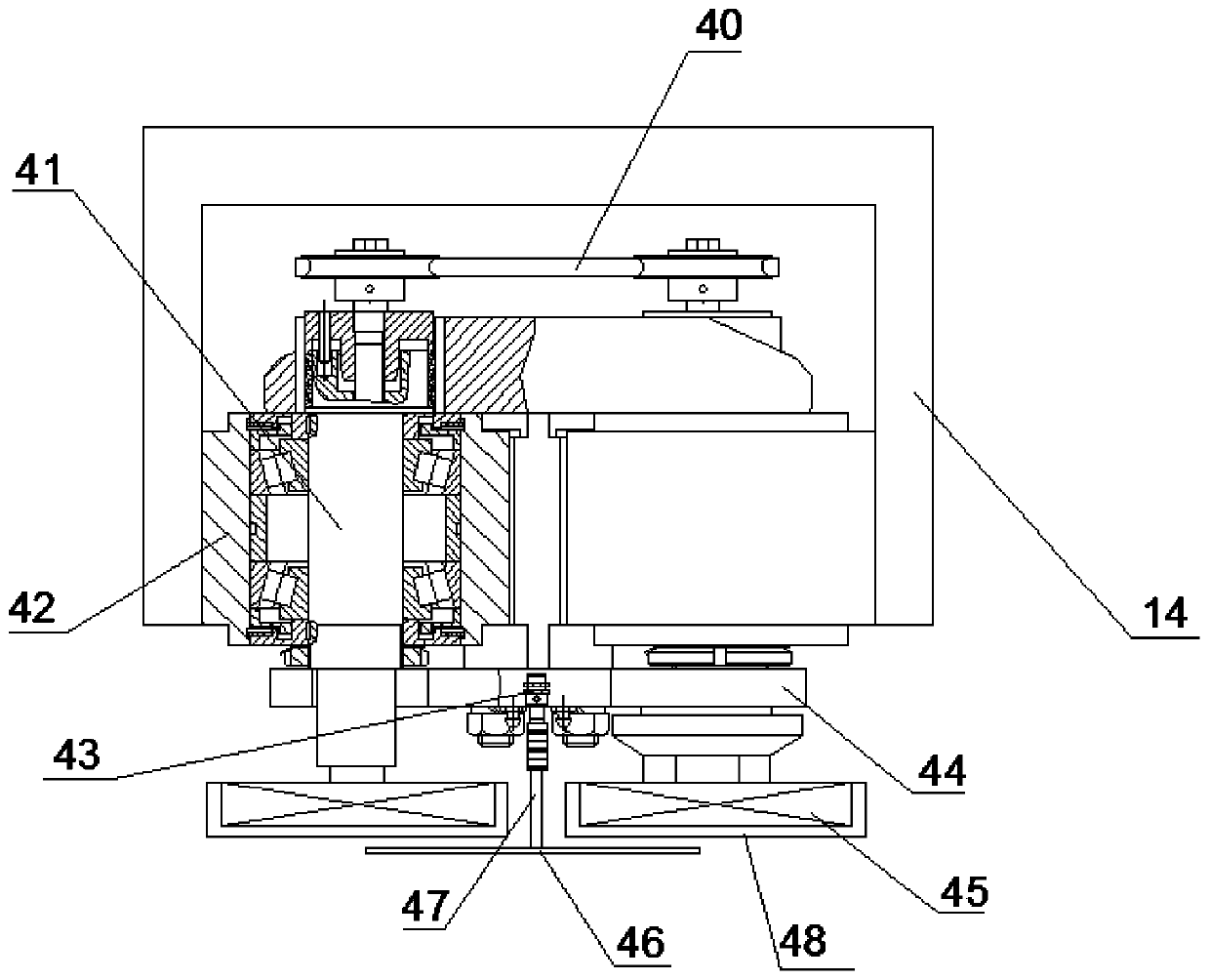

Tooth surface quenching device for rack

PendingCN111411200AImprove quenching effectNo deformation and upturningFurnace typesHeat treatment furnacesMachinePhysics

The invention provides a tooth surface quenching device for a rack, and belongs to the technical field of machines. The problem that an existing quenching device is poor in quenching effect is solved.The tooth surface quenching device for the rack comprises a machine frame, a quenching head, a quenching liquid nozzle, a quenching disc with a mounting cavity and a clamp used for clamping and positioning the rack, the quenching head and the quenching liquid nozzle are fixed to the machine frame, the quenching head and the quenching liquid nozzle are located above the clamp and are opposite to the clamp, the quenching disc is mounted on the machine frame and can slide back and forth in the horizontal direction relative to the machine frame, the clamp is mounted in the mounting cavity of thequenching disc, the bottom face of the clamp is a plane, the quenching disc is provided with a sucking part, the sucking part can suck the bottom of the rack to enable the rack to be tightly attachedto the bottom face of the clamp, the sucking part can generate sucking force to enable the bottom of the rack to be firmly sucked, in the quenching process, even if the rack is heated, deforming and upwarping cannot be generated, the tooth surface quenching effect is improved, and the product quality is ensured.

Owner:台州莱德齿条有限公司

Excrement removing device for bird rearing house

The invention discloses an excrement removing device for a bird rearing house. The device comprises a rack and a base. The rack is divided into a descaling frame and a cleaning frame, a first motor isinstalled on the upper plane of the descaling frame, a first rotating shaft is installed at the rear end of the first motor, a transmission wheel is installed at the tail end of the first rotating shaft, a transmission shaft is installed in the middle of the rear wall of the descaling frame, a driven wheel is installed at the rear end of the transmission shaft, the transmission wheel and the driven wheel are connected through a belt, an axle seat is installed at the front end of the transmission shaft, connecting rods are installed on the periphery of the axle seat, and descaling shovels areinstalled at the outer ends of the connecting rods; due to the rotating type descaling device, dirt is thrown into a dirt storage box under the effects of centrifugal force and gravity, automatic dirtremoval is achieved, and the device is easy and convenient to operate.

Owner:季梅

Domestic garbage treatment equipment

InactiveCN110774644AEfficient crushingImprove crushing effectGrain treatmentsPressesStructural engineeringRefuse Disposals

Owner:榆林市中源商贸有限公司

Waste sorting and screening device for waste disposal

InactiveCN112675948ANo need for manual secondary sortingImprove efficiencyCleaning using toolsMagnetic separationEnvironmental engineeringRefuse Disposals

The invention relates to the technical field of waste screening, in particular to a waste sorting and screening device for waste disposal. The device comprises a bottom plate, a sorting box, a feeding device, a screening device, a jaw crushing device, a smashing device and an adsorption device, wherein four support columns are arranged on the bottom plate, the classification box is arranged on the four support columns, inclined installation grooves are formed in the two inner walls of the classification box, a feeding port is formed in the sorting box, a water inlet pipe is arranged above the classification box, a plurality of nozzles are arranged on the water inlet pipe and all communicates with the interior of the sorting box, the feeding device is arranged in the sorting box, the screening device is arranged in the sorting box of the jaw crushing device below the feeding device, the smashing device is arranged below the jaw crushing device, and the adsorption device is arranged on the bottom plate. According to the waste sorting and screening device for waste disposal, through mutual cooperation operation of all the devices, construction waste can be automatically sorted and screened, manual secondary sorting is not needed, and sorting and screening effect and efficiency are improved.

Owner:王子腾

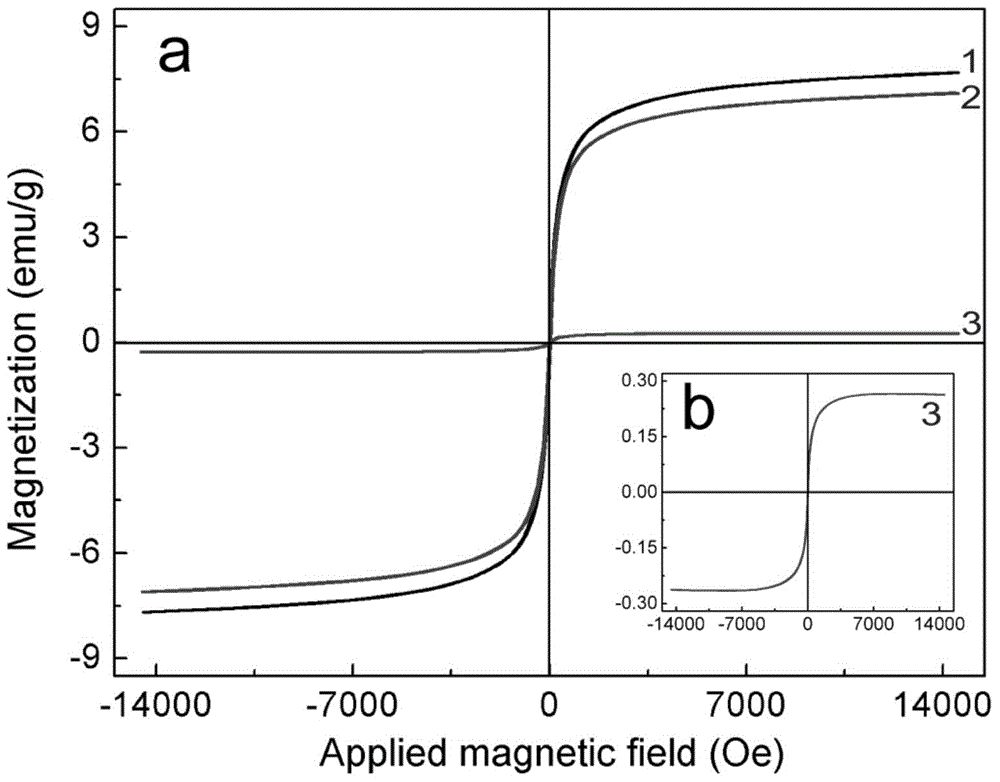

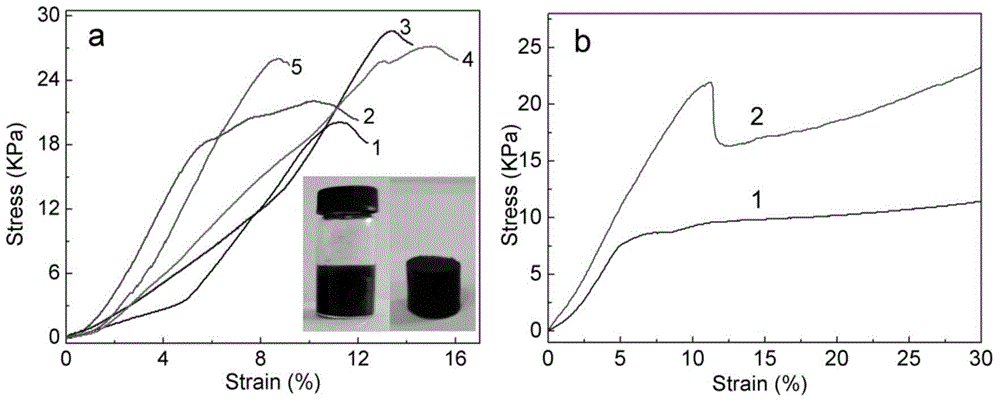

Preparation method for conveniently-recyclable magnetic supramolecular gel dye adsorption material

InactiveCN104874358AObvious adsorption interfaceFacilitated DiffusionOther chemical processesAlkali metal oxides/hydroxidesDye adsorptionEthylene glycol

The invention discloses a preparation method for a conveniently-recyclable magnetic supramolecular gel dye adsorption material. The method comprises the following steps: mixing halloysite with absolute ethyl alcohol, and adding ferric nitrate into the mixture; stirring so as to enable ethanol to volatilize naturally; then dropwise adding glycol into a solid substance, subsequently calcinating, and further treating with a silane coupling agent so as to obtain a magnetic halloysite subjected to surface hydrophobic modification; and dispersing the modified magnetic halloysite into a solvent, adding a gel factor, heating for completely dissolving gel factors, and cooling, thereby obtaining the magnetic supramolecular gel dye adsorption material. According to the preparation method, a halloysite nano tube loaded with magnetic nano particles is added into a supramolecular gel, so that the defects that the supramolecular gel is low in mechanical strength, difficult in machine shaping, high in recovery difficulty and not beneficial to practical application are overcome; the enhanced magnetic supramolecular gel has favorable dye adsorption performance; furthermore, since the magnetic responsiveness is achieved, separation and recovery after adsorption are convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

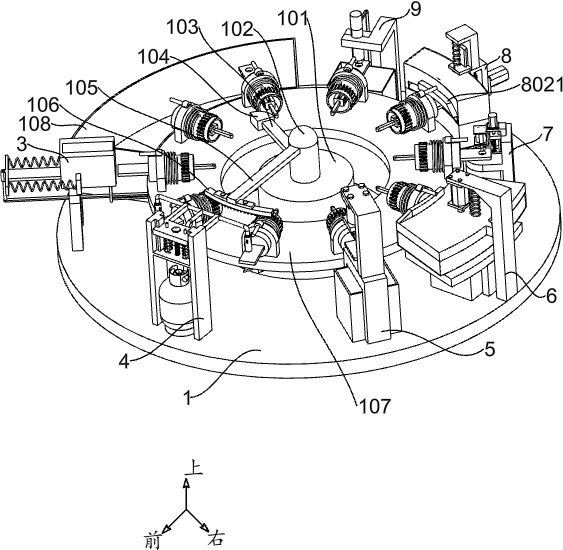

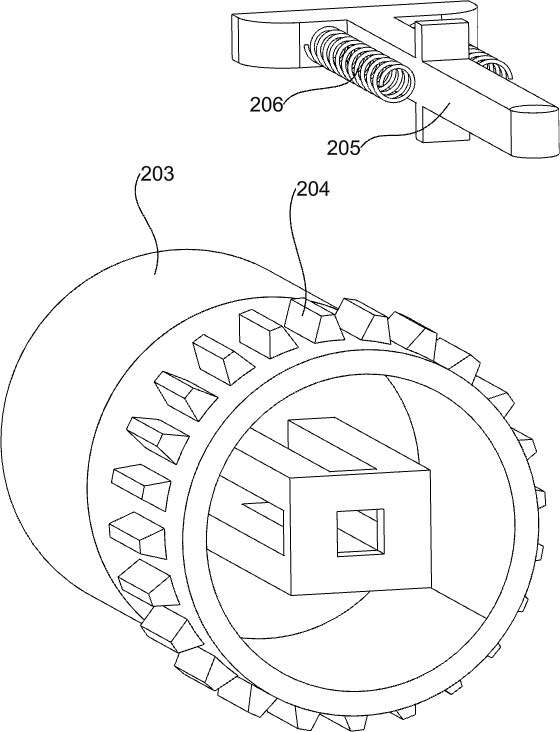

Hammer processing device capable of cleaning and recycling chippings

ActiveCN114799932AAvoid it happening againReduce wasteShaping toolsPolishing machinesPunchingArchitectural engineering

The invention discloses a hammer machining device capable of cleaning and recycling chippings. The hammer machining device comprises a bottom plate, a first fixing column, a second fixing column, an index plate, a punching machine, a first waste collecting frame and the like. A first fixing column is fixed to the middle of the top wall of the bottom plate, a second fixing column is fixed to the middle of the top wall of the first fixing column, an index plate is installed on the top of the bottom plate, a punching machine is installed on the right side of the bottom plate, and a first waste collecting frame is arranged on the lower side of the punching machine. According to the steel plate punching device, a steel plate can be punched, meanwhile, crushed materials, sweeps and the like generated during machining can be collected in the steel plate machining process, follow-up recycling is facilitated, and resource waste is reduced; when the index plate rotates, the sliding material pushing plate slides in the material storage frame through cooperation of the feeding gear ring and the L-shaped sliding rod, the sliding material pushing plate can push the steel plate into the magnetic material carrying barrel while sliding, and the automatic feeding function is achieved.

Owner:徐州淘沙生态农业有限公司

Method and apparatus for pretreatment of chlorinated resin polymerization mother liquor

InactiveCN105600979ASimple structureSimple processZinc oxides/hydroxidesMultistage water/sewage treatmentChlorideFilter press

The invention provides a method and apparatus for pretreatment of chlorinated resin polymerization mother liquor. The apparatus comprises a muddy water separation tank, a filter press, a filtrate collecting tank, a reaction vessel and a centrifuge, wherein the centrifuge is provided with a filtrate outlet and a product outlet and the filtrate outlet is communicated with the filtrate collecting tank. The method for pretreatment of the chlorinated mother liquor comprises the following steps: S1, adding the resin polymerization mother liquor and a resin flocculating agent into the muddy water separation tank and carrying out stirring; S2, adding a solid-liquid mixture into the filter press; S3, collecting filtrate obtained after filtering in the S2 into the filtrate collecting tank; S4, collecting the filtrate collected in the filtrate collecting tank in the S3 into the reaction vessel, adding NaOH into the reaction vessel at the same time and adjusting the pH value of the filtrate in the reaction vessel to 7; and S5, adding a reaction product of S4 into the centrifuge so as to separate out a white precipitate. The apparatus provided by the invention is simple in structure, convenient in flow and low in investment cost and operation cost. The mother liquor is directly pretreated and then neutralized with alkali to produce the zinc oxide precipitate; so good recovery effect is obtained, and subsequent recovery of zinc chloride is facilitated.

Owner:JIANGSU JINKAI RESIN CHEM

Method and device for classification collecting small sized garbage and organic matters

InactiveCN1202917CEfficient separation and collectionImprove convenienceSolid waste disposalWet separationEnvironmental engineeringOrganic matter

The invention discloses a method and device for sorting and collecting small-scale garbage and organic matter. It mainly utilizes the specific gravity, fluidity, floating and sinking properties of water, and creates a method using water as the medium and filtering through several channels. And the intercepting mechanism to effectively classify the floating matter, organic matter and sediment garbage in the garbage, and then achieve the method and device for effectively sorting and processing small garbage.

Owner:无锡市长江机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com